The bankrupt manufacturer of solar modules is still negotiating with potential investors and tells them that he will be able to quickly launch production at a closed factory in the Dutch Zaanstad in the shortest possible time.

Energyra, the Dutch manufacturer of solar (photovoltaic) modules, has not abandoned its plans to resume the plant in Zanstad after filing for bankruptcy in April 2019 due to a lack of working capital and delays in the supply of equipment (these delays caused downtime for workers who had to pay wages Perhaps Energyra does not pay rent for land, since in April 2018, agreements were reached with the regional government of North Holland, about which there is no data anywhere - approx .

Energyra co-founder Daniel Kuijk told PV Magazine that he, along with a small team, is working on both the technical and business components of the problem in order to still restart the plant.

“We have reliable investors interested in this,” said Kuik, noting that he managed to enlist the support of both technology partners and suppliers of key equipment (namely, “suppliers of key equipment”, according to the management, brought the plant to the monastery last time - approx. .per.) .But the last piece of the puzzle needed to restore the plant is the need to find a co-investor. And Daniel would have preferred a partner from the solar industry.

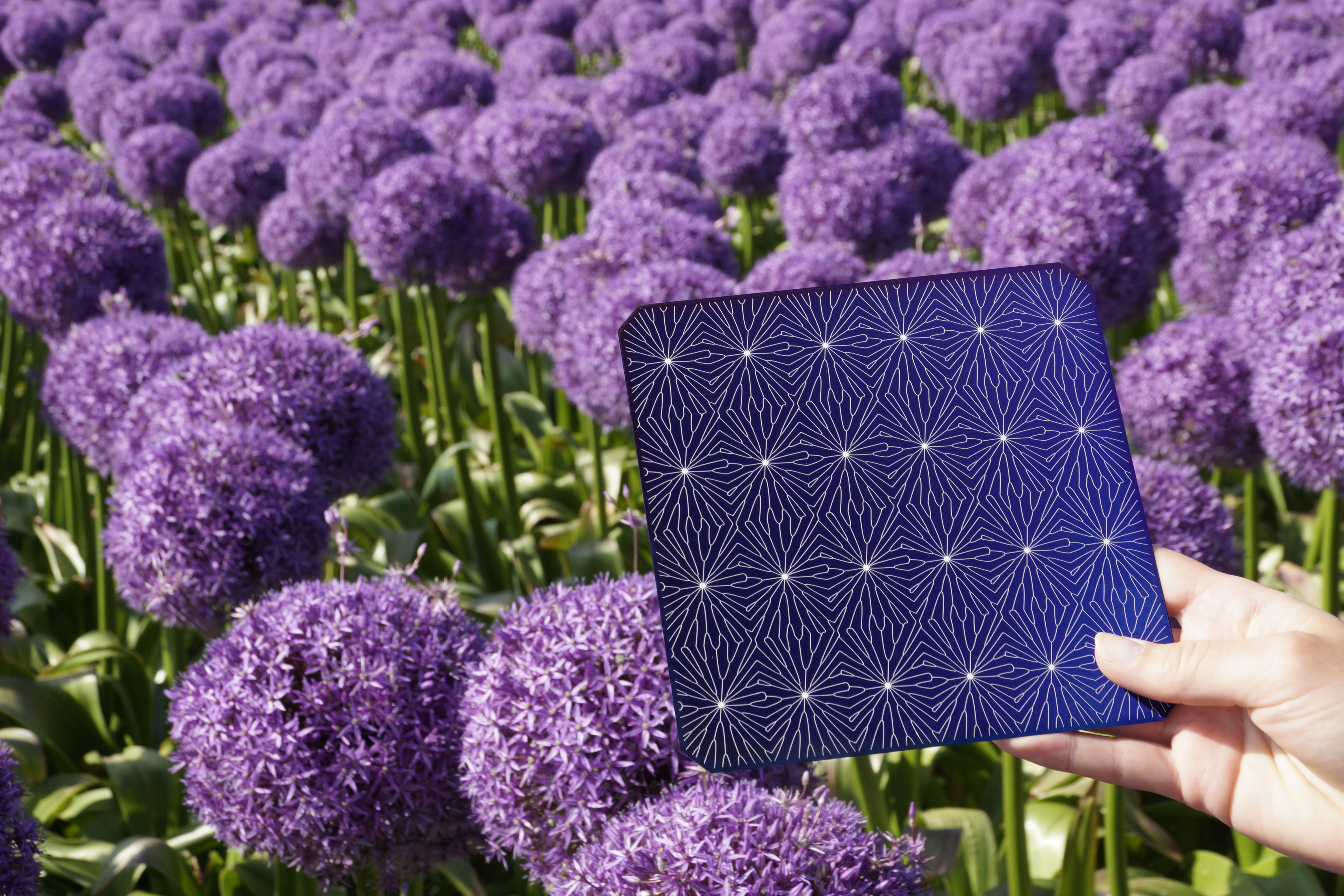

Daniel Kuik on the left and and CFO Bert Shuvs on the right with the plant's products

Nearly eight months have passed since Energyra filed for bankruptcy, but Kuik attributes this to “seasonal factors," claiming that it took time to increase investor interest. This summer, interested parties began to appear in the purchase of parts of the plant, especially this shakes the production line with a capacity of 100 MW. But, as the main creditor, Rabo Lease (a subsidiary of Rabobank ) has so far opposed any offers to sell the plant in parts, advocating a complete restart.

The Zanstad plant is still in good condition, Kuik said, saying that it is still “as if from a needle”. Rabo Lease made sure to keep the production line in perfect condition.

According to Kuik, a number of former (failed - approx. Per.) Distributors also want the plant to resume production. But the next few weeks can play a decisive role in the onset of clarity regarding the desired restart of production, which will enable it to bring to the market its solar modules with through contacts (MWT) (or in other words, the technology of transferring current collector contacts to the back of photomultipliers with laser holes - approx .

From the translator. Since 2014, the section “News” on Energyra’s website says that such modules are “an innovation, the latest developments” and all that.

However, since 2015, MPEI students have studied increasing the efficiency of solar panels thanks to end-to-end contact technology for OS Popelya textbook and Fortova V.E. "Renewable energy in the modern world . " And two years earlier, there was already a gorgeous instructional video from the California team of nanolearning science popularizers to distinguish between different types of current collection from solar cells.

A long but informative video about the types of current collection

But, even more interesting is the fact that the technology for transferring tires to the rear surface of PECs (MWT and WT) was developed back in the 1960s.

(screenshot from ScienceDirect, article from the 2013 Solar Cells book in the right column)

For space, of course, but still in the last century. Not quite true, comrades Dutch. Ugly

In any case, I personally hope that Energyra, if it does launch its own plant, will not suffer the fate of other European solar panel plants that have not withstood competition with China.

Because in the "solar wars" that are waged with the Celestial United States and Europe, the first win so far.