Industrial uranium-graphite reactor ADE-2

A nuclear reactor is a device in which a controlled chain reaction of fission of heavy nuclei (for example, uranium or plutonium) takes place. In this case, a large number of other nuclear reactions occur that can be used for various tasks. When in the early 1940s, physicists began to search for fissile materials that are most suitable for creating a nuclear bomb, it turned out that enriched uranium and the artificial element of plutonium, which does not exist in nature, are suitable for its role. As a result, both options were implemented. The bombs dropped on Hiroshima and Nagasaki were prototypes of these two different types - from enriched uranium and from plutonium. As a result, plutonium for several reasons seemed more preferable to use. But in order to obtain it, it is necessary to build reactors in which uranium will be irradiated with neutrons and turn into plutonium, and then unload the fuel and process it (this process led at the time to the formation of a large amount of liquid waste, as I wrote in a previous post ) and separated from him plutonium. It was with this purpose that they began to build industrial reactors in the United States, and then in the USSR, and next to them whole plants for the processing of nuclear fuel and the separation of plutonium.

The world's first industrial reactor was built in the United States as part of the Manhattan Project. It was the “B” reactor; it was launched in September 1944 at the Hanfor plant, where a total of 9 industrial reactors were built. As a result, this allowed the Americans to conduct the first ever nuclear test of a plutonium bomb on July 16, 1945 at a Nevada training ground, and then a military explosion on August 9, 1945 in Nagasaki. In Hiroshima, a uranium bomb was detonated without a test explosion.

In the USSR, by analogy with the Handford Combine, the Mayak Combine (formerly Plant No. 817) was built in Ozersk (formerly Chelyabinsk-40) in the Chelyabinsk Region. There, the first industrial reactor "A" was launched in 1948. It was he who gave plutonium for the first Soviet nuclear bomb, the test of which took place on August 29, 1949.

The designs of the first industrial plutonium-producing reactors were roughly similar. These are channel thermal neutron reactors with a graphite moderator and once-through water cooling. The reactor core itself (the space where the chain reaction takes place) was collected from graphite, which acted as a neutron moderator. The slowing down of neutrons in graphite made it possible to use natural, unenriched uranium as fuel. This greatly simplified and accelerated the production of plutonium. In the graphite masonry of the reactor, channels were drilled into which fuel was loaded in the form of uranium metal block cylinders. Water was supplied through these channels for cooling, as Uranium fission generated a lot of heat. Blocks with fuel were loaded on one side of the channel, irradiated in the reactor, plutonium was formed in them (a few percent of the loaded uranium), and after a while they were unloaded on the other side of the channel and went to reprocess - dissolving and releasing plutonium by chemical methods. Reactors of this design and purpose in the USSR were called PUGRs - industrial uranium-graphite reactors.

The main and striking difference between the PUGRs in the USA and the USSR was that the Americans had horizontal channels, and ours were vertical. Despite the fact that in many respects we were catching up with the Americans and following their trail saving time, this option seemed to the Soviet developers more profitable due to the solution of a number of problems with uneven heat flow.

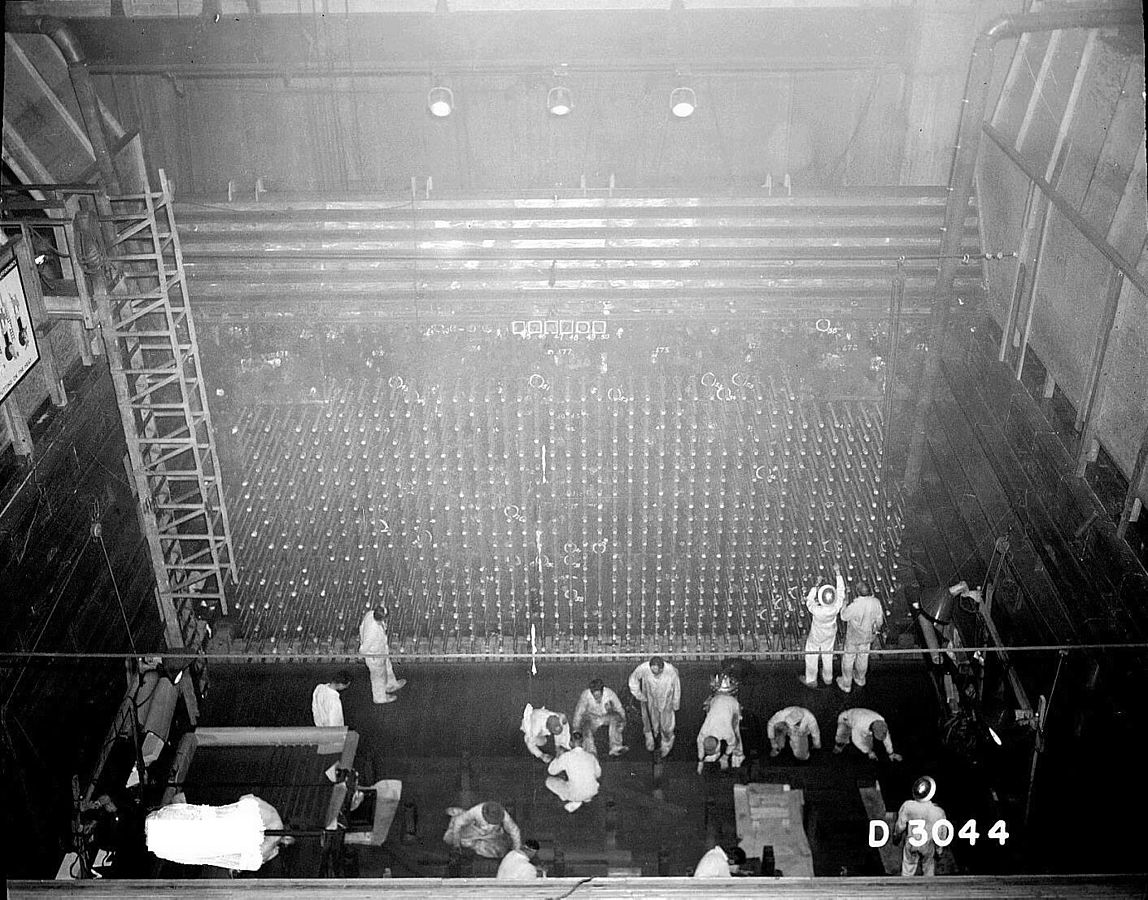

The world's first B industrial reactor in Hanford, USA. You can see the front panel with horizontal channels where fresh fuel was loaded. A source

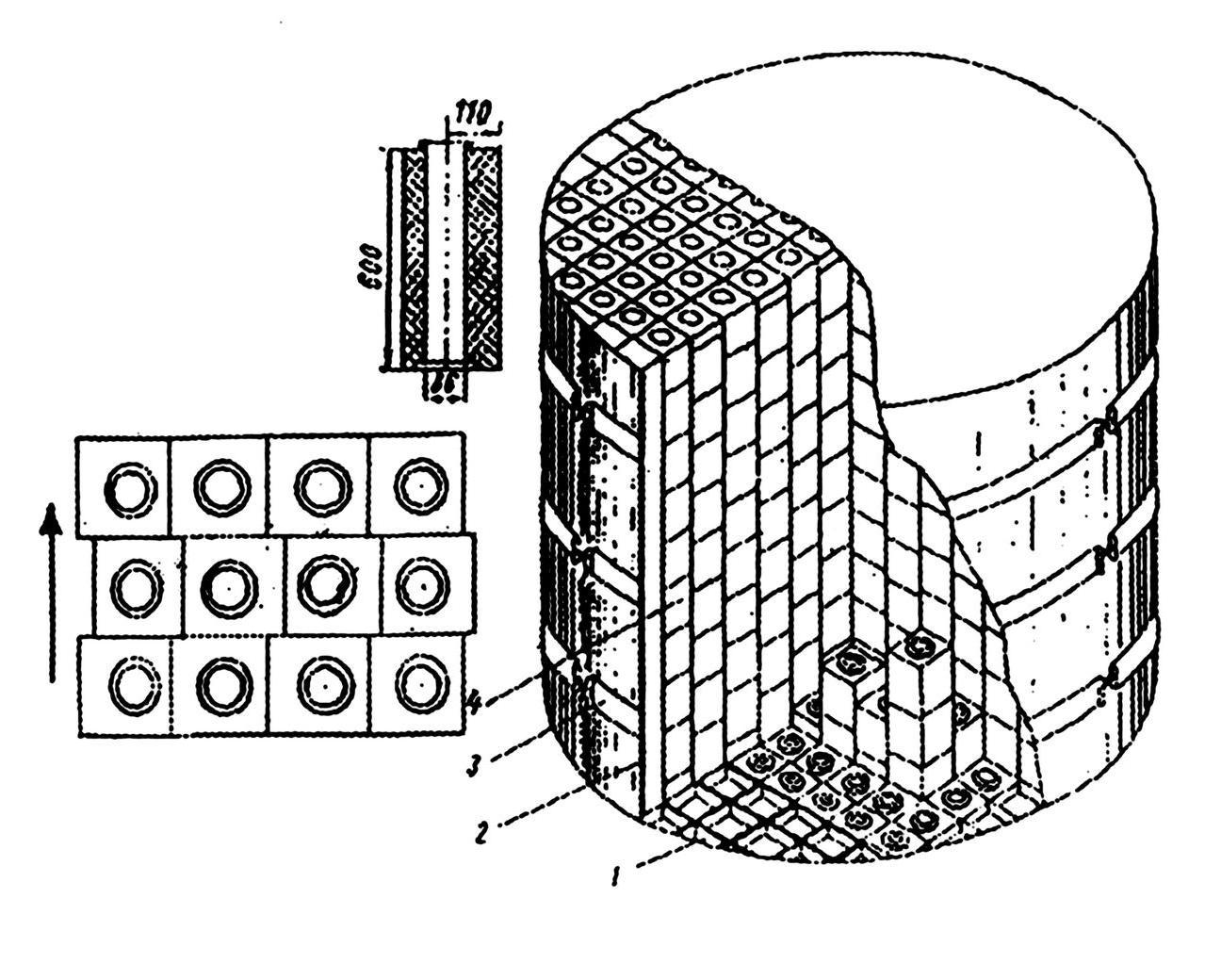

Scheme of graphite masonry in the active zone of the Soviet PUGR. The size of the cylinder is about 9 m in diameter and the same in height.

Thus, the reactor acted as a conveyor for the irradiation and formation of plutonium from natural uranium - it was a very simple but effective way to produce explosives for bombs. True, in this case, the reactor had to be cooled with water, which must be taken somewhere and then (often already contaminated with radionuclides from the fuel) drained, and when plutonium was released at radiochemical plants, a large amount of liquid radioactive waste was generated. But the time was such that the main task was solved in the first place - the creation of weapons. Alas, problems with waste were postponed until later and laid the foundation for many environmental consequences, now called the nuclear legacy.

Three plants were built in the USSR for the production of weapons-grade plutonium - PA Mayak (Ozersk, Chelyabinsk Region), SCC (Seversk, Tomsk Region) and the State Chemical Plant (Zheleznogorsk, Krasnoyarsk Territory). In total, 13 PUGRs were put into operation from 1948 to 1965 on them.

The first reactors at the Mayak Production Association

The first-born and the largest industrial site of the USSR’s nuclear complex is the Mayak Production Association (Mayak Production Association, formerly Plant No. 817, Magpie), located in Ozersk (formerly Chelyabinsk-40) in the Chelyabinsk Region, and has been operating since 1948. On June 8, 1948, the first uranium-graphite industrial reactor A (Annushka) in the country was launched at FSUE Mayak PA.

In August 1946, the project was approved and the construction of the reactor began. With minimal mechanization, in the conditions of a harsh Ural winter, by the spring of 1947, the hardest soil work was carried out at the plant's construction site - an excavation pit of 80 by 80 meters and a depth of 53 m was dug.In total, 157 thousand cubic meters of soil were excavated. At the final stage of excavation of rocky soil, 11 thousand diggers were employed.

The building of the first reactor "A". A source.

The cylindrical core of the reactor was 9.2 m in diameter and 9.2 m high. Graphite columns were made up of blocks of 600 mm high with a square section of 200x200 mm and a central hole with a diameter of 44 mm. Graphite masonry was vertically pierced by 1200 thin-walled aluminum pipes with a wall thickness of 1 mm, through which water flowed and in which uranium blocks (diameter 35 mm, height 100 mm) with an aluminum alloy shell were located. Each channel loaded 74 blocks. In the lower part of the pipes, they abutted the unloading device, which, if necessary, could issue one block from any vertical pipe. Under their own weight, the blocks fell into the water and fell into the overload shaft. Then they entered the transport gallery, where they were stored under a layer of water for 2 months, after which they went for processing.

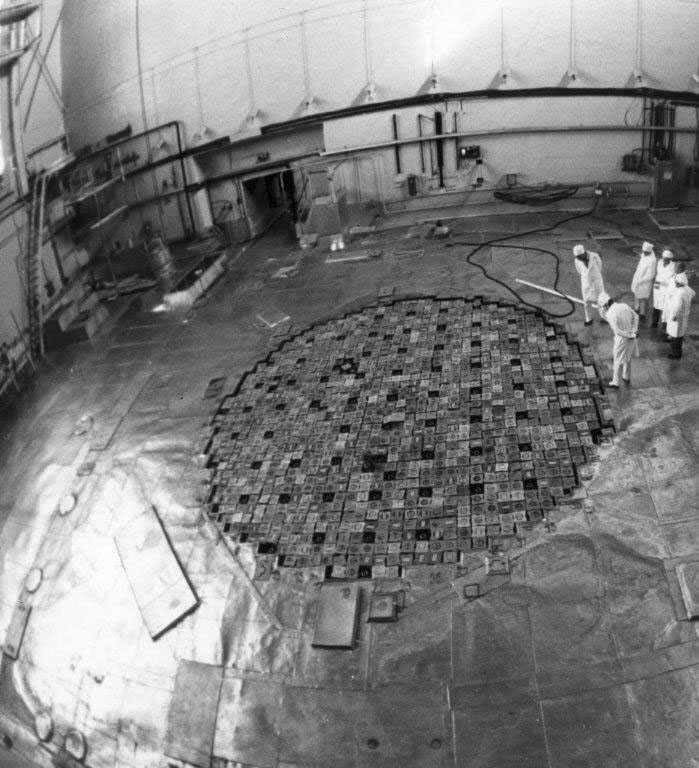

Reactor Hall A at the Mayak Production Association. ( Source )

On June 8, 1948, Kurchatov personally launched the reactor physically with a charge of about 75 tons of uranium. And a little less than a year later, on August 29, 1949 - the first atomic bomb of the USSR from plutonium obtained at the reactor was tested at the Semipalatinsk test site. According to the project, the first industrial reactor “A” was supposed to work for 3 years, but it worked for 39 years - until 1987. Read more about reactor "A" here .

In total, over the years the enterprise has existed, ten industrial reactors have been operating at the Mayak Production Association, two of which are currently in operation. Among them, 5 industrial uranium-graphite reactors - A, AI, AV-1, AV-2 and AV-3, were commissioned from 1948 to 1952. Their initial lifespan was short, but they worked for more than 30 years, modernizing during major repairs. They were stopped in the period from 1987 to 1990, and since then work has been underway on them to decommission.

Underground blood pressure at the Mining and Chemical Combine.

Mining and chemical plant, the third plutonium producing plant in the USSR, a unique enterprise located underground in a rock mass. At the site of FSUE "MCC" in Zheleznogorsk near Krasnoyarsk there are three PUGRs - AD, ADE-1 and ADE-2. Together with auxiliary equipment and communications, they are located in the rocky mine workings - in mines lined with monolithic concrete. According to the project, the reactors were supposed to be located in rocky soil at a depth of about 200 m in transverse workings 8-18 m wide, 60-80 m long and 5-30 m high.

Electric train to the underground mill of the Mining and Chemical Combine. Source

The PUGR AD was a single-purpose flow reactor with thermal neutrons. He worked from 1958 to 1992. Not only did this reactor have twice as much plutonium productivity as its predecessors, its design and specific power allowed it to raise the temperature of the cooling water at the outlet to the state of the turbine working fluid. In fact, it was a power reactor project.

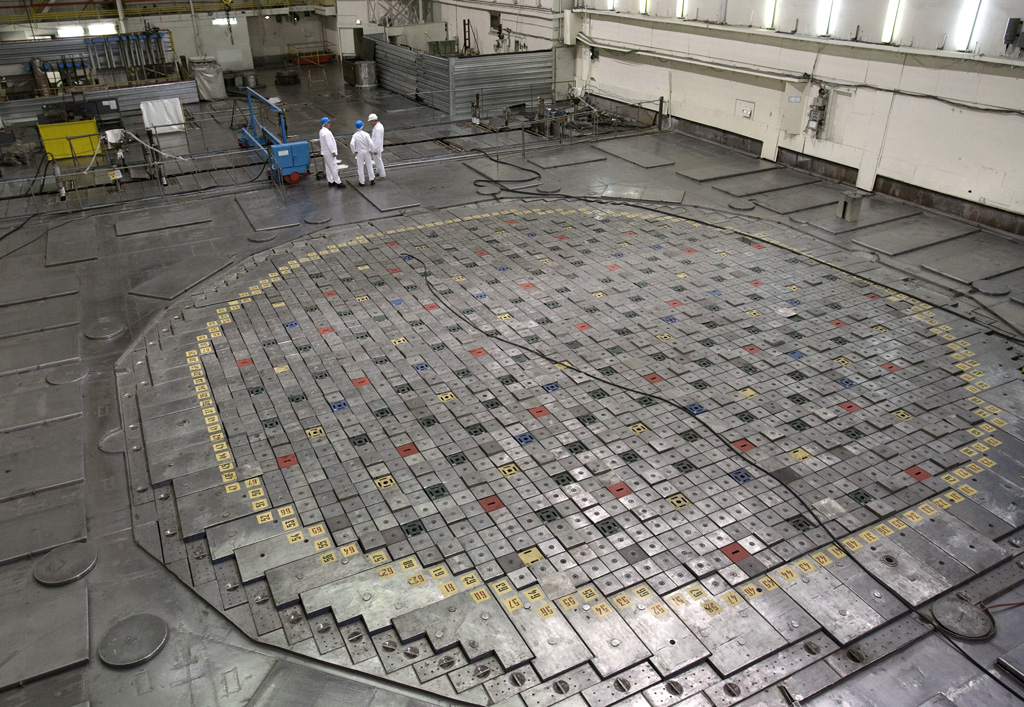

Shutdown of the ADE-2 reactor at the MCC on April 15, 2010 ( Source )

ADE-1 was designed as an energy reactor, but was operated as a single-purpose flow-through reactor from July 20, 1961. Stopped for decommissioning on September 29, 1992. ADE-2 has been operating in dual-purpose mode since 1964 (plutonium + electricity), and was stopped for decommissioning on April 15, 2010.

The first nuclear power plant at the Siberian Chemical Plant

In the period from 1953 to 1964, at the sites of the Siberian Chemical Plant in the city of Seversk (Tomsk Region), PUGRs I-1, EI-2, ADE-3, ADE-4, ADE-5 were built and put into operation. The I-1 reactor was intended solely for producing weapons-grade plutonium, the remaining reactors combined the functions of producing plutonium and generating electricity. For the first time in the world, the EI-2 reactor combined these functions. With the launch of this reactor in 1958, the first stage of the Siberian NPP with a capacity of 100 MW was launched, which became the second nuclear power station in the USSR after Obninsk, commissioned 4 years earlier. The reactors of the ADE series, as they were put into operation, gradually increased the capacity of the Siberian NPP. With the launch of ADE-5, the station’s capacity was 600 MW.

Siberian NPP at SCC is the first large nuclear power plant in the USSR and the only nuclear power plant in Siberia.

On the basis of the ADE-4 and ADE-5 reactors, a distant heat supply system was designed and implemented. The city of Tomsk was provided with cheap thermal energy due to the use of heat from the reactors ADE-4 and ADE-5. The reactors provided 30–35% of the heat needed for heating the housing estate of the city of Tomsk, and more than 50% - for the city of Seversk and the industrial sites of the plant. In 2008, the last industrial nuclear reactors were shut down in Seversk.

The legacy of industrial reactors

The experience of working with uranium-graphite reactors in the USSR not only provided the country with excess nuclear material, which is still utilized even as fuel for conventional nuclear power plants, but also opened the way to peaceful nuclear energy. The reactor of the world's first nuclear power plant in Obninsk, opened in 1954, the Siberian nuclear power plant, the first two power units of the Beloyarsk nuclear power plant, all units of the Bilibino nuclear power plant and a series of powerful RBMK-1000 reactors were developed on the basis of experience in the construction and operation of channel uranium-graphite reactors. But in addition to gaining experience, developing energy directions, PUGRs have become sources of many environmental problems. Frequent breakdowns, depressurization of fuel rods and failure led to the dumping of radionuclides into the environment with cooling water that got into the Yenisei and Tom rivers. The radiochemical redistribution of fuel during the separation of a valuable product, plutonium, led to the formation of the largest part of the USSR’s nuclear legacy - storage reservoirs of liquid radioactive waste in the form of the Techen cascade of reservoirs, Karachay and Staroe Bolot lakes at Mayak PA, underground storage strata at SCC and MCC.

RBMK-1000 reactors operating at the Leningrad, Smolensk and Kursk NPPs are the conceptual development of industrial uranium-graphite plutonium producers. Only plutonium was no longer extracted from their fuel.

Removal from service

In 1991, the United States and Russia signed an agreement on the final shutdown of weapons-grade plutonium reactors. To date, all PUGRs in Russia have been stopped and are at one or another stage of decommissioning.

As part of the federal target program of the Federal Target Program YaRB-1 (2008-2015), preparation was carried out and the first and unique operation was carried out to disassemble and preserve the PUGR on site. In 2010, on the basis of the SCC, the "Experimental Demonstration Center for Decommissioning Uranium-Graphite Nuclear Reactors" (ODC UGR) was formed. In September 2015, the UDC UGR completed the operation on the final decommissioning of the EI-2 reactor. Now it is essentially a hill. More than 100 thousand m3 of insulating materials based on local clays were used. The result of the work: nuclear materials were removed, the ground part and non-project storage facilities were liquidated. Graphite masonry is mothballed.

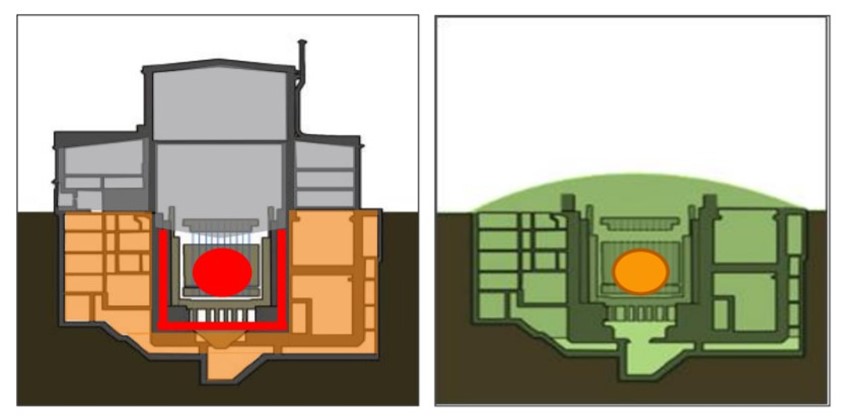

Schematic view of the EI-2 reactor at the SCC before (left) and after (right) the final conservation.

Decommissioning and mothballing of the PUGR “on the spot” is currently considered the most optimal concept, which allows reducing personnel loads during the decommissioning process, avoiding the movement of a large amount of radioactive materials and the creation of additional storage facilities for radioactive waste. However, not all reactors can be buried in this way. Within the framework of the federal target program “Ensuring Nuclear and Radiation Safety for 2016-2020 and for the Period Until 2030”, it is planned to additionally withdraw and finally conserve 8 out of 13 PUGRs, as well as solve issues related to the disposal of irradiated graphite.

A memorial plate on the background of the lawn at the site of decommissioning of the EI-2 reactor at the SCC. ( Source )

At present, reactors at the Mayak Production Association are preparing for decommissioning on-site based on the experience of SCC. In 2018, public discussions were held on the project on decommissioning of five industrial uranium-graphite reactors of the plant. As part of the upcoming decommissioning process, each reactor will be decontaminated (if necessary), dismantled the equipment and systems located in the reactor building and on the site. Then, the internal cavities of the reactor, the reactor shaft, and the building volumes of the reactor building premises will be filled with sorbing and waterproofing materials to zero, i.e. to the surface of the earth. After that, an additional barrier in the form of an upper hermetic protective plate will be created above the reactor shaft.

Instead of conclusions

The industrial uranium-graphite reactors that provided the USSR with the plutonium needed for nuclear weapons laid the foundation for the peaceful use of atomic energy at first-generation nuclear power plants and for launching a large-scale series of nuclear power plants with RBMK reactors, which still account for almost half of all atomic electricity in Russia. In the same way, after the end of their work, the PUGRs will become a testing ground for the development of technologies for the treatment of irradiated graphite necessary for decommissioning nuclear power plants with uranium-graphite reactors.

PS: It so happened that the other day at one of the nuclear facilities in the Sverdlovsk Region (I’ll write a separate post about it) I met specialists from SpetsAtomService, who will soon be working on decommissioning another PUGR at SCC. Funny matches sometimes happen.

Sources:

1. Chronicle of Rosatom. History of reactors.

2. Problems of nuclear legacy and ways to solve them. Volume 1

3. Experience on decommissioning of PUGR HELL by the “on-site burial” method

4. Five reactors producing weapons-grade plutonium at Mayak PA are planned to be buried on site

5. Technical solutions, technologies and experience of JSC “UDC UGR” on decommissioning of nuclear power plants