ADAM-6200 I / O Modules

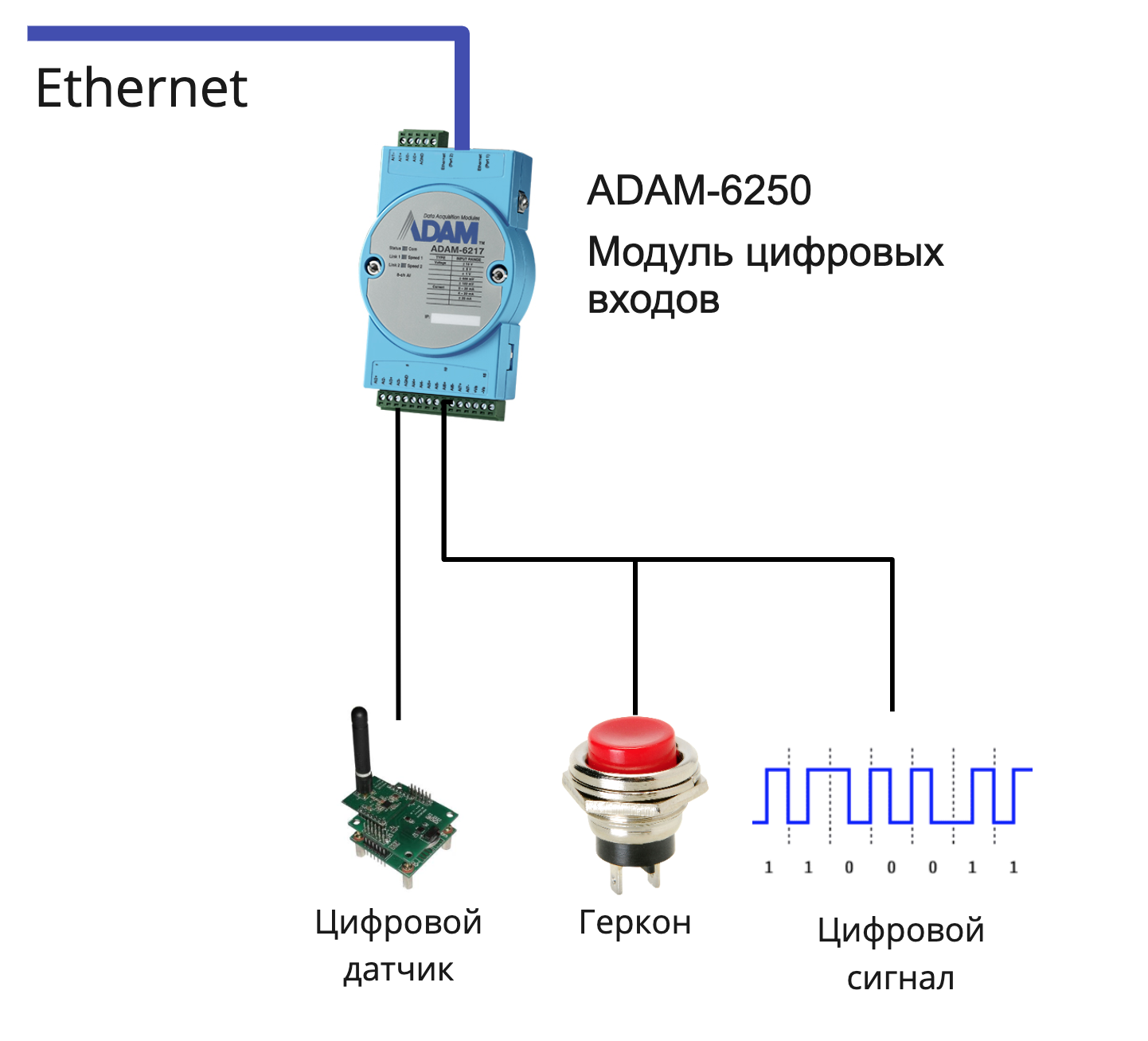

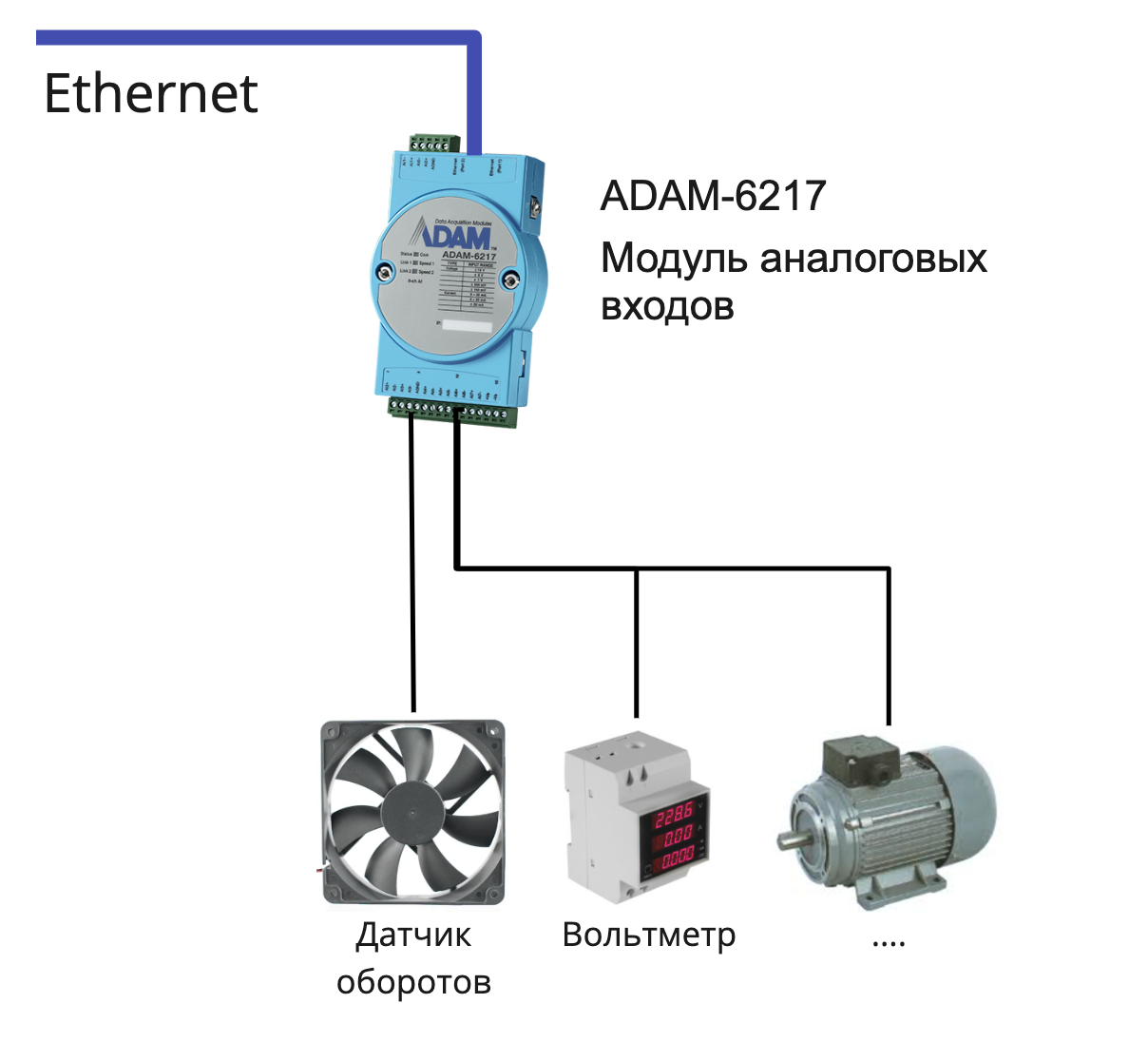

Remote I / O modules are designed to communicate with various types of peripherals. This is an essential element in building industrial systems. They can both receive signals from other devices, and send control signals to devices, integrating with SCADA central control systems via MODBUS TCP, MQTT, HTTP , etc.

The previous-generation I / O devices used in industry were usually connected using RS-232/485 serial interfaces, which made scalability of such systems difficult. The ADAM-6200 series of modules is distinguished by the ability to connect via Ethernet, as well as built-in switches for 2 Ethernet ports, which allows connecting devices in series in a chain.

In addition to signal transmission, the ADAM-6200 modules can play the role of programmable logic controllers to solve simple automation tasks. Thanks to the support of the language of conditional-graphic logic, they can be programmed even without knowledge of programming languages.

The article deals with the characteristics of devices, the scope and additional functions of protection against failures.

Specifications

The ADAM-6200 series is presented by various models for any industrial needs. Devices can be connected for joint autonomous work (peer-to-peer), which allows you to get any combination of the necessary ports.

- ADAM-6217 - 8 channels of analog inputs

- ADAM-6224 - 4 channels analog outputs

- ADAM-6250 - 15 channels of digital I / O

- ADAM-6251 - 16 channels of digital inputs

- ADAM-6256 - 16 channels of digital outputs

- ADAM-6260 - 6 relay channels

- ADAM-6266 - 4 relay channels

Supported Protocols

- Modbus TCP is an industry standard for connecting devices over IP. All devices in the series support this protocol.

- MQTT is a modern IoT protocol, often used to connect to a cloud system like Microsoft IoT hub and the like. Messages inside MQTT are transmitted in JSON format .

- HTTP REST API - web interface and REST API make it easy to integrate devices into existing solutions based on any platform: NodeJS, PHP, Python, etc.

- SNMP - used to configure network settings and collect statistics.

HTTP REST API

The versatility of the HTTP API makes it easy to integrate ADAM-6200 devices into any existing platform, without the need for specific industry protocols.

For example, let's analyze the request for receiving the status of an analog input:

Query analog input values

# : /analoginput/_/ curl http://10.0.0.1/analoginput/0/range

Answer

You can see the current value of current, equal to 7mA

<?xml version="1.0" ?> <ADAM-6217 status=”OK”> <AI> <ID>0</ID> <RANGE>7</RANGE> <NAME>4~20 mA</NAME> <MAX>20</MAX> <MIN>4</MIN> <UNIT>mA</UNIT> </AI> </ADAM-6217>

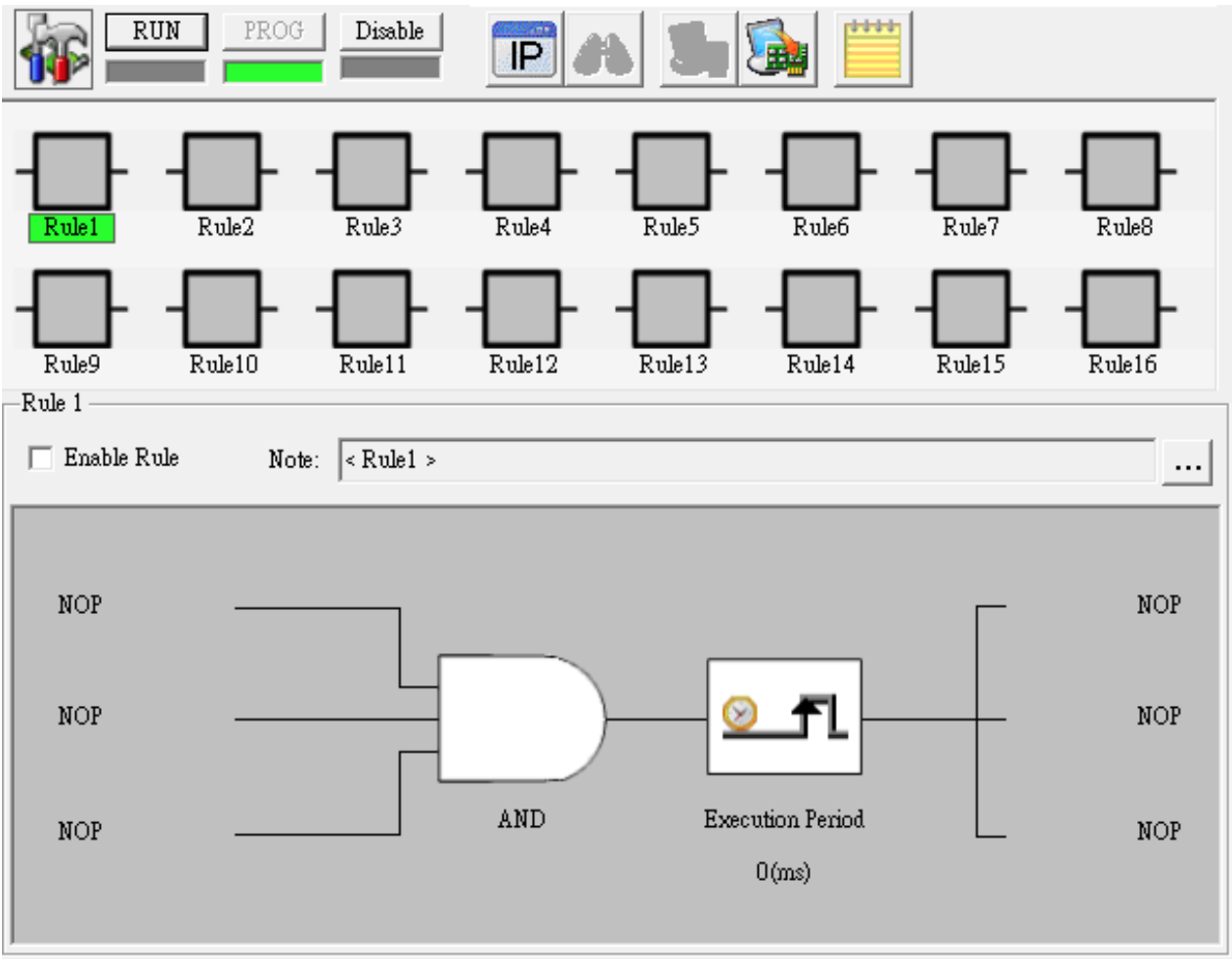

Programming Using Conditional Logic

Simple automation tasks that do not require large processing power can be programmed directly on ADAM controllers using the Graphic Condition Logic. For example, activate the siren in the event of an accident, close the valve in the event of a sensor, etc. The GCL environment almost does not require programming skills and allows you to create a full-fledged automation script using the mouse cursor.

Development of GCL scripts in the Adam / Apax .NET Utility program. As conditions, the states of digital or analog inputs, a discrete signal counter, an internal timer, etc. can be used. Rules can refer to each other and form more complex conditions. Read more about the GCL development environment in the documentation .

Conditional Logic Development Environment

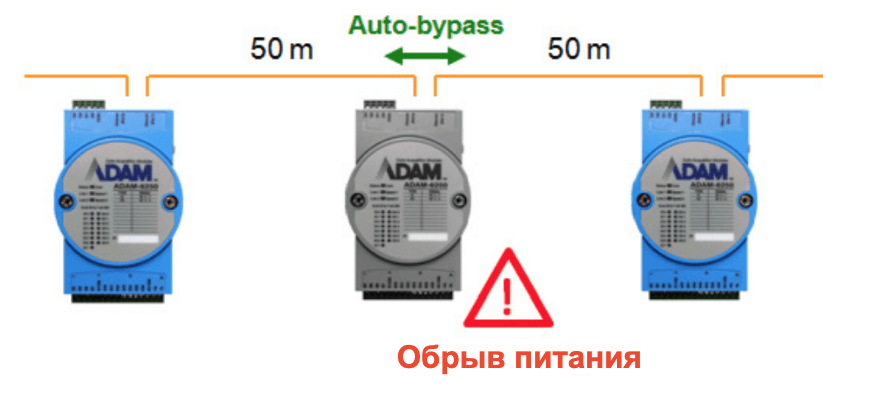

Serial Connection (Daisy Chain)

The devices of the ADAM-6200 series have two ethernet ports on board, which allows them to be connected in series, with a daisy chain. This greatly simplifies the network topology and eliminates the need for additional switches when building remote sections of the network.

In contrast to the connection using RS-232/485 interfaces, the ethernet connection allows you to easily integrate controllers into any IP network, as well as connect remote objects via the Internet using VPN tunnels, without the need to use additional interface converters.

Power Break Protection (Auto-Bypass)

The Auto-Bypass function is automatically activated when power is lost on an intermediate device in the chain. In this mode, the device acts as a passive connection, as if the cable was connected directly. In this case, there are restrictions for UTP connections, so it is important to take into account the total cable length between two neighboring points and not exceed 50 meters on each side, since the maximum length of the passive connection is 100 meters. The battery life of the function is up to 4 days.

Thanks to Auto-Bypass, communication does not break even when the intermediate device is de-energized

Conclusions

Universal ADAM-6200 I / O modules have wide protocol support: Modbus TCP, MQTT, HTTP REST, and can be easily integrated into both classic SCADA systems and any modern software products.

Support for programs in the GCL language allows you to solve simple automation tasks without the use of additional devices. Peer-to-peer interoperability enables data exchange directly between devices, without the use of intermediate data processing servers.

The ability to sequentially connect devices in a chain makes it easy to build large segments of the network without additional equipment, and the Auto-Bypass function protects against line breaks due to failure of devices in the chain.

Welcome to the Advantech Partner Forum

The Advantech Forum will be a unique platform for discussing local and global trends in the Internet of Things. Here you can exchange experiences using new technological solutions and products, find new customers and partners. You will have a chance to see the products that we described in articles and not only. We will feature industry leaders and representatives of key partners - NVidia, Intel and other companies that are actively involved in the development of the industrial Internet of Things for the coming years.

We will be glad to see all the experts in the field of industrial automation and the Internet of things at the event. Hurry up to register .

All Articles