In the skeleton of an adult, there are 206 bones, which together perform a musculoskeletal and protective function. Unfortunately, like all other parts of the human body, bones are also susceptible to various diseases, injuries, deformations and injuries. One of the most studied problems of the skeleton is osteoporosis, due to which the internal structure and bone density are disturbed. Previously, this disease was studied through x-rays, which allow to study the structure of bones and identify weak and strong points. Most often, scientists considered bone strength in terms of the maximum possible single load. However, a group of researchers from Cornell University decided to look at the problem of osteoporosis from a different angle. They suggested comparing a bone with a car part that has been working fine for quite a while, but somehow breaks down due to prolonged use. What did the scientists say about the new method of bone analysis, what structural changes in the bones can be prevented or changed, and how can this work contribute to the fight against osteoporosis and even help aviation? We learn about this from the report of the research group. Go.

Study basis

The central thesis of this work is: the mechanical properties of microarchitectural materials can be improved due to the geometry of the material, and not due to its composition (composition).

Ultralight microarchitectural materials may initially have increased rigidity and, therefore, strength, but they must also withstand multiple load cycles, that is, not only strong, but also durable. If we talk about the natural equivalents of such materials, then the bones of the human skeleton perfectly describe such structures.

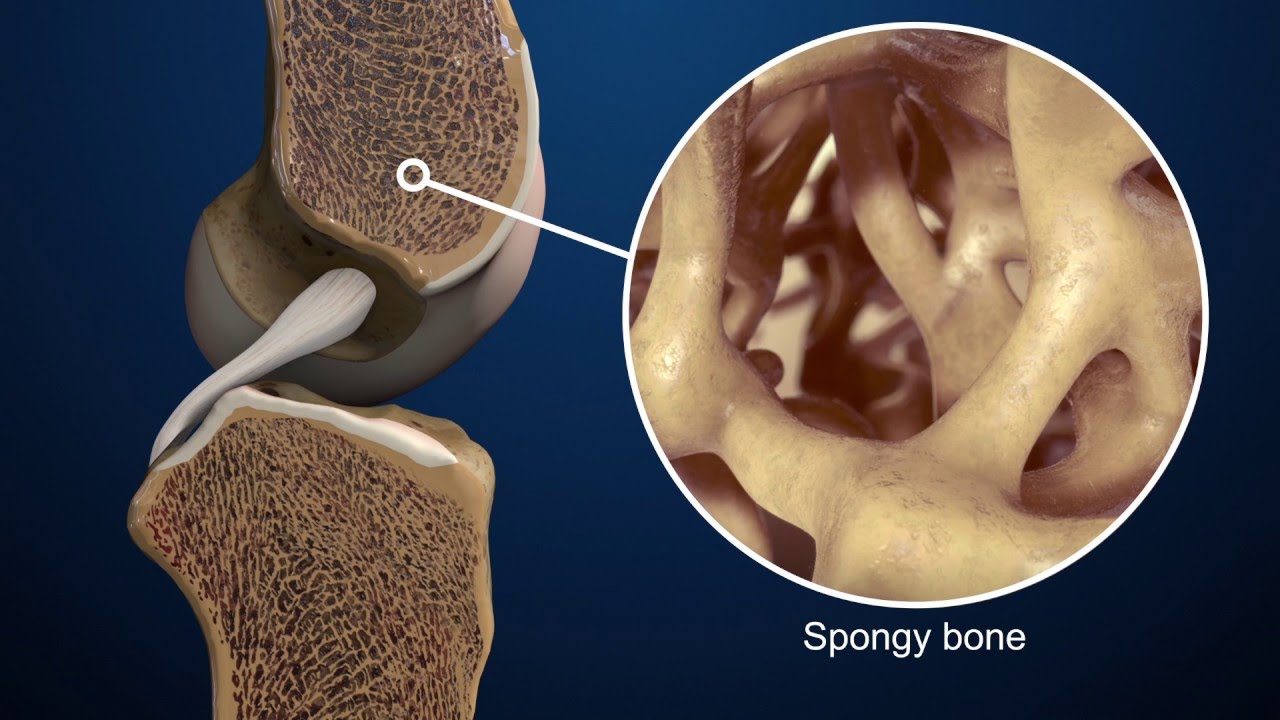

Bones in their structure consist of several basic building materials: compact bone substance, spongy bone substance and periosteum. The latter is a membrane of the bone, which consists of certain connective tissues containing blood vessels and cellular elements involved in the nutrition, growth and restoration of bones.

The compact bone substance is the upper layer of bone and is very uniform and hard. But the spongy, which is located inside the bone, consists of many plates intersecting in different directions.

The researchers believe that thickening of some of the spongy platelets can improve the overall mechanical properties of the bone, i.e. increase its strength and durability.

This theory is based on the fact that microarchitectural materials may be subject to material fatigue * , as their complex internal geometry leads to stress accumulation.

Fatigue of the material * - the process of the gradual accumulation of damage, leading to a change in the mechanical properties of the material.Scientists believe that the most important thing in their study is to find a balance between the strength of the material and its resistance to fatigue. And since there is no better mastermind than nature, scientists decided to seek this balance in natural microarchitectural material, i.e. in the bones.

As we already know, bones contain many plates (septa) that intersect at different points, forming a spongy substance. These plates are also called trabeculae. They are most often located in the direction of stresses caused by normal physical activity, which leads to the formation of a transverse isotropic microstructure.

Previous studies have revealed that the main factor affecting the strength of the trabecular bone is the density / porosity and tissue tensor (a measure of anisotropy * ).

Anisotropy * - the difference (heterogeneity) of the properties of the medium in various directions within it.But other aspects of microarchitecture and their effect on bone strength have not been studied.

The rigidity and strength of the cancellous bone and other cellular solids are associated with density through power laws * .

The power law * is a functional relationship between two quantities, in which a relative change in one leads to a proportional change in the second.Scientists note that there is already an analytical method linking the density of the spongy substance and the fatigue of the material (number of cycles to complete wear, N f ). However, fatigue of spongy substances, in their opinion, is better explained by the normalized ratios of stress and resource ( AN ) of the material:

σ / E 0 1 / √ ψ = AN B f

where σ is the maximum compression stress;

E 0 is the initial Young's modulus (alternatively, the yield strength or plateau stress is used);

A and B are empirical constants (in the cancellous bone, A varies from 0.0091 to 0.013, and B ranges from -0.121 to -0.094).

It is worth noting that this method of assessing material fatigue, although it is very successful, but some variables (for example, A and B) may differ for materials of different origin (for example, spongy bone tissue of a person and a dog).

Research results

To understand the relationship between microarchitecture and material fatigue, scientists analyzed highly porous (> 90%) spongy bone tissue of human vertebrae (44 samples from 18 donors).

A cyclic compression load was applied to each sample in the direction of the usual physiological load.

The material fatigue load was stopped at a certain value of stress cycles, determined by the accumulation of cyclic load. After that, the number and location of all microscopic lesions in the microstructure were evaluated by using contrast agents ( 1A and 1B ).

Image No. 1: the effect of microarchitecture on the accumulation of fatigue injuries in the cancellous bone.

The microarchitecture was evaluated using three-dimensional images and analyzed using the morphological decomposition approach, which isolates each individual partition in the structure and classifies it as lamellar or rod-shaped, and also determines its orientation relative to the load ( 1C and 1D ).

It was found that the number of tissue damage caused by fatigue loading correlated with the maximum applied strain, but did not correlate with the density of the sample or other microstructure averages in the image.

Curiously, the degree of tissue damage was less in samples with thicker rod-shaped septa ( 1E ). This observation was very unexpected, since the rod-shaped septa in the cancellous bone are primarily oriented transversely to the applied load, amounting to

this is only 20% of the hard volume of the spongy bone of high porosity. In addition, they carry only a small fraction of longitudinally oriented loads and have little effect on stiffness and strength in the longitudinal direction.

Scientists then investigated the distribution of tissue damage at different points during the process of fatigue loading, which allowed them to better understand the effect of rod-like partitions on bone fatigue. It was found that the destruction of individual trabeculae during fatigue loading occurs non-linearly with the cycle number and differs in type / orientation of the trabeculae. Initially, damage occurs in rod-shaped trabeculae, and in plate-shaped trabeculai, a significant accumulation of damage does not occur until the entire structure ( 1F ) is clearly destroyed.

The nature of the destruction of the septum is also associated with its orientation: the damaged rod-shaped trabeculae are predominantly oriented in the transverse direction, while the damaged plate-shaped trabeculae are predominantly oriented in the longitudinal direction.

Researchers believe that this behavior of the destruction of individual partitions depends on the distribution of tensile stress caused by the load. Modeling showed that the compression load leads to tensile stresses in rod-shaped trabeculae (mainly transversely oriented) and compressive stresses in plate-shaped trabeculae (mainly longitudinally oriented).

These observations suggest that in the spongy tissue of the bone, it is precisely the transversely oriented trabeculae that act as a “justifiable victim” during cyclic loading, accumulating tissue damage and thus protecting the longitudinally oriented lamellar trabeculae, the destruction of which will lead to the complete destruction of the structure.

Image No. 2: Sponge bone models obtained using 3D printing show that fatigue strength is sensitive to small changes in microarchitecture.

Another important component of damage accumulation in the trabecular bone is tissue heterogeneity. To isolate the effects of the microstructure from those associated with the heterogeneity of the material, scientists have created three-dimensional models of the microstructure of the cancellous bone ( 2A and 2B ).

The spongy bone microstructure ( 2B ) was modified by adding material to the surface of the transverse trabeculae. There were three types of modifications: unchanged (initial geometry); +20 μm on the surface (average increase in trabecula thickness by 20 ± 5%); +60 μm on each surface (average increase in trabecula thickness by 45 ± 14%).

Since the transverse rod-shaped trabeculae make up only a small part of the solid volume and carry only a small part of the longitudinal loads, the thickening of the rod-like partitions had only a small effect on the density, which increased by 11 ± 8% ( 2C ), and on the stiffness, the increase of the longitudinal Young's modulus of which was 22 ± 19% ( 2D ).

If such changes take place uniformly throughout the microstructure, then the fatigue strength varies very slightly. If such changes are applicable only to rod-shaped trabeculae, then the fatigue strength increases by two orders of magnitude ( 2E ).

To confirm that damage accumulation proceeds in the models as well as in the cancellous bone, damage studies in three-dimensional printed samples were carried out after a certain load using a radiopaque dye.

It was found that in models the damage accumulation sites defined by contrast are distributed throughout the structure, as well as in the spongy bone tissue studied previously ( 2F ). But the models, when printed which were set thicker rod-shaped partitions, showed a reduced accumulation of damage ( 2G ).

Therefore, damage accumulation due to fatigue loading can be reduced by changing the thickness of the rod-shaped trabeculae within the structure of the spongy bone tissue or similar septa in a three-dimensional printed sample.

It also became clear that the average tensile stress in rod-shaped trabeculae (mainly transversely oriented) was higher than that of lamellar trabeculae (mainly longitudinally oriented). This suggests that the localization of the damage corresponds to the distribution of stresses in the microarchitecture, as was found in real cancellous bone.

Summarizing the above observations, scientists suggest that a slight increase in mass, concentrated on the transversely oriented structural components of the microarchitecture, can reduce tensile stress, which is a significant contribution to fatigue strength.

Image 3: The effect of the transverse volume on the fatigue strength of porous (cellular) solids.

The researchers then decided to check whether their discoveries are applicable to other porous solids and other deformation mechanisms. For this, models of conventional and modified octet trusses * ( octet truss ) were created. The latter differed from the usual ones in that they had elements in the form of plates and rods, simulating the microstructure and anisotropy of the trabecular bone ( 3A ).

Farm * - in this case, it is not agricultural land that is meant, but the core structure, which remains unchanged after replacing rigid nodes with articulated ones.The microstructure of the cancellous bone shows a behavior in which bending deformation predominates, the usual octet truss is tensile strain, and in modified octet trusses, a combination of bends and stretching is observed.

An example of an octet farm.

Octet farm * - this type of construction in 1961 was proposed by Richard Buckminster Fuller (1895–1981). The structure is based on an octahedral-tetrahedral geometric pattern, which consists of lines connecting the centers of the balls so that each ball is surrounded by twelve other balls.

As a result, an increase in the transverse thickness of the rods in bone-shaped microarchitectures led to an increase in fatigue strength by 8 times ( 3V ), while the density increased slightly (+ 4%), as did the longitudinal stiffness (+ 20%).

In an octet farm, an increase in the transverse thickness of the rods led to an increase in fatigue strength by a factor of 5 ( 3B ), the density increased by 10%, and the longitudinal stiffness by 14%.

But with the modified octet farms, the situation was much more interesting. When this model was rotated 90 ° so that the thickened elements were vertically oriented and inclined to the applied loads, the fatigue strength decreased by 9 times compared to the model without thickened struts. This suggests that the effect of the transverse elements on the fatigue strength is associated with the proportion of the material oriented across the load, and not with the thickness of the transverse rods per se. In order to understand exactly how the transversely oriented elements influence the accumulation of fatigue damage, the finite element method was applied for several load cycles.

Fatigue damage involves a local, irreversible process of energy dissipation, leading to an increase in energy dissipation. The finite element models of the first 5-25 load cycles showed that the fatigue strength of the octet and bone-like microarchitecture with and without thickened rods is closely related to plastic energy dissipation per working unit ( 3C ).

Therefore, an increase in the transverse volume fraction ( ψ is the fraction of the solid volume oriented in the transverse direction to the load) in these microarchitectural materials reduces energy dissipation and damage accumulation during cyclic loading. Such an observation resembles the situation with rod-shaped trabeculae (mainly transversely oriented), which experienced less accumulation of damage in the trabecular bone, if their thickness was slightly increased ( 1E ).

The use of a single super-load (deformation of 50%) showed that bones and microarchitectural materials are able to repair most of the damage after an applied stress, which is explained by elastic (reversible) deformations in transversely oriented rods.

Thus, it becomes clear that it is precisely the transversely oriented rods or partitions (trabeculae) that play an important role in resisting fatigue failure. In other words, the observations show that it is the geometry of the structure that is important, and not its chemical composition.

For a more detailed acquaintance with the nuances of the study, I recommend that you look into the report of scientists and additional materials to it.

Epilogue

In this work, researchers were able to establish that microstructures can be extremely durable and resistant to deformation. The main conclusion is the fact that the origin of the material (biological or synthetic) does not matter when the correct geometry of the internal elements of the microarchitecture is applied. Changing the thickness of the individual components allows you to extend the life of the entire structure, without significant losses from stiffness, strength or other important mechanical characteristics.

This study, according to its authors, can find its application as in medicine, allowing a better understanding of the processes associated with osteoporosis. For osteoporosis is characterized by a deterioration in the microstructure of the cancellous bone, which is expressed in a sharp decrease in the number and strength of transversely oriented trabeculae. It was previously believed that stiffness, strength, and energy absorption of the trabecular bone depend almost entirely on longitudinally oriented trabeculae. But in this study, it was proved that transversely oriented ones play an important role, especially in the framework of the fatigue strength of bones. Researchers do not reject the fact that many bone injuries in patients with osteoporosis are caused by a single overload (fall, weight lifting, etc.). However, the most common injuries associated with osteoporosis are nevertheless spinal injuries, which often occur in the absence of any super-loads, i.e. are a consequence of the loss of fatigue strength. That is why it is necessary to pay attention not only to longitudinally oriented, but also to transversely oriented trabeculae.

As for aviation and other industries, the results of this study may push engineers to develop new types of parts that will be super-strong and durable, while remaining ultra-light, which is important for aircraft wings, for example.

Thank you for your attention, remain curious and have a good working week, guys! :)

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to your friends, cloud VPS for developers from $ 4.99 , a 30% discount for Habr users on a unique analog of entry-level servers that was invented by us for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share a server? (options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

Dell R730xd 2 times cheaper? Only we have 2 x Intel TetraDeca-Core Xeon 2x E5-2697v3 2.6GHz 14C 64GB DDR4 4x960GB SSD 1Gbps 100 TV from $ 199 in the Netherlands! Dell R420 - 2x E5-2430 2.2Ghz 6C 128GB DDR3 2x960GB SSD 1Gbps 100TB - from $ 99! Read about How to Build Infrastructure Bldg. class c using Dell R730xd E5-2650 v4 servers costing 9,000 euros for a penny?