What is the most durable material on the planet? There is no definite answer to this question, since it all depends on how exactly you will evaluate strength, and what you mean by this term. Someone will name diamond - the most durable mineral, someone will name a web with a tensile strength of up to 2.7 GPa, i.e. about 2 times more than steel. In other words, there are a lot of strong materials of organic and inorganic origin. Scientists from all over the world spend years studying these materials in order to establish all the physical and chemical processes that lead to their formation. The mother of pearl, an organic-inorganic material that covers the inner walls of mollusk shells and is the basis of pearls, is considered to be a unique object of one of these long-term studies. Today we will meet with you a study in which scientists from the University of Michigan decided to reveal the secret of one of the most durable natural materials by observing it in real time. What did scientists manage to find out, what unusual characteristics are mother of pearl, what nanomechanical processes occur in it, and what do these discoveries mean for humanity? We learn about this from the report of the research group. Go.

Study basis

Noble pinna

The mollusk of the species Pinna nobilis or noble pinna was chosen as the source of nacre for research. The shell of these endemic Mediterranean Sea can reach 120 cm in length. In shape, it resembles a drop, the sharp end of which is attached to the surface by means of unusual “roots” - byssus threads. The organism of the mollusk secretes byssus (1-2 grams), which hardens in the form of threads 5-6 cm long. People used these threads to create fine linen (sea silk), which, of course, was considered very expensive and difficult to manufacture. Considering the volume of byssus produced by one mollusk, for the manufacture of 200-300 grams of fine linen it was necessary to “uproot” thousands of mollusks. In addition, people also ate shellfish meat, which also negatively affected their population. It is difficult to call the noble pinna itself dangerous for anyone other than phytoplankton, since it, like many bivalves, is a filter.

Chiara Vigo, a fine linen master, talks about his craft.

Mother of pearl differs from many other materials in that it is of both organic and inorganic origin. The fact is that the main chemical compound in the mother of pearl is the mineral aragonite (CaCO 3 ), more precisely, hexagonal plates of aragonite 10–20 μm wide and 0.5 μm thick. These mineral plates are arranged in parallel plates (layers), separated by layers of an organic matrix, consisting of elastic biopolymers (chitin, lustrin and silk-like proteins). Previously, it was found that nacre consists of 95-98% CaCO 3 , and 2-5% are biopolymers. Separately, these constituent elements are quite fragile, but together they make the mother of pearl very strong and elastic (Young's modulus of dry mother of pearl is 70 GPa). The placement of aragonite slabs resembling a brick wall also plays a positive role in the indicators of the strength of nacre, which prevents crack propagation.

The inner walls of the shell of a noble pinna.

The appearance of mother-of-pearl has always been admired: a smooth and silver surface, shimmering in the light with all the colors of the rainbow. Similar observations also have a completely scientific explanation, of course. The bottom line is that the thickness of the plates of aragonite is very close to the wavelength of visible light. And if we take into account that there are a lot of these plates, then the light falling on each of them undergoes interference, from which we see different colors from different angles.

A box for documents covered with mother of pearl (XIX-XX century, an exhibit at the National Museum of South Korea).

Mother of pearl has been known to man for many thousands of years. This material was used, for obvious reasons, to decorate a wide variety of objects: from cups and brooches to daggers and powder flasks.

But for the primary owners of nacre, that is, for mollusks, this material was not for beauty. The mantle mantle tissue epithelial cells secrete nacre, which is constantly deposited on the inner walls of the shell. The resulting protective layer fights against parasites and various microscopic debris, enveloping it with mother of pearl. As a result of this process, a blister pearl is attached to the inside of the shell, or a free pearl in the mantle tissue.

Studies of mother-of-pearl were carried out repeatedly, and each of them added a bit of knowledge necessary for understanding this material.

Mother of pearl plate architecture.

For example, it was found that when a crack occurs, the mother of pearl exhibits a crack resistance 40 times higher than that of the monolithic / monocrystalline calcium carbonate of which it consists. Consequently, the strength of nacre is not particularly dependent on its chemical composition, and its mechanical properties are much more important.

If we examine in more detail the composition of nacre (aragonite + biopolymers), it turns out that the mollusk Pinna nobilis has a percentage of organic matter in the nacre of 3.4 ± 1.0% and consists of organic interlamellar membranes and intracrystalline organic substances embedded in 5-20 nm mineral plates .

Aragonite Crystal

The surface of the plates contains nano-irregularities, presumably playing an important role in preventing their slipping. The surface irregularities between the opposite mother-of-pearl plates sometimes form narrow (20–50 nm) internal mineral bridges without external stress, connecting across the interlamellar membranes. A wider (150-200 nm) main internal mineral bridges are involved in the initial formation of new plates.

In previous studies, scientists suggested that preventing the propagation of cracks on the mother of pearl is caused by the controlled sliding of aragonite layers on top of each other, which contributes to the visco-plastic energy dissipation into the organic layer. However, one cannot say for sure that this mechanism is the main, and even more unique.

In the study we are considering today, scientists observed the deformation of nacre using TEM and PREM (transmission and transmission scanning electron microscopes) in combination with nanoindentation * .

Nanoindentation * - study of a material by pressing a special tool, an indenter, into the surface of a sample.The nanoindentation method showed that while the indenter pressed the sample, the mother of pearl showed strong adhesion, i.e. inorganic plates come into contact with each other through organic interfaces. After the indenter is removed, the interface is completely restored, while maintaining its mechanical strength. During compression, aragonite grains and organic inclusions rotate and deform reversibly, which indicates the nanoscale elasticity of mother of pearl plates.

When fracture does occur, organic components prevent the propagation of cracks within and between the plates, supporting a common macro-scale architecture to provide further structural loading. This is what allows mother of pearl to absorb significantly more mechanical energy than monolithic aragonite. It was found that nacre absorbs about 3 times more mechanical energy than geological (i.e., inorganic origin) aragonite, before the onset of destruction.

Scientists also measured the yield strength at the time of compression along the c axis (direction of plate growth). It turned out that this indicator is three times higher for the mother of pearl plate than for the bulk mother of pearl.

And now we proceed directly to a more detailed examination of the results of observations.

Research results

During microscopy, at the contact area of the indenter and the sample in the range 0.04-0.2 μm 2 , nonlinear processes of nanoscale elastic deformation * and hardening were observed.

Elastic deformation * is a type of deformation that disappears after an external force that causes the appearance of deformations ceases to act on the object.

Image No. 1

Figure 1a shows the inside of a noble pinna shell. And on 1b we can see the interface between the plates before the pressure test.

Microscopy made it possible to single out a number of strengthening processes due to the hierarchical structure of the mother of pearl: (i) plate adhesion, (ii) deformation damping, (iii) blunting of cracks, and (iv) intracrystalline deformation and rotation of nanograins and organics.

Despite the fact that organic elements make up only a few percent of the total mass (2-5%) of nacre, they provide a number of functions that absorb the energy of the applied loads.

Dark-field microscopy made it possible to accurately estimate the volume fraction of organic matter in the mother of pearl: 7.1 ± 2.2% (3.4 ± 1.0% of the total mass), consisting of 2.5 ± 0.3% (1.2 ± 0.1% of the total mass) of interlamellar material and 4.6 ± 1.9% (2.2 ± 0.9% of the total mass) of intracrystalline material.

These organic inclusions allow mother of pearl to restore its original (before deformation) morphology at the nanoscale. At high loads (0.7 GPa per 1d ), opposing plates begin to cling to each other through the mineral-organic interface, forming temporary inorganic compounds. In addition, the entire volume of the plate is compressed, which leads to a slight deformation of organic inclusions.

After the load is deactivated, the mineral compounds at the deformed organic interface and the intrastructural nanostructure perfectly restore their original morphology without any stable deformation ( 1e ). Scientists conducted similar tests with a pressure load in different parts of the pinna shell, and all of them showed the same result - a complete restoration of the mother of pearl morphology.

Image No. 2

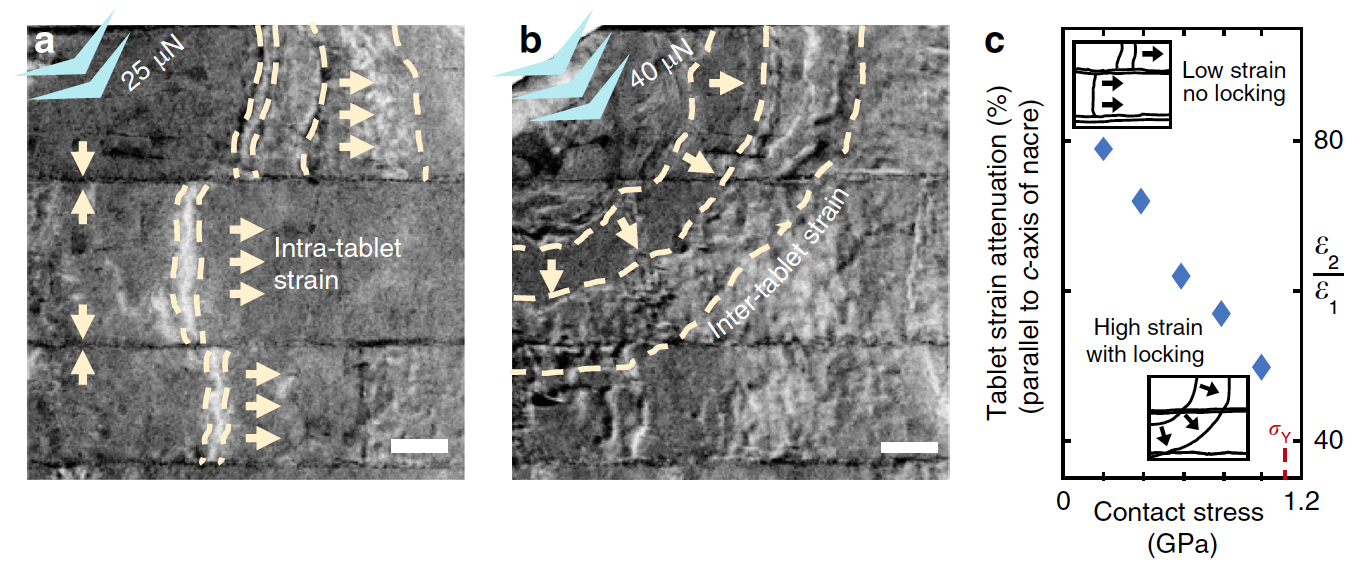

During the TEM study, it was revealed that the mother of pearl exhibits various mechanical responses to strong and weak compression, visible in the deformation contours. The next compressive load, applied along the growth direction of the plates, creates a deformation contour that extends transversely into each plate ( 2a ). But the shear of the interlamellar membranes prevents longitudinal propagation to adjacent plates.

At higher loads, the plates are connected, coming into direct contact with each other, which allows deformation contours to propagate along the plates in a radial direction from the indentation point ( 2b ).

In the case of applying ~ 3% of the engineering voltage (nominal) in the first plate, the contours are distributed continuously, and at ~ 6% of the voltage, the adhesion between the plates is clearly visible.

With a further increase in contact stress, the adhesion of the plates propagates farther and farther from the contact point, and the strain attenuation decreases linearly. That is, the deformability * of the plates decreases, since the pearl begins to behave as a monolithic material ( 2c ).

Deformability * - the ability of a material to take the required shape under the influence of a load without fracture.During experiments using pressure, the strongly deformed nacre fully recovered to ~ 80% of its initial state.

Image No. 3

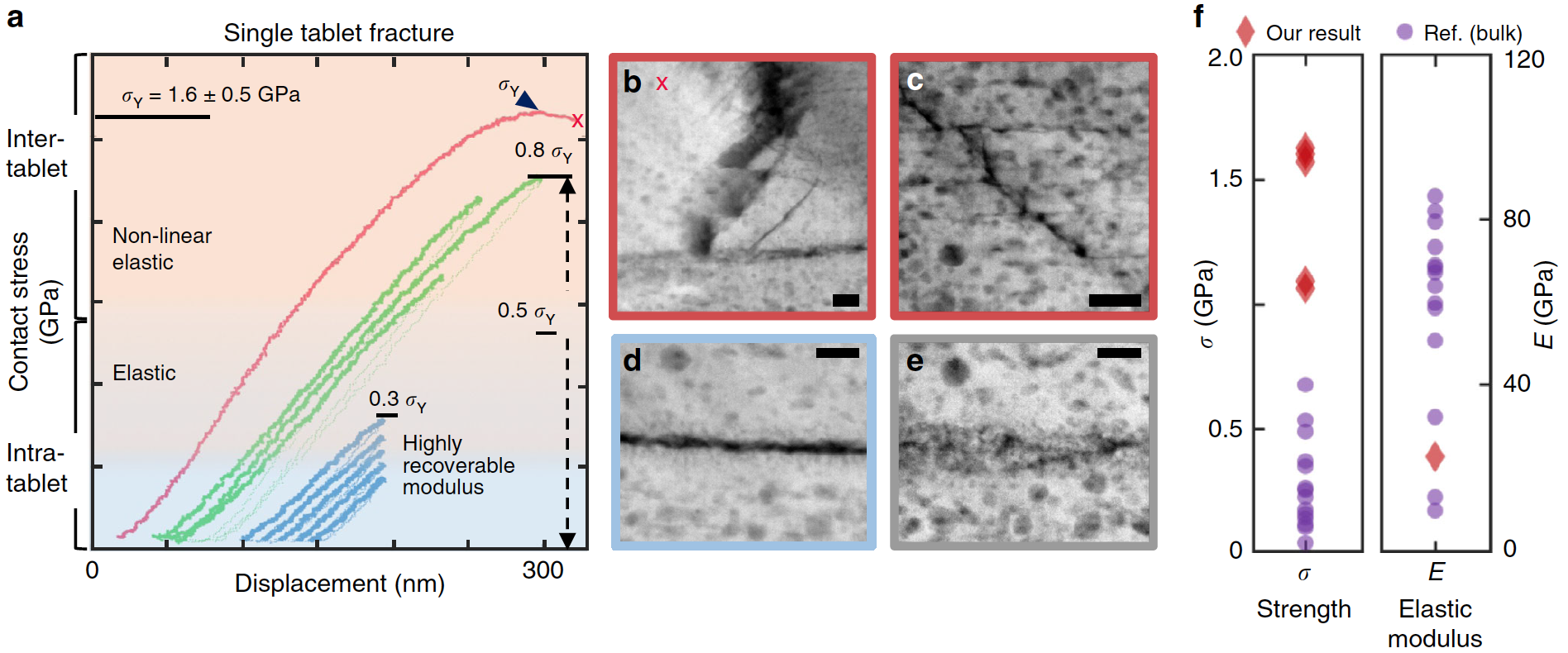

This is clearly seen in graph 3a , where the elastic modulus remains unchanged for eight consecutive compressions (blue and red lines). Pictures of the sample in 3d and 3d show that after increasing the load to 0.8 GPa and above, the mother of pearl begins to show signs of nonlinear elastic deformation. However, unlike traditional plastic deformation * , the original structure is preserved after stress relief. Complete recovery was observed even in severely deformed nacre (~ 0.8 - 1.1 GPa).

Plastic deformation * is a type of deformation, the consequences of which do not disappear even after removal of the load that caused it, i.e. it is irreversible. Plastic deformation is the opposite of elastic.Such a preservation of mechanical strength during repeated load cycles suggests a nonlinear process of elastic deformation, characterized by nanomechanical elasticity, which is absent in traditional bulk materials. This, according to scientists, is uniquely related to the process of adhesion of adjacent plates.

In addition to this, it can be assumed that the rotation and deformation of organic inclusions and mineral nanograins also affect the mechanism of viscoelasticity.

This statement was confirmed by TEM analysis, which showed that individual aragonite nanograins change contrast, as they reorient, and organic inclusions slightly change their volume.

The deformation of these nanometer-sized organic inclusions upon compression of the material distributes the load, avoiding irreversible damage to the inorganic matrix ( 1c - 1e ).

Unlike nano- or microgranular metals, which are hardened by reducing the mobility of dislocations at grain boundaries, the protein organic components of the mother of pearl contain flexible molecular bonds that elastically distribute the deformation and rotation of the nanograins, thereby returning the system to its original state after the external load is removed.

The energy absorption during stretching / development of the protein and the subsequent release of energy during the repeated convolution of elastomeric molecules provides high elasticity in the mother of pearl. But nanocrystalline or nanodoubled metals, on the contrary, have lower elasticity, since they exhibit ductility solely due to dislocations.

If the external load nevertheless leads to failure at the point of contact, then the organic components in the mother of pearl prevent the propagation of cracks both inside and between the plates ( 3b , 3c and 4c ). If in more detail, then small organic inclusions in the inorganic matrix prevent the propagation of cracks inside the plate, blunting the cracks deflecting their direction ( 3c ). And the interlamellar membrane prevents the cracks from spreading between the plates ( 3b ).

After each damage, the general macro-scale architecture of the mother of pearl remains low and retains its mechanical properties ( 4a - 4c and the video below).

Image No. 4

Maintaining the integrity of the mother of pearl architecture after several voltage cycles.

In solid fracture mechanics, the ability to resist fracture is quantified by crack resistance in the presence of a crack. Mother of pearl is a very complex system with many components, because of which local stresses can lead to many responses. An analysis of the exchange sample of nacre showed that its crack resistance is 10 MPa · m 1/2 , which is 40 times higher than that of single-crystal aragonite ~ 0.25 MPa · m 1/2 .

Given that nacre can withstand several damages (load cycles) until it is completely destroyed due to the mixed structure of organics and mineral components, it is impossible to determine its crack resistance by initiating cracks.

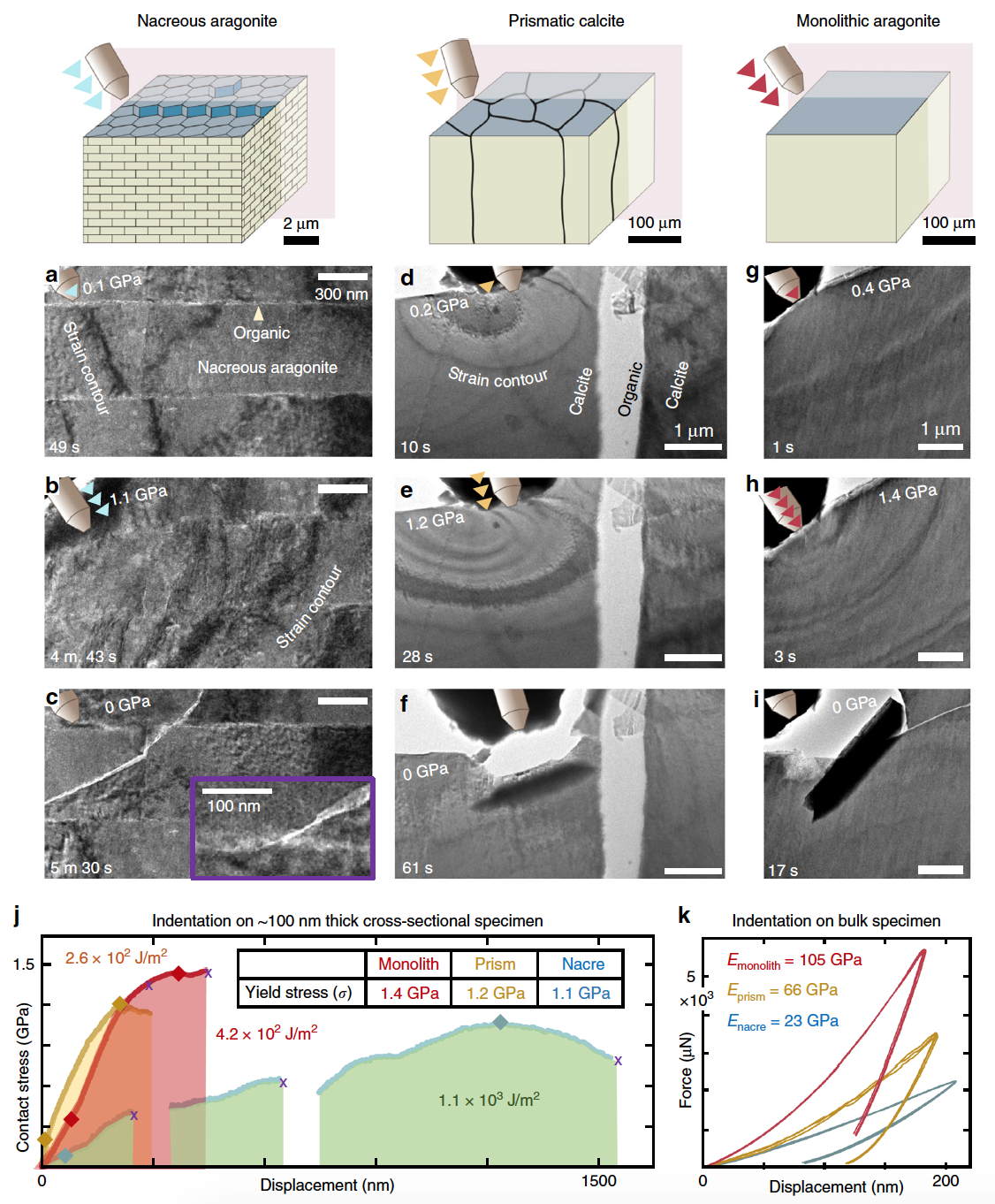

But prismatic calcite and monolithic aragonite exhibit limited deformation before catastrophic failure or fracture rupture occurs ( 4d - 4i ).

Monolithic aragonite reacts to deformations by means of voltage loops emanating from the point of contact. Prismatic calcite from the shell of the mollusk P. nobilis behaved like a monolithic aragonite, however, a depression near the organic interface showed significant attenuation to the neighboring prism ( 4e ).

Therefore, it can be accurately stated that the interlamellar nacre membranes change the shape of the compression strain fields. Biogenic calcite from the prismatic layer of P. nobilis and geological monolithic aragonite were noticeably harder ( 4k ), and, as a rule, reached higher yield strengths than mother of pearl ( 4j ). However, the hybrid architecture of mother of pearl (organic + minerals) absorbed mechanical energy better before the onset of complete destruction - 3 times more than prismatic calcite and monolithic aragonite.

Scientists also note that studies conducted earlier can be slightly clarified. The fact is that the nanoindentation method allows measuring the mechanical behavior at the level of one plate, and not the entire sample. This makes it possible to evaluate the contribution of the hardening and elasticity increasing mechanisms on the scale of the entire sample.

For example, the elastic modulus of nacre and calcite from the P. nobilis shell, established in this study, was comparable with those determined for bulk samples. However, the strength of nanoindented mother of pearl measured in this work reached 1.6 ± 0.2 GPa, which is 3 times more than previously thought for bulk samples.

It is important to note that the samples in this study were dry. It has been shown that dehydrated nacre has a higher strength and elastic modulus, but lower impact strength than hydrated nacre, due to the plasticization of the organic matrix with water. Therefore, in the native habitat, i.e. under water, the mother of pearl shell noble pinna strength will be even higher.

For a more detailed acquaintance with the nuances of the study, I recommend that you look into the report of scientists and additional materials to it.

Epilogue

Mother of pearl has always been considered the inheritance of the rich and noble for its amazing beauty. But this material has not only a beautiful cover, but also a very interesting content. Being one of the most durable materials, nacre surpasses even its ancestor - aragonite in this indicator. Thus, mother-of-pearl shows that not always monolithic means durable, because its complex structure combined from organics and minerals is able to withstand stress 3 times greater than single-crystal aragonite.

Flora and fauna is rich in its secrets, which scientists from all over the world are trying so hard to reveal. And the matter is not only in the immense human curiosity, but also in the benefits that we can get from new knowledge.

For example, this study made it possible to better understand the properties of hybrid materials consisting of organics and mineral components. Such natural composites have increased strength, which has never been superfluous in the world of technology. Understanding the interaction of seemingly opposing substances will not only allow us to better study such compounds, but also create them.

The very first technology can be safely called evolution, because this long, painstaking and very complex process gives breathtaking results. Man cannot compete with what nature has created, but he can learn from it.

Friday off-top:

Unfortunately, climate change, including an increase in water temperature in the Mediterranean Sea, has led to the active spread of parasitic organisms that threaten populations of noble pinn, of which there are very few left.

Unfortunately, climate change, including an increase in water temperature in the Mediterranean Sea, has led to the active spread of parasitic organisms that threaten populations of noble pinn, of which there are very few left.

Thank you for your attention, remain curious, take care of nature, and have a great weekend for everyone, guys! :)

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending it to your friends, a 30% discount for Habr users on a unique analog entry-level server that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to divide the server? (options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

Dell R730xd 2 times cheaper? Only we have 2 x Intel TetraDeca-Core Xeon 2x E5-2697v3 2.6GHz 14C 64GB DDR4 4x960GB SSD 1Gbps 100 TV from $ 199 in the Netherlands! Dell R420 - 2x E5-2430 2.2Ghz 6C 128GB DDR3 2x960GB SSD 1Gbps 100TB - from $ 99! Read about How to Build Infrastructure Bldg. class c using Dell R730xd E5-2650 v4 servers costing 9,000 euros for a penny?