Where does IIoT work?

Wherever there is production. Industrial IoT solutions can be implemented in the barn and factory. The main objective of the technology is to make complex work processes more efficient: eliminate theft, minimize downtime, increase safety or simply save electricity.

While in Russia many entrepreneurs cautiously look at new technologies, preferring to cope with problems “manually”, large multinational companies in the European Union and the United States automate production processes as much as possible now.

We explain with examples:

Case 1. Amazon

Amazon's Arizona Distribution Center covers 28 football pitches. And at such facilities, you need to look for the right products every day, pack them and send them to customers.

To reduce the number of employees in the warehouse (which may simply be lost there), Amazon began to use drones. They deliver light loads in an average of 30 minutes (and it costs the company just one dollar).

At the same time, drones work in conjunction with Kiva industrial packaging robots. It is also a merit of the industrial Internet of things, which allows two complex systems to interact. Now robots are used in 13 Amazon centers out of 110 around the world, this has already reduced the company's costs by 20%. When implemented everywhere, it will save up to $ 800 million by lowering costs.

Case 2: Walmart

Walmart uses drones in warehouses to quickly conduct an inventory. UAVs take 30 pictures per second, then the information from them is transferred to the database and compared with the original data.

As a result, the system without human participation generates an instant report on any indicators: how full the warehouse is, how much specific product is left, and so on. Walmart spends one day on smart inventory; it would take a month to carry it out manually.

What else do they do with warehouses?

- Climate monitoring systems are connected (many products require special storage conditions)

- Distribute "smart lighting" into zones to save electricity

- The optimal place for products is determined depending on their dimensions, storage conditions and shelf life and free space in the warehouse - all this for 100% full storage of warehouses.

Case 3: Mount Sinai

Mount Sinai, one of the largest medical centers in New York, receives up to 50 thousand patients annually. When the number of beds there increased to 1100, a serious problem arose: the staff simply did not have time to process information about the patients and place everyone.

It turned out that 10% of the places did not bring profit due to the irrational distribution of customers. Despite the fact that there were empty beds in the hospital, the lines did not end.

The problem was solved by smart beds: with the help of sensors and controllers they were connected to the medical system of the hospital. Now the IoT solution prepares a report on the workload of all rooms and places patients. The program can simultaneously process up to 80 applications - the waiting time is halved.

What else is done with hospitals:

- They buy smart bracelets for patients, which record key indicators - pulse, temperature - and notify about critical changes.

- Connect all the equipment to the general monitoring, so you can remotely check the availability of the equipment, prevent breakdowns and detect downtime

Case 4. Harley Davidson

Harley Davidson, an American motorcycle and military manufacturer, has introduced IoT solutions to track every step of the way. Using sensors, all the machines were connected to a common network, through which information was transmitted about each stage of product assembly.

So the company managed to reduce downtime and minimize equipment failures. Previously, machines could break due to high humidity or heat, but now the microclimate is controlled by smart sensors - up to the fan speed.

After all these decisions, production of serial motorcycles increased by 25%. If earlier it took 21 days to collect one Harley, now they are assembled in six hours on the basis of the SAP IT system.

How else can you optimize the plant:

- Improve safety - ignition, smoke detectors will warn of a fire, leakage sensors will stop flooding.

- Eliminate theft - the operation cycle of each connected machine can be easily checked for all indicators: hours of operation, volume of product produced.

- Analysis of the state of each machine will prevent malfunctions

5 case. From the practice of Kauri

Given: a large amusement park with a high load

Problem: ensure safety for children and give parents the necessary control

What can we offer?

When entering the park, the child is given a bracelet with an RFID tag (miniature storage device). Each bracelet has its own number, information about the visitor is entered in it (for example, the full name and phone number of one of the parents).

Each area of the park is equipped with antennas that respond to the bracelet. The database receives information: “Bracelet number 1 issued to visitor Ivan Ivanov crossed the food court zone at 15:15.” The bracelet also includes information about all activities and purchases in the park.

So the parent will see that their Vanya at five in the evening rolled on a roller coaster, and then bought soda and now runs into the area with toilets.

Everyone is calm, everyone knows where the child is and what he is doing (for this, parents install a control application that is synchronized with the child’s bracelet). In the event of an unforeseen situation (for example, the child left the park, removed the bracelet or bought something expensive), the parent will receive a push notification. The bracelet itself can be complicated by customer requests: add an SOS button or messages to the child.

The system is convenient not only for parents, but also for the customer, that is, the park. An analysis of the data from all the bracelets gives big data: statistics of visits by zone - which attraction is popular and which is not, what they spend money on, how much time children spend in which zone.

At the exit, the park receives a detailed database of customers: Ivanov and his children come to the park twice a month, spend an average of 1000 rubles per visit, most often ride on carousels. Under such statistics, you can further send out individual offers about promotions or make up special conditions for subscriptions.

So what's the problem?

If the industrial Internet of things really effectively solves the problems of the industry and there are examples of successful cases, why in Russia there is still little talk about it?

Solutions are still expensive, not all companies are ready to invest a large sum once to optimize production processes, then to wait for the return on the solution. The Russian government so far is financing the industry rather in words.

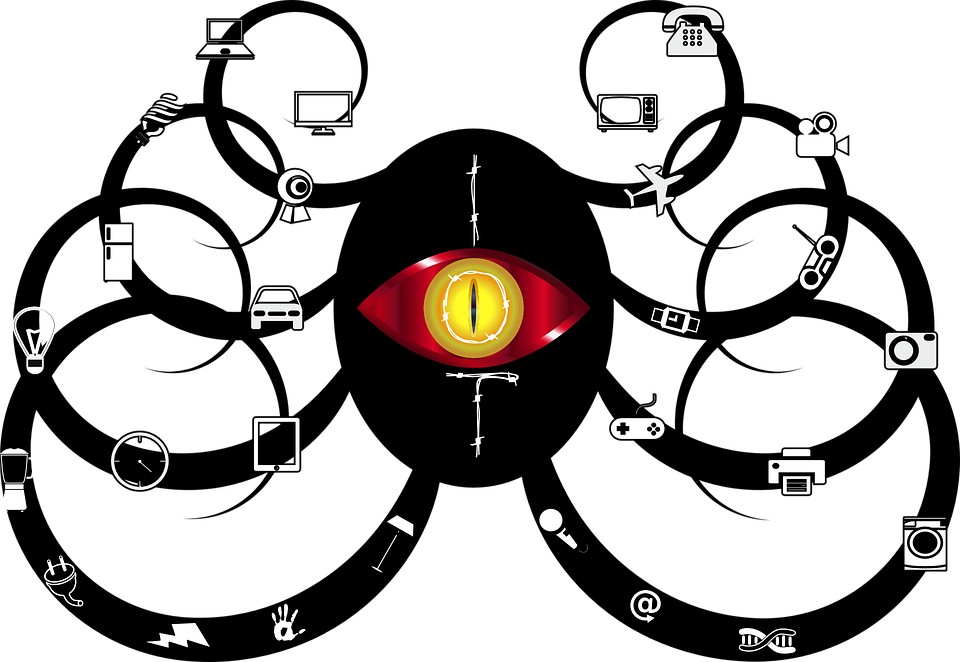

Another unpleasant topic is technology security. Each IIoT decision is associated with the collection of information: and if the "merged" data on the state of the fields with corn can not do serious harm, then the medical base of a large medical center with detailed information about each patient, his passport data is a completely different matter.

The level of functional reliability also raises many questions - of course, no one will suffer from the fact that an attacker will connect to a coffee machine in your house, but if he turns off the security system?

Developers cannot embed a security system in every connected device. And despite the fact that in 2018, according to Gartner, almost $ 2 billion was spent on strengthening IoT security in the world, there are still many weaknesses in the system: device certification, the use of text protocols and unnecessary open ports, the use of insecure cloud infrastructure .

However, compliance with basic safety rules will significantly reduce all risks:

- Use a secure channel for data exchange - information is transmitted in encrypted form

- Monitor code integrity at all stages

- Use certified devices

- Embed anti-virus and anti-malware programs in the operating system of each device

- Provide secure software updates

- Regular audit of the event log (first of all, analysis of all uses of USB ports)