Review of the exhibition of additive technologies Formnext 2017

Frankfurt am Main, November 14-17, 2017.

Formnext is an international exhibition and conference on the next generation of production technologies.

Review of Vasily Kiselev, Top 3D Shop.

We began to prepare this review while we were at the exhibition, then we processed photos and video materials, edited clips, collected information, concluded contracts with manufacturers and suppliers. Now we can share everything we saw at the exhibition.

What is it

Formnext 2017 in Frankfurt is the largest exhibition in the world devoted to additive technologies. This is the largest such exhibition I have recently visited in the USA, Europe, China, Japan, and England. This year it has become even more compared to previous ones. Two full-fledged halls appeared here, the first is devoted to 3D printing and 3D scanning technologies, the second to additive technologies in working with metal.

In the voice accompaniment, the wrong price of da Vinci Color is named (at the time of recording the exact prices were unknown), the actual information on the links:

da Vinci Color , PartPro 350 xBS

In this video, we talked about what he saw at the exhibition: these are 3D printers for printing with high-temperature plastics, 3D printers for printing with metals, solutions for the shoe industry and other interesting innovations.

This first part is a general overview of the exposure. In the following publications we will take a closer look at individual categories of exhibits.

High-Temperature FDM 3D Printers

Devices for printing high-temperature plastics were presented by models of companies INTAMSYS , ROBOZE , VSHAPER , 3DGENCE , APIUM and other manufacturers.

These printers print a huge range of materials, including carbon and metal composite plastics, fiberglass, all traditional materials for FDM and high-temperature industrial materials such as PEEK, PETG, TPU and others.

Products made of high-temperature plastics are used in industry, in design - for the manufacture of functional parts in prototype devices, and in some places in small-scale production. Mechanical and chemical characteristics of such prints - wear resistance, durability and low weight - allow them to successfully compete with metal at some sites.

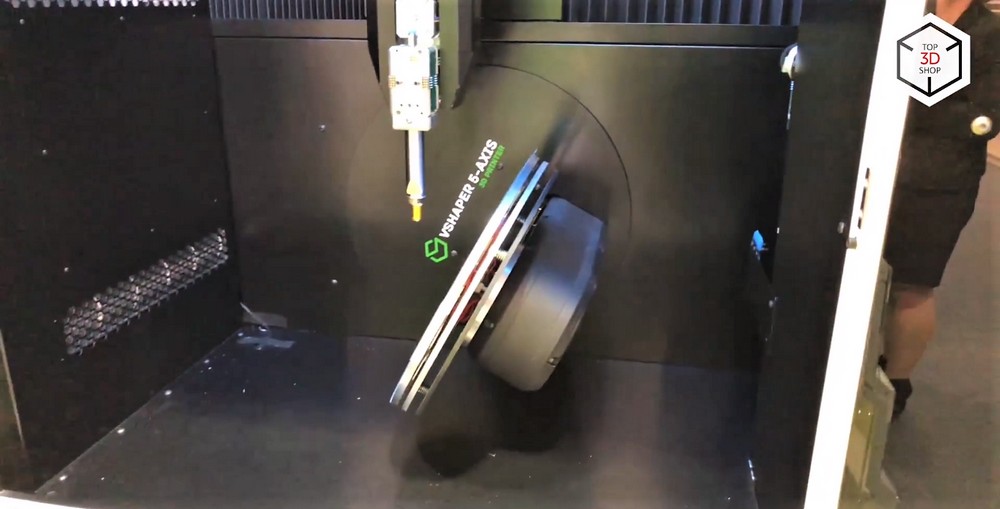

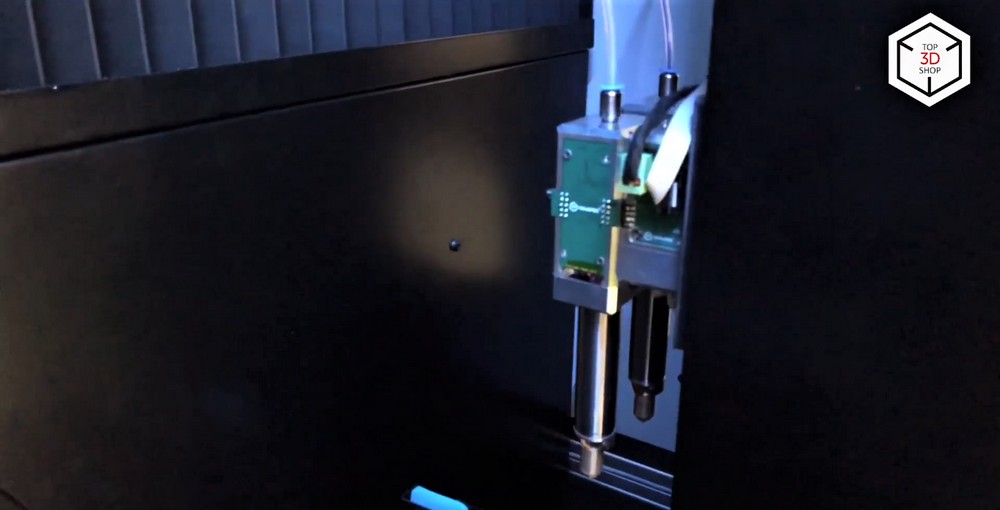

VSHAPER introduced a five-axis printer with an automatic change of working tools - extruders with different materials.

Movement in five planes, the ability to change high-temperature materials in the printing process and the platform with multi-zone heating at different temperatures allow you to print a part of complex shape from several different plastics at the same time and without supports.

Multifunction device

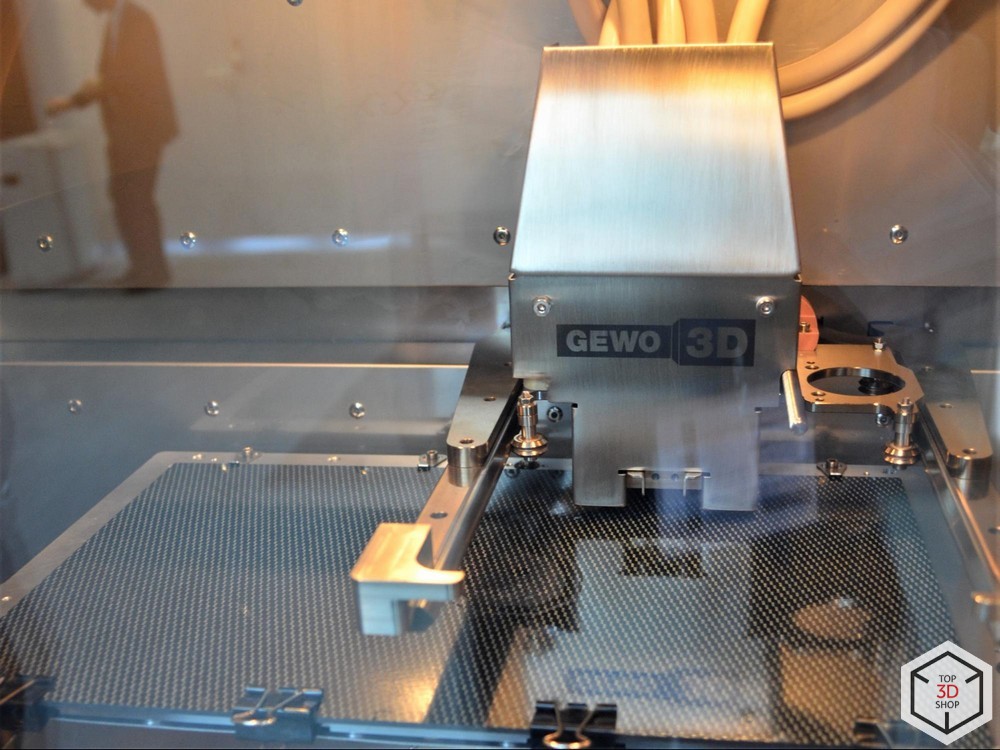

GEWO 3D introduced a high-temperature 3D printer capable of not only printing, but also performing operations on automatic 3D-milling.

Metal printing

New devices for 3D metal printing were presented by such manufacturers as AIM3D , APIUM , GEWO 3D and many others.

They print a filament consisting of metal particles and a binder, after baking, this gives the print a monolithic metal structure.

This is an FDM-like seal containing metal materials, followed by baking. The exhibition also presented a huge number of 3D printers for direct metal printing using other technologies, about which we will write a separate interesting article a little later.

Among them - Orlas Creator and Aurora LABS S-Titanium Pro .

Orlas Creator fuses metal powder in an agron or nitrogen atmosphere with a 250-watt fiber-optic laser and promises performance 30% higher than that of counterparts from other manufacturers. The size of the created parts fits into a cube 110x110 mm, and the focus of the beam is only 40 nm - nanometers, not microns, and this allows you to create visually smooth and much more accurate surfaces.

Aurora Labs S-Titanium Pro can print metal parts in argon atmosphere up to 200 × 200 × 500 mm and weighing up to 150 kg, equipped with a 300-watt laser, or rather, two 150-watt lasers with 170 watts of peak power, and also the resolution is 100 nm in XY and 25 nm in Z.

The resulting surfaces are not as smooth as Orlas, but the volume of the construction chamber and the increased power offer their advantages.

The device is able to both sinter (DMLS) and alloy (DMLM) metal powder, as well as work on the third technology - DED (Direct Energy Deposition), which allows you to print a part from three different materials, including several grades of stainless steel, titanium, Inconnel and other structural alloys.

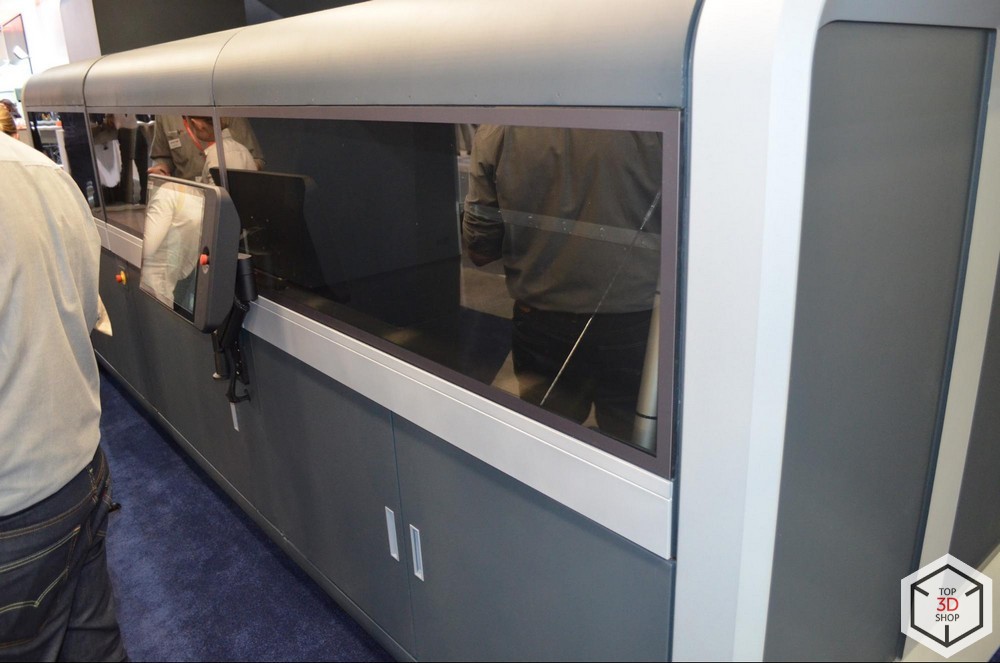

Desktop Metal introduced a system for the mass production of complex metal parts. The company claims that its devices are capable of creating complex metal parts 100 times faster than modern 3D laser printers.

Studio System is a solution for prototyping and use in small groups.

Production System - a larger system for production.

In the Production System, molten metal injection is used (Metal Injection Molding, literally - “injection molding of metal”) - a process similar to inkjet printing. MIM can use inexpensive high-quality alloys available on the market, sprayed in various ways.

This process does not require uniform particle size, as required by 3D laser printing systems, which makes materials for it 80% cheaper.

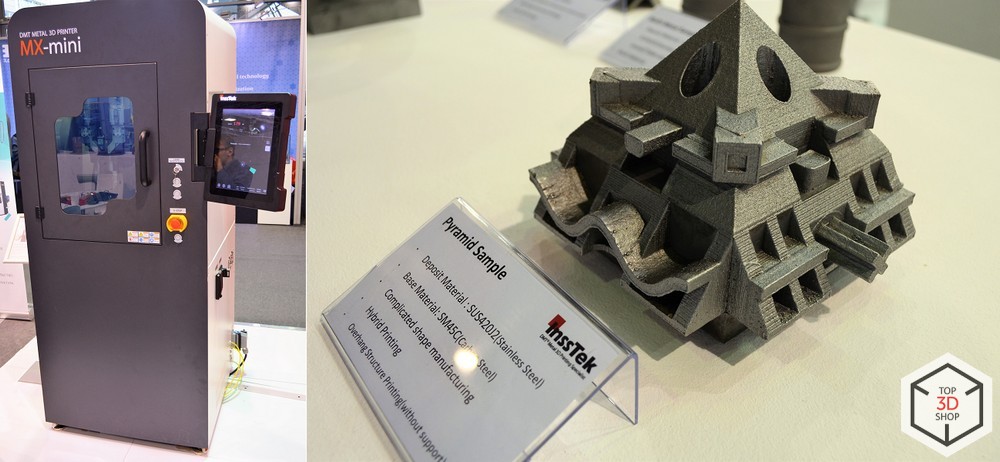

InssTek has prepared a compact and economical model MX-Mini for the exhibition.

This is a 3D printer with a 300-watt ytterbium fiber laser, a five-axis DMT Motion system and two metal printing in sizes up to 200x200x200 mm.

SLM Solutions showed an updated SLM 280 2.0 , a new SLM 800 with a print area of 500x280x850 mm, which we will write about later, and other new products.

The fourth generation of the SLM 280 2.0, with laser power up to 2 x 700 W, received a new filtering system, monitoring the material supply and monitoring the laser power for multi-laser operations, improved software and an additional vacuum powder feeder.

Additive Industries showed the modified The MetalFAB1 , which automatically removes the print, clears the print area and prints the next part.

His system Dynamic Laser Allocation optimizes the work of four lasers that can work simultaneously on one part of the part, increasing power, or on different parts, making printing faster.

Concept Laser , which is now owned by GE, presented a new Atlas project with a kilowatt laser, 1.1x1.1x0.3 meters and an integrated scanning system.

Detailed characteristics are classified, even photographing the device near the exhibition was forbidden - either because of its defense and aerospace significance, or to create a stir.

Also at the exhibition there were many other “metallic” 3D printers, read about them in one of our following articles.

SLS

New laser sintering presented the company SHAREBOT , SINTERIT and XYZprinting .

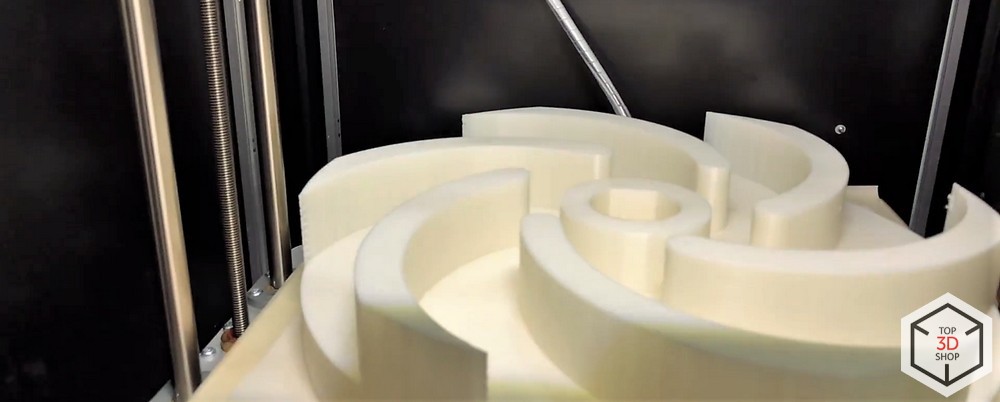

Such 3D printers are designed for layer-by-layer laser sintering of polymer powders, including composite powders. They print with accuracy exceeding the resolution of FDM printers.

Prices for such devices, previously available only to large enterprises, declined markedly in 2017. At a cost of 20-40 thousand dollars, they provide industrial print quality and have more compact dimensions than traditional industrial installations.

The quality of prints does not require post-processing.

The devices can be used in heavy industry, automotive and aerospace.

Full color

XYZprinting introduced solutions for full-color 3D printing - this is a compact da Vinci Color and professional PartPro 350 xBS . The quality of prints speaks for itself.

Printouts da Vinci Color:

PartPro 350 xBS printouts:

And the prices for these devices promise to be not exorbitant, starting from about 100 thousand rubles - XYZprinting seems to be going to make full-color 3D printing available for any small advertising agency.

Photopolymer

XYZPrinting also revealed the new Dent Pro 100 xP. This is a DLP printer for jewelers and dentists, which can be understood from its name.

About 200 thousand of this printer will cost in Russia, which is quite inexpensive for a professional machine with such print quality.

Fdm

In the traditional FDM, XYZPrinting also distinguished itself by presenting devices such as XYZPrinting MFG Pro600 xT , featuring a large print area (580x400x500 mm) and work with plastics with a print temperature of up to 245 degrees, XYZPrinting da Vinci Super , printing objects up to 300 mm each axis and with an extruder up to 260 degrees Celsius, and da Vinci 1.0 Pro - a cubic working area of 200 mm on each axis and an extruder up to 240 degrees. Some of them are capable of printing with high-temperature plastics.

Others simply print large, high-quality plastic models from more traditional ones.

Insoles

Also at the exhibition were presented solutions for the production of individual insoles for shoes from the companies ECCO and HP .

We will also describe them in detail in a separate article.

All named printers and solutions can be seen in the video. We will soon have a separate detailed article about each presented category of new products - these will be reviews on high-temperature printers, SLS printers and special solutions for the production of individual orthopedic shoes.

Follow the publication!

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

All Articles