Automated helper cooking kebab "E-Mangal"

Dinner is served! Sit down to eat, please!

Gentlemen of Fortune

Cooking meat requires attention, and when in a warm friendly company you forget to control this process, then you have to gnaw coals. It is necessary to periodically turn the meat on skewers and, depending on the design of the skewers, it is difficult to ensure uniform roasting of the meat.

At night it is necessary to use a flashlight to assess the readiness of meat, to highlight the table. Of course, the meetings do not take place without your favorite music. Periodically, either a flashlight, or a player, or something else needed is forgotten. The longer the meeting, the more uplifted and want to make the music louder. But the battery life of the player is not enough and it is discharged depriving musical accompaniment.

And on one of these evenings, watching the inconvenience of each meeting with friends, the idea of a device that combines many functions, like the “Swiss knife” for cooking meat and pleasant meetings with friends, was born.

The idea was born, and then, as usual, I suffered to invent new functions of this new device. The experience of creating " Alkomat " spurred on new achievements. So to speak so you can eat something. Total we have the device "E-Mangal".

Details below. A lot of great photos.

E-Mangal features:

- Rotates skewers, thereby evenly roasting meat;

- Has a music player with recorded favorite music tracks. The choice can be made by genre: military, Soviet, world rock, our selection, space, drinking. Built-in 3W amplifier;

- Has a FM-receiver with the ability to install an external USB-flash or SD-card;

- Has a Bluetooth module to play music from external devices, such as smartphones;

- Color music;

- Portable lights lighting barbecue and the table;

- External fan for coal blowing;

- Functions for charging external devices, such as smartphones or music players. At the same time, you can charge two devices through a conventional USB-microUSB adapter;

- In the composition of the E-Mangal is a container with water at 0.5 liters to extinguish the flashes of fire;

- Coal temperature sensor in the grill;

- Built-in network battery charger;

- Wi-Fi module to control E-mangal from a smartphone;

- Real time clock.

Operating procedure

The brazier gathers, coal is poured and kindled.

After energizing the device, a mechanic test occurs. Reed switch on one of the gears is used to determine the fact of rotation of the wheels. After that, the gears are installed in the starting position and the signal about the readiness of the equipment is given. In case of jamming of the gears, the process stops and a message about the accident is issued.

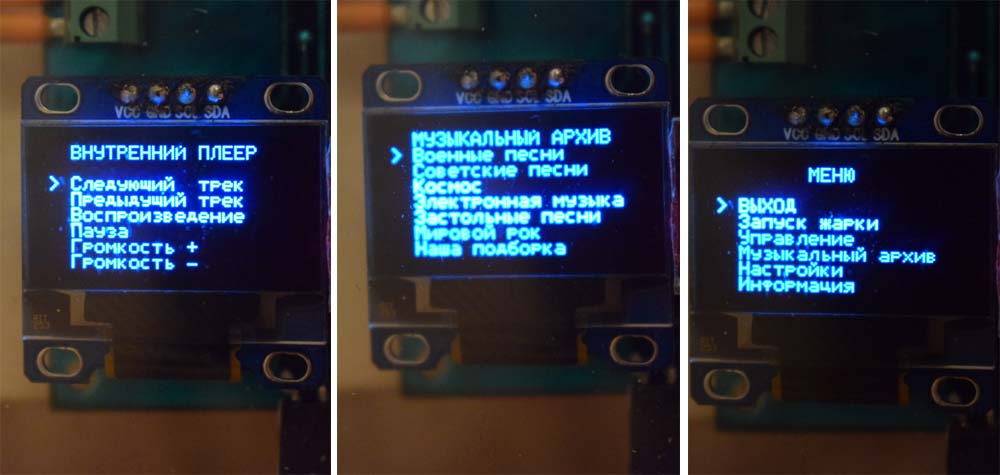

Using the menu buttons you can control all the functions of E-Mangal. The buttons on the top panel serve for the operational control of the start / pause of the frying process, for selecting the backlight operation mode, for turning on the flame extinguishing pump and for the Pause / Play mode of the internal player.

After the coals have reached the necessary condition, the skewers are set with the impaled meat. The flat end of the skewer is placed in the flat hole of the holder.

After installing all the skewers, you can start the frying process. This can be done either with the operational red button on the top panel, as well as from the system menu or via the device web page from the smartphone. Through the use of an additional metal panel with holes worn on the grill, the skewers rotate in parallel and touch the walls of the barbecue.

After starting the frying process on the large seven-segment display, you can see the countdown to the readiness of the meat. Alternately, this time is replaced by the current temperature inside the barbecue. If there is a fire, then direct the nozzle to the fire and click on the blue button on the top panel of E-Mangal. The pump is turned on and the jet of water extinguishes the flame.

On average, the process of frying to readiness of meat takes about 30 minutes. 5 minutes before the end of this time, the informant E-Mangal announces the readiness of meat with the phrase “To eat is served! Sit down to eat, please! ”. Next, you need to assess the degree of readiness and, if necessary, add some more time to fry. If the meat is ready, then the red button on the top panel stops the rotation process or turns off the frying mode through the menu system.

Regardless of the cooking mode, you can use all other functions of the device. To illuminate the grill with meat, you can install an external lamp in the USB-connector on the top panel and turn on the lamp with the yellow button or from the WEB-page. If there is a need to illuminate the table or space around the barbecue, then you can install another lamp in another connector on the top panel. You can also illuminate the area around E-Mangal and without the use of external lamps. Enough internal lighting translate into white light mode. In the case when during the frying process it is necessary to inflate the coals, you can install an external fan in the USB connector of the top panel and direct it to the brazier.

The internal music player contains pre-prepared favorite music tracks of various subjects and genres. The choice is made from the menu system or through the WEB-page.

The external player allows you to play music from removable media and via Bluetooth. You can also connect an external device through the line input.

In case of poor reception in the FM receiver mode, it is necessary to extend the telescopic antenna.

Circuitry

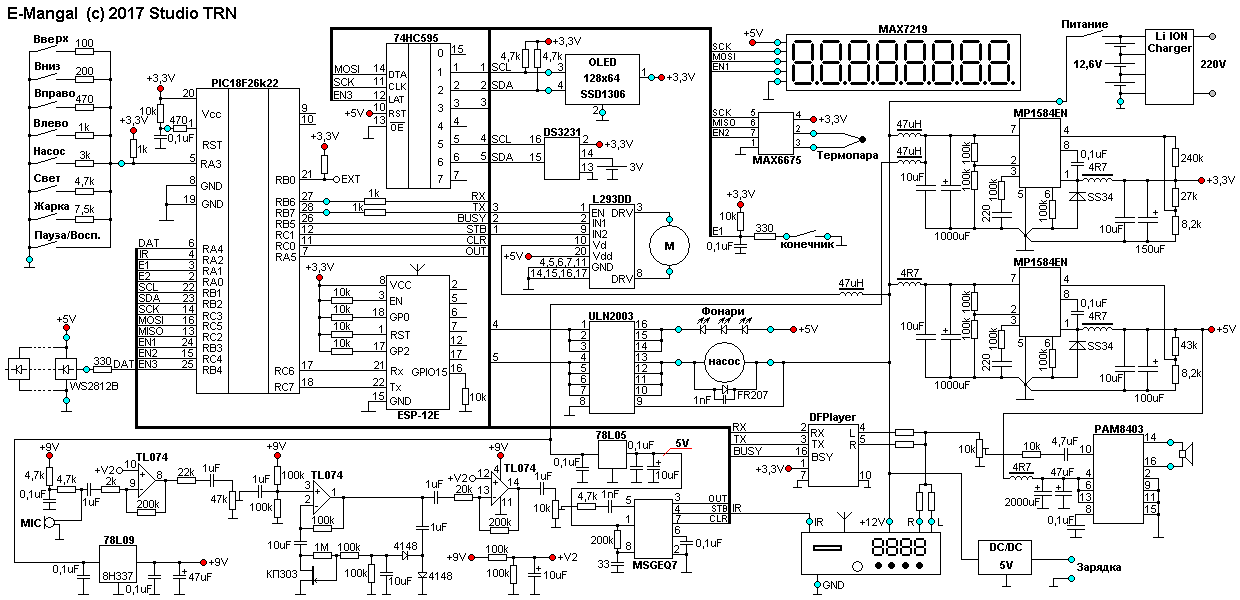

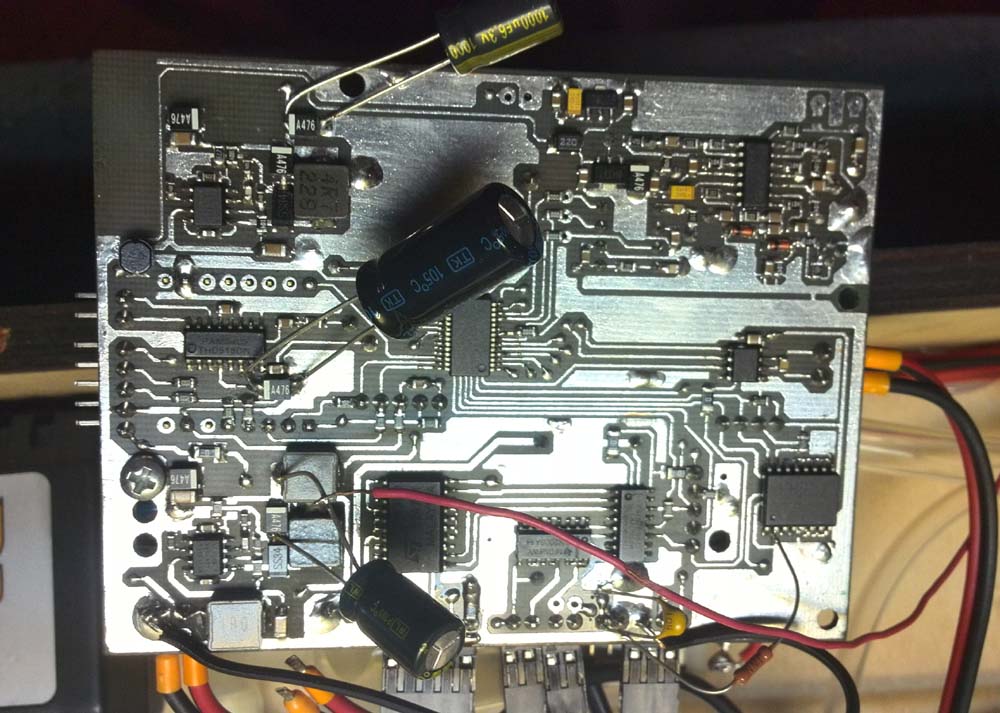

- All processes are controlled by the PIC18F26k22.

- For internal player I used DFPlayer mini. It is controlled by commands via the COM port. Not very happy with it, but small and simple. And for a specific application in E-Mangal is more than enough.

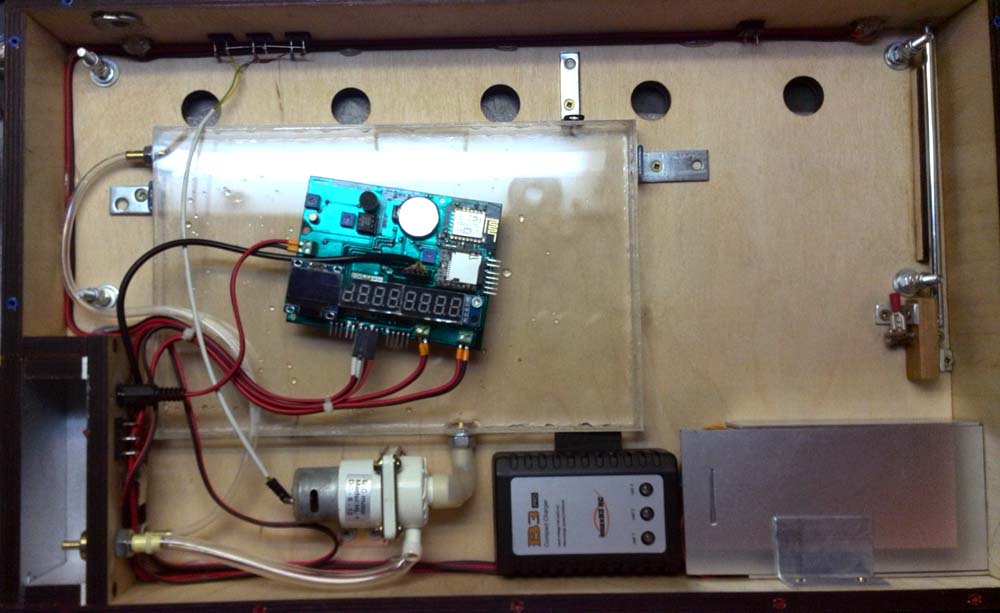

- OLED display on SSD1306 version i2c. The entire image frame generated in the RAM of the PIC controller is transferred to the screen.

- Wi-Fi module ESP-12E. A lot has been said about him. It runs its own program WEB-server, contains a WEB-page. Data exchange is carried out on the COM port. The applied PIC controller has two independent serial ports.

- Real time clock based on DS3231. Managed by i2c. I like this chip very much with its precision and lack of external elements.

- Seven-segment indicator based on MAX7219. Not bad, but very sensitive to interference. It is necessary to periodically carry out initialization of the display in order not to permanently lose the information on the display and additionally hang blocking capacitors on it.

- The external player panel is a Chinese development. To control the panel from the menu system connected in parallel with the IR receiver panel. On the central PIC controller, I generate the sending protocol and the panel thinks that the commands came from her own console.

- Digital power amplifier on the PAM8403. The audio signal from the internal and external players is mixed and fed to the power amplifier. If you need to mute a channel, simply give the MUTE command to the appropriate module.

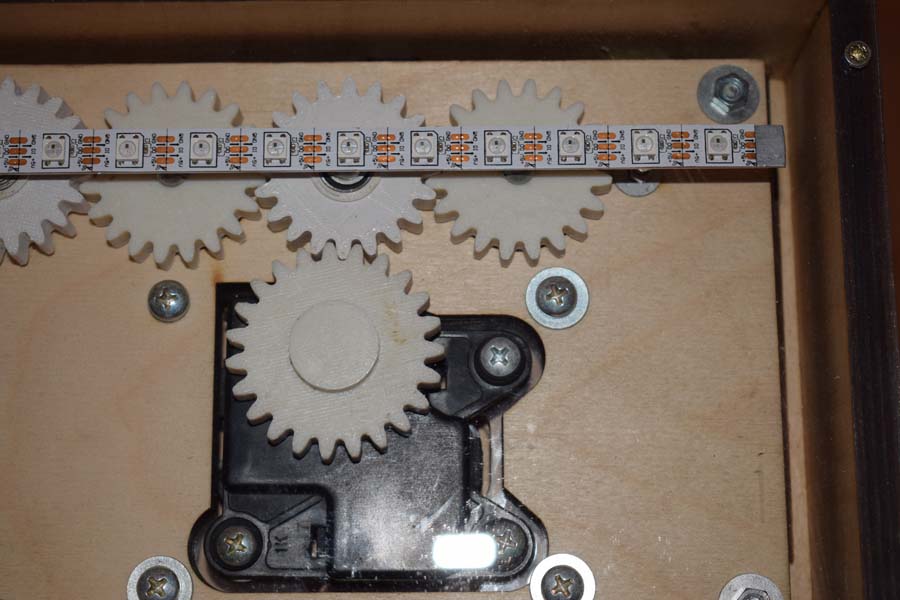

- For color music applied "smart" LEDs WS2812b. The routine for servicing the protocol of these LEDs is written in assembler and calculated according to the clock frequency of the operating frequency of the controller. When accessing the procedure, all interruptions are prohibited. At the heart of the color music is MSGEQ7 chip. This is a 7-channel spectrum analyzer. A lot of blood drank the chip. It turned out that half of the chips that I had were just faulty. And for the tests just got the faulty.

- The temperature of the brazier is measured by a thermocouple and converted to digital form MAX6675. Initially I tested it with the more advanced MAX31855, but I also got it faulty.

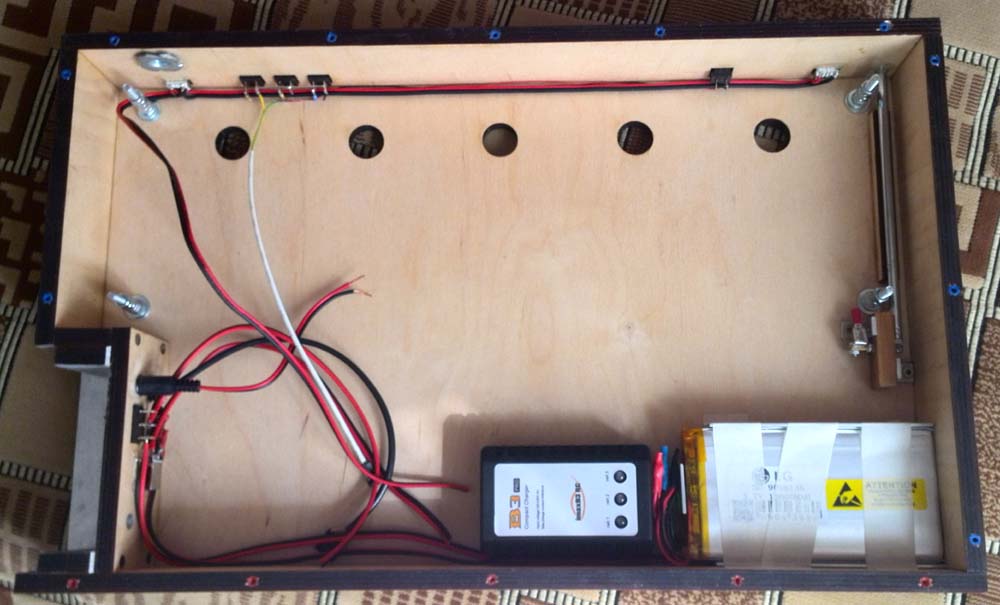

- Since many functions are combined in one device, including the energy-consuming functions of charging external devices, it was necessary to choose a reliable power supply system. For this, I applied three batteries at 10 Ah. The batteries are connected in series, thereby the system itself is powered by 12 volts. Charging is carried out through a regular network charger-balance.

Details

The device turned out to be 480x300x60. The size of the barbecue 400x250. As a barbecue for a shish kebab the usual one-time brazier and usual flat skewers 60 cm long are applied.

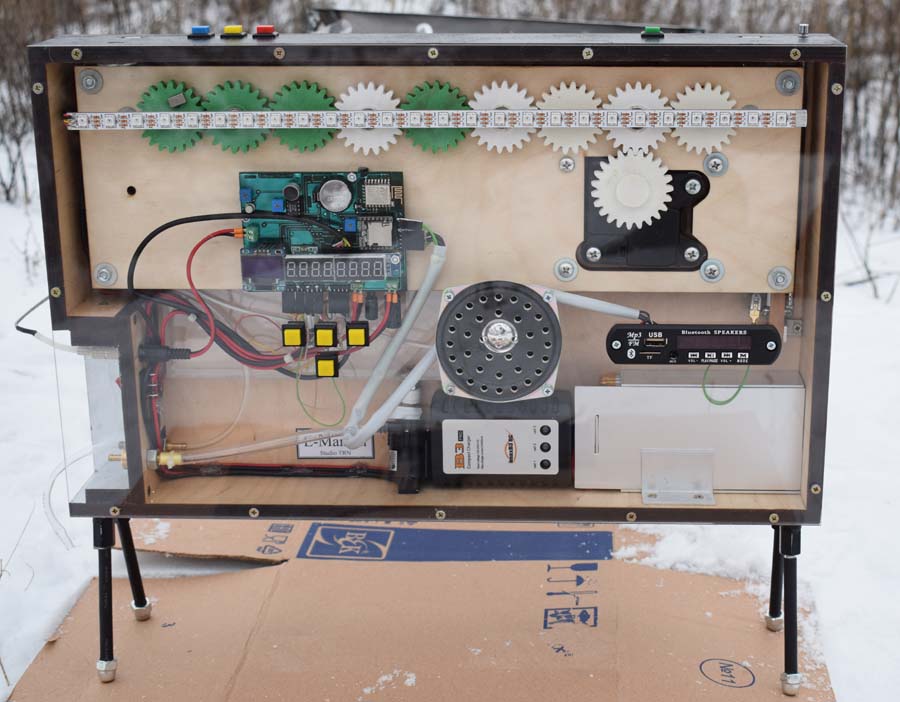

The hull was developed in Compass-3D environment and cut by laser cutting from 10 mm plywood. The front panel is also laser cut from acrylic 4 mm. The front panel is specifically conceived transparent to see the whole process of work.

Separate parts of the body are fastened with screws, covered with PVA. On top of the case is painted with spray paint.

The case has a side cover that closes the compartment with the power button and fittings during transport. Also, both fittings are shunted with a tube to prevent water leakage.

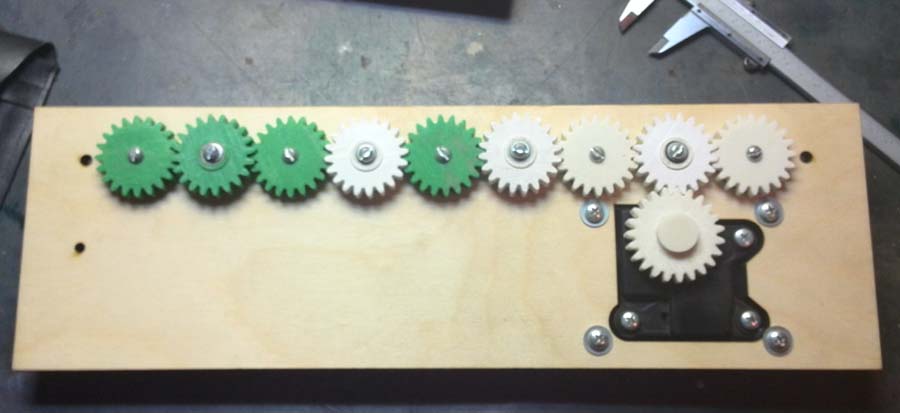

The gears are also designed in Compass and printed on request on a 3D printer. The engine, which rotates the gears, is a motor-reducer from the heater valve of the VAZ 2110. The worm pair gives a lot of effort with a low current consumption, which is just necessary for my purposes.

The legs are made of construction studs with a diameter of 6 mm. The stub nuts are screwed onto the ends and glued together with an epoxy compound. On the studs pulled shrink. The legs are screwed into the nut bush for building studs. Nuts are welded to a square plate at a slight angle. The depth of screwing the legs achieve structural stability.

The water tank was also cut from acrylic with a thickness of 2 mm using laser cutting and glued with a mixture of acrylic sawdust with dichloroethane. On request, the fittings are machined on a lathe, lubricated with a sealant and installed in a container. The pump initially took a thermopot from the kettle, but did not suit its performance. In the end, applied another, from China. The tank has two fittings: drain / bulk and emergency. Water is poured through the working tube.

The upper connection is emergency, for draining water in case of overflow, as well as for air intake.

A stud is screwed into the upper panel of the housing, on which the tube is fixed, which is directed by a nozzle towards the barbecue.

Basically, all the details were taken in China, with the exception of plywood, acrylic and aluminum corner. Funny and sad.

Different pictures

Electronics debugging process

Accessories included

Lighting test

Testing E-Mangal as PowerBank for charging two smartphones

Installation of thermocouples and fittings

Some frames of the menu system

Metal skirt holder

Transport position E-Magnal (compartment cover)

Leg mounting

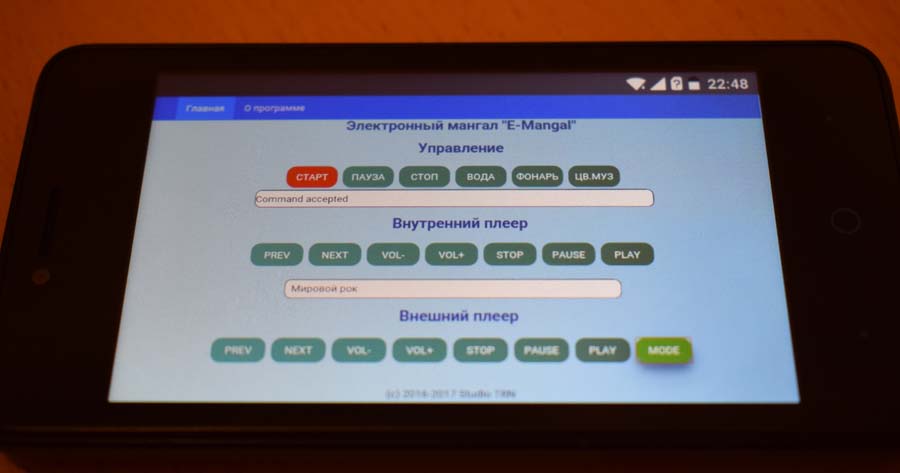

WEB-page E-Mangal

E-Mangal Test Result

Enhancements

1. Initially, the idea was to make an open flame sensor for automatic extinguishing of flames. But then it was decided to do it without him, as there was not enough time for debugging.

To connect the sensor using USB-connectors on the top panel. For this, unused D-, D + USB connectors can be used. The controller also has expansion inputs.

2. Sew a bag for the E-Mangal to order, where all that is needed is placed in the compartments.

Idea

The idea came in the summer of 2016, just during one of the meetings with friends. Embody began December 30, 2016. And so the work was completed on December 24, 2017. The work was going slowly, there was not enough time and mood. But in the end I am very glad that it is completed. Thanks to China for the freedom to choose different elements to make dreams.

Well, I really want to say a big thank you to friends who helped me in mechanics, 3D printing and carpentry. Thanks to Eugene, Alexey and Natalia !

Video demonstration of the work of E-Mangal

All Articles