New 3D printer prints 10 times faster than existing models.

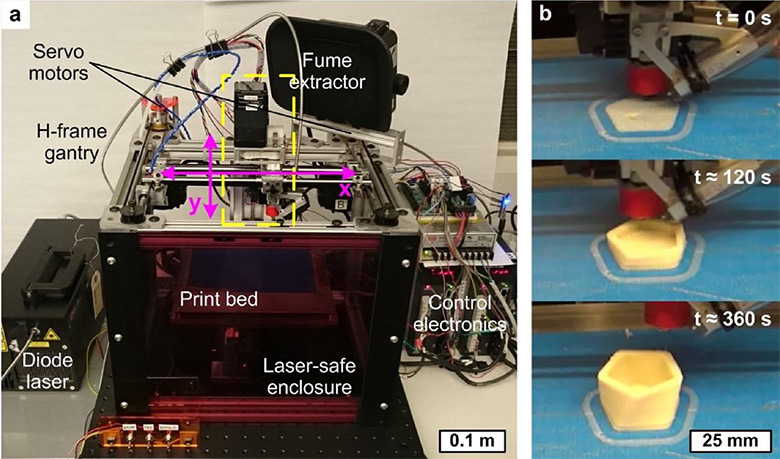

On the left: the appearance of the FastFFF printer with a work area size of 185 × 125 × 200 mm, the H-shaped support frame, fiber-optic cables for connecting the print head and control electronics are visible. Right: photos taken while printing a spiral cup made of ABS plastic at the time of the start of printing, after 120 seconds and 360 seconds

MIT engineers have developed a new design of the print head for 3D printing using the FDM / FFF method, that is, modeling by layer-by-layer fusion. Instead of the traditional wheel, they used the “screw” method of feeding a textured thread. This increased the contact area with the thread, due to which the heating rate, extrusion force and printing speed increased dramatically.

FDM / FFF is the most common printing method used in low-cost desktop 3D printers. A tenfold acceleration of printing allows you to print small plastic parts not in an hour, but in a few minutes (see the illustration above). The assembled prototype showed a speed of 127 cm³ / h, which is about 7 times faster than commercially available FDM printers. The maximum extrusion speed (282 cm³ / h) is about 14 times greater than theirs. In modern conventional 3D printers, the speed usually does not exceed 20 cm³ / h, this is really slow.

The existing technology of 3D printing using the FDM / FFF method has a number of built-in limitations on the maximum printing speed - these are limitations on the speed of movement of the print head on the support frame, extrusion force and the length of the thinner chamber. MIT engineers managed to overcome these limitations with a special design extruder, a laser-heated thread breaker and a H-shaped support frame with two servomotors. This made it possible to increase the extrusion force, the heating rate of the thread and the speed of movement of the printhead, respectively.

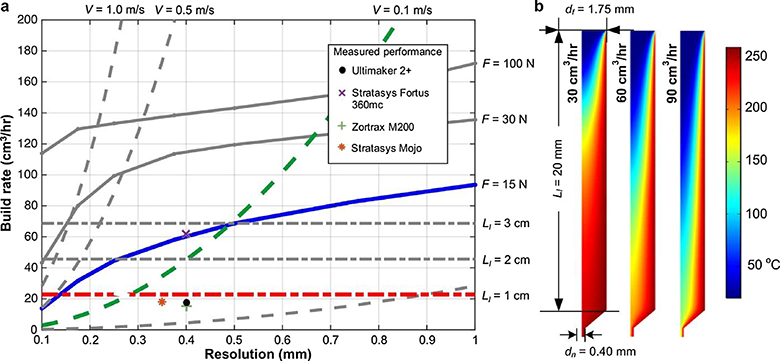

The dependence of the speed of printing by layer-by-layer welding on the printing resolution in various models of printers, with restrictions on the speed of movement of the print head on the support frame, the extrusion force and the length of the thinner chamber. The total area under all three restrictive curves corresponds to the theoretically possible speed of the system. The icons show the performance of four commercially available 3D printers. The right shows the temperature penetration through a heat-conducting material, which at high flow rates does not have time to heat up.

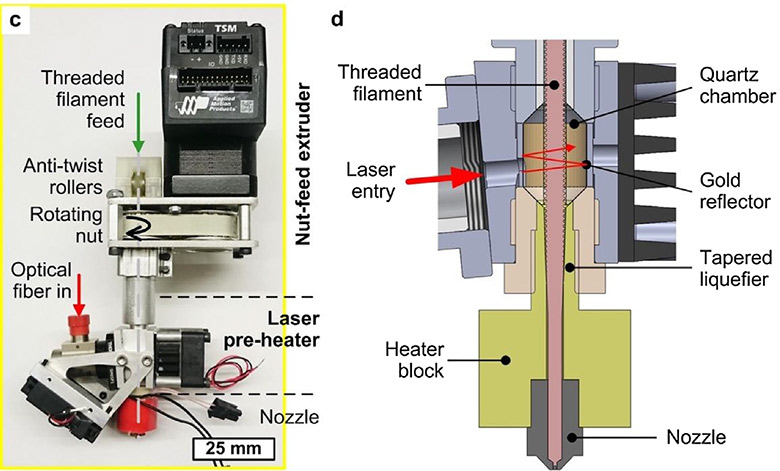

The extrusion and heating mechanisms are placed in a compact printhead that accepts textured plastic yarns and heats them quickly before printing.

Left: a photo of a print head with a feeder and a laser end of a working end (hot end). Right: sectional model of the working part. It shows how the laser interacts with the filament, passing through a quartz chamber covered inside with a reflective gold foil. After the laser heating chamber, the thread enters the contact heating chamber

The speed of printing depends on the speed of movement of the printhead, and it, in turn, depends on the print resolution. Thus, maximum speed and maximum resolution are unattainable at the same time, so you have to look for an acceptable compromise, sacrificing one of these two characteristics.

The developers of FastFFF believe that high-speed 3D printing opens up opportunities for new ways to use this technology and for new business models, when compact parts are made in a couple of minutes rather than an hour. The cardinal acceleration suggests that the use of 3D printing will expand. “If I can prototype a part, maybe a bracket or a gear, in five to ten minutes, not in an hour, or in most of the lunch break instead of the next day, then I can develop, create and test products more quickly,” says Anastasius John Hart (Anastasios John Hart), Adjunct Professor and Director of the Laboratory for Manufacturing and Productivity of the MIT Mechanosynthesis Group (Laboratory for Manufacturing and Productivity and the Mechanosynthesis Group). “If I’m a repairman and translate a fast 3D printer in a car, I can print parts for repair upon request as soon as I find out the cause of the breakdown. No need to go to the warehouse and look for this item. ” The professor mentioned the possibility of using high-speed 3D printing in emergency ambulance and in areas remote from civilization.

There is another option to adapt the described technology to thermoplastic printing at high temperatures and composite materials that require large extrusion forces.

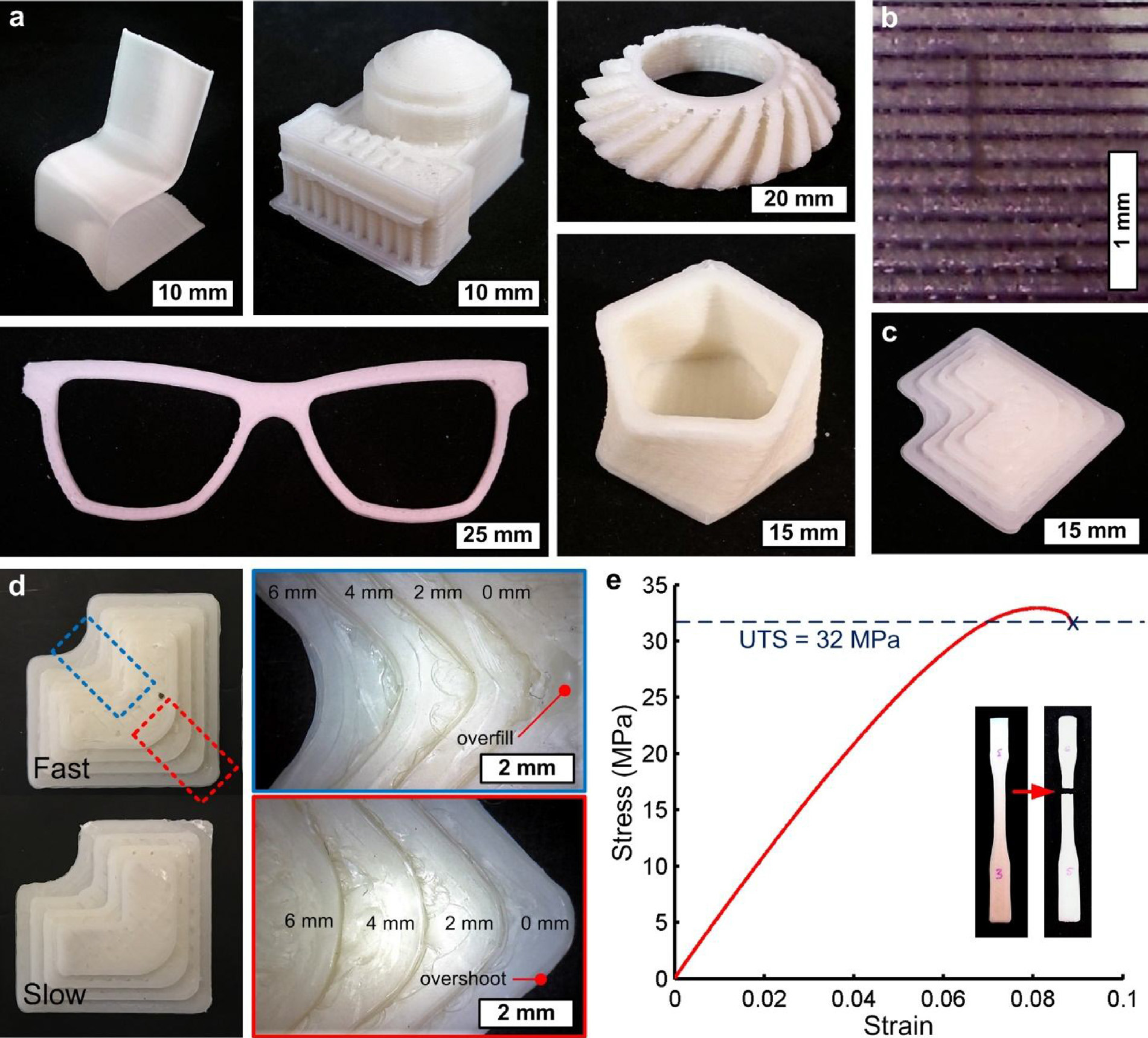

Engineers demonstrated the capabilities of the new 3D-printer by printing details of different shapes (in the photo below). Each one took a few minutes to print.

The scientific article is published on the site of preprints arXiv.org on July 2, 2017 (arXiv: 1709.05918v1), and also published on October 14, 2017 in the journal Additive Manufacturing (doi: 10.1016 / j.addma.2017.10.016).

All Articles