What we inspect?

Hi Giktayms!

In connection with the widespread introduction of inspection systems, many are asking this question. In this post, the author wants to start a cycle of articles on various inspection systems, on the principles used to detect dangerous objects and on the design of inspection equipment up to “iron”.

To begin, consider the X-ray inspection systems.

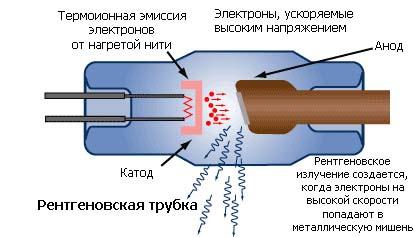

Most often in X-ray inspection systems, or by memory of television systems, such as “Search”, - an X-ray tube is used in the RTU (X-ray television installation). Yes, the one that was invented by Kondrad X-ray and most often without an anode cooled by rotation.

The image acquisition scheme was initially simple - by projecting onto a luminescent plate under X-rays .

How to find explosives using X-ray inspection systems?

The history of the development of inspection systems for screening luggage.

Let's tell the story of the development of X-ray inspection systems.

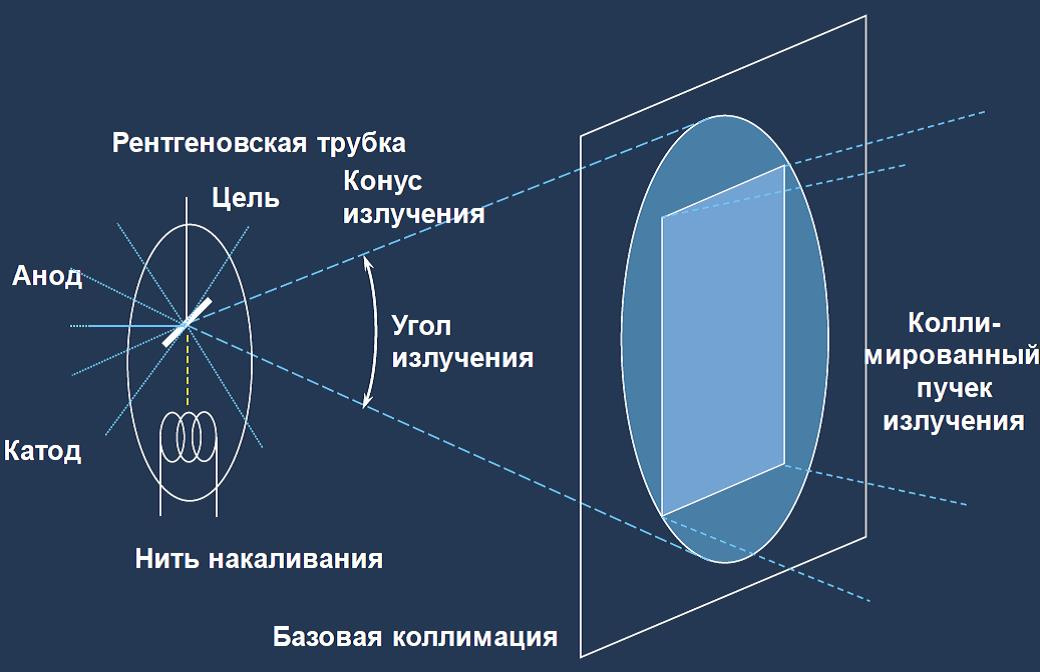

To begin with some explanatory drawings.

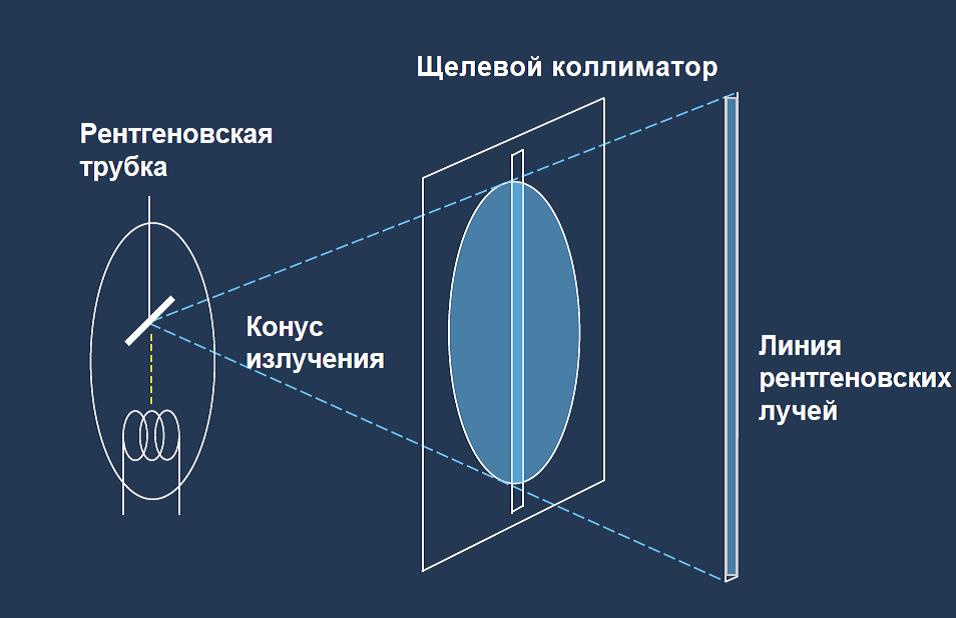

Basic x-ray geometry for fluorography

This image shows how the x-ray flux is projected onto a fluorescent screen. Initially, X-ray inspection systems did not differ in many ways from the X-ray technique. The principle of operation was simple.

X-ray radiation from the source passes through a controlled (translucent) object, is converted on a special fluorescent screen into a light relief corresponding to the x-ray image of the object (the so-called "shadow image") and through the protective glass is visually perceived by the operator.

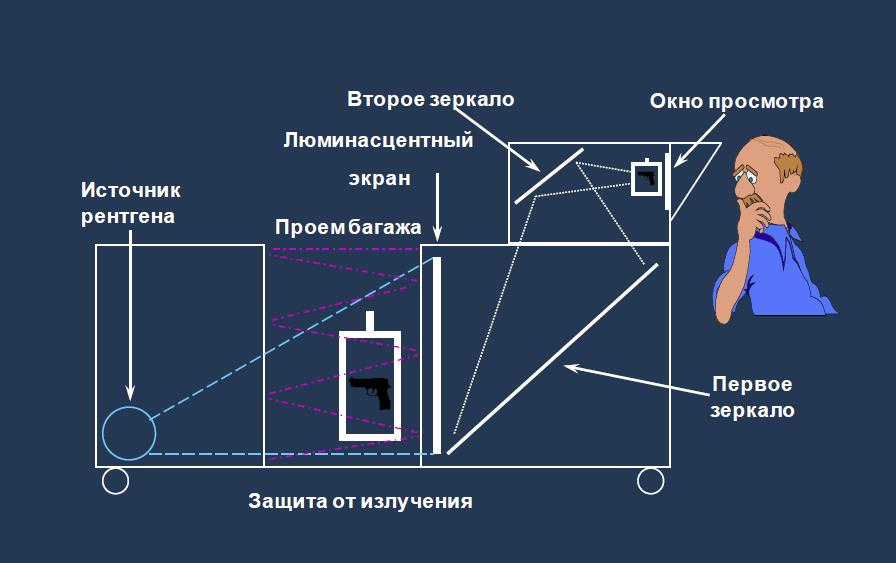

Direct imaging fluoroscopy:

Later, to protect against radiation, they thought of closing the radiation in a leaded box, observing the resulting image, through mirrors and optical systems with the possibility of magnification.

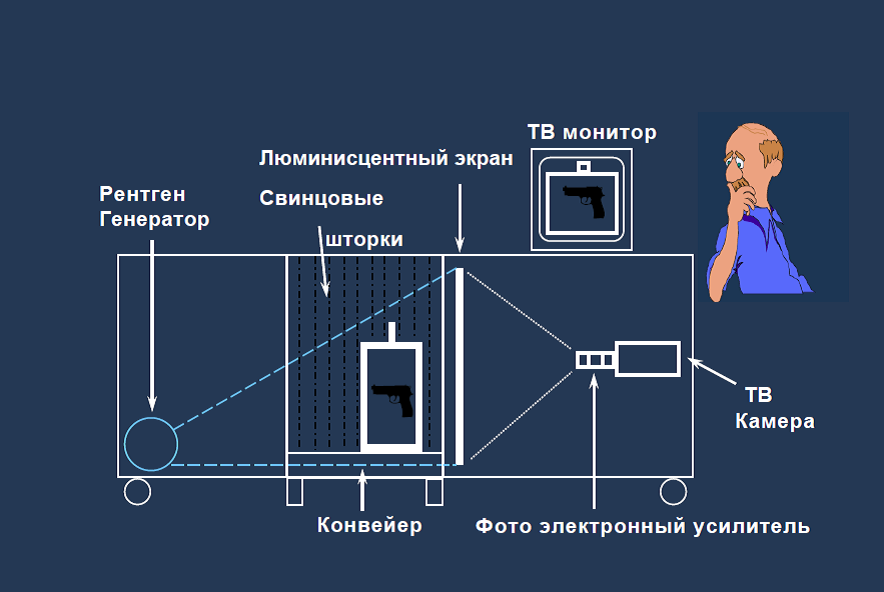

Image enhancement with a TV camera

Further development proceeded along the path of amplification of the resulting image, with the help of photoelectronic amplifiers and transformation into a television signal viewed on a monitor.

But soon came the "digital revolution", which radically changed the principles of scanning.

Modern X-ray inspection facilities, often use other principles that have reduced the side study and greatly improved:

- Image quality

- Visibility of materials

The image quality has improved due to the use of highly sensitive semiconductor detectors (photodiodes), with a layer of luminescent substance (usually cesium iodide) deposited on them, as well as digital processing on a computer.

The x-ray beam is projected as a strip, exactly on the line of detectors, past which the scanned object (baggage) is moving, along a conveyor belt. The tunnel window in which the scan takes place is closed at the entrance and exit with leaded curtains. This is done to protect against scattered radiation.

Next, the received signal is read and converted by an analog-to-digital converter - ADC, is aligned and transmitted to the computer for processing and adding the "consecutive slices" of the object into a single image.

Slot collimation scheme

Microdose digital X-ray scan

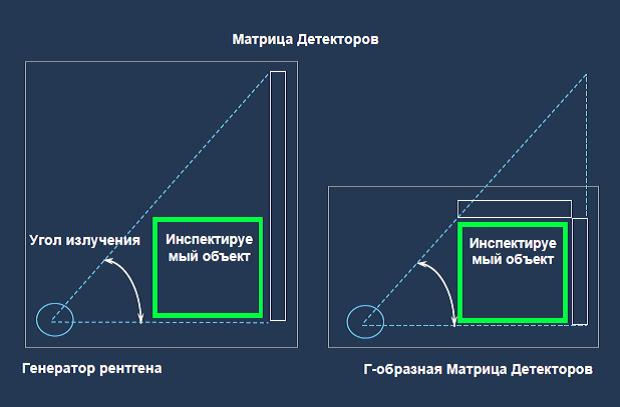

Soon, in order to reduce the size of the X-ray inspection facility, a l-shaped detector placement was invented, as can be seen in the figure.

The advantages of the L-shaped matrix of detectors.

Modern X-ray inspection systems distinguish materials using the Compton effect and determine two x-ray energy, high and low.

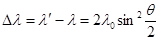

→ Effect of Compton (Compton effect, Compton scattering)

In 1923 A. Compton, investigating the scattering of X-rays (high-energy photons) by various substances (mainly light: graphite, paraffin, etc.) containing free or weakly bound electrons, found that in the scattered rays, along with the emission of the original wavelength l also rays with a wavelength l ¢ greater l (l ¢> l). Moreover, the difference Dl = l ¢ -l turned out to be independent of l and the nature of the scattering substance, and was entirely determined by the scattering angle. The following pattern was established experimentally:

where q is the angle formed by the direction of scattered radiation with the direction of the primary beam; l0 is a constant for all substances, a value equal to l0 = 0.0242 = 2.42 × 10-12 m.

DEFINITION: The scattering of electromagnetic radiation by a free or weakly bound electron, in which a single photon as a result of an elastic collision with an electron transmits to it a part of its momentum (part of the energy), is called the Compton effect or phenomenon.

In simple terms, the following happens:

When an X-ray quantum collides, energy is transferred to the electron. An excited electron dumps the energy received from a quantum in the form of an x-ray photon, a lower energy.

It is important to understand:

When radiation is scattered by substances with small atomic numbers, practically all the scattered radiation has an offset wavelength. Thus, two energies appear in the X-ray spectrum: low and initial - high.

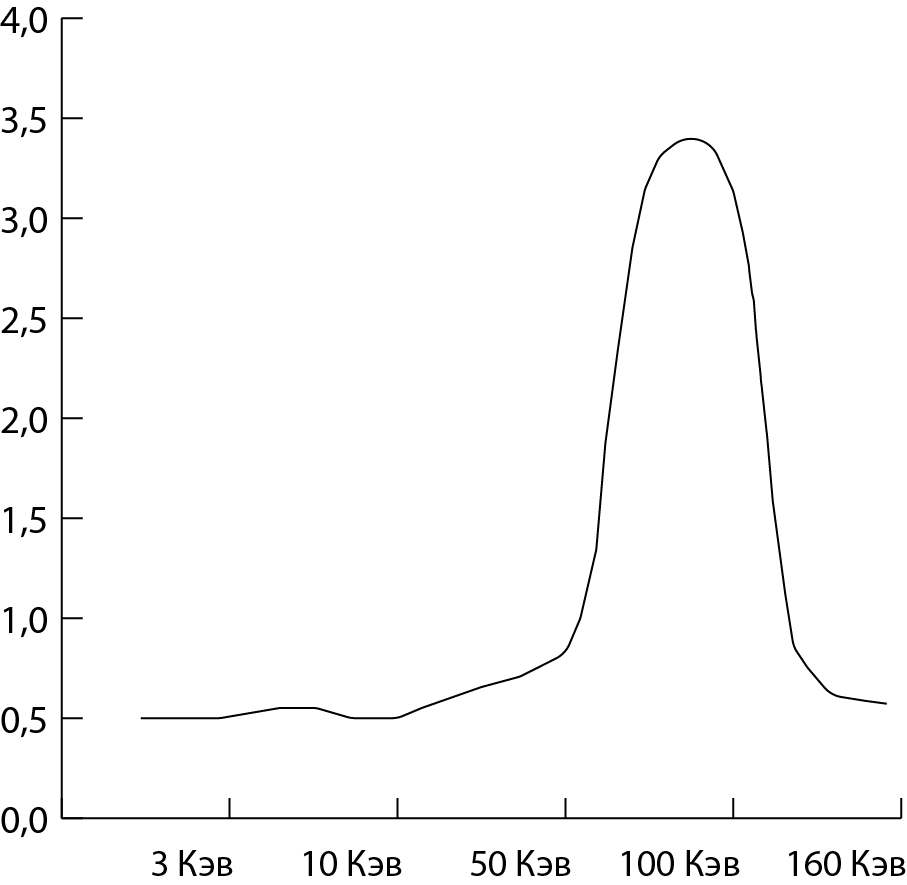

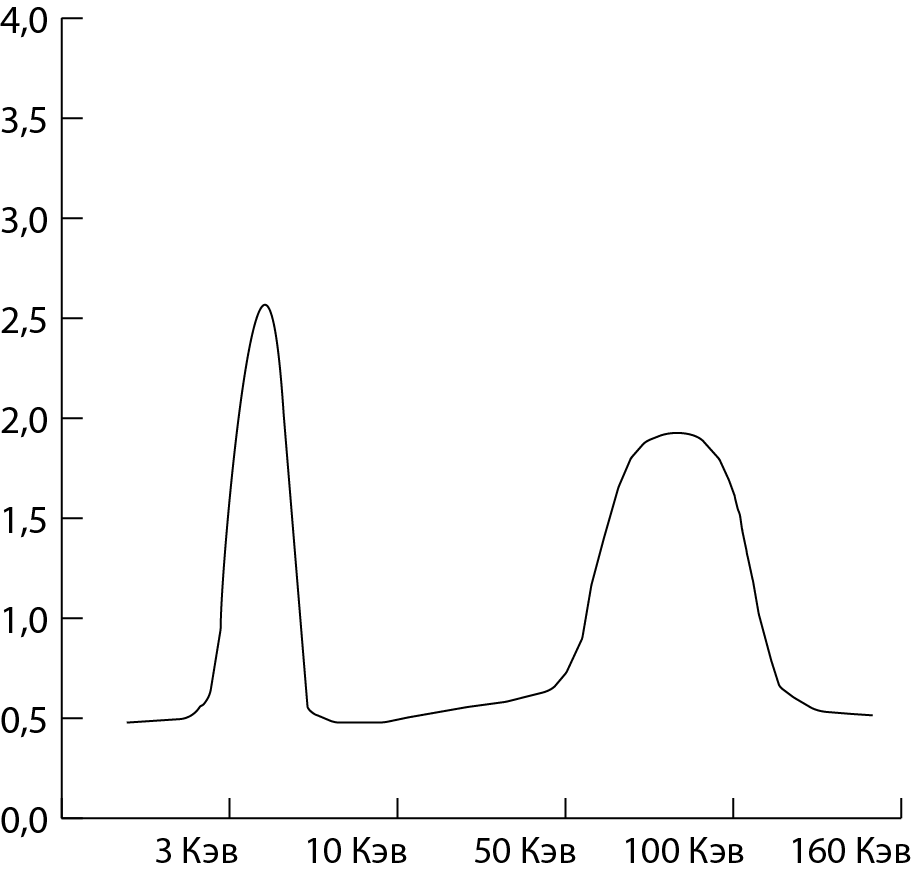

The original x-ray spectrum is high energy.

X-ray spectrum, after origin through organic matter.

X-ray inspection complexes are produced by different companies. In Russia, the equipment of the firms Nuctech, Smits Detection, Rapiscan, L3 Communication, Astrophysics, Medrentech, Berg and many others is mainly present. These companies are from different countries: Russia, China, America, United Kingdom, Germany.

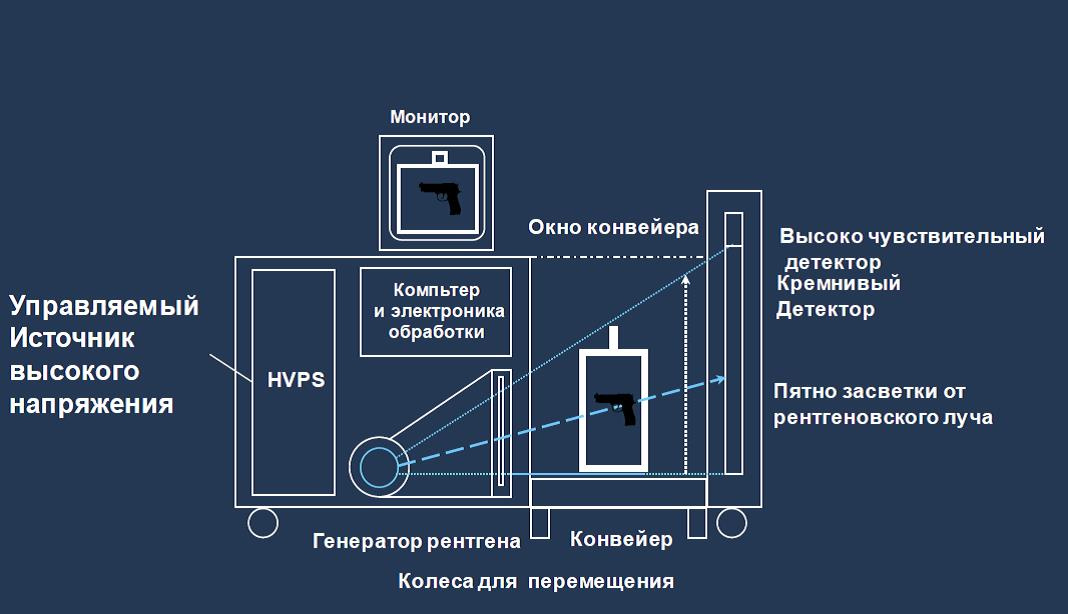

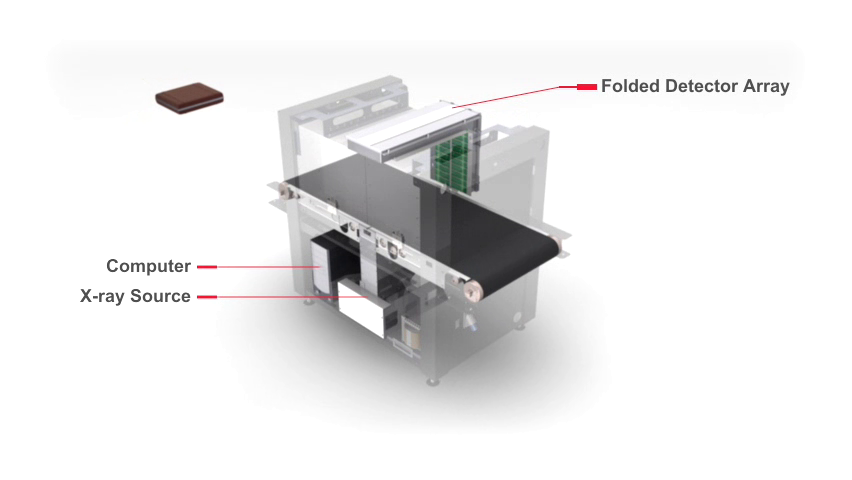

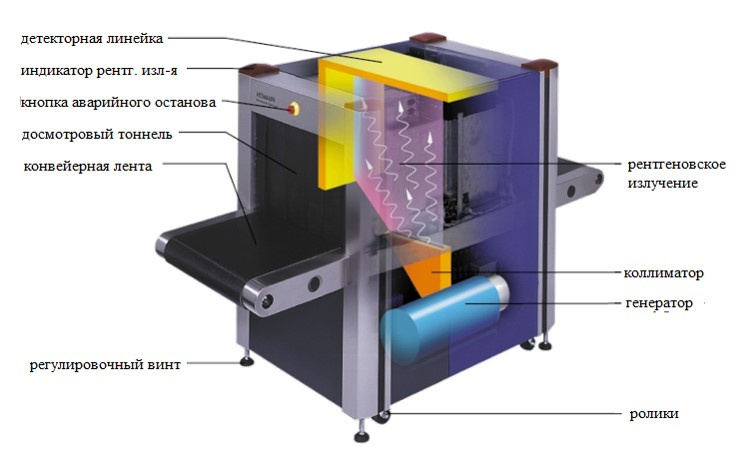

Consider the usual design of X-ray inspection system for inspection of hand baggage.

X-ray inspection system.

An X-ray generator (X-ray Soure), an L-shaped array of Folded Detector Array detectors and a computer are clearly visible in Figure.

Principles of operation of X-ray inspection system:

When the inspected object enters the tunnel and overlaps the photoelectric sensor, the signal from the sensor enters the control unit, which starts the x-ray generator.

X-ray radiation exits the collimator, penetrates the object being scanned and hits the detector.

The system uses two energy detectors. The number of detector modules is two times more than in one energy system. Two sets of detectors with sensitivity, respectively, to low-energy and high-energy X-rays are placed together to receive X-rays.

Depending on the signals received from both detectors, the image processing system can recognize the types of materials (mainly organic, inorganic, and mixtures) of the inspected object.

The modules of the detectors of the system are assembled in protected panels located in the shape of G and installed diagonally from the X-ray generator, for X-rays to scan the entire cross section of the tunnel.

In this arrangement, "blind" zones are excluded and inspection of any part of the objects passing through the tunnel is allowed.

Additional image of X-ray inspection system

A highly efficient detector converts X-rays into weak current signals, which are amplified and fed to the ADC.

These analog signals are converted to 16-bit digital signals that are transmitted to the computer.

The computer first corrects the discrepancy and offset of the digital signal from each pixel, then classifies organic and inorganic materials according to the corrected high and low energy signals and performs basic image processing functions, such as improving image edges, correcting 16-bit high and low energy signals.

The signal of each X-ray graphic object slice turns into a “line” of the image on the display screen.

The gray level of the image indicates the degree of X-ray absorption in the inspected object.

Since the object is transported along the tunnel with a conveyor at a constant speed, the system scans with its successive "X-ray graphic slices". The processed x-ray images of the object are sequentially displayed on the display for viewing.

All X-ray graphic images of the object being scanned are combined and form a complete X-ray image.

So that inspectors can better understand the details of the image and make the right decision, the system provides them with a number of functions for analyzing and evaluating the image.

The use of these functions does not change the image data itself. Disabling such functions restores the original image.

Scanned X-ray inspection equipment test bag as follows:

In this case there is a whole gentleman’s terrorist kit - a revolver, a grenade, a bomb with a timer, a set of keys from a Boeing aircraft, a cell phone and a Samsung Galaxy Note 7.

The resulting image is colored in different colors.

Different materials correspond to different colors of objects in accordance with the table:

Category | Effective atomic number Z eff | Colour | Typical material |

Organic matter | Below 10 |

| Light element compounds, such as hydrogen, carbon, nitrogen, and oxygen, including most explosives (such as nitroglycerin), plastics (such as polypropylene), paper, cloth, food, wood, and water |

Mixed material | Between 10 and 18 |

| Metal elements of average weight (for example, aluminum) and salts. |

Inorganic substances | More than 18 |

| Heavy metal elements (for example, titanium, chromium, silver, nickel, iron, copper, zinc and lead). |

Zeff is the atomic weight of the materials that are illuminated in a given area of the image. This parameter is determined by the Compton effect and low and high energy X-ray detectors.

There are different functions for processing the image of the object being scanned. Inspector favorite black and white mode is used to detect thin, metallic objects.

For example: wires, knives in vertical projection, or explosives with wires and fuses.

Black and White (B / W) Image

For the detection of metallic objects using the mode of eliminating organic materials. As a result, on the image in blue, metallic objects are marked. Looking ahead a bit, I can tell you that light metals are painted in green — for example, aluminum or metal salts.

Elimination of organic

To determine trotyl or other plastic explosives, and also drugs, the exclusion mode of inorganic materials - metals and salts is used. As a result, organic materials are visible, for example, fruits and vegetables, plastics, including plastic explosives and narcotic substances.

Display only organic matter when excluding inorganic materials

Also during the inspection, the possibility of determining materials by atomic numbers — Z eff.

Effective atomic numbers (Zeff) of explosives and drugs are in the range [7,9], as shown in the Table.

Table Effective atomic numbers of explosives and drugs

Zeff | Material |

7 | Water and plastic explosives |

eight | Drugs or explosives |

9 | Pure Narcotic Drugs |

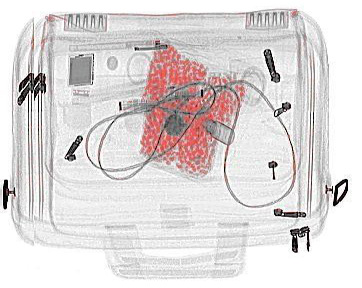

Z7 / Z8 / Z9 function is used to select materials with Zeff equal to 7, 8 or 9 on the image. With this function you can view organic materials with Zeff parameter equal to 7, 8 or 9, respectively. The areas of the image with organic materials with the specified Zeff are shown in red, and the remaining areas are shown in gray. Thus, you can easily select explosives or drugs.

Z9 function application

The figure clearly shows the grains of amphetamine in the package, shown using the Z9 function.

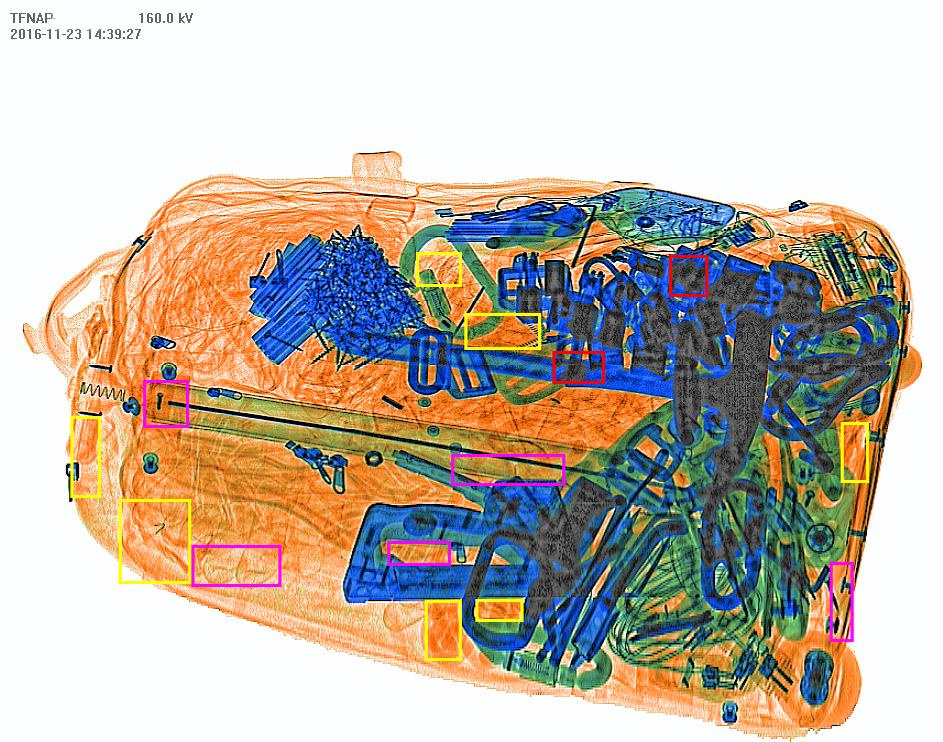

Also used mode "auto" - automatic detection. In this mode, hazardous substances are surrounded by colored, rectangular contours.

The real image of the baggage on the monitor X-ray inspection and inspection installation.

Yellow frames outlined objects similar to explosives. Pink frames surround objects like drugs. The red frames are a warning about objects that are not exposed to X-rays.

Consequently, something not visible to the inspector may be located behind this item. And if much of the baggage is hidden, the inspector is obliged to inspect it.

It is important to understand that, this framework is a warning for the inspector. Not so often frames indicate a real threat.

The next article will discuss the training methods of operators, the capabilities and functions of the software and the design of X-ray inspection systems.

All Articles