"Alchemy" of black gold of music lovers: mastering, production, first ressy and 180 grams of mistrust

As you probably already understood from the title, it will again be about vinyl. More specifically, about gramophone records. The dynamically growing trend, about the reasons for which I have already expressed my thoughts , poses a number of interesting questions for record fans, which are annually discussed in the appropriate forums. Many of these questions are related to the carrier itself (recording records, mastering, production, mass-dimensional characteristics).

So, many people who are not indifferent to vinyl ask themselves questions: which discs sound better (33 or 45 vol. Per minute) than first presses are good, does recording speed affect quality. Arguments about the higher quality of "heavy vinyl" (plates with a mass of 180 - 200 grams) compared to standard ones are not rare. A lot of vigorous disputes are caused by comparing the quality of old and new "layers", the problem of mastering and remastering.

In this post, I will try to consider in detail how some aspects of recording and production affect the sound quality of records, such as speed, mastering, and the serial number of the press. And also to answer the question: “does the mass of the vinyl disc influence the final result of the playback?”. I will step by step through each of the stages of production with lyrical digressions concerning the issues outlined above.

This time I will try to avoid reasoning about the "liveliness" of the vinyl sound. The data of objective measurements and psychoacoustic studies are ignored by people with a severe degree of vinyl dependence. The subjectivity of warm vinyl rhetoric does not allow for any useful discussions on this topic. Meanwhile, I think it makes sense to conduct a rather detailed “anatomy” of some nuances in order to shed light on the issues that are troubling the growing army of record lovers.

To understand what depends on the quality of sound on vinyl, it makes sense to consider the entire production cycle of recording. I suppose such an educational program will be useful for people who are not familiar with the way vinyl “magic” is created.

The first step in creating a plate is the manufacture of a lacquered pattern (lacker). Round aluminum disc covered with a layer of nitrocellulose lacquer. After drying nitrocellulose varnished discs are subjected to selection. Quality control specialists assess the condition of the coating. The detection of minimal irregularities leads to the "rejection" of the lacker. "Survives" not much more than 50%.

Theoretically, any defective laquer, who has missed the control and has not been noticed during the “cutting”, will affect the reference press, and further on the entire series of plates that will be printed with it. In practice, such defects are extremely rare, and any defect is noticed at a particular stage of quality control. It is believed that if such plastic still goes on sale, the defect can significantly increase its collectible value through N-tsat years.

Before applying (cutting) a record on a lacquer, it is necessary to conduct a special mastering, in which the recording will be processed in such a way that it sounds as good as possible on vinyl. It is at this stage that almost everything that we will hear later when playing a record is formed.

As a record material, vinyl is “pretentious” enough, and mastering for recording is a kind of compromise. On the one hand, the mastering engineer seeks to preserve the maximum of the original recording (transferring all the musical nuances), on the other - to make the recorded track not cause problems during playback.

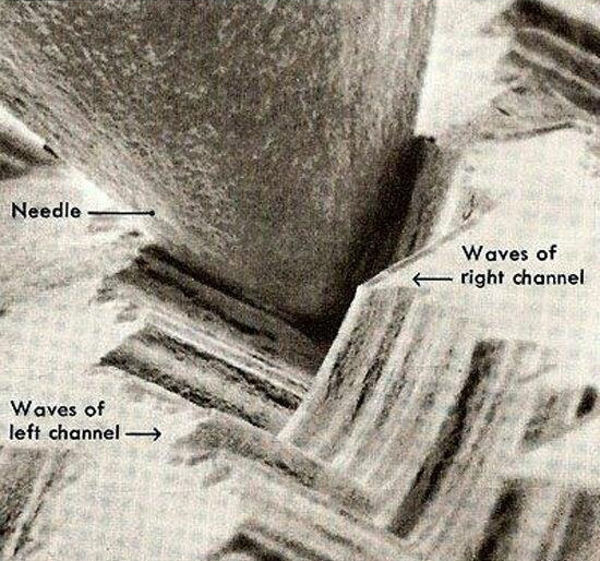

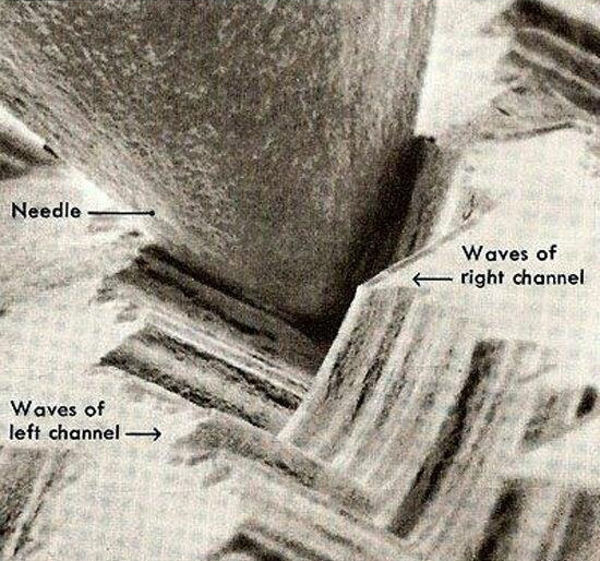

The complexity of vinyl mastering is due to the fact that louder and lower-frequency waves occupy a greater width and depth on the track. Accordingly, the higher the dynamic range and the wider the frequency range, the larger the area will be occupied by the track with such a recording. Based on this, we can conclude that the maximum sound quality on a record is obtained by cutting the deepest and widest tracks, the maximum step between them and using the maximum speed of rotation of the disc during recording / playback.

The ideal format for high quality recording is considered by many engineers to be a single track on one side of a 12 inch disc, at a speed of 45 revolutions per minute (RPM). The 78 RPM speed is practically not used in modern recording. The vast majority of modern records are recorded / reproduced at a speed of 33 revolutions per minute (RPM). At the same time, records with a higher playback speed wear out faster and, due to uneconomic use of space, contain fewer records. Accordingly, the creation of a collection of such discs will require more investments.

The essential aspect of mastering records is the correction of the frequency response and the “softening” of the so-called “problem” ranges. The most critical in this respect is the part of the spectrum from 5800 to 7900 Hz, as well as single resonant frequencies.

In addition, any stereo recorded on vinyl has a number of limitations on panning. In the “vinyl” mastering, the antiphase of the left and right channels should not be allowed in the low-frequency range. Such a signal cannot be reproduced in LP format, due to the wide trajectory of recording low-frequency waves. In the case of “non-phased” recording channels, the player’s needle may simply fly off the desired trajectory during playback. That is why the low-frequency signal on correctly processed gram-notes is reproduced in mono, and MF and HF in stereo.

An equally important nuance is the level of the RMS (meter of effective values) of the original record. When cutting the lacquer, the RMS level should not exceed 12 dB RMS. A higher rate (especially in the HF area) can lead to overheating of the head of the turning cutter.

After the selection, the lakers are sent to the studio, and the second stage begins - the recording of the standard. Cutting is carried out using a special machine tool - a turning tool, in which a special sapphire (diamond, ruby) cutting head is used. Control is carried out using a microscope.

When recording, the cutter head requires constant cooling, which is carried out using compressed helium. Lacquer chips from the cut out track is cleaned with a kind of vacuum cleaner.

A laker with a record is sent to production, where it is successively coated with tin and silver dichloride in an aerosol manner. The tin allows silver to “stick” to the disk. After that, to increase strength, the disk is electroplated with nickel.

After nickel plating, the metal part of the standard is separated from the lacquer. In the future, metal impression is used for stamping serial plates.

The stamping of the finished serial disk is carried out with the help of a press that creates a pressure of about 1000 kPa or 100 tons of force per cm 2. A hot press, with established reference stamps, flattens the pieces of PVC (in the professional jargon "cookies"), stamping a record on them.

After this, the practically finished plate is cooled. Then the edge is trimmed, a quality control, packing procedure is carried out, and the finished vinyl goes on sale, but this is already a story that is far from recording quality issues.

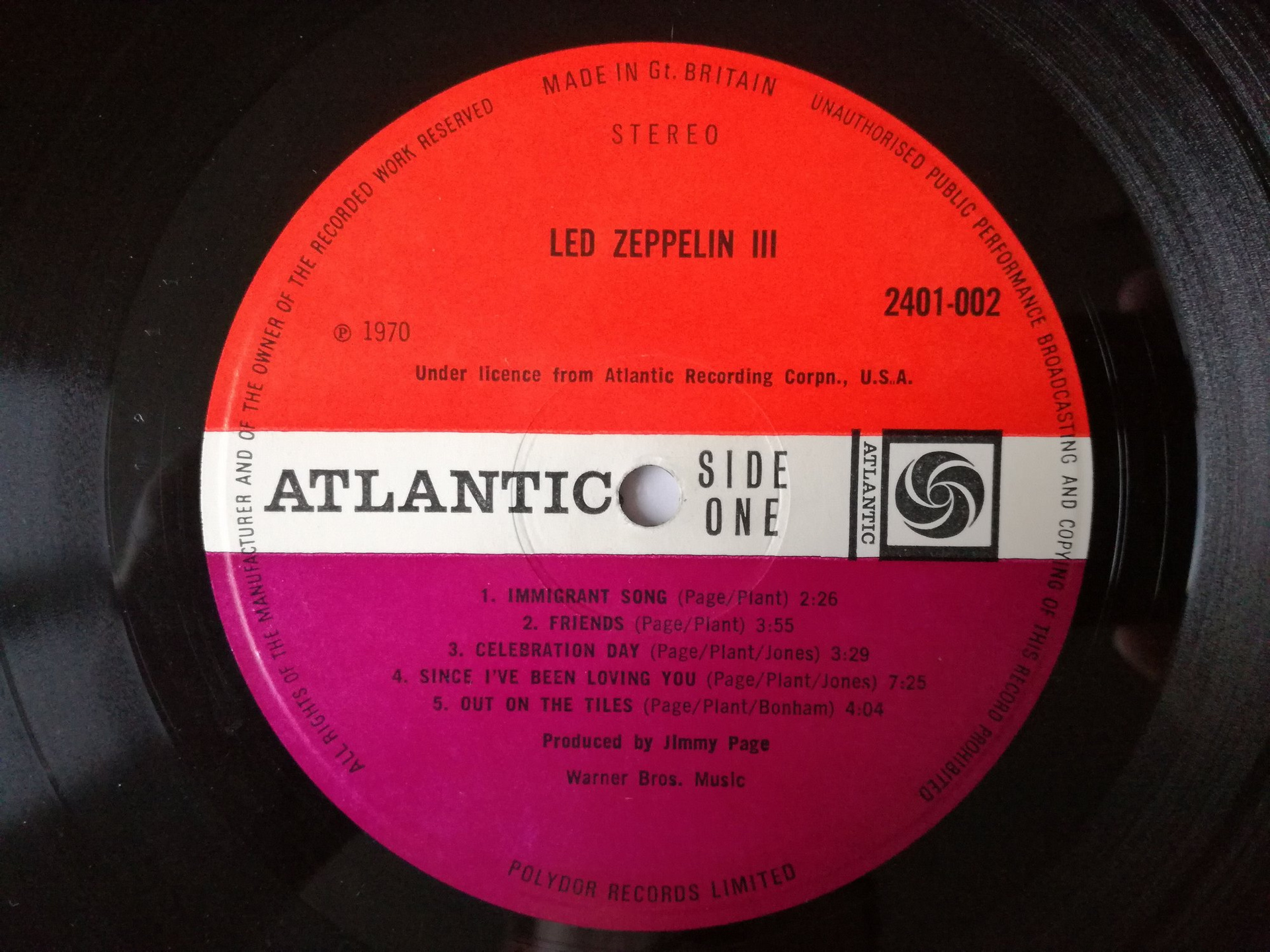

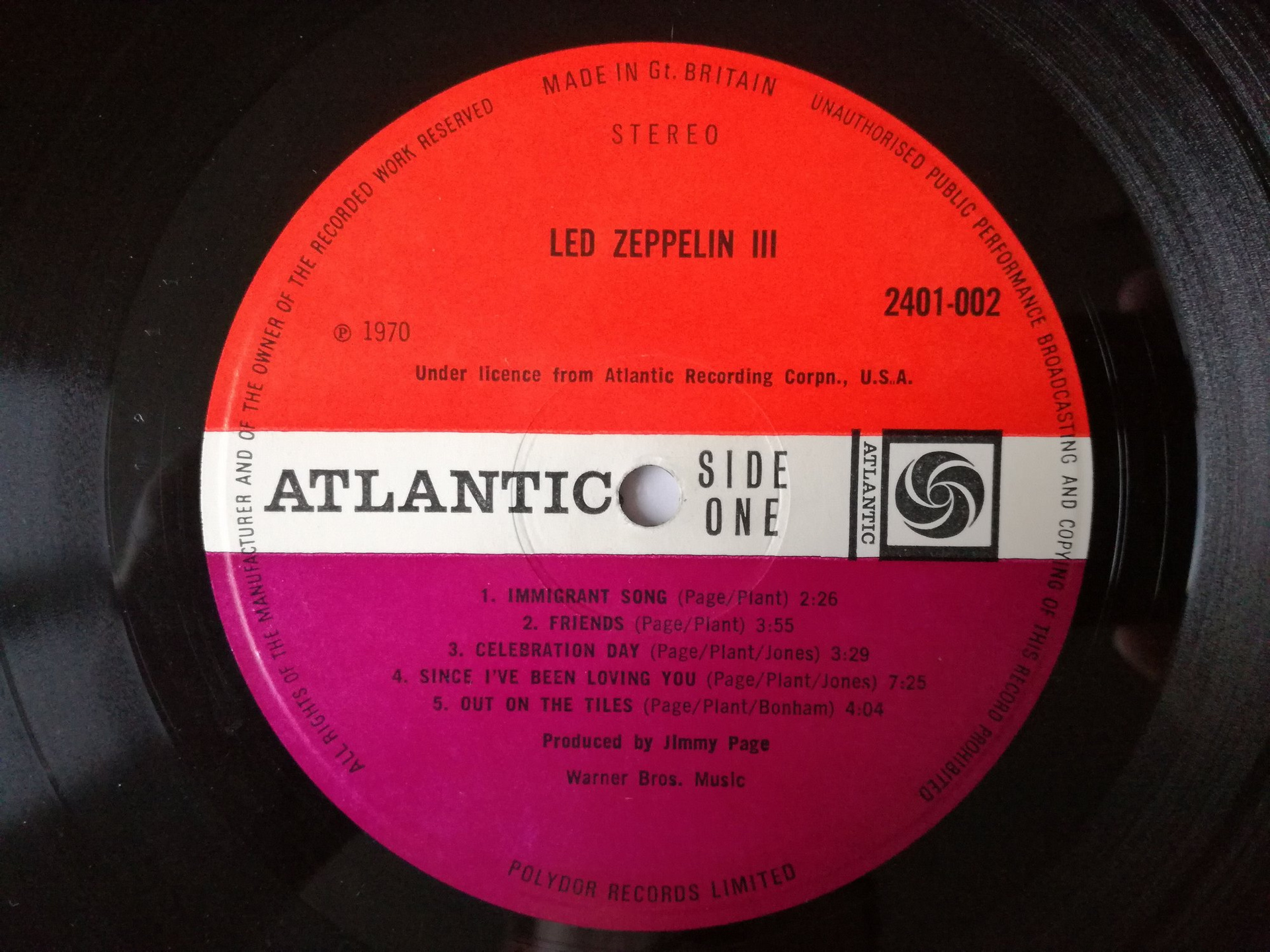

In the context of questions about the first press, we are most interested in the processes of stamping and mastering, as well as what happens to the standard during a thousand-fold application. As already noted, the character of the sound depends on the mastering, carried out before the creation of the standard, the quality of the lacker and the accuracy of the recording on the cutter. But the standard is not eternal and wears out in the process of mass production. Therefore, a reasonably reasonable assumption has arisen that the sound of the record that was released earlier will be better and more accurate.

The producers of records themselves admit that the technology of making vinyl discs does not allow getting two absolutely identical carriers. Accordingly, each plastic will sound different in some tiny details. At the same time, those legendary “first presses” in some minor (for most people) nuances will sound closer to the original original.

When reissuing, especially modern, long-recorded vinyl albums, re-mastering is necessary. There are no uniform standards for mastering. A new process of preparing a record for publication is usually conducted by a new mastering engineer, who is often not associated with either the performer or his producer. This engineer may have his own "look" on what and how it should sound. Therefore, it is not uncommon for the first and subsequent editions to be significantly different in sound (although it is sometimes difficult to determine for the worse or better).

Naturally, “as if TRUE” is considered the very edition that the mastering engineer associated with the team or performer worked on. As a rule, this is the first release or a super rare promo series. At the same time, even convinced vinilopoklonniki, who ate more “dogs” on this topic, consider the first press only a relative advantage. This attitude was summarized well in his article by the author of the auditorium resource inthouse.ru, Oleg Bocharov:

These simple and understandable views on the “first presses” served as the basis for the “decaying” Western countries to have marketing-specific pricing models for “rare” and sort of “good-sounding” records. The goal of implanting ideas about the “uniqueness of the sound” of individual series of plates into the collective consciousness is a banal divorce of music lovers for the maximum amount of bubble for vinyl antiques (dusting in Uncle John’s warehouses since 197). Thus, the price of some series of records for a half or two years can take off from $ 40 - $ 50 to $ 1,000 and above. The most active propagandist of such views is Tom Port (a dealer in collection presses), who, by the way, cannot tolerate contemporary records.

In some cases, the views of the Port are relatively reasonable. So, some small studios in Europe do not take into account many features of mastering and publish outright hack. But, contrary to his opinion - this phenomenon is not an absolute truth, a prerequisite for a modern release, and even widespread practice. More than 70% of current releases and reissues can compete with vintage records in terms of recording quality. I can also note that some modern editions are almost indistinguishable from old ones. Quite a few modern mastering engineers deliberately use the sound concepts of their colleagues from the past to achieve that very vintage “true vinyl sound”.

Many argue that heavy and thick plates (from 180 g and more) sound much better than less heavy ones. The rationale for such allegations is often not given.

Historically, high-quality releases, at the time of the appearance of heavy presses, were produced on heavier “formations” with a mass of 180 - 200 grams. There the mastering was more perfect, and the original master tapes were applied, and the production technology was more perfect. But this applies only to the western records of the late 60s - early 70s. The Soviet recordings of the early 60s were also thick and weighty (mainly to increase strength), but did not have a high sound quality. In the tradition, a stereotype has been established that heavy vinyl is good and thin as it will.

Today, heavy vinyl (like any other) can turn out to be absolutely anything. Quite a few companies produce thick plates intentionally, in order to attract a customer with the cherished inscription "180 g", recalling the time when sugar was sweeter and the grass is greener. At the same time mastering can remain completely none, as well as the source code and the quality of the material of the plate itself.

Meanwhile, heavy vinyl has a number of quite tangible advantages: higher strength, the ability to withstand longer the violation of storage conditions, as well as stability during playback (which is not too important for owners of high-quality players with heavy discs and tables).

Speaking more simply, as we have already found out, the most significant factor determining the quality of the recording sound is mastering, and an increase in mass and thickness rather serves to increase durability.

The bottom line is the following conclusions:

Oh yeah, I almost forgot! Mastering is divided not into digital and analog, but into high-quality and low-quality. I will not add anything about this, since it is well known that the capabilities of studio digital systems are not inferior to analog.

I sincerely hope that the article was useful to those who are not looking for easy ways and risk contacting vinyl or are simply interested in this topic.

We remind you that you can purchase from us :

→ Players

→ Phono stage units

→ Records

Photographic materials used:

dastereo.ru

dayrecords.ru

vinylrecords.ru

mixed.news

Stereo.ru

The text used quotes from the article by Oleg Bocharov, published on the pages of the resource inthouse.ru, as well as from the article “Why audiophiles are paying $ 1,000 for this man's vinyl” www.wired.com .

The preparation of the material was influenced by the creativity of the video blogger stalker29218 I.V.

So, many people who are not indifferent to vinyl ask themselves questions: which discs sound better (33 or 45 vol. Per minute) than first presses are good, does recording speed affect quality. Arguments about the higher quality of "heavy vinyl" (plates with a mass of 180 - 200 grams) compared to standard ones are not rare. A lot of vigorous disputes are caused by comparing the quality of old and new "layers", the problem of mastering and remastering.

In this post, I will try to consider in detail how some aspects of recording and production affect the sound quality of records, such as speed, mastering, and the serial number of the press. And also to answer the question: “does the mass of the vinyl disc influence the final result of the playback?”. I will step by step through each of the stages of production with lyrical digressions concerning the issues outlined above.

This time I will try to avoid reasoning about the "liveliness" of the vinyl sound. The data of objective measurements and psychoacoustic studies are ignored by people with a severe degree of vinyl dependence. The subjectivity of warm vinyl rhetoric does not allow for any useful discussions on this topic. Meanwhile, I think it makes sense to conduct a rather detailed “anatomy” of some nuances in order to shed light on the issues that are troubling the growing army of record lovers.

Lacker - selection and defects

To understand what depends on the quality of sound on vinyl, it makes sense to consider the entire production cycle of recording. I suppose such an educational program will be useful for people who are not familiar with the way vinyl “magic” is created.

The first step in creating a plate is the manufacture of a lacquered pattern (lacker). Round aluminum disc covered with a layer of nitrocellulose lacquer. After drying nitrocellulose varnished discs are subjected to selection. Quality control specialists assess the condition of the coating. The detection of minimal irregularities leads to the "rejection" of the lacker. "Survives" not much more than 50%.

Theoretically, any defective laquer, who has missed the control and has not been noticed during the “cutting”, will affect the reference press, and further on the entire series of plates that will be printed with it. In practice, such defects are extremely rare, and any defect is noticed at a particular stage of quality control. It is believed that if such plastic still goes on sale, the defect can significantly increase its collectible value through N-tsat years.

Mastering - cut frequencies, leaving the music

Before applying (cutting) a record on a lacquer, it is necessary to conduct a special mastering, in which the recording will be processed in such a way that it sounds as good as possible on vinyl. It is at this stage that almost everything that we will hear later when playing a record is formed.

As a record material, vinyl is “pretentious” enough, and mastering for recording is a kind of compromise. On the one hand, the mastering engineer seeks to preserve the maximum of the original recording (transferring all the musical nuances), on the other - to make the recorded track not cause problems during playback.

The complexity of vinyl mastering is due to the fact that louder and lower-frequency waves occupy a greater width and depth on the track. Accordingly, the higher the dynamic range and the wider the frequency range, the larger the area will be occupied by the track with such a recording. Based on this, we can conclude that the maximum sound quality on a record is obtained by cutting the deepest and widest tracks, the maximum step between them and using the maximum speed of rotation of the disc during recording / playback.

The ideal format for high quality recording is considered by many engineers to be a single track on one side of a 12 inch disc, at a speed of 45 revolutions per minute (RPM). The 78 RPM speed is practically not used in modern recording. The vast majority of modern records are recorded / reproduced at a speed of 33 revolutions per minute (RPM). At the same time, records with a higher playback speed wear out faster and, due to uneconomic use of space, contain fewer records. Accordingly, the creation of a collection of such discs will require more investments.

The essential aspect of mastering records is the correction of the frequency response and the “softening” of the so-called “problem” ranges. The most critical in this respect is the part of the spectrum from 5800 to 7900 Hz, as well as single resonant frequencies.

In addition, any stereo recorded on vinyl has a number of limitations on panning. In the “vinyl” mastering, the antiphase of the left and right channels should not be allowed in the low-frequency range. Such a signal cannot be reproduced in LP format, due to the wide trajectory of recording low-frequency waves. In the case of “non-phased” recording channels, the player’s needle may simply fly off the desired trajectory during playback. That is why the low-frequency signal on correctly processed gram-notes is reproduced in mono, and MF and HF in stereo.

An equally important nuance is the level of the RMS (meter of effective values) of the original record. When cutting the lacquer, the RMS level should not exceed 12 dB RMS. A higher rate (especially in the HF area) can lead to overheating of the head of the turning cutter.

Lacquer Sapphire - Press on PVC

After the selection, the lakers are sent to the studio, and the second stage begins - the recording of the standard. Cutting is carried out using a special machine tool - a turning tool, in which a special sapphire (diamond, ruby) cutting head is used. Control is carried out using a microscope.

When recording, the cutter head requires constant cooling, which is carried out using compressed helium. Lacquer chips from the cut out track is cleaned with a kind of vacuum cleaner.

A laker with a record is sent to production, where it is successively coated with tin and silver dichloride in an aerosol manner. The tin allows silver to “stick” to the disk. After that, to increase strength, the disk is electroplated with nickel.

After nickel plating, the metal part of the standard is separated from the lacquer. In the future, metal impression is used for stamping serial plates.

The stamping of the finished serial disk is carried out with the help of a press that creates a pressure of about 1000 kPa or 100 tons of force per cm 2. A hot press, with established reference stamps, flattens the pieces of PVC (in the professional jargon "cookies"), stamping a record on them.

After this, the practically finished plate is cooled. Then the edge is trimmed, a quality control, packing procedure is carried out, and the finished vinyl goes on sale, but this is already a story that is far from recording quality issues.

Pervopress - appropriate or not

In the context of questions about the first press, we are most interested in the processes of stamping and mastering, as well as what happens to the standard during a thousand-fold application. As already noted, the character of the sound depends on the mastering, carried out before the creation of the standard, the quality of the lacker and the accuracy of the recording on the cutter. But the standard is not eternal and wears out in the process of mass production. Therefore, a reasonably reasonable assumption has arisen that the sound of the record that was released earlier will be better and more accurate.

The producers of records themselves admit that the technology of making vinyl discs does not allow getting two absolutely identical carriers. Accordingly, each plastic will sound different in some tiny details. At the same time, those legendary “first presses” in some minor (for most people) nuances will sound closer to the original original.

When reissuing, especially modern, long-recorded vinyl albums, re-mastering is necessary. There are no uniform standards for mastering. A new process of preparing a record for publication is usually conducted by a new mastering engineer, who is often not associated with either the performer or his producer. This engineer may have his own "look" on what and how it should sound. Therefore, it is not uncommon for the first and subsequent editions to be significantly different in sound (although it is sometimes difficult to determine for the worse or better).

Naturally, “as if TRUE” is considered the very edition that the mastering engineer associated with the team or performer worked on. As a rule, this is the first release or a super rare promo series. At the same time, even convinced vinilopoklonniki, who ate more “dogs” on this topic, consider the first press only a relative advantage. This attitude was summarized well in his article by the author of the auditorium resource inthouse.ru, Oleg Bocharov:

“It is not cheap to buy first-presses in good condition, but it’s not so difficult to find the second or third edition and get just as adequate joy. If there is a choice, I would advise not to save 200-300 rubles, and if possible to take English or American release. Plus, the original Japanese vinyl is not so expensive in Moscow now, but it sounds quite at the level - for example, I calmly found Pink Floyd "Meddle", a 1971 samurai print run from English matrices (that is, a twin of the first press), the sound is a miracle, but it costs only $ 40. ”

These simple and understandable views on the “first presses” served as the basis for the “decaying” Western countries to have marketing-specific pricing models for “rare” and sort of “good-sounding” records. The goal of implanting ideas about the “uniqueness of the sound” of individual series of plates into the collective consciousness is a banal divorce of music lovers for the maximum amount of bubble for vinyl antiques (dusting in Uncle John’s warehouses since 197). Thus, the price of some series of records for a half or two years can take off from $ 40 - $ 50 to $ 1,000 and above. The most active propagandist of such views is Tom Port (a dealer in collection presses), who, by the way, cannot tolerate contemporary records.

“The port is confident that all modern reissues worth $ 30 are worth nothing at all. No posters, pictures and booklets save this nonsense. To all the bonuses and inscriptions like "printed from the original master record" Tom Port treats with contempt. "

Quote: Stereo.ru

In some cases, the views of the Port are relatively reasonable. So, some small studios in Europe do not take into account many features of mastering and publish outright hack. But, contrary to his opinion - this phenomenon is not an absolute truth, a prerequisite for a modern release, and even widespread practice. More than 70% of current releases and reissues can compete with vintage records in terms of recording quality. I can also note that some modern editions are almost indistinguishable from old ones. Quite a few modern mastering engineers deliberately use the sound concepts of their colleagues from the past to achieve that very vintage “true vinyl sound”.

180 grams or what is the mass

Many argue that heavy and thick plates (from 180 g and more) sound much better than less heavy ones. The rationale for such allegations is often not given.

Historically, high-quality releases, at the time of the appearance of heavy presses, were produced on heavier “formations” with a mass of 180 - 200 grams. There the mastering was more perfect, and the original master tapes were applied, and the production technology was more perfect. But this applies only to the western records of the late 60s - early 70s. The Soviet recordings of the early 60s were also thick and weighty (mainly to increase strength), but did not have a high sound quality. In the tradition, a stereotype has been established that heavy vinyl is good and thin as it will.

Today, heavy vinyl (like any other) can turn out to be absolutely anything. Quite a few companies produce thick plates intentionally, in order to attract a customer with the cherished inscription "180 g", recalling the time when sugar was sweeter and the grass is greener. At the same time mastering can remain completely none, as well as the source code and the quality of the material of the plate itself.

Meanwhile, heavy vinyl has a number of quite tangible advantages: higher strength, the ability to withstand longer the violation of storage conditions, as well as stability during playback (which is not too important for owners of high-quality players with heavy discs and tables).

Speaking more simply, as we have already found out, the most significant factor determining the quality of the recording sound is mastering, and an increase in mass and thickness rather serves to increase durability.

Total

The bottom line is the following conclusions:

- the first priority for LP sound quality is mastering and master tape quality;

- most preferred, to provide a wider dynamic and frequency range, is to use a speed of 45 revolutions per minute (RPM) with deep, wide tracks and large steps;

- far from all modern releases are significantly inferior to quality first-presses, especially when using original master tapes, adequate mastering;

- prices for first-presses are often astronomically overpriced, due to the existing hype, and their real collectible cost can be significantly lower;

- a mass of 180 grams for a modern record is not an indicator of sound quality and can most likely be said about durability.

Oh yeah, I almost forgot! Mastering is divided not into digital and analog, but into high-quality and low-quality. I will not add anything about this, since it is well known that the capabilities of studio digital systems are not inferior to analog.

I sincerely hope that the article was useful to those who are not looking for easy ways and risk contacting vinyl or are simply interested in this topic.

We remind you that you can purchase from us :

→ Players

→ Phono stage units

→ Records

Photographic materials used:

dastereo.ru

dayrecords.ru

vinylrecords.ru

mixed.news

Stereo.ru

The text used quotes from the article by Oleg Bocharov, published on the pages of the resource inthouse.ru, as well as from the article “Why audiophiles are paying $ 1,000 for this man's vinyl” www.wired.com .

The preparation of the material was influenced by the creativity of the video blogger stalker29218 I.V.

All Articles