Good old spool valve 394 is still used on rolling stock

1. Driver's cranes - a brief introduction

A-priory

Train driver’s crane - a device (or a set of devices) designed to control the magnitude and rate of pressure change in the brake line of a trainThe train cranes of the driver currently in use can be divided into direct control devices, and cranes with remote control.

Direct control devices are a classic of the genre, installed on the vast majority of locomotives, wagon trains, as well as special-purpose rolling stock (various road cars, railcars, etc.) No. 394 and conv. No. 395. The first of them, depicted on the KDPV, is installed on freight locomotives, the second on passenger ones.

In the pneumatic sense, these cranes do not differ from each other at all. That is absolutely identical. The crane 395 on the upper part has a tide cast with it, with two threaded holes where the “bank” of the electro-pneumatic brake control controller is installed

395th driver's crane in natural habitat

These devices are most often painted in bright red color, which indicates their exceptional importance and special attention that should be given to them by both the locomotive team and the process personnel serving the locomotive. Another reminder that the brakes on the train is all.

The pipelines of the feed (PM) and brake line (TM) are directly connected to these devices and, by turning the handle, the air flow is directly controlled.

In cranes with remote control on the driver’s console, it’s not the crane itself that is installed, but the so-called control controller that sends commands to a separate electropneumatic panel via the digital interface, which is installed in the engine room of the locomotive. On domestic rolling stock, a long-suffering crane operator No. 130, for quite some time making its way onto the rolling stock.

Crane controller No. 130 on the remote control of an electric locomotive EP20 (on the right, next to the gauge panel)

Pneumopanel in the engine room of an electric locomotive EP20

Why is this done? To ensure that in addition to manual brake control, the standard ability to control an automatic, for example, from a train's automatic driving system, has appeared. For locomotives equipped with a 394/395 crane, this required the installation of a special console on the crane. As planned, the 130th crane is integrated into the train control system via CAN bus, which is used on domestic rolling stock.

Why did I call this device long-suffering? Because he was a direct witness to his first appearance on rolling stock. Such devices were installed on the first numbers of new Russian electric locomotives: 2ES5K-001 "Ermak", 2ES4K-001 "Donchak" and EP2K-001.

In 2007, I participated in the certification tests of the 2ES4K-001 electric locomotive. The 130th crane was installed on this machine. However, already then there was talk of its low reliability, moreover, this miracle of technology could spontaneously release the brakes. Therefore, he was soon abandoned and Ermaki, Donchaki and EP2K went into series with 394 and 395 cranes. Progress has been delayed until the completion of the new device. This crane returned to Novocherkassk locomotives only with the launch of the EP20 electric locomotive in 2011. But Ermaki, Donchaki and EP2K did not receive a new version of this crane. EP2K-001, by the way, with the 130th crane, is now rotting on the basis of the stock, as I recently learned from a video of one fan of railway abandonment.

However, railroad workers do not have full confidence in such a system, therefore, all locomotives equipped with a crane 130 are also equipped with backup control valves, which allow, in a simplified mode, to directly control the pressure in the brake line.

EP20 backup brake control valve

A second control device is also installed on locomotives - the auxiliary brake valve (KW), designed to control the brakes of the locomotive, regardless of the brakes of the train. Here it is, to the left of the train crane

Auxiliary brake valve No. 254

In the photo is a classic auxiliary brake valve, conv. No. 254. It is installed in many places until now, both on passenger and freight locomotives. Unlike car brakes, on a locomotive brake cylinders are never filled directly from the spare tank. Although both a spare tank and an air distributor are installed on the locomotive. In general, the locomotive’s brake circuit is more complicated due to the fact that the locomotive has more brake cylinders. Their total volume is significantly higher than 8 liters, therefore, filling them out of the reserve tank to a pressure of 0.4 MPa will not work - it is necessary to increase the volume of the reserve tank, and this will increase its charging time compared to wagon spares.

On the locomotive, the shopping centers are filled from the main reservoir, either through the auxiliary brake valve or through a pressure switch that is actuated by an air distributor driven by the train crane of the driver.

The crane 254 has the peculiarity that it itself can work as a pressure switch, allowing the release of (stepped!) Brakes of the locomotive with a braked train. Such a scheme is called a circuit for turning on the KVT as a repeater and is used on freight locomotives.

The auxiliary brake valve is used during shunting movements of the locomotive, as well as to secure the train after stopping and during parking. Immediately after the train stops, this crane is put in the latest braking position, and the brakes in the train are released. Locomotive brakes are able to hold both the locomotive and the composition on a fairly serious bias.

On modern electric locomotives, such as EP20, other KVT are installed, for example, conv. No. 224

Auxiliary brake valve No. 224 (on the right in a separate panel)

2. The device and principle of operation of the crane operator conv. No. 394/395

So, our hero is old, time-tested and millions of kilometers of the way crane 394 (and 395, but it is similar, so I will talk about one of the devices, referring to the second). Why is it, and not the modern 130th? Firstly, 394 cranes are more common today. And secondly, the 130th crane, or rather its pneumatic panel, is similar to old man 394 by the principle of its action.

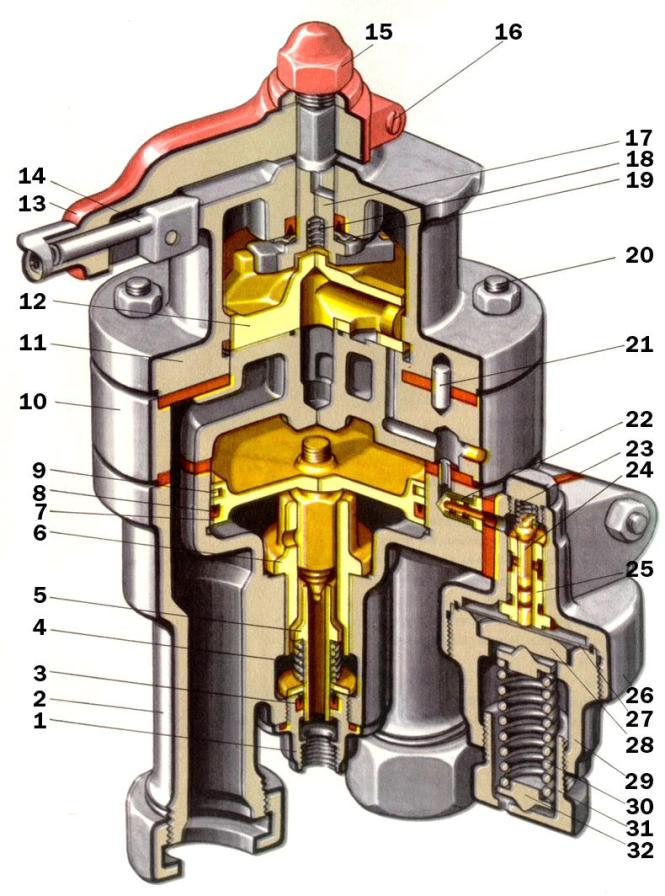

The crane operator No. 394: 1 - base of the tail of the exhaust valve; 2 - case of the lower part; 3 - sealing cuff; 4 - spring; 5 - exhaust valve; 6 - a sleeve with a saddle of the exhaust valve; 7 - equalizing piston; 8 - sealing rubber cuff; 9 - sealing brass ring; 10 - the body of the middle part; 11 - upper body; 12 - spool; 13 - control handle; 14 - handle lock; 15 - nut; 16 - clamping screw; 17 - a core; 18 - spool spring; 19 - a clamping washer; 20 - mounting studs; 21 - pin retainer; 22 - filter; 23 - spring feed valve; 24 - feed valve; 25 - sleeve with a seat of the feed valve; 26 - aperture of the gear; 30 - an adjusting spring of a reducer; 31 - an adjusting glass of a reducer

How do you like it? Serious device. This device consists of an upper (slide) part, a middle (intermediate) part, a lower (equalization) part, a stabilizer and a gearbox. The gearbox is shown at the bottom right in the figure, the stabilizer will be shown separately

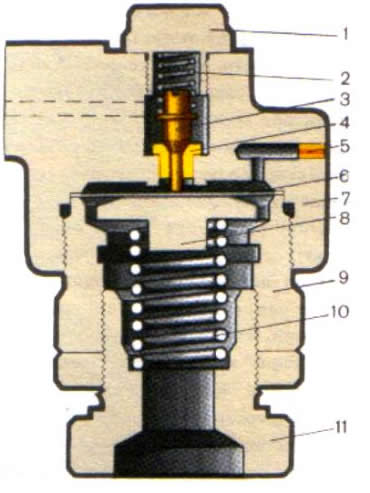

Stabilizer crane operator conv. No. 394: 1 - cork; 2 - throttle valve spring; 3 - throttle valve; 4 - throttle valve seat; 5 - calibrated hole with a diameter of 0.45 mm; 6 - aperture; 7 - stabilizer body; 8 - emphasis; 10 - an adjusting spring; 11 - an adjusting glass.

The operation mode of the crane is set by turning the handle, which rotates the valve, tightly grated (and carefully lubricated!) To the mirror in the middle part of the valve. Seven provisions, they are usually denoted by Roman numerals

- I - vacation and charge

- II - train

- III - overlap without power leaks in the brake line

- IV - floor with power supply leaks from the brake line

- Va - slowdown braking

- V - braking at a service pace

- VI - emergency braking

In the mode of movement in traction, on the coast and in the parking lot, when it is not necessary to activate the brakes of the train, the crane handle is set to the second, train position.

The spool and the spool mirror contain channels and calibrated holes through which, depending on the position of the handle, air flows from one part of the device to another. It looks like a spool and its mirror

In addition, the so-called surge tank (UR) of 20 liters is connected to the crane driver 394. This reservoir is a pressure regulator in the brake line (TM). The pressure that is set in the equalization tank will be maintained by the equalization part of the driver’s crane and in the brake line (except for the positions I, III and VI of the handle).

The pressures in the surge tank and brake line are displayed on the control gauges mounted on the dashboard, usually next to the driver’s crane. Often use a two-pointer pressure gauge, for example, such

The red arrow shows the pressure in the brake line, the black arrow in the surge tank

So, when the crane is in the train position, the so-called charging pressure is set and maintained in the surge tank. For motor-car rolling stock and passenger trains with locomotive traction, its value is usually 0.48 - 0.50 MPa, for freight trains 0.50 - 0.52 MPa. But most often it is 0.50 MPa, the same pressure is used on the Sapsan and the Swallow.

The devices supporting the charging pressure in the UR are the gearbox and the crane stabilizer, which operate completely independently of each other. What does the stabilizer do? It constantly releases air from the equalization tank through a calibrated hole with a diameter of 0.45 mm, available in its housing. Constantly, without interrupting this process for a moment. The air discharge through the stabilizer is at a strictly constant rate, which is maintained by the throttle valve inside the stabilizer - the less the pressure in the surge tank, the stronger the throttle valve opens. This pace is much lower than the pace of service braking, and it can be adjusted by turning the adjustment cup on the stabilizer body. This is done to eliminate overcharging (i.e., exceeding charging) pressure in the surge tank.

If the air from the surge tank constantly leaves through the stabilizer, then will it all sooner or later go away? He would leave, but the reducer wouldn’t give. When the pressure drops in the SD below the charging one, the feed valve opens in the gearbox, which communicates the equalization tank with the feed line, replenishing the air supply. Thus, in the surge tank, in the 2nd position of the crank handle, a pressure of 0.5 MPa is constantly maintained.

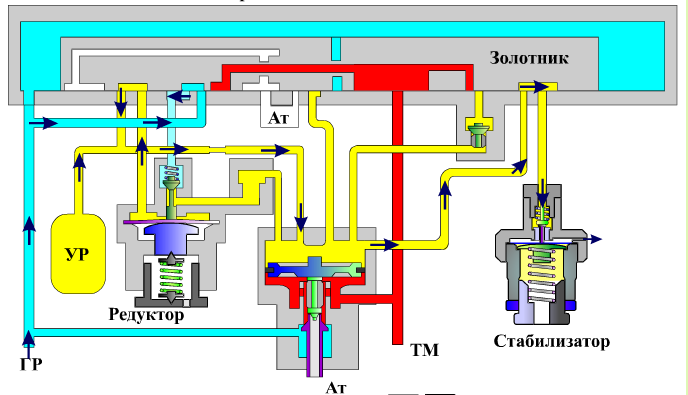

This process is best illustrated by such a scheme.

The action of the crane operator in the II (train) position: GR - the main reservoir; - brake line; UR - surge tank; At - atmosphere

And what about the brake line? The pressure in it is maintained equal to the pressure in the equalization tank using the equalization part of the valve, which consists of the equalization piston (in the center of the circuit), the feed and exhaust valves, which are actuated by the piston. The cavity above the piston communicates with the surge tank (yellow area) and under the piston - with the brake line (red area). With increasing pressure in the SD, the piston drops down, communicating the brake line with the nutrient, causing an increase in pressure in it, until the pressure in the TM and the pressure in the SD become equal.

When the pressure in the equalization tank decreases, the piston moves upward, opening the exhaust valve, through which air from the brake line enters the atmosphere, until then, again, when the pressure above and below the piston does not equalize.

Thus, in the train position, the pressure in the brake line is maintained equal to the charging. At the same time, leaks from it are also fed, since, and I constantly talk about it, it has unambiguous and always leaks. The same pressure is set in the spare tanks of the cars and the locomotive, as well as leakage.

In order to activate the brakes, the driver puts the crane handle in the V position - braking at a service pace. In this case, air is released from the equalization tank through a calibrated hole, providing a rate of pressure drop of 0.01 - 0.04 MPa per second. The process is controlled by the driver on the pressure gauge of the surge tank. While the crane handle is in the V position, air leaves the surge tank. The equalizing piston is activated, rising up and opening the exhaust valve, relieving pressure from the brake line.

To stop the process of exhausting air from the equalization tank, the driver puts the crane handle in the shutoff position - III or IV. The process of exhausting air from the surge tank, and therefore from the brake line, is terminated. This is the stage of service braking. If the brakes are not efficient enough, one more step is performed, for this the handle of the crane operator is again moved to position V.

With standard, service braking, the maximum depth of discharge of the brake line should not exceed 0.15 MPa. Why? Firstly, it makes no sense to discharge deeper - because of the ratio of the volumes of the spare reservoir and the brake cylinder (TC), the pressure on the wagons in the TC will not be more than 0.4 MPa. A discharge of 0.15 MPa just corresponds to a pressure of 0.4 MPa in the brake cylinders. Secondly, a deeper discharge is simply dangerous - at low pressure in the brake line, the charging time of the spare tanks when the brake is released will increase, because they are charged from the brake line. That is, such actions are fraught with exhaustion of the brake.

An inquisitive reader will ask - what is the difference between overlapping positions III and IV?

In position IV, the valve spool covers absolutely all the holes in the mirror. The gearbox does not feed off the surge tank and the pressure in it is fairly stable, because leakage from the SD is extremely small. At the same time, the equalizing piston continues to work, replenishing leaks from the brake line, maintaining in it the pressure that has been established in the equalizing reservoir after the last braking. Therefore, this provision is called "shutoff with power leaks from the brake line"

In the III position, the valve spool communicates between itself the cavities above and below the equalizing piston, which blocks the operation of the equalizing organ - the pressure in both cavities decreases simultaneously with the leak rate. Make-up for this leak does not occur. Therefore, the III position of the crane is called "shut off without power leaks from the brake line"

Why are there two such provisions and what kind of overlap does the driver use? Both, depending on the situation and type of service of the locomotive.

When controlling passenger brakes, according to the instructions, the driver is obliged to put the crane in the III position (overlapping without power) in the following cases:

- When following the prohibition signal

- When controlling EPT after the first stage of regulatory braking

- When following a steep descent or dead end

In all these situations, spontaneous release of the brakes is unacceptable. How can it happen? Yes, it’s very simple - passenger air diffusers operate at a difference of two pressures - in the brake line and the spare tank. When the pressure in the brake line increases, the brakes are fully released.

And now imagine that we slowed down and put in the IV position, when the crane feeds leaks from the brake line. And at this time some idiot in the vestibule opens, and then closes the stop-cock - the bastard indulges. The driver’s crane fills this leak, which leads to an increase in pressure in the brake line, and the passenger air distributor sensitive to this gives a full vacation.

On trucks, the IV position is used mainly - cargo BP is not so sensitive to pressure increase in heavy metals and has more severe tempering. In the III position put only with suspicion of unacceptable leaks brake line.

And how is the brake released? For a full vacation, the cranes of the driver are put in position I - vacation and charging. At the same time, both the surge tank and the brake line are connected directly to the supply line. Only the filling of the equalization tank goes through the calibrated hole at a fast, but fairly moderate pace, allowing you to control the pressure on the pressure gauge. And the brake line is filled with a wider channel, so that the pressure there immediately jumps to 0.7 - 0.9 MPa (depending on the length of the train) and holds it until the crane handle is put in the second position. Why is that?

This is done in order to push a large amount of air into the brake line, sharply increase the pressure in it, which will allow the vacation wave to reach the last carriage with guarantee. This effect is called pulsed supercharging . It allows you to both speed up the vacation itself and provide faster charging of spare tanks throughout the train.

Filling the equalization tank with a predetermined rate allows the tempering process to be controlled. Upon reaching the pressure in it of the charger (on passenger trains) or with some overstatement, depending on the length of the train (on the freight), the cranes of the driver’s crane are put in the II train position. The stabilizer eliminates overcharging of the surge tank, and the surge piston quickly makes the pressure in the brake line equal to the pressure in the surge tank. Here's how the process of fully releasing the brakes to charge pressure from the point of view of the driver

Gradual tempering, in the case of EPT control or on freight trains during mountain operation of the air distributor, is carried out by setting the crane handle in the II train position, followed by transfer to the roof.

And how is the electro-pneumatic brake controlled? EPTs are controlled from the same crane operator, only the 395th, which is equipped with an EPT controller. In this "bank", worn on top of the handle shaft, there are contacts that, through the control unit, control the supply of positive or negative potential relative to the rail to the EPT wire, and also remove this potential to release the brakes.

When the EPT is on, braking is performed by setting the driver's crane in position Va - braking at a slower pace. In this case, the brake cylinders are filled directly from the electric air distributor at a rate of 0.1 MPa per second. The process is controlled by a pressure gauge in the brake cylinders. The discharge of the surge tank in this case occurs, but rather slowly.

EPT can be released in stages, by setting the crane in position II, or completely, with setting in the I position and overstating the pressure in the SD by 0.02 MPa above the charge pressure level. It looks like this from the point of view of the driver

How is emergency braking done? When setting the handle of the crane operator in the VI position, the valve spool opens with a wide channel, directly, the brake line into the atmosphere. Pressure drops from the charger to zero in 3-4 seconds. The pressure in the surge tank also decreases, but more slowly. At the same time, emergency braking accelerators are activated on the air distributors - each BP opens the brake line to the atmosphere.

Emergency braking is used in any situation that threatens traffic safety, which in itself is a stress for the driver. Therefore, if you step onto the rails, slip under the barrier to move by car, remember that for your mistake, stupidity, whim and bravado, the living person, the train driver, is ultimately responsible. And those people who then have to wind up the guts from the axles of the wheelsets, remove the severed heads from the traction gears ...

I don’t really want to frighten anyone, but it’s true - the truth is written in blood and colossal material damage. Therefore, the brakes of the train are not as simple as it might seem.

Total

I will not consider the operation of the auxiliary brake crane in this article. For two reasons. Firstly, this article is oversaturated with terminology and dry engineering and can hardly fit into the framework of the popular science. The second - consideration of the operation of the HWC requires involving a description of the nuances of the pneumatic circuit of the brakes of the locomotive, and this is a topic for another discussion.

I hope this article has inspired superstitious horror in the readers ... no, no, I'm joking of course. No kidding, I think it became clear that the brake systems of trains are a whole complex of interconnected and extremely complex devices, the design of which is aimed at the efficient and safe management of rolling stock. In addition, I really hope that I discouraged making fun of playing with a stop crane over a locomotive brigade. At least someone ...

In the comments I am asked to tell you about the Peregrine Falcon. There will be a Sapsan, and it will be a separate, good and large article, with very subtle details. This electric train gave me a short, but very creatively saturated period in my life, so I really want to talk about it, and I will certainly fulfill my promise.

I want to express my gratitude to the following people and organizations:

- Roman Biryukov (Romych RZHDUZ) for photographic material on the EP20 cabin

- Website www.pomogala.ru - for schemes taken from their resource

- Once again, Roma Biryukov and Sergey Avdonin for consultations on the subtle moments of the brakes

See you again, dear friends!