Solid Edge with synchronous technology helps Brunner Elektronik significantly accelerate development processes and ensure the release of a large number of different product designs.

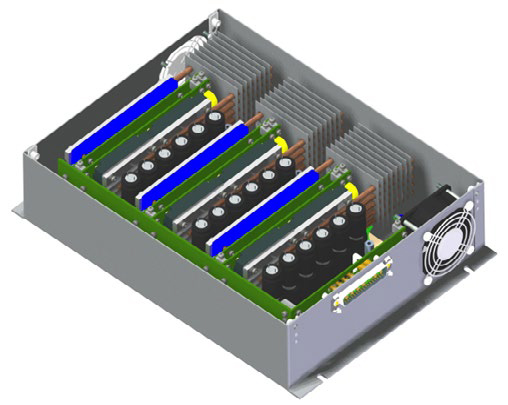

Photorealistic image created in the Solid Edge system. The mobile platform of the flight simulator contains powerful and accurate mechanical drives, as well as sophisticated control systems.

5 minutes video on synchronous Solid Edge technology:

Expert in the development of drives and control systems

When developing complex products, Brunner Elektronik solves the problem of combining mechanical and electrical components in the most efficient way. High customer requirements set no less high quality standards for product creation. Brunner needs to achieve the optimal combination of appearance and functionality, as well as perform thermal calculations. With the introduction of the Solid Edge system from Siemens Digital Industries Software, Brunner is developing new products faster and more efficiently.

Video 4 minutes, Designing electrical wiring and harnesses in Solid Edge Wiring and Harness Design:

For 47 years, Brunner Elektronik has been manufacturing custom-made products of high complexity - control systems and electric drives, as well as supplying turnkey integrated solutions. The company, located in Heathnau, near the city of Zurich (Switzerland), gained wide fame thanks to its vast experience in the production of power electronics and mechatronic systems. In most cases, this is the design and manufacture of unique products to order. Among the customers are engineering enterprises, the medical industry, as well as manufacturers of training systems. The company carries out full-cycle production, equipped with the most modern CNC turning and milling machines, as well as with everything necessary for the design and technological preparation and production of mechanical units.

Analysis of the design of the moving platform of the simulator, designed in the Solid Edge system. Visualization of the most important interdependencies and identification of problems already at the design stage increases the manufacturability of products.

Using the Solid Edge CAD system, Brunner engineers optimize all aspects of the structures being created, and also perform numerical engineering analysis based on digital layouts. Brunner Elektronik is currently using Solid Edge with integrated data management. “The capabilities of these systems have enabled us to improve product quality and respond more quickly to customer requests,” said Robert Brunner, founder and owner of Brunner Elektronik. For 10 years, the company has successfully used the Solid Edge system in its work.

Intuitive interface and great performance

Robert Brunner, an electronic systems engineer, loves his job with all his heart. He became convinced of the effectiveness of the Solid Edge system, which he first met more than 10 years ago, and since then has been using it to create increasingly complex projects. His son, Thomas Brunner, heads the mechanical design department. Together with his colleagues, he designs enclosures and printed circuit boards in Solid Edge.

“What I especially like about Solid Edge is its intuitive interface,” says Thomas Brunner. - Almost the first time I was able to use the system to solve real problems. Earlier, I tested one well-known competing product and I should note that I was completely convinced of the superiority of Solid Edge. This system has a clear and understandable structure of the design process, which is undoubtedly a great advantage. " The need for shorter development times and faster response to customer requests set Brunner Elektronik to increase efficiency and reduce costs. By optimizing the process of making changes in accordance with the wishes of the customer and within the tight work schedule, Brunner and his employees bring new products to the market much faster than competitors. The work of the company as a whole has become more flexible, which helps to successfully conduct activities in highly competitive international markets.

From the design of complex mechatronic assemblies to the development of documentation

Solid Edge delivers significant performance gains.

At Brunner Elektronik, Solid Edge is used in the development of not only mechanical, but also electrical and electronic components. In mechatronic structures, electronic components are used, and the small dimensions of the nodes pose very difficult tasks for designers and technologists. The system also provides special tools for finding the best technical solutions when designing heat sink radiators.

“We are actively using Solid Edge in the design of electronic components,” says Thomas Brunner. - The unique capabilities of the system in the field of numerical modeling of complex structures help us to track the kinematics of movements and immediately identify possible collisions of parts. Virtual design should be carried out using the most modern CAD technologies. Solid Edge is perfect for this. ”

The wide capabilities of Solid Edge in the field of modeling parts and chassis of electronic devices, design development structures, creating photorealistic images, as well as the availability of additional modules for numerical modeling, design of wiring harnesses, foundry molds and assembly processes allowed Brunner Elektronik to quickly create special videos for customers. For small businesses, the proposed functionality opens up new opportunities not only in terms of preparation for production and manufacturing of products, but also in marketing.

Design development from the first sketches to the finished helm of the optimal shape with built-in electronics. Design was implemented in the Solid Edge system, and prototypes were made on a 3D printer.

Thomas Brunner believes that the system has clear competitive advantages, which were fully utilized when working on one of the recent projects - the central node of the flight simulator. He explains: “On the computer, you can view in detail all the movements of the simulator platform. It is very convenient for us and for customers. In addition, we use Solid Edge in the development of all product documentation. The images created by the system are so realistic that we practically refused to take pictures. ” The refusal to additionally attract photographers led to significant cost savings.

Brunner Elektronik's design bureau often receives orders from local and foreign aerospace companies, which are especially useful for the functions available in Solid Edge for modeling kinematics, checking for collisions of parts, and strength calculations.

The implementation of the Solid Edge system in the design office has led to a noticeable reduction in design time. In addition, Solid Edge helps you track all the necessary product requirements for product certification.

Automatic detection of possible collisions of parts, as well as integration with other processes of production preparation are especially important when creating prototypes. At the touch of a button, data on all parts and assemblies are transferred to a centralized repository, where milling machine setups are automatically generated on their basis. “Compared to manually creating drawings, even this one function saves a ton of time,” says Thomas Brunner. And he adds: “What I like most is the extremely user-friendly Solid Edge interface.”

Design freedom and high technology

Creating free-form surfaces that meet the requirements for ergonomics and the placement of electronic components, as well as the technological limitations of the injection molding process, is a very difficult task for a small enterprise. Therefore, companies such as Brunner Elektronik, which have extensive experience in this field, are very important partners.

Recently, Robert Brunner completed work on an airplane helm project entirely created in Solid Edge. At first, Thomas Brunner tried to use other software products, but came to the following conclusion: modeling can be performed in other programs, but the models obtained in them are unsuitable for further development of plastic molding technology. Therefore, the company introduced the Solid Edge system.

The implementation was greatly supported by Robin Wornholt, senior consultant at Bytics AG (Volketswil), a system integrator and partner at Siemens PLM Software. With its help, the design department of Brunner Elektronik mastered 3D modeling in Solid Edge. The individual training conducted by Bytics became the basis for further development of the system, its many additional modules and wide functional capabilities. “We are very pleased with the results,” says Thomas Brunner. - For many years, the system has been working flawlessly. From the first days of collaboration, we consult with Bytics specialists. It is important for us that the technical support engineers are well aware of our system and can be contacted at any time. We are very pleased with our cooperation. ”

The first batch of helms and control units has already been released and sent to customers, and the second is in stock in Hitnau. According to Robert Brunner, it was training that became a critical success factor. “In no case should one give up training,” he says. “The system has a ton of capabilities, most of which will remain unclaimed without training.”

Thanks to the powerful yet at the same time easy-to-use tools for modeling free-form surfaces in Solid Edge, Brunner Elektronik is receiving more and more orders from aerospace companies to create complex products such as control sticks. “We are able to flexibly fulfill the individual needs of the customer, which gives us another competitive advantage,” says Thomas Brunner.

Full compliance of data at all stages - from the 3D model created in the CAD system to the control program for the CNC machine - allows you to supply complete turnkey solutions from a single supplier.

Application of synchronous technology

Since the founding of Brunner Elektronik, customer needs have changed significantly. This is not only about designing individual nodes and devices, but also about creating complete control systems. “Today, customers need full-featured turnkey solutions from a single vendor that eliminate the complexity of the interaction between different systems,” explains Thomas Brunner. “This poses new challenges for manufacturers such as Brunner Elektronik.” We are constantly looking for new, more effective tools, and Solid Edge is always the ideal choice. It allows us to quickly and flexibly fulfill customer requests.

3D-image of the internal design of the helm with autopilot control display and LCD panel of the radio station.

Timing the product to market is another critical factor. Technologies of 3D-modeling and forecasting of kinematics of mechanisms help us to quickly find and implement design solutions. " The system’s capabilities allow the company to develop products without expensive and time-consuming production of physical samples requiring metal processing operations, and successfully launch production the first time.

Brunner Elektronik appreciated the direct modeling tools implemented in the Solid Edge system using synchronous technology. “We have a large customer who works in another well-known CAD system,” says Robert Brunner. - Thanks to synchronous technology, we can easily make changes to the models received from this customer. Communication with other systems does not cause any problems. "

Successfully solving problems and removing barriers

Another task successfully solved by Thomas Brunner and his employees was to organize the interaction between their own CAM system, CNC machines, Microsoft Excel and Solid Edge. Close collaboration of designers with technologists improves the quality of work and eliminates design errors.

“Errors in data are immediately detected, emerging problems are resolved instantly, so we eliminate the boundaries between different systems,” says Thomas Brunner. “In the future, distances will not matter at all: it will be possible to access data in the system from anywhere, which will significantly speed up work processes.” Brunner also emphasizes the importance of the interaction between the stages of development: "In our company, data transfer at all stages is error-free, which significantly reduces our risks."

High-performance solution with an optimal price-quality ratio

“We were able to significantly improve the interaction with customers and suppliers, significantly reduce and in some cases completely eliminate risks at the early stages of development, and also drastically reduce the time for production preparation,” says Thomas Brunner. “Solid Edge is a high-performance solution with the best value for money, which we rely on in our daily work.”

Brunner Elektronik also received a number of other benefits. Visualization capabilities in Solid Edge allow you to present your customers critical design elements at an early stage, coordinate with them a project, and discuss emerging issues.

“Paperless workflow is an important advantage,” explains Robert Brunner. - Almost all documentation is presented in electronic form. Today I just can’t imagine how I managed to work in the past using only 2D drawings. Electronic workflow is truly a great achievement. ”

10-year experience with Solid Edge confirmed the beliefs of Thomas Brunner: “The program works stably, and we are very pleased with it. Now we carry out almost all types of work on our own. The flexibility of our work with customers, the reduction of costs are the clear advantages of Brunner Elektronik. ”

Optimization of the design of the hull and individual elements of the aircraft power supply systems in order to achieve maximum compactness.

Tasks of Brunner Elektronik:

- Improving the design and manufacturing of products

- Transition to 3D CAD / CAM system

- Simplification of key processes: from modeling to prototyping and production

- Customer satisfaction

Keys to success:

- Numerical simulation based on a digital product layout

- High efficiency and design flexibility

- Data consistency and organization of information exchange with the CAM system

- Collaboration of various departments of the company

Results:

- Significant reduction in design time

- Workflow simplification

- Risk reduction

- Cost reduction, high return on solution implementation

- Fast market launch of new products

- Labor Reduction

Website Brunner Elektronik AG

Photographs: M. Frutig, Brunner Elektronik AG.

Download the free version of Solid Edge for 45 days at the link