It takes a lot of microprocessors to process 100 million lines of code in order to run a premium car ( 2009 ). And it will soon become even more difficult.

The avionics system in the F-22 Raptor, a US Air Force fighter jet, consists of approximately 1.7 million lines of code. F-35 Joint Strike Fighter, introduced in 2010, requires about 5.7 million lines of code for on-board systems. And the new Boeing 787 Dreamliner needs about 6.5 million lines of program code to operate on-board electronic equipment systems.

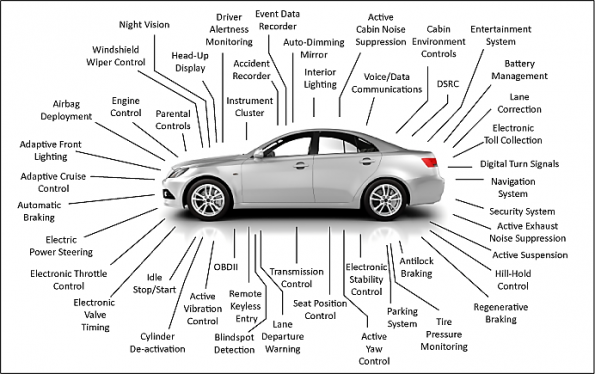

Impressive, isn't it? But if you recently bought a premium car, it probably contains about 100 million lines of code. So says Manfred Broy, a professor of computer science at the Technical University of Munich, a leading expert on automotive software. All this software runs on 70-100 microprocessor-based electronic control units ( ECUs ) distributed throughout your car.

Alfred Katzenbach, director of information technology management at Daimler, said the current Mercedes-Benz S-Class radio navigation system requires more than 20 million lines of code. The car contains almost as many ECUs as the new Airbus A380 (excluding the entertainment system on board). Software in cars will grow not only in quantity. The complexity of the software each time increases more and more. At the end of last year, the research firm Frost & Sullivan calculated that for machines in the near future 200 to 300 million lines of code would be required.

Even in budget cars, there are now from 30 to 50 ECUs built into the body, doors, dashboard, roof, trunk, seats. They can be found almost anywhere. It all depends on the imagination of car designers. This means that most new cars process tens of millions of lines of program code, controlling everything from your brakes to the volume of the radio.

“Cars are no longer just a battery, a distributor or an alternator and a carburetor; they are extremely modern in their complexity, ”says Thomas Little, a professor of electrical engineering at Boston University of Massachusetts. Thomas is developing intelligent transportation systems. “With the goal of saving energy, reducing [emissions] and improving safety, we have also come up with the introduction of electronics.”

I recently experienced this difficulty on myself. Last year I bought a new car and was amazed when I opened the user manual. It had 500 pages. Another 200 pages explained the operation of GPS and radio systems. One of the new features advertised was an increase in the glove section, but sizes were probably indicated somewhere inside the endless manual.

My new car comes with front and side airbags. Dozens of sensors provide electronic airbag controller data. These sensors should work for years at any temperature - both in severe frost in Minnesota and under the hot summer sun in Arizona.

Most of the time, the airbag system simply monitors the condition of the car. But sometimes airbags are triggered, say, due to a collision of several vehicles. In this case, the software in the ECU that controls their deployment has 15 to 40 milliseconds to determine which airbags are activated and in which order, Broy says.

In the near future, according to Broy, airbag control systems will not only use information about the probability of a collision. For example, BMW has many 2009 models equipped with BMW Assist. This system calculates the “risk of serious injury” based on information received from the vehicle’s airbag controller and its other ECUs. Emergency services receive information not only about the scene of the accident, but also about the likelihood of serious injury to passengers.

The amount of software in cars these days is astounding.

The first serial ECU of an automobile microcomputer was a single-function controller. It was used for electronic ignition in 1977 at General Motors in an Oldsmobile Toronado car. In 1978, GM offered to put its Cadillac Trip Computer on the Cadillac Seville. The computer was a modified microprocessor chip Motorola 6802. It displayed information about speed, fuel, ride and engine. However, the chip performed a different function: GM used it to test how well the microprocessor can control several functions, such as fuel injection, electronic ignition timing and cruise control.

By 1981, GM was using microprocessor-based engine control in passenger car manufacturing. They processed about 50,000 lines of code. Other car companies quickly followed suit.

Jonas Bereisa, a GM engineer, wrote in an IEEE Transactions article on industrial electronics in 1983 that "software development will be the most important factor in new product development." He was damn right. Broy estimates that over 80 percent of automotive innovation comes from computer systems. Software has become the main source of value in automobiles, including price list. The ratio of the cost of electronics and the cost of vehicles as a percentage increased from 5 percent in the late 1970s to 15 percent in 2005 (excluding the cost of final assembly).

Hybrids have the amount of software needed for only one engine control, almost twice as much as a standard car. The ratio of the cost of electronics and the cost of vehicles in them is approaching 45 percent. Within 10 years, according to some experts, the percentage of the cost of electronics of the cost of a vehicle will increase to 50 percent for ordinary vehicles and up to 80 percent for hybrids.

For modern premium cars, “the cost of software and electronics can reach 35–40 percent of the cost of a car,” Broy says. Software development accounts for about 13-15 percent of this cost. He says that if each line of developed software costs $ 10 — which is very small — for a premium car, its software alone is an investment worth about a billion dollars.

John Voelcker, IEEE Spectrum editor, wrote in April 2007 about the GMC Yukon hybrid car and its dual-mode automatic transmission. Voelcker said that "of all the working hours spent creating a dual-mode gearbox ... about 70 percent ... went to the development of management software."

Voelcker noted that the control software logic analyzes hundreds of input data every 10 milliseconds, including vehicle load, engine performance, battery parameters and temperature in high-voltage electrical components.

Due to the complexity of the code, reliability issues arise. IBM claims that approximately 50 percent of car warranty costs are currently related to electronics and their embedded software. According to 2005 data, automakers in the United States cost about $ 350 per car, and European automakers $ 250.

In 2005, Toyota recalled 160,000 of its 2004 Prius hybrids, and some models began in 2005 due to a software problem - cars stalled or suddenly stopped. The time required to repair the software was estimated at about 90 minutes per vehicle — about 240,000 working hours. It cost them dearly.

Only last year, there were several car reviews related to software issues. For example, in May 2008, Chrysler withdrew 24,535 of its 2006 Jeep Commanders due to a problem in automatic transmission software. Then in June Volkswagen withdrew about 4,000 of its 2008 Passats and Passat Wagons and about 2,500 Tiguans due to a problem in the engine control module software. This problem can lead to an unexpected increase in engine rpm when air conditioning is turned on. In November, GM recalled 12,662 of its 2009 Cadillac CTS cars due to a software problem in the passenger detection system that could deactivate the front passenger airbag when it should be turned on, or turn it on when it should be turned off . Nevertheless, it is worth paying tribute to the developers of automotive software, as there are not so many car reviews due to software.

The wider use of the software not only affected the cost of the car warranty, but also complicated the repair of cars. It is easier for insurance companies to declare the total loss of a car damaged in an accident than to repair it.

It’s easy to understand why. “The premium car has 2,000 to 3,000 unique software-related features,” says Broy. Then they are combined into 250-300 functions used by the driver and passengers to control vehicle systems.

Most commercial aircraft have firewalls between mission-critical on-board systems and on-board entertainment systems. In machines, unlike airplanes, there is a more complex transmission of information between the electronic systems used to control the car and systems designed to entertain the driver and passengers. An article was posted at Wharton Business School under the heading "Automobile Issues: Should the US Automotive Industry Be Revoked?" A few years ago, some Mercedes drivers found that the driver's seat shifted when they pressed a certain button; the problem was that the button was supposed to control the navigation system.

According to a former automotive engineer with whom I spoke, about a third of all software in automobiles is devoted only to diagnostics. But even with all this diagnostic information, auto mechanics often cannot determine the exact cause of the problem.

Broy told me that more than 50 percent of the ECUs that mechanics replace in cars are technically error-free: they have no problems with either hardware or software. Mechanics replace the ECU simply because they cannot fix the car otherwise.

“Car service workers and car-lovers in the garage are really in a reality where car repair is too complicated and expensive [for them],” says Broy. Remote diagnostics and repairs can make mechanics unnecessary for many tasks.

According to Broy, in the not so distant future, when you have problems with the computer system in the car, you will go to the garage, where your car will be connected to the network. Third-party OEMs will be able to download the data, do the analysis, and then download the software patch.

According to Voelcker, he would not be surprised to see that on-board systems such as BMW Assist, Ford Sync and GM OnStar begin to regularly transfer operational data parameters back to centralized systems controlled by car manufacturers. And manufacturers, in turn, will analyze data for parts that are outside the specification or for software that needs to be updated. The driver will be automatically informed that the car must be taken for repair.

In addition to monitoring the state of their internal parts, cars begin to analyze the world around them. “We are entering an era when, in addition to knowing what is happening inside the car, we use things like radars to detect the presence of external objects, lasers to measure the distance at the cruise control, and video and ultrasound to detect objects behind you, says Little. “The trend will be to retrieve information that applies to your car and other vehicles. This information will then be used to increase security. For example, the cars in front of you will tell your car if there is ice on the highway or if an accident has occurred.

Little says: “We give up small parts of control in exchange for security. At what point will you and I be ready to say: “Good. I'm not going to drive a car, let it drive me.

about the author

Robert N. Charette is an IEEE Spectrum editor, a self-proclaimed “risk ecologist,” who explores the impact of a changing risk concept on technology and society. Charette also writes IEEE Spectrum Online's The Risk Factor.

We go further

Manfred Broy and his colleagues wrote a comprehensive article for the February issue of Proceedings of the IEEE entitled Engineering Automotive Software in February 2007. It is probably one of the best reviews on how to develop and use car software.

For a good early historical point of view on the use of software in automobiles, see Jonas Bereisa's article, published in May 1983 in IEEE Transactions in industrial electronics entitled “ Applications of Microprocessors in Automotive Electronics .” It presents an interesting chronology of many microcomputer applications that were used in automobiles from 1977 to 1982.

about IEEE Spectrum magazine

(Based on Wikipedia)

IEEE Spectrum is a monthly magazine published by the Institute of Electrical and Electronics Engineers (IEEE). Official Journal Description:

The IEEE Spectrum magazine is read by over 385,000 engineers worldwide, making it one of the leading scientific and engineering journals in the world. The journal covers a wide range of technical problems and advances in computer technology, communications and electronics. As in standard magazines, IEEE Spectrum articles are attempted to be made accessible to non-specialists, although their engineering background is contemplated. Journal materials are respected and often cited by other publications.

(Based on Wikipedia)

IEEE Spectrum is a monthly magazine published by the Institute of Electrical and Electronics Engineers (IEEE). Official Journal Description:

“The IEEE Spectrum Magazine, the flagship publication of IEEE, explores the development, application, and consequences of introducing new technologies. It anticipates trends in engineering, science and technology, and also serves as a forum for understanding, discussion and leadership in these areas. ”

The IEEE Spectrum magazine is read by over 385,000 engineers worldwide, making it one of the leading scientific and engineering journals in the world. The journal covers a wide range of technical problems and advances in computer technology, communications and electronics. As in standard magazines, IEEE Spectrum articles are attempted to be made accessible to non-specialists, although their engineering background is contemplated. Journal materials are respected and often cited by other publications.