Hundreds of meters of drawings and huge multi-volume files of design, working and executive documentation for each project. The harsh deadlines for printing materials and ruthless demands on the reliability of the fleet of printing equipment.

In fact, we received roughly such comments from one of the largest customers at Epson regarding the selection of a printer for engineering printing (they are also printers for CAD and GIS).

Due to the fact that the customer had a lot of sensible questions during the discussion, we decided to select the most interesting ones and compile them into a small educational program dedicated to this type of Epson wide format printers.

This post will be interesting if:

- you need prompt printing of drawings "here and now" without any involvement of the printing house. And it happens that the documentation is confidential or there is no right to transfer it to the press to a “third party”;

- You are looking for a universal color wide-format device: so that prints and drawings, and advertising posters, and renderings, and other beauty for presenting projects to the customer. Or, maybe, you generally select a widescreen analogue of the “MFP” in a complete set. For example, with a color scanner of a "hefty" format - up to A0;

- You are interested in what modern engineering printers have “features” that facilitate the work of the “printer” engineer;

- you are curious what “robust design” is and what does Epson have to do with it.

Basic requirements for an engineering printer

In most cases, customers are subject to the following requirements:

- excellent print quality. In the drawings, a bunch of small details, there must be an accurate study for readability;

- high performance. When printing a large number of documentation, speed is very important ;

- equipment reliability. Well, here it’s clear: you need to minimize the downtime of the fleet of devices due to malfunctions;

- profitability in calculation of the press of each square meter. Where without her;

- pigment ink. Water-soluble ink is cheaper, but they are not suitable for archiving documents, and project documentation must be stored for a very long time;

- ease of use. Facilitates the work of the operator and reduces maintenance time;

- non-replaceable print head. In fact, some customers are aware that many manufacturers have GHG as a consumable. The cost of manufacturing a GHG is much higher than the same cartridge, so with a large print volume, the replacement flies a pretty penny. Here I will run ahead and immediately note that in all Epson inkjet printers, the heads are piezoelectric and stationary (read: non-replaceable).

Why did I put these requirements on a separate list? To emphasize that a good engineering printer is not just a “widescreen four-color flower”! Such an apparatus should provide most of the above requirements .

And better - all seven points.

The main types of models of engineering printers

Among the lines of almost all manufacturers of engineering solutions there are devices:

- entry-level - affordable, but the performance and functionality of devices have certain limitations; (in our case, these are models of the SC-TX 1 00 series);

- medium level - the initial cost of equipment increases, but along with this, productivity increases and the cost of the print decreases, due to the use of cartridges of increased capacity; (this is a series of SC-TX 4 00);

- high-performance devices for users with increased requirements for print speed, functionality, the number of options available and the cost of prints; (the most productive at Epson is the SC-TX 2 00 series);

- Separately, you can select a class of devices with a scanner (built-in or optional).

For clarity, we presented a line of Epson devices for CAD and GIS in this form (clickable):

The main "chips" plotters for CAD and GIS using the example of Epson SureColor SC-T5400M

The MFP of the middle segment is the most popular class of devices of this type. Just here we will soon have a novelty that can be considered as a "standard" modern engineering printer. And, of course, color.

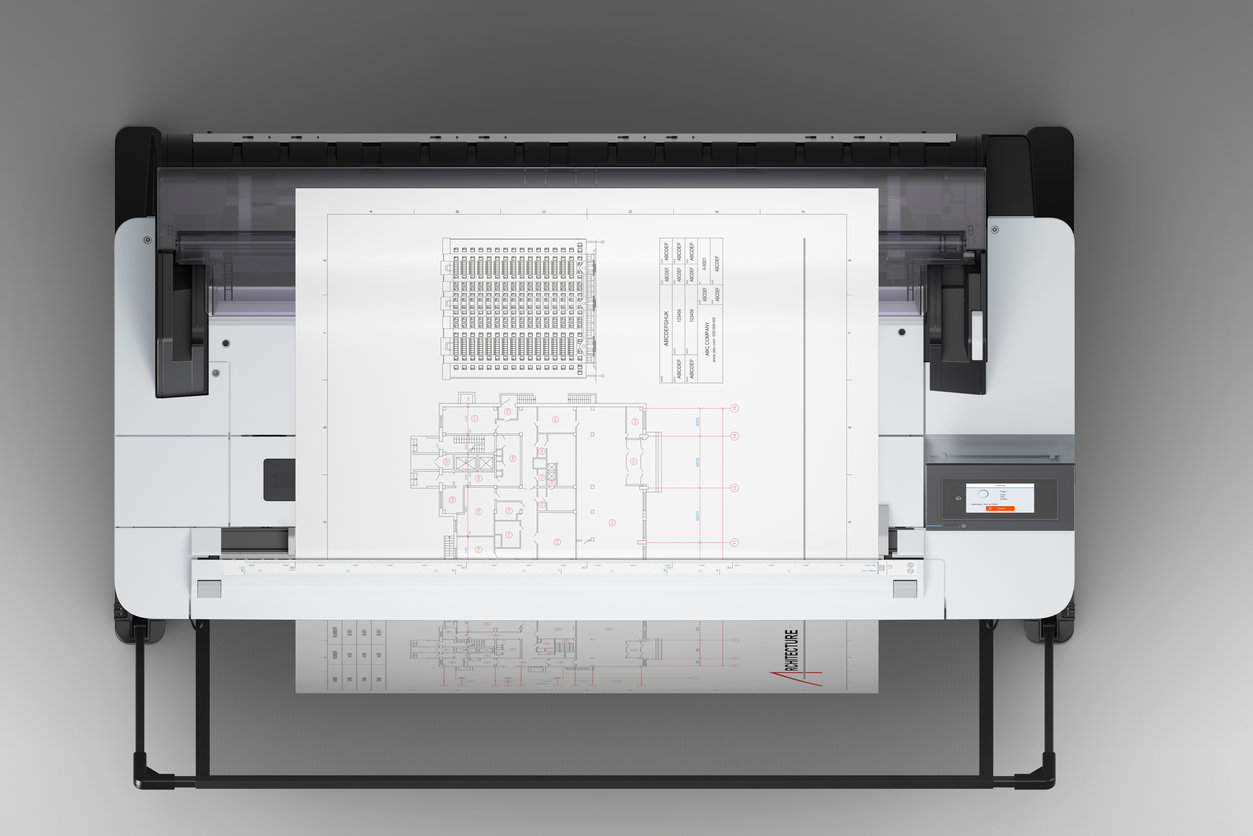

The Epson SureColor SC-T5400M is an 36-inch (~ 90 cm) inkjet MFP with an integrated color scanner, which will go on sale this December. The model is equipped with cartridges in 4 colors: CMYK with pigment ink. The advantages of pigment inks are well known to many: such inks are “tightly” fixed on the media, so that you can’t wash them with water or smear them with a marker.

With a good engineering printer, the housing should have dust protection: tightly fitting housing parts and a minimum of slots and ventilation holes significantly reduce the risk of dust penetrating into the housing, which means that the printhead is not at risk, and you can install such a printer almost in the coordination center in the form of a change house with a broken window on the object (and this happens) . The SC-T5400M has good dust protection.

Print quality

Engineering printers have very high demands on the minimum line thickness when printing data from CAD software.

In the case of our MFP, the minimum drop size is only 4 picoliters. Picoliter (pl or pl) is the trillionth part of a liter. A drop of this size allows you to print a line with a thickness of 1.5 microns (0.0015 mm). This is possible thanks to a branded print head that has been tested for decades.

Prints on good paper are so detailed and "smooth" that you wonder. If you want to see this personally - you are welcome to our showroom .

Separately, I note that the entire line of devices when printing gradients performs just fine shading. Those. You will not see any banding, nor "step" when printing smooth transitions from one color to another . What does it give? What I mentioned at the beginning of the post: this makes the printer universal . It is possible to print high-quality POS color materials on it when there are no special requirements for the full coverage of the Pantone range, but you do not want the prints to be full of "grain".

One such machine can print a colorful poster, and a color interior "render" or floor plan, and a drawing of the object.

Print speed

I think there is no need to explain once again why the “engineer”, especially if he is the only one in the department, should print quickly (the faster, the better) .

Printing an A1-format document with the SC-T5400M will take about 22 seconds .

At the same time, such trifles as a printing table with a ruler are provided - it is immediately clear what format the document was sent for printing. A trifle, but makes work easier.

Such an important part of the workflow as “thoughtful organization of the workspace”, in other words - “total jamming of the printer with prints” - is found everywhere. Someone sent something large for printing, but didn’t take it until the next task - and now the second or third employee is looking for where to put the prints so as not to throw them on the floor, swearing.

Including Therefore, the current line of our devices has a wide and even upper part of the body .

By the way, the Epson SureColor SC-T5400M model can hold (paws!) A scanned document, i.e. after the scan is completed, the sheet remains “hanging”, and does not fall into the basket. This is useful when scanning thin media because paper does not wrinkle when dropped.

Media and formats

Because good engineering printer = universal printer , it is desirable that it can be printed both on a roll and on sheet paper. The SC-T5400 has such a “chip”, and the minimum paper size that the new series of printers work with is A4.

In addition, the Epson SureColor SC-T5400M is one of the few printers in this class that supports rolls with a maximum diameter of up to 170 mm.

Wireless printing

There are no comments. Again, 2019 is the year in the yard. The T5400 can print and scan over Wi-Fi (and without connecting to a router - thanks, Wi-Fi Direct) and using Air Print. Very and very easy to install printing devices on the site.

Borderless Printing

Made a separate paragraph, because often interested in such an opportunity.

“Why does an engineering printer need borderless printing?” You ask? The answer is: for versatility . Borderless printing automatically turns such a printer into a printing device, incl. POS materials or GIS images. Including and color, of course.

A few words about the scanner

You might be surprised to find out that an A0 color scanner is a rarity. Many customers, without a second thought, believe that any scanner is color. Alas, this is not so. A color scanner is designed to be noticeably more complex than a monochrome one and therefore more expensive and larger.

Once again, I turn to universality and boast that the scanner in the same Epson SC-T5400M is not only color, but differs in a couple of features:

- RGB filters improve the quality of the scan and clearly reproduce the elements highlighted by markers even in fluorescent colors.

- The dual light source allows you to scan even complex media without shadows from creases:

Scanning speed - 4.5 inches / second (11.43 cm) for color prints, 7.5 inches / second (19.05 cm) for b / w. If you look at the market - this is a fairly high speed.

You can scan immediately in TIFF or PDF. You can also use special preset modes that automatically improve the quality of the original image depending on the type of media or print category:

- watercolor paints (smooth gradations of colors and transitions of shades);

- recycled paper (lightens a tone of paper from yellowish to familiar white);

- tracing paper (adjusts the tone of the original medium for better readability);

- blue print (support for scanning blue print, i.e. drawings with old ink on a blue or color background);

- invert blue print to a pattern with a white background and black text.

And for “dessert” - a unique feature of the scanner: the maximum length of the scanned original is 30.5 m (600 dpi, PDF / TIFF). Just imagine, this yacht Sunseeker 95 from the English shipyard is only 28 meters in length:

This builder’s opportunity will be appreciated by road builders and other “long track engineers”.

TCO - supplies and service

All this is wonderful, but what about the "expense"? If consumables during regular printing will cost the cost of the aforementioned yacht, then no one needs such a printer for nothing. I have already mentioned that the print head of Epson printers is not a consumable item and it is designed for the entire life of the printer . Epson's piezoelectric printing technology does not use heat to print, so the head does not wear out from heat.

There are only three consumables for Epson SureColor SC-T5400M and they are replaced by the user himself without contacting technical support:

- four 350 ml cartridges (one of the most capacious in this segment);

- capacity for waste ink (the resource depends on the print volume, an average of 1.5 - 2 sets of cartridges);

- borderless printing kit (special absorbent pads for absorbing excess ink when printing “to the edge” - this is mainly required for working with cards and POS materials).

What service does the printer and scanner need?

A good engineering printer should not create problems, but created to solve them.

The printer is equipped with an automatic cleaning system for the print head, and to clean the optical unit of the scanner, it is enough to open the front cover and wipe the diode panel with a lint-free cloth (paper dust may accumulate over time and impair scan quality).

The device as a whole is unpretentious and has a corporate guarantee of 2 years, and without restrictions on the number of printed sheets.

Printing supporting documentation

... of course, it is possible on T'shka, since it can work with A4 as well, but for this Epson has a range of productive office printers , as well as the “monstrous” Epson WorkForce Enterprise , which prints at speeds up to 100 pages per minute. I recently talked about him in a blog post - here and here .

And a few words about "robust design"

Translating another press release about a new engineering printer, they hung out with colleagues over the bulletin: “Robust design.”

On the one hand, everything is clear: a “solid / reliable case” or something like that.

“Wait, what a sturdy case? - a colleague objects to me - “Robust design is a special term!” And, indeed, it turns out that:

in Japan, designing quality systems (quality engineering) is called robust design (Taguchi method). This is such a design approach, which consists in reducing the variation in output characteristics by using methods that reduce sensitivity to the sources of variation. (Shchipanov V.V., Chernova Yu.K., Krylova S.A. Mathematical modeling of educational processes. - Tolyatti, 2005)

So it goes. We check with the product manager - that's right - we are talking about a special method that improves the reliability of products by ensuring a minimum variation in the characteristics of devices.

Questions?

If you are interested in testing an “engineer” at work, visit our showroom (it is advisable to warn about your visit in advance ). In the Moscow showroom, in particular, you can look at the Epson WorkForce Enterprise A3 + format with an optional folding - a high-speed solution for printing project documentation with pigment.

Traditionally, the whole team is ready to answer your questions.