The greedy luminary: why solar energy did not conquer the world and how the “Russian mineral” can save it

Solar energy is one of those areas where the good intentions of mankind are almost always ahead of technical capabilities and economic realities. The creator of the first solar panel, the American inventor Charles Frits, predicted back in 1881 that very soon ordinary power plants would be replaced by solar ones. And this despite the fact that the installation he created had an efficiency of only 1%, that is, exactly so much sunlight turned into electricity. After 140 years, Charles Fritts’s dream never came true: solar energy is still struggling for a place in the sun with windmills, generators, geothermal springs and minerals. What slows down the solar revolution and what methods are trying to improve solar panels?

It would seem that having come up with solar energy, we extended an invisible wire to the most powerful reactor in our planetary system, which will not go out for at least another five billion years (and we'll think about it). But it took humanity almost a century to increase the efficiency of the solar panel by only five percentage points - this happened when scientists from Bell Labs created a more powerful battery in 1954.

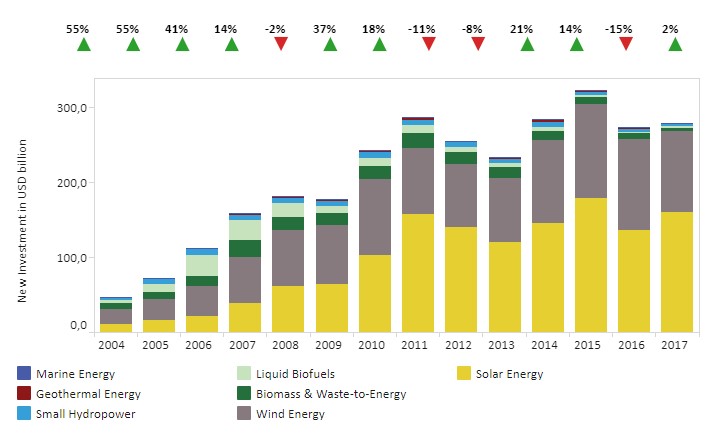

Nevertheless, progress in solar energy in recent years has been impressive. They invest more in it than in any other renewable energy source (RES). At the same time, the average cost of "solar electricity" since 2010 decreased from $ 0.371 to $ 0.085 per kWh.

In recent years, investments in solar energy have stagnated. Source: International Renewable Energy Agency (IRENA), Frankfurt School-UNEP Center / BNEF

And yet, solar power has not yet conquered the world. Even Germany, which for the first half of 2019 generated more energy on renewable energy than on coal and atom, is in no hurry to part with brown coal capacities. By 2030, it is planned to reduce them from the current 45 GW to 37 GW. At the same time, the economic success of solar energy is still largely ensured by tax policies and subsidies. This explains one paradox: wholesale electricity prices in Germany are among the lowest in Europe, and the final ones are among the highest.

Why do solar power still need “financial crutches”? The reasons are as follows:

- solar energy remains not the most efficient - the installed capacity utilization factor (KIUM), that is, the ratio of actually generated energy to the projected energy set by the manufacturer for solar panels, is 13-18% in winter and 30-35% in summer, which is the lowest among others RES, as well as gas and coal;

- hence the higher cost of solar energy - the world average is $ 0.085 per kWh, while in bioenergy - $ 0.062, for geothermal sources - $ 0.072, hydroelectric power plants - $ 0.047; only the closest competitor is more expensive - wind farms away from the sea with an indicator of $ 0.127, although offshore coastal ones provide energy at $ 0.056 per kWh;

- the instability of the receipt of photons from the luminary forces us to use additional devices for the accumulation and distribution of energy (we, by the way, talked about the solution to this problem);

- the solar power system needs a lot of space, whether it be a huge station in the field (and the land near the cities is expensive) or a home electrical installation, to which you need to not only connect the inverter and battery, but also provide access for maintenance.

To solve these problems, you need to make solar panels cheaper, more efficient and - in the truest sense of the word - flexible.

Silicon Dictate

Solar panels are made of material that captures the energy of light well. Typically, this material is sandwiched between metal plates that carry trapped energy down the chain. In that same 1954 solar panel produced by Bell Labs engineers, silicon played a major role. With many modifications, he still dominates the production of solar cells for solar cells, making up the basis of 95% of the panels.

For half a century, humanity has developed several types of silicon solar cells. The largest share of the world market is occupied by polycrystalline silicon panels. They are in demand due to relative availability, which is due to cheaper production technology. But the efficiency of such panels is lower than that of analogues (14-17%, maximum - 22%). A more expensive, but also more effective option is single-crystal silicon panels. Their efficiency is about 22% (maximum - 27%).

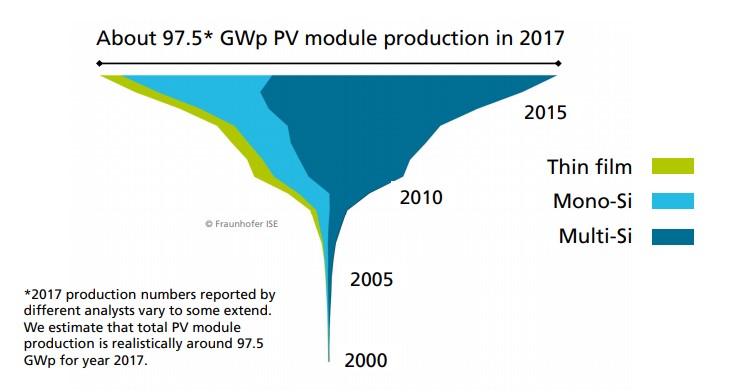

What technologies for the production of solar panels dominate the world. As you can see, polycrystalline solar modules (61%) are mostly produced, mono (32%) to a lesser extent, and very few thin-film (amorphous) - 5%. Source: Fraunhofer Institute for Solar Energy Systems; PSE Conferences & Consulting GmbH

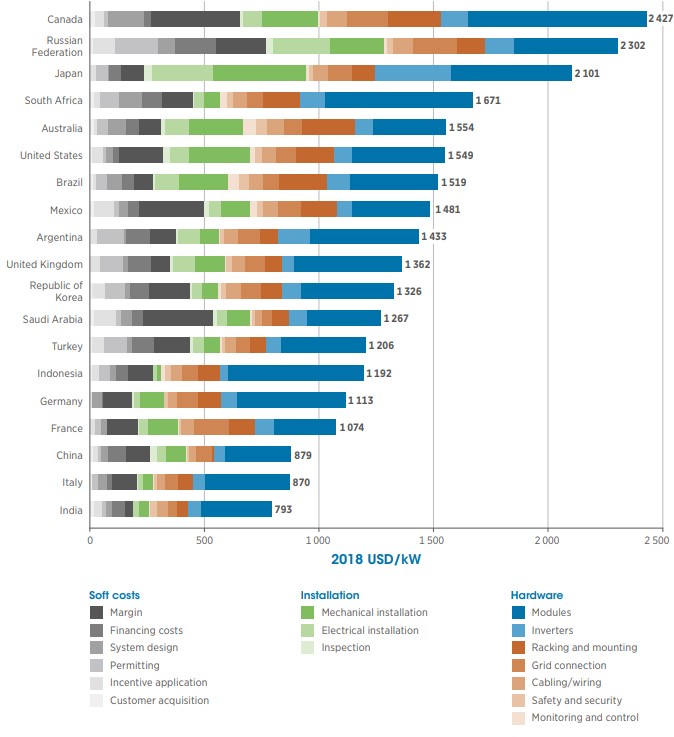

Despite progress in the economy and technology of solar panels, their cost remains high. To it must be added the costs of creating the actual power plant (controller, inverter, battery), without which the battery does not work. In different countries, these values fluctuate, but the share of expenses, in fact, on the photovoltaic unit is still high.

What makes up the cost of a “solar kilowatt" in different countries? As you can see, in the leading countries of the introduction of solar energy from a third to almost half of the costs is the cost of the module. Source: International Renewable Energy Agency (IRENA)

Not silicon single

In an attempt to develop more efficient panels, thin-film (amorphous) modules were created. Their essence is simple: the light-trapping material is applied in a very thin layer to the film, making the panel easier and more flexible, and its production requires less materials.

True, their efficiency is much less than that of their colleagues in the solar shop - 6-8% for silicon options. Nevertheless, thin-film solar cells benefit at cost because they require a layer of light-trapping substance with a width of only 2 to 8 microns, which is only about 1% of what is used in conventional crystalline modules.

But thin-film panels are not ideal: due to their low efficiency, they require approximately 2.5 times more floor space. This prompted scientists to continue to look for more effective material, which, on the one hand, is suitable for film technology, and on the other, it will be more effective. This is how panels appeared, based on more exotic compounds: cadmium telluride (CdTe) and indium-copper-gallium selenide (CIGS). These elements have greater efficiency - in the first case, the indicator reaches 22%, and in the second - 21%. Such systems lose less efficiency with increasing temperature and work better in poor lighting conditions. However, their cost is higher than silicon analogues due to the rarity of the materials used. Some scientists even believe that such panels will never dominate the market, because they will not have enough natural resources. Therefore, this type of solar panel has become a niche product suitable for the specific purposes of a narrow circle of consumers. Most often, thin-film panels are used by consumers with a large supply of space: manufacturing enterprises, office buildings, universities and research centers, large apartment buildings (with a spacious roof), as well as, in fact, solar farms - large power plants. The economies of scale and the relative ease of installation of the stronger and lighter thin-film panels helps to level their relatively lower (compared to crystalline silicon) efficiency. Meanwhile, the search for the ideal “catcher” of photons continues.

Hello from the Russian Count

A candidate called perovskite may become a candidate for the role of a possible savior of solar energy. The first of these, calcium titanate, was found in 1839 by the German Gustav Rosa in the depths of the Ural ores and named him by the name of the Russian rock collector Count L. A. Perovsky, which is why he is sometimes called the “Russian mineral”.

Today, when talking about perovskite, most often they mean a whole class of substances that have the same three-part crystalline structure, first detected in calcium titanate. Although in pure form such substances are rarely found in nature, they are easily obtained from the mass of other compounds, and perovskite crystals can be grown artificially. Each part of the perovskite structure can be made of various elements, which gives a very wide range of possible compositions of the “photon catcher”, including lead, barium, lanthanum and other elements. So, it has already been established that the combination of perovskite with some alkali metals allows the creation of a solar photocell with an efficiency of up to 22%, and the theoretical power of perovskite-based compounds reaches 31%.

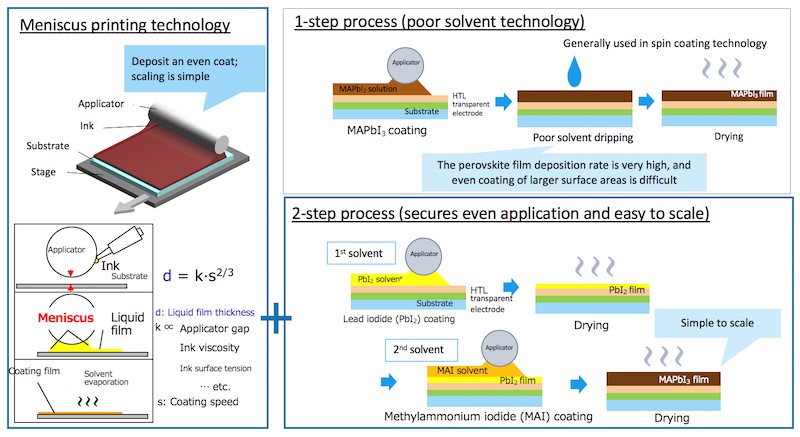

However, working with perovskite is not so simple, and we at Toshiba were convinced of this. After applying to the film, perovskite crystallizes very quickly, which makes it difficult to create an even layer over a large area. Meanwhile, this is the main task when creating a solar cell: to achieve the largest possible surface area while maintaining high energy conversion efficiency.

In June 2018, Toshiba produced a thin-film perovskite-based solar cell with the largest surface area and the highest energy conversion efficiency in the world. How did you manage to do this?

We divided the ingredients necessary for the formation of perovskite (lead iodide solution - PbI₂, methyl ammonium hydroiodide - MAI). First, we coated the substrate with a PbI solution, and then with a MAI solution. Thanks to this, we were able to adjust the crystal growth rate on the film, which made it possible to create an even and thin layer of a large area.

Perovskite-based solar module manufacturing technology. In fact, we create “ink” from the constituent elements of perovskite and “smear” them on the substrate. Source: Toshiba

Perovskite Economics

Although it is too early to speak about specific economic indicators of perovskite use, since the wide practical use of this material in solar panels is predicted after 2025, the “Russian mineral” has the prerequisites for a great and successful future. According to experts of the National Renewable Energy Laboratory (NREL), the production of perovskite panels will be ten times cheaper than that of silicon counterparts. Not least because, for the manufacture of the prevailing silicon solar cells, it is necessary to process the material at a temperature of more than 1,400 degrees and, accordingly, sophisticated equipment. Perovskites, meanwhile, can be controlled in a liquid solution at a temperature of 100 degrees on simple equipment (as in our experiment).

The perovskite-based module we created has an area of 703 square meters. see. And the energy conversion efficiency we obtained reached 12%. Source: Toshiba

There are two other advantages of perovskite photocells - flexibility and transparency. Thanks to them, perovskite solar panels can be installed in a variety of places: on walls, on the roofs of vehicles and buildings, on windows and even on clothes.

By adjusting the thickness of the perovskite layer, it is possible to control the transparency of solar cells based on this material. For example, it can be used in covering greenhouses : plants will receive the right amount of photons, and part of them will be supplied by the farm’s electric grid. Experiments to determine the reasonable ratio consumed by plants and light panels are already being conducted in Japan.

Another possible field of application is the equipping of electric cars with solar panels based on perovskite. While we are at the very beginning of this path, but there are already first achievements. So, scientists from the Western Reserve University of Cayes (Ohio, USA) experimented with the use of small solar cells based on perovskite to recharge electric car batteries. They connected four perovskite-based solar cells to lithium batteries. When connected to charging small coin-sized lithium-ion batteries, the team of scientists achieved a conversion efficiency of 7.8%, which is half that of conventional thin-film solar cells.

It is also possible that soon ribbons from perovskite solar panels will decorate your shirt or jacket . It is already known about the application of perovskite on a polyurethane substrate, the efficiency of which in the absorption of the sun reached 5.72%.

And in Russia, they went even further in experiments with perovskite. As it turned out, this material can be a good emitter and is suitable for generating light. Scientists from the Moscow Institute of Steel and Alloys (MISiS) and the St. Petersburg University of Information Technology, Mechanics and Optics have developed a perovskite-based solar cell that can simultaneously operate as a battery and as an LED . The basis is halogen perovskite. To switch functions, it is enough to change the voltage supplied to the device: at a level of up to 1.0 V, the prototype works as a solar cell, and if more than 2.0 V is supplied, the LED mode is turned on. In the future, scientists can develop glass films that will generate energy in the daytime, and emit light in the dark. In this case, the maximum film thickness does not exceed 3 microns, which will preserve the transparency of the glass. That is, it will not be dark.

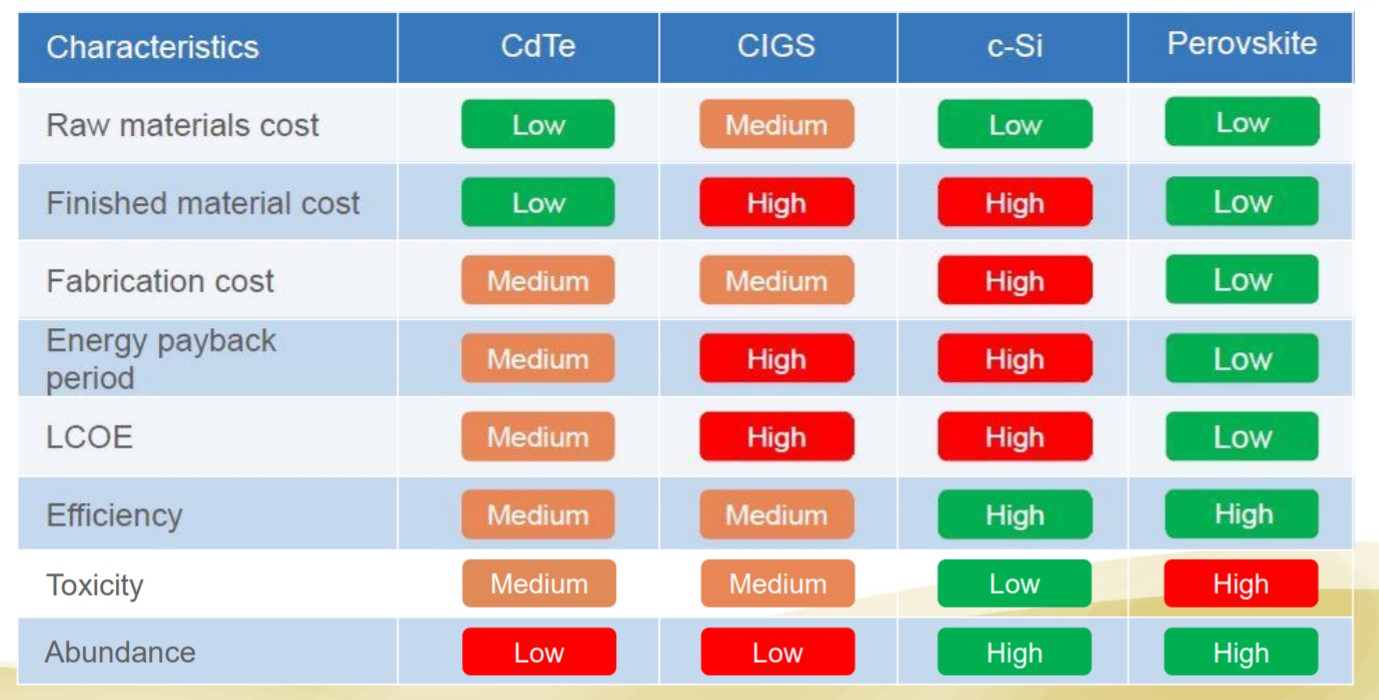

In almost all respects, perovskite is superior to its competitors, including the average cost of electricity throughout the life of a solar battery from a given material (Levelised Cost of Energy, LCOE). Difficulties are possible only with the disposal of obsolete panels due to the toxicity of perovskite compounds. Source: Group for Molecular Engineering of Functional Materials (GMF), Switzerland

Economies of scale

So, perovskite can help promote solar energy not only due to its economic affordability, but also due to its much wider scope: in addition to industry, urban and agriculture, perovskite-based panels can be used even in everyday life, in particular in the production of small cars electronics, household appliances and even clothes. And the wider the range of applications, the higher the market capacity, which will attract new investors and reduce the cost of solar electricity.

All Articles