3D printing: amazing cases and a little more interesting

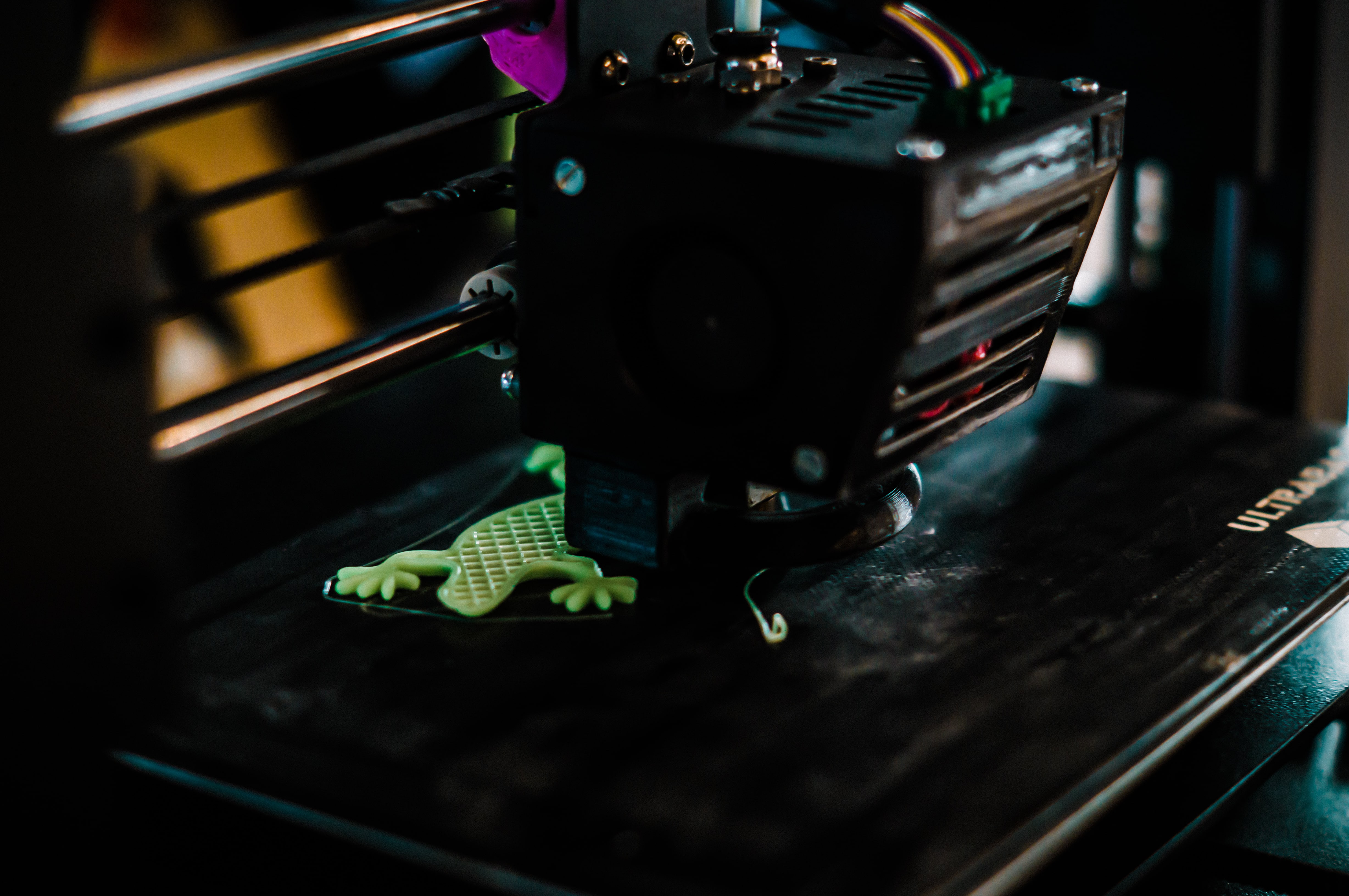

I was inspired to write this article by the internal 3D printing mitap, which was held relatively recently in our company. At the meeting, my colleague told a lot of interesting things on this topic, and even delivered his printer to the office, with the help of which he clearly demonstrated the process of creating various objects.

At this meeting, I learned a lot of new things that I didn’t even have to think about before. In general, after I decided to study the issue in more detail. As a result, this article was born.

Probably only the lazy now do not speak and are not at all interested in this topic. The industry is no longer new, but is gaining momentum every day: it is predicted that by 2021 3D printing will become a multi-billion dollar industry ( about $ 21 billion ). First of all, this is because now everything that is necessary for 3D printing is becoming more and more accessible - printers, materials, open source software for modeling.

Many European schools even buy printers and teach children 3D modeling. Everything is developing: more and more models appear with advanced and at times unimaginable capabilities.

Just imagine - without leaving your home, spending a little time getting to know the program and a couple of 3D printing guides, and quite a bit of money, you can create a lot of things: from a simple plastic toy to all kinds of fixtures, tools.

It seems to be going to the fact that soon everything will be possible to print on such printers. There are some interesting cases that, if presented in the right order, can very clearly demonstrate the evolution of 3D printing.

The very first that comes to mind is custom handles for razors . The guys from the Boston startup Formlabs once decided to print pens - different designs, colors, materials - it got a wide response. Now they are partners of Gillette. Anyone can go to their site and come up with their own handle design. It remains only to wait until the package arrives.

Adidas has another interesting case - they recently released Alphaedge4d sneakers with polymer soles printed on a 3D printer. Manufacturers promise that such a shoe sole provides greater stability, support for the foot and improved cushioning.

There are two overlapping, quite touching stories that have already thundered in all the world media for quite some time. One inventor from Washington posted a video showing a palm prosthesis model that anyone can download and print on a 3D printer. The father of a little boy who was born without fingers was inspired by the idea of creating a prosthesis for his son, and successfully implemented it. A suitable printer for this cost about $ 2,000 (by the way, a prosthesis developed by orthopedic companies would cost tens of thousands on average), and the cost of plastic needed to print one prosthesis is only about $ 10.

The second story is about a carpenter Richard from South Africa who lost his fingers on his hand due to an accident at work. Buying a prosthesis was expensive, so he armed himself with a 3D printer and the help of a familiar designer, and as a result, they all worked out. It has a more complex mechanism and is more functional than the prosthesis from the first history, but it still cost inexpensively. Thanks to the media, the public became interested in this story. Now Richard helps many people by printing similar prostheses almost for free.

There are many more stories of using 3D printing in prosthetics, of course most of them relate to dentistry and orthopedics . But there are too many of them to fit in one article. Here I talk only about those who inspired me the most.

3D printing is also widely used in industry. There are giant printers that can print huge metal parts - even for airplanes and missiles, without having to collect anything - a 3D printer will print a ready-made one-piece version.

There is a Big Delta 3D printer - 12 meters high and 6 meters in diameter, which can "print out" budget houses ... And what is there, there is a StarGate printer that can fully print a space rocket. It is called a 3D printer, although, in fact, it is a mini-factory based on robotic systems.

Now they are already printing tissue and organs . Skin, muscles, cartilage, liver, bladder. They are already even transplanted and they are well taking root, just like other donor organs. Isn't that amazing?

The process of creating an object is quite simple. The first stage is, of course, the idea and pondering of the implementation method. Do you want to create something simple or something complicated? If some simple figure is enough for you, then all that is needed is to load the finished model into a special program, or create it. But if you need something more complex, you may need to develop some details first, print them and assemble them. Post-print processing may be required. Much depends on the printer and what you want to print.

A wide selection of printers is now available. The main differences are in the method of applying the layers and the materials used. Some methods rely on smelting or softening materials to create layers: this includes selective laser sintering (SLS), selective laser sintering (SLM), direct laser sintering of metals (DMLS), and fusion deposition printing (FDM or FFF). Another area is the production of solid models through the polymerization of liquid materials, known as stereolithography (SLA).

For home printing, only FDM and SLA are suitable. The second is better in quality, but with it there is more trouble, you need an ultrasonic resin cleaner, plus the resin can be toxic.

When you have already decided on the complexity, and know the type of printer, you need to follow a simple plan: create a model, set the slicing and start printing. And then wait.

To create a model, a special editor is used, which allows you to simulate projects in 3D. The simplest, according to my colleague who led the mitap, is tinkercad , it allows you to make a 3D model directly in the browser, but there is extremely limited functionality there. For more complex work, you will need Fusion 360 or something like that.

In general, you can talk about this topic for a long, long time. Perhaps this is only the first part and I will write something else: more interesting cases, more subtleties of 3D printing. I thank my colleague Eugene for an exciting mitap on this topic. Thank you for reading to the end.

All Articles