In the train driver’s cab

The yellow button at the top is one of the oldest and most important legacy: this is the opening of the sand bunker to spill sand in front of the wheels of the locomotive for emergency braking. Sandboxes are put on trains from the first steam locomotives. The big red button is the opening of the brake line to the atmosphere for an emergency stop of the train and a complete blackout of the train to the battery.

When we saw a set of signal firecrackers in the train cabin, we immediately realized that we did not know anything about trains to the end. And then they decided to watch live on the launch of the train and the work of the driver with modern interfaces. A modern train is a data bus, which contains all the equipment, on-board computers and electronic interfaces. Everything is fine-tuned with touchscreens, and only the most important, such as braking, is placed on the physical levers and buttons.

In general, welcome to the cabin of the Aeroexpress train and on the driver’s working day. And it’s not ordinary, but Aleksei Aleksandrovich Nazarov - the person who tested the first Swiss trains of the Stadler company, received them for Russia and taught other drivers to handle them.

Alexey Alexandrovich now operates a two-story aeroexpress train from Kievsky Station to Vnukovo Airport - special trains run on this route, which are modified by Stadler KISS for a special project for Russian railways (the base is wider than the European one) and taking into account the requirements of Russian Railways and Aeroexpress, in particular, for a large number of integrated equipment. We already talked about their differences from older versions of trains when we went to the depot where electric trains are serviced.

You need to be at work at seven in the morning, so Alexey Alexandrovich wakes up at five in the morning exactly, washing himself, having breakfast and going to the terminal of the Kiev station. There passes security control at the entrance (like all passengers) and goes to work.

The first thing a driver does in the morning is to watch documentation updates. Aeroexpress has a separate internal portal where data from all sources is pulled. Most often, these are internal data on the repair of rolling stock, the results of applications to mechanics for equipping “their own” trains and Russian Railways telegrams, which indicate the current schedule changes. In the huge infrastructure of Russian Railways, various current repairs and routine maintenance are often carried out, so somewhere they block the path, somewhere you need to move for a few minutes in the grid and so on. There are also instructions from the rolling stock operation department, which stipulate special working conditions and the order of operations: for example, recently there have been minor updates to the procedure for passing the assistant train driver during inspection, minor changes to the departure schedule, and so on.

Then - a physical examination. Engineers come to the first-aid post, present documents (that they are they), and in response they are issued medical records in which they sign. They include data: the date of the inspection, time, shift between hours, data on pressure and pulse. Necessarily examination with a breathalyzer. The next step is the design of the route sheet: you need the seal of the first-aid post with the signature of the paramedic.

Then you need to take an admission to the infrastructure: the Moscow Railway checks the documents, enters the fact that the driver entered the work, his route, train, and so on into the IT system. After entering the data, the service puts a mark in the route sheet that the driver is ready to work. If there are urgent things in the procedures (warnings about changing speeds) - they are given under the signature.

Next you need to proceed to the line point where the brigades enter. There are a few minutes to wait for the train to arrive.

At 7:36 a train arrives from Vnukovo on the second way. At 8:00 you need to leave from Moscow to the Vnukovo station, then wait there and go back. In total, there will be five such pairs per shift. Lunch - from 12:30 to 13:30, and the end of the work shift - at 20:00.

A working shift of a locomotive crew lasts from 10 to 12 hours, work in the daytime and at night is evenly distributed. The quarterly work rate is 528 hours. Locomotive crews working in the morning and evening are brought to the night shift. The night can work according to the scheme from 18:00 to 2:30, two hours of lunch and then from 4:30 to 8:00.

As soon as the train arrived, you need to take it at the beginning of the day, and hand over the crew that controlled it accordingly. Another train "turns around", that is, you need to "turn off" the cabin at the end of the train (which is closer to the station) and go to activate the head cabin (which is further from the station). The train travels with two cabs at once, in which there are controls, and they are equivalent, but you cannot connect to any network from any car. In the Moscow Metro, for example, the scheme is even more interesting: there you can use the hand-held remote control to crash into the control loop in any car and control it like from a cab. A hand-held console is such an engineering simulator of the driver’s cab, and it is very convenient for maneuvering in parts of trains. Aeroexpress trains are considered as whole objects; they do not disengage otherwise than for maintenance. And for maintenance they are only split into two parts, even to replace the carts: a new depot allows you to lift them immediately in blocks of several cars.

So, Alex with his assistant arrives at 7:36 in the head cabin, where they are met by a team that will hand over the train. They report the status of the composition and operating modes. Then Alex receives a general key - a physical key for activation-deactivation of the cabin. It is almost like a mythical “key-to-start” for astronauts and is used in the same way.

Then the driver follows the opposite cabin, which will be the lead on the next flight. On the way, a visual inspection of the train on the bottom, that is, equipment under the wagons, is performed. Then you need to activate the cabin, join the bus (local area network) of the train and view the monitoring. Put the fixation cassette (action logging tool):

Check hitch:

Loading a train is a bit like loading old BIOS with beautiful system health checks. Here's a video:

That is, you need to check the condition of the batteries, the temperature characteristics of the traction in the engine, heating, ventilation, air conditioning in general, lighting, axle boxes. Then - checking passenger compartment data: you need to check the configuration and set new parameters. The temperature is usually maintained around 22 degrees. The setting is 20 plus or minus two degrees, that is, 22 or 18. Then the diagnostics of the toilets is started (more precisely, the display of information about it, the diagnostics of the nodes works constantly). If one of the toilet complexes is in denial, then you need to inform the dispatch center to call a specialist.

Here are some more monitoring:

The configuration is corrected by hand even according to the weather, according to the voltage conditions, the condition of the rails (also depends on the weather). Active checks are already being made: the operation of the compressors, the pressure in the train lines, to try two types of brakes - both on the train are frictional, but of a different operating principle. At the end, the passenger notification system (IPR) is set up: a display board, voice alerts at departure, screens with train services, and in general, so that the robot can talk with passengers.

Further preparation for the launch continues:

After that, you need to wait until the doors open (15 minutes before the departure of the Aeroexpress), pick up the passengers and set off.

The main controls are mechanical, although one of the handles is actually “cruise control” for the train:

The assistant driver’s braking button is also physical and also large:

You already know the sandbox:

On the way, the driver controls the entrance, route, weekend, checkpoints, repeat, barrage, shunting traffic lights. Traffic signals from the locomotive brigade give an order and require either a decrease in speed, or a stop of a train, or following at a set speed. Critical signals are duplicated, but the signaling on the railway is a topic for a separate post.

After arriving in Vnukovo, the driver activates the parking brake, opens the door, and disconnects the safety devices.

In the photo, one of the unusual safety devices - TSKBM, it is now working, but is not included in the management. He is needed to control the train by one person (without an assistant), and this robot controls the correctness of human actions and in general his condition. This device can act as a kind of autopilot in emergency situations. After testing with biometric bracelets, there will be a decision on whether it is possible to use this system and remove the second person from the cab. Now it is duplicated by a safety device, which periodically checks the driver’s vigilance with a buzzer, and he must confirm by pressing a button that everything is in order. If you do not confirm in a few seconds, the train will be stopped.

Then it turns off the electropneumatic valve of the hitchhiking. After all operations, the cabin is deactivated. The driver passes along the platform in the opposite direction to the second cab. This time, the upper part of the train is inspected, visual defects on current collectors, damage to the wagon cover are searched (chips without paint can begin to rust).

That is, at the Kiev station, the train is inspected from below, and in Vnukovo - from above from the outside. But only on the one hand. Then, when it is served on the platform, you can stand on both the left and the right path and then examine the train from the other side. When you need to specifically look at the other side, the driver can request a certain path through the dispatcher in advance.

The assistant to the driver at this time remains in the tail cabin in touch. In general, there is always someone in touch on the train. Among other things, the assistant monitors messages from passengers who often forget their phones. The same messages are often accessed by security.

Next - activation of the cabin again, pre-launch procedures, monitoring check, active equipment check, configuration, waiting, opening doors, loading passengers and the return trip.

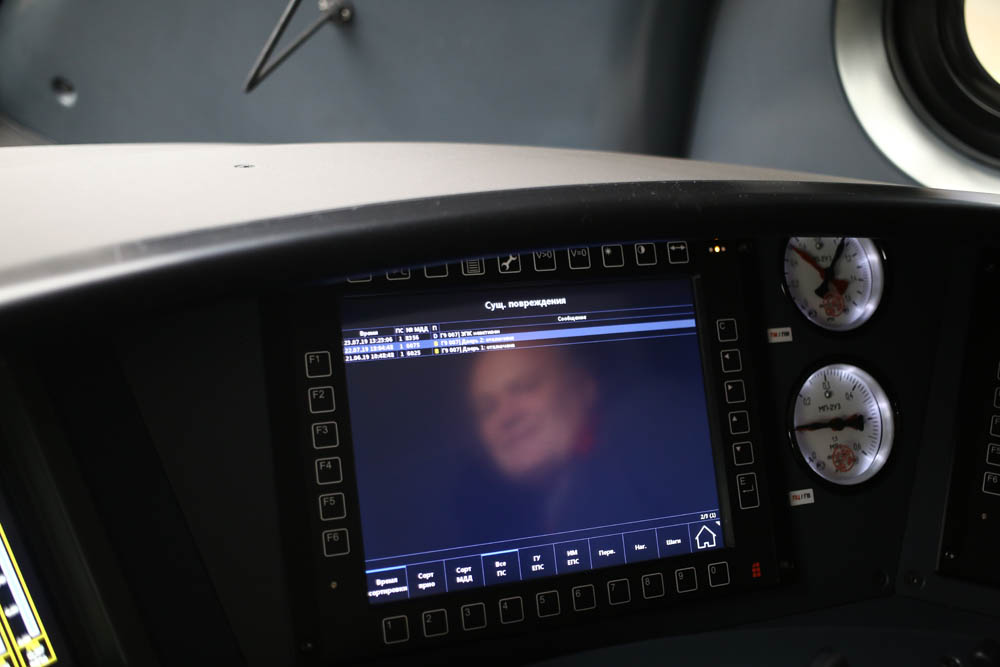

Breakdowns are extremely rare on the road. A train with closed communications (most routes are connected between the inner and outer vestibules, which protects them from getting any objects from the outside like jumping tires on the tracks that the hooligans leave to see what happens). Here is a list of current train malfunctions in monitoring (these are bugs, these are disabled right now in the parking lot of the subsystem):

That is, most problems are closed either by a mechanic between flights (the same toilets), or during maintenance at the depot. From what can happen on the road, increased wear of the current collector or damage to it is possible. Old current collectors were badly damaged during freezing rain, new contact inserts are already much better. The contact network should be well regulated, if this is not so, there may be outages. During the passage on the train, the condition of the carts and equipment, cables, inter-car transitions, body paint, double-glazed windows, doors and windows in them is checked. This all needs a visual inspection, either due to the fact that monitoring needs to be duplicated, or due to the fact that it is impossible to obtain this data (about a double-glazed window) in monitoring.

Here in this part of the settings you can omit one of the current collectors: they are duplicated, and the train will not lose in speed and power:

At night, the Vnukovo direction electric trains are standing on the platform tracks of the Kiev railway station and the Vnukovo terminal. That is, they do not go to the depot, but spend the night right near the station. They go to the depot only for inspection, and now this happens much less often (and the procedure itself is faster) than on trains of past generations.

What else is in the cab?

Here are the stop cranes (one is at the rear of the cab, that is, there is always a means to stop the train in the radius of the arm from the driver):

The same are installed in passenger compartments. Let me remind you that the trains are equipped with a pneumatic line, where compressed air presses the brakes. If a hole is formed in the line, then pressure immediately drops in it, and the brakes "wring out", the train starts to stop. A hole in the line can form when the composition is damaged, uncoupling, standard braking (opening the valve into the atmosphere) and emergency braking (failure of the stopcock with the subsequent opening of the valve into the atmosphere). These stopcocks are electric; they are connected to an independent emergency brake circuit. If a passenger drives it, the electrical circuit is physically broken, which feeds the electromagnets that hold the valves in a locked state. When voltage drops, the valves open and air escapes from the line. When the stopcrane breaks down, the driver sees this action, and he has a choice: cancel emergency braking (it is necessary in specific cases of a fire in the tunnel, on the bridge or under contact devices before leaving a difficult area) or duplicate the command via the second independent emergency braking circuit . This is optional, but it is a standard procedure in case of damage to one of the networks. The length of the braking distance depends only on the load - in fact the number of passengers and baggage, duplication does not change it. Braking is not particularly sharp - the mechanism is the same as with the usual, but the train stops a little harder.

Screen with camera data: there you can conveniently watch what passengers do in the parking lot, and at the moment of movement - what happens in the cars. When a driver is called through an internal passenger-driver communication, one of the screens of the quadrator immediately automatically shows the situation in the car.

You can configure any display at any time, but there are already ready-made switching scripts like the one described.

The seat is adjustable very widely, because seat comfort is important for precise control and tiredness:

Behind the driver’s back is a refrigerator:

Cabinet with different equipment:

This cabinet contains dielectric gloves and two insulating self-rescuers in case of fire. Below are the stairs and ashtrays:

Ashtrays for drivers are set according to the German standard, which tells how the workplace should be equipped. But in Russia you can’t smoke on the train, so they are clean. And this is a pyrometer:

It is necessary to control the temperature of axleboxes on wheelsets in case of failure of monitoring sensors.

There are three cameras in the cab. Two look at the actions of the driver and assistant, another one is similar to the traffic recorder:

And this is a very sensitive microphone in the ceiling that records all the conversations in the cockpit:

Smoke sensor:

This part of the cab (controls, driver and assistant) is separated from the second by a strong door, which, when closed, is locked by default for protection. Another same door separates the second part of the cab from the passenger compartment. At the rear of the cab are two exits from the locomotive and also cabinets with equipment.

The door is metal, the train is an electric train, so these are potential removal systems.

From household - microwave:

Here is another piece of equipment:

And, in fact, firecrackers:

Signal firecrackers are needed to protect the electric train (stacked on rails) during an emergency stop on the stage. This is to prevent a collision with a train oncoming direction or following. Firecrackers are also used by distance track workers in identifying railroad malfunctions. The explosion of at least one firecracker requires the train driver to emergency stop the train to find out the reasons. Here is an example of an instruction .

Actually, this is how it looks from the inside. Here are our posts about railways, the arrangement of trains: features of the Universiade transport , in the Aeroexpress depot , about the trans-Siberian railway, Grand Express , what kind of trains there are , wagon power systems , how a passenger wagon is arranged , how wagons are assembled , how they evolved , about Leningradsky railway station , about steam locomotives , about old wagons . Great FAQ about long-distance trains and unobvious rules . And the working day of the bus driver of our colleagues from Tutu. Buses.

All Articles