Courier robot - delivery in 30 minutes, or how to build the future in Russia

Deliver the purchase to the suburbs in 30 minutes and for $ 1 - a challenge that no carrier will accept. But take a robot that moves along the monorail. From the idea to the first prototypes: economics, competitors, mistakes and their understanding. For an aperitif - the answer to the existential question “Why?”

To live not in the center of the urban agglomeration - inevitably put up with inconveniences: the time spent on the road to work, the lack of a full-fledged infrastructure. Moreover, the quality of life in the suburbs is influenced by the level of everyday products, hot food, which can be found within walking distance, as a rule, it is a mass segment of a corresponding quality. The choice of online stores is limited to those who carry in the specified area, tariffs at the same time from 250 rubles and driven longer than 12 hours.

The only solution that is found by residents of the suburbs like me is to sit in a car and drive to the nearest civilized center for what is necessary, drive in there after work, stand in traditional traffic jams. In a word - to burn an already limited time.

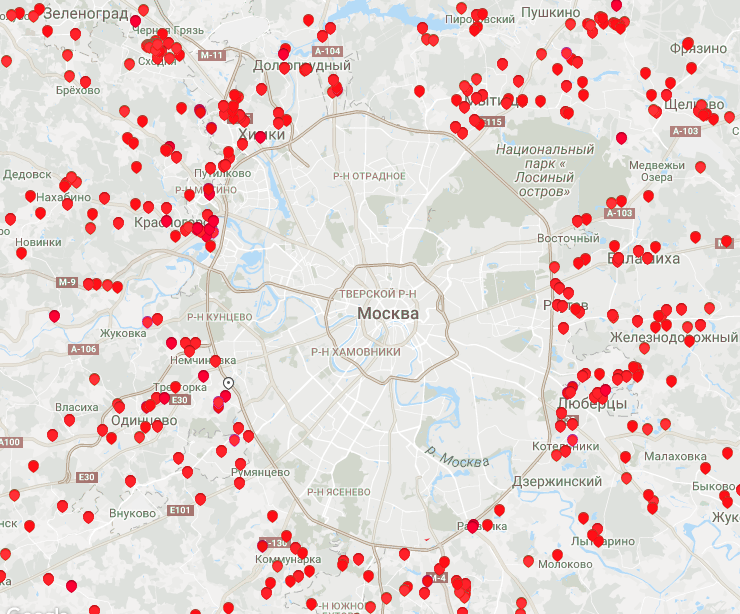

If we multiply this problem by the number of people involved in it, there will be 8,000,000 people in the middle command circle alone. According to statistics, 70% of Internet users are among them, and according to GfK research , one third are active buyers of online stores. Bottom line: 1,866,400 people in Moscow and the Moscow region alone need fast and inexpensive delivery.

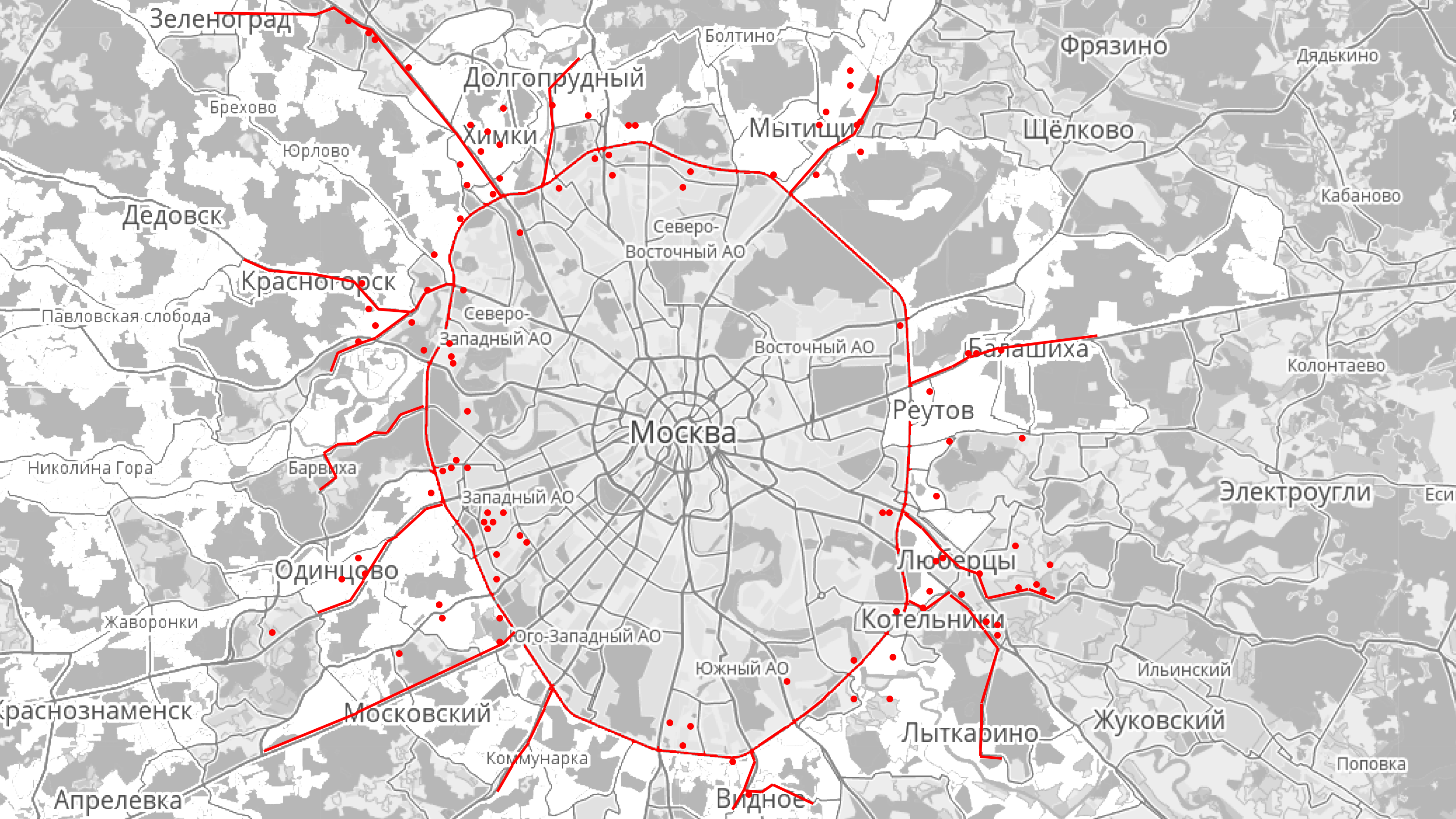

The map shows the new buildings, from the zero stage to the currently entered.

What solution we are looking for: delivery is faster than 2 hours and cheaper than 150 rubles - in logistics this task is called the last mile. But, strictly speaking, the world has not yet encountered a fast, cheap and massive solution.

Consider the alternatives and start with the exotic ones (hereafter, the points technically insurmountable are underlined in red):

Carts on wheels do not require complex infrastructure, are hardy and show efficiency in low-rise America, but also have drawbacks:

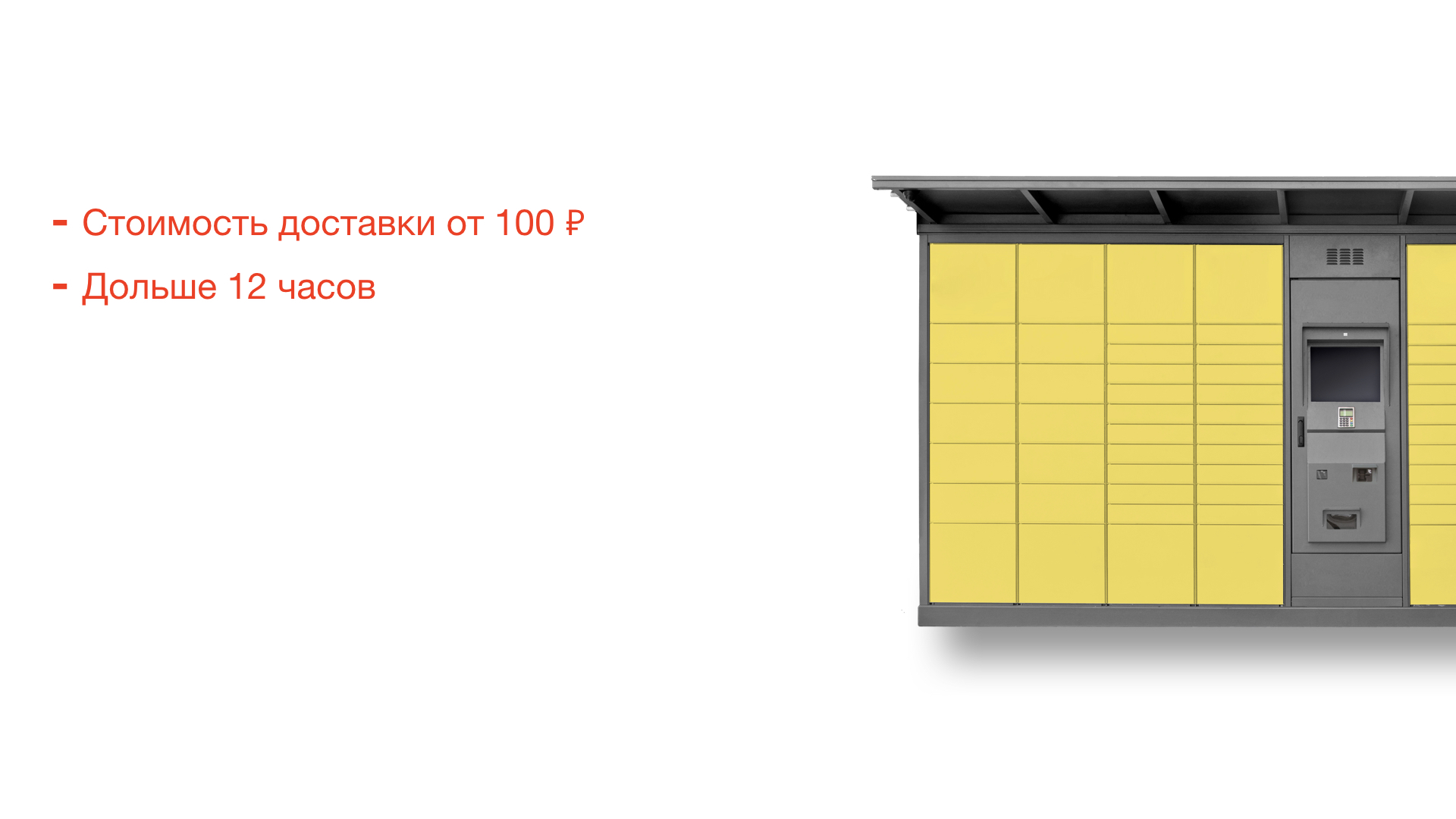

This decision is more positive from the point of view of the economy and the parcel can be picked up the next day, as the cargo is delivered at night in the absence of traffic on the roads. However, if we take into account that we are talking about a 15-year horizon of events, will the delivery of people of the future suit us in 12 hours?

In the future, increased risk is represented by unmanned vehicles that drive on roads on which traffic is established without traffic jams.

Pros:

Image source

There arises the only obstacle on which everything depends: can the roads be unloaded after 15 years with the arrival of auto-piloted transport, taking into account population growth, the modernization of road infrastructure?

I do not think that there is a person who could answer this question authentically.

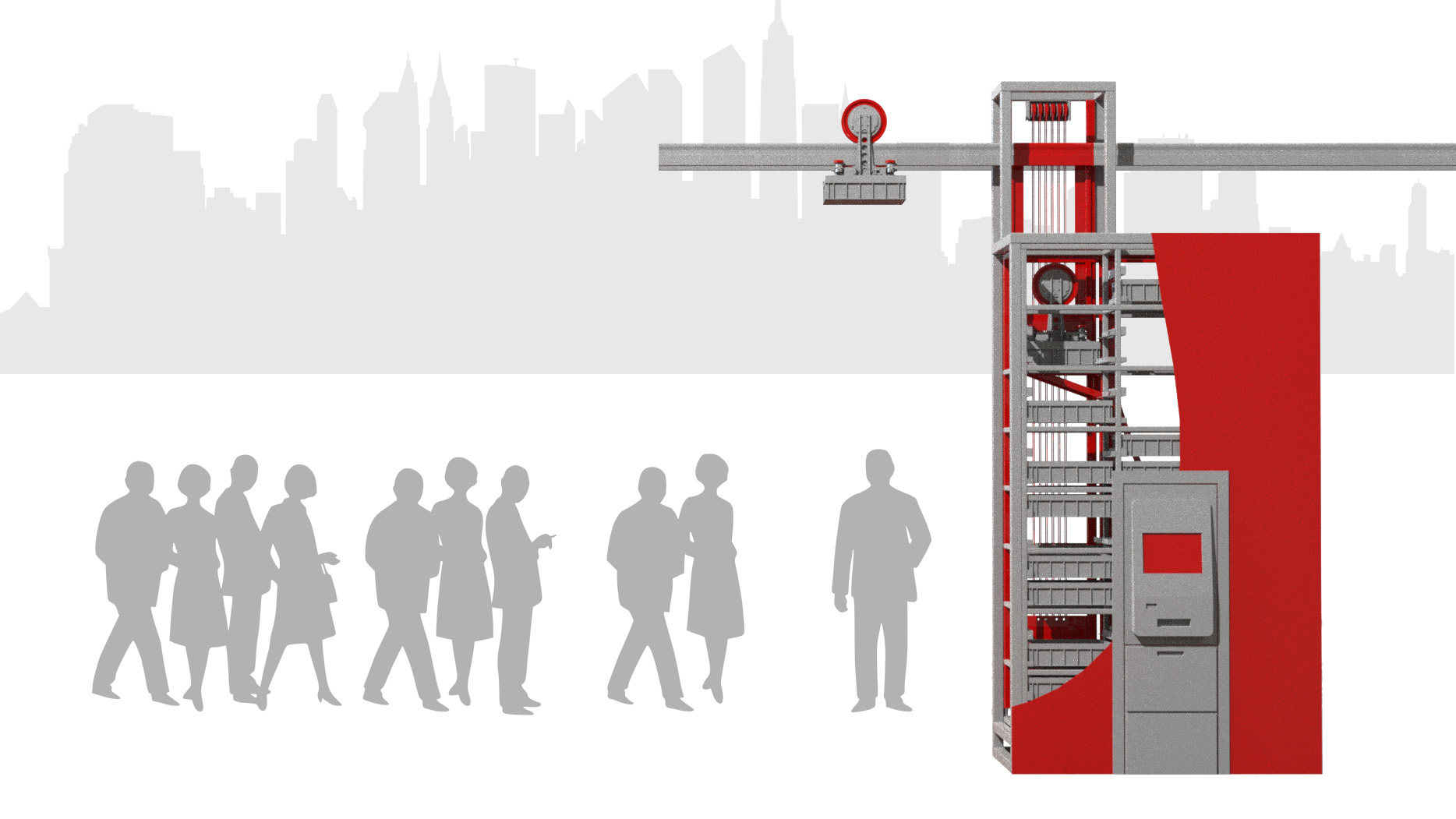

We also propose a different solution to the problem - laying the infrastructure over the already existing roads in the form of a compact monorail and rolling stock (shuttles), capable of moving cargo in weight and dimensions covering 90% of the daily need for delivery.

Of course, the infrastructure includes quarterly postamats and specialized depots on the side of warehouses that accept cargo for shipment. And such a system does not involve the participation of a person - from the moment of the click on the store’s site until the moment the package is collected.

Despite the fact that “The last mile report 2017” by Barclays belongs to the British audience, a survey of residents of Moscow and the Moscow region indicates similar results. People are not ready all day to wait for the parcel, not knowing what time it will arrive and in rare cases are ready to overpay for the speed of delivery.

It can be assumed that in the next 10 years the situation will change and people will need instant delivery for impulsive everyday purchases, for example, this has already become popular in some US cities, where delivery takes place in an hour , thanks to the coordinated work of warehouse staff, robots and Amazon courier . The distance to the client at the same time is no more than a couple of kilometers.

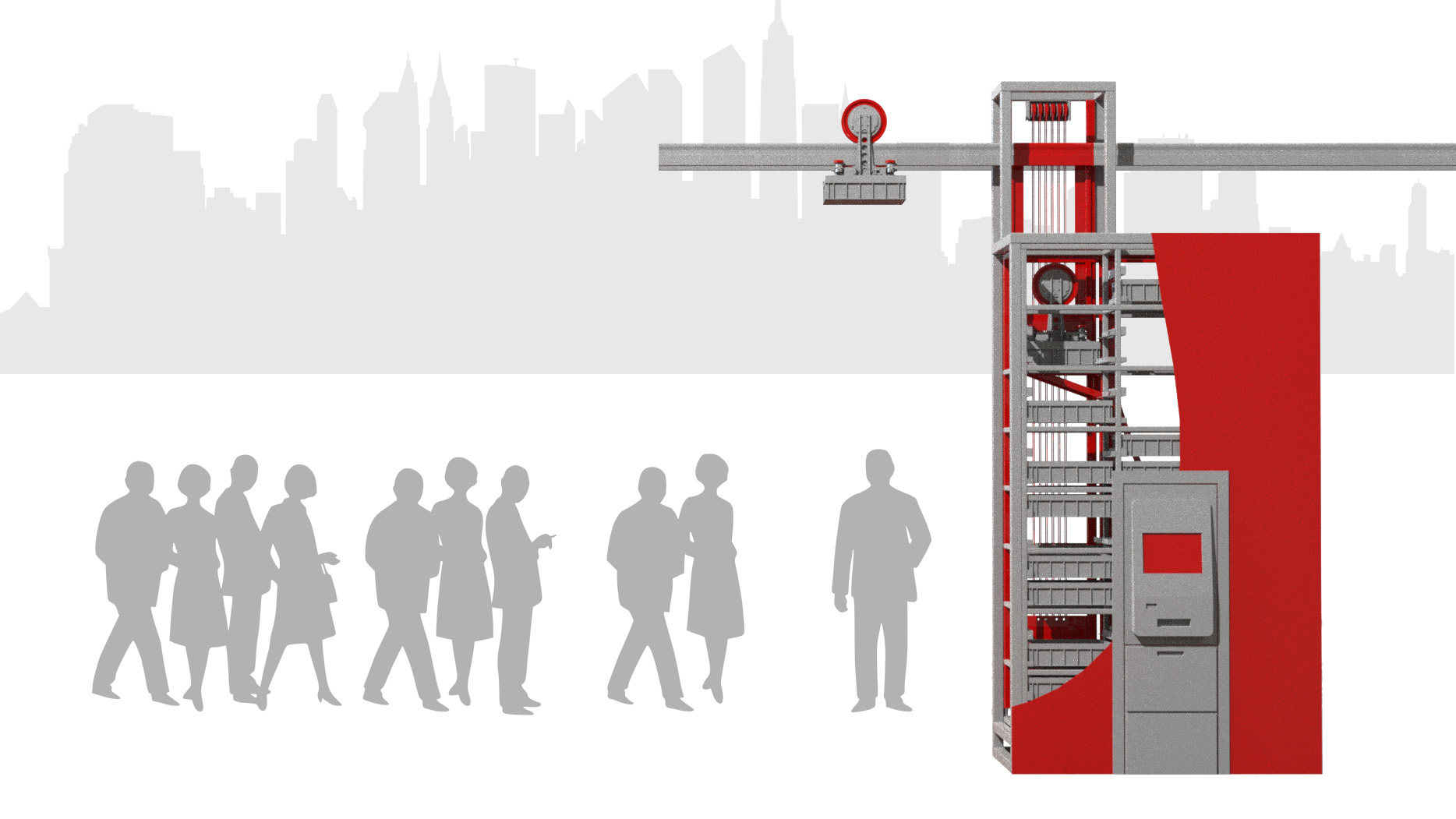

Postamat in the neighborhood - around the clock accepts and stores the goods on demand. If you do not want to go to him on foot - the local courier will do this part of the work for you. Due to short distances, he, as a postman, will serve up to 30 addresses per day, which means one-time service will be five times cheaper than a courier from the city.

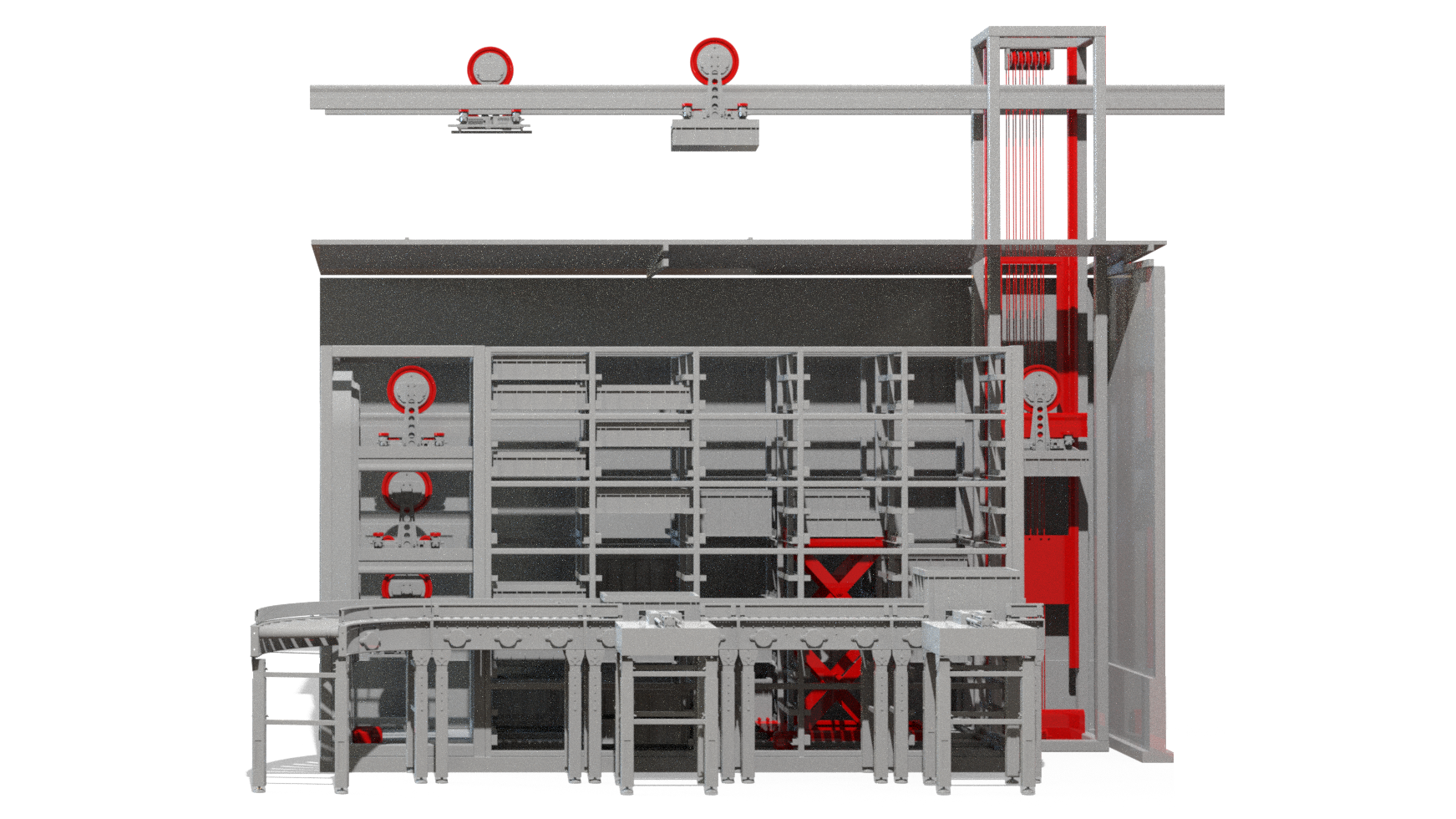

Warehouse depot - an automatic terminal for shipping goods on the warehouse side is integrated into the internal logistics, and its own fleet of shuttles ensures no delays in the shipment.

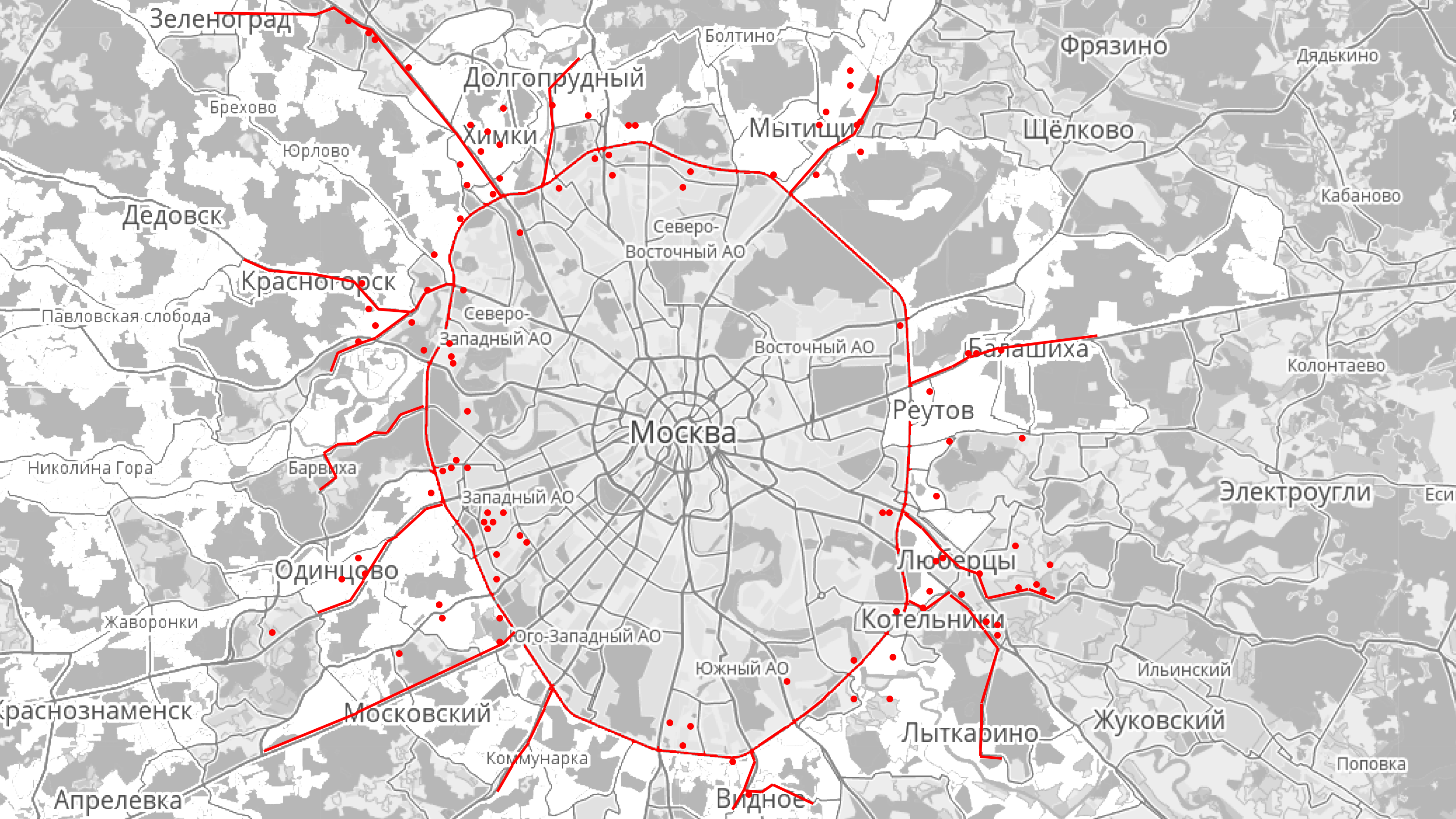

At the first stage of the network development, it encircles the city along the Moscow Ring Road and connects all the warehouses located in the kilometer zone. Suburban branches are built over the existing road infrastructure, over the dividing lane of the highway or along the railway tracks.

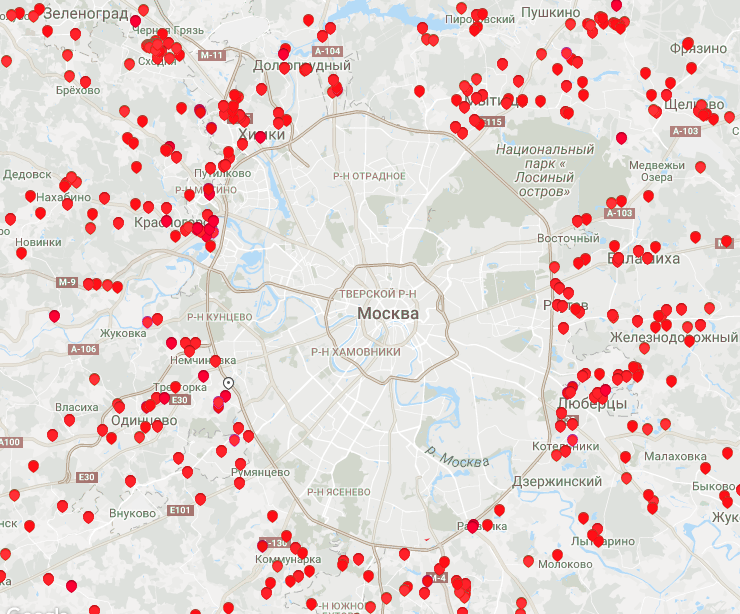

Postamats are located near the concentration of traffic of residents with the maximum coverage of the audience.

This is the topic of a separate article with detailed calculations (if I’m going to publish the interest of the audience), I’ll therefore mention the key figures: the capital cost of building a 1 km highway is $ 420,000.

Thus, equipping the Moscow and Moscow region agglomeration with a monorail network for the Moscow Ring Road will cost $ 129,756,000.

Based on the fact that each user brings $ 12, and the active audience will be 1,866,400, the return on investment will be in the 5th year.

We will consider such an assessment optimistic.

After we reviewed the possible rolling stock composition options, the task fell apart into two possible solutions: the active shuttle is a passive path, the active path is a passive shuttle (this is about changing the direction of motion at intersections).

So on the railways, the traditional monorail and in the workshop logistics, this problem is solved by the arrows, who transfer rolling stock from one direction to another. This solution has a number of indisputable advantages: rolling stock is simple to manufacture and it has high reliability. All decisions about the direction are made by the system, which means there is no need to equip the shuttle itself with brains.

The arrows must be maintained, in the cold season to warm up, so as not to freeze the moving parts. And with the growth of traffic, they will also be a limitation of the bandwidth of the system, since they will have to constantly switch to a particularly active fork. And it will affect the resource arrows.

The path with passive transitions, when the decision of where to move takes the shuttle and itself moves from track to track. Analogues of such a solution are already less common, where it comes to heavy traffic.

The ease of track maintenance, traffic density, and traffic range is limited only by the ability of the shuttle to move from track to track.

The complication of the design of the shuttle, the increase in cost with a simultaneous drop in reliability and the shuttle must be made smarter.

Without giving us an unequivocal answer, we decided to conduct experiments and start from the passive shuttle - the active path.

Always choose between simplicity of design and its functionality. From simple metal cable harnesses and a whole system of two or more rails that hold the rolling stock in the required position. In addition, the rail must contain a pair of contact wires, if it is not a battery solution.

You can also paint the process of organizing the movement, protection from vandalism, the process of cleaning the path from soot, dirt, ice and droppings, but risking to tire the reader. However, if necessary, I am ready to tell about everything in details in one of the following posts.

The problem of the last mile requires a solution that fits into the reality of a weighted economy and the presence of corresponding demand in the market, and its maturity is still an open answer; and the USA.

The economy of the decision looks well off, but with the full support of the cities. At the same time, it gives the city itself a relative unloading of peripheral roads and highways from local logistics transport, a proportional reduction in CO2 emissions and an improved environmental situation.

The parity of technologies was formed around the two-dimensional and three-dimensional transport control tasks, but the one-dimensional task is a monorail, belongs to the category of solved, and, therefore, it is not necessary to test the technical hypothesis. It remains to confirm the consistency of the economic model on the cargo flow and establish a reasonable payback period, by reducing capital costs in infrastructure and rolling stock. Under equal conditions in the market, the solution will have an advantage, which will begin to scale first and an easy monorail claims to this role.

The following posts will be devoted to the prototype of the shuttle and the postamat, the device of the monorail overpass.

Existing problem

To live not in the center of the urban agglomeration - inevitably put up with inconveniences: the time spent on the road to work, the lack of a full-fledged infrastructure. Moreover, the quality of life in the suburbs is influenced by the level of everyday products, hot food, which can be found within walking distance, as a rule, it is a mass segment of a corresponding quality. The choice of online stores is limited to those who carry in the specified area, tariffs at the same time from 250 rubles and driven longer than 12 hours.

The only solution that is found by residents of the suburbs like me is to sit in a car and drive to the nearest civilized center for what is necessary, drive in there after work, stand in traditional traffic jams. In a word - to burn an already limited time.

If we multiply this problem by the number of people involved in it, there will be 8,000,000 people in the middle command circle alone. According to statistics, 70% of Internet users are among them, and according to GfK research , one third are active buyers of online stores. Bottom line: 1,866,400 people in Moscow and the Moscow region alone need fast and inexpensive delivery.

The map shows the new buildings, from the zero stage to the currently entered.

How to be? Analogs and competitors.

What solution we are looking for: delivery is faster than 2 hours and cheaper than 150 rubles - in logistics this task is called the last mile. But, strictly speaking, the world has not yet encountered a fast, cheap and massive solution.

Consider the alternatives and start with the exotic ones (hereafter, the points technically insurmountable are underlined in red):

Drone

Five drone engineering problems:

- Still working at the limit of their power (this is unsafe for those who are below).

- While not able to work in autorotation mode (and again, the problem for the people below).

- Small resource of mass batteries, which affects the range (waiting for a new generation).

- The economy of the drone, as a transport, makes the hair on the head of logisticians move: the cost of transporting 1 ton of cargo per mile is $ 2000 . This is the most expensive transport available, and all because of the lack of light, cheap and not energy-intensive brains.

- Finally, the dimensions of the drone , which moves a load of 20 kg.

Starship

Carts on wheels do not require complex infrastructure, are hardy and show efficiency in low-rise America, but also have drawbacks:

- Involving a person, even if the robot takes over some of the functions. For example, in cases where the wagon does not know how to behave at an intersection.

- The cost of equipping such a device with brains is still high, but will reach acceptable values in the next 3 years.

- Speed, this is probably the key drawback - to move along the sidewalk faster than 15 km an hour will fail for reasons of pedestrian safety.

- And the small radius of action, which, according to the manufacturers , does not exceed 2 miles so far, which seriously limits the scope.

Now to the existing solutions:

Postamats + courier

This decision is more positive from the point of view of the economy and the parcel can be picked up the next day, as the cargo is delivered at night in the absence of traffic on the roads. However, if we take into account that we are talking about a 15-year horizon of events, will the delivery of people of the future suit us in 12 hours?

Unmanned vehicles

In the future, increased risk is represented by unmanned vehicles that drive on roads on which traffic is established without traffic jams.

Pros:

- the most capital-intensive part of the infrastructure is ready - the road;

- transportation is relatively cheap;

- loading capacity from 300 kg;

- access is limited by the availability of the road.

Image source

There arises the only obstacle on which everything depends: can the roads be unloaded after 15 years with the arrival of auto-piloted transport, taking into account population growth, the modernization of road infrastructure?

I do not think that there is a person who could answer this question authentically.

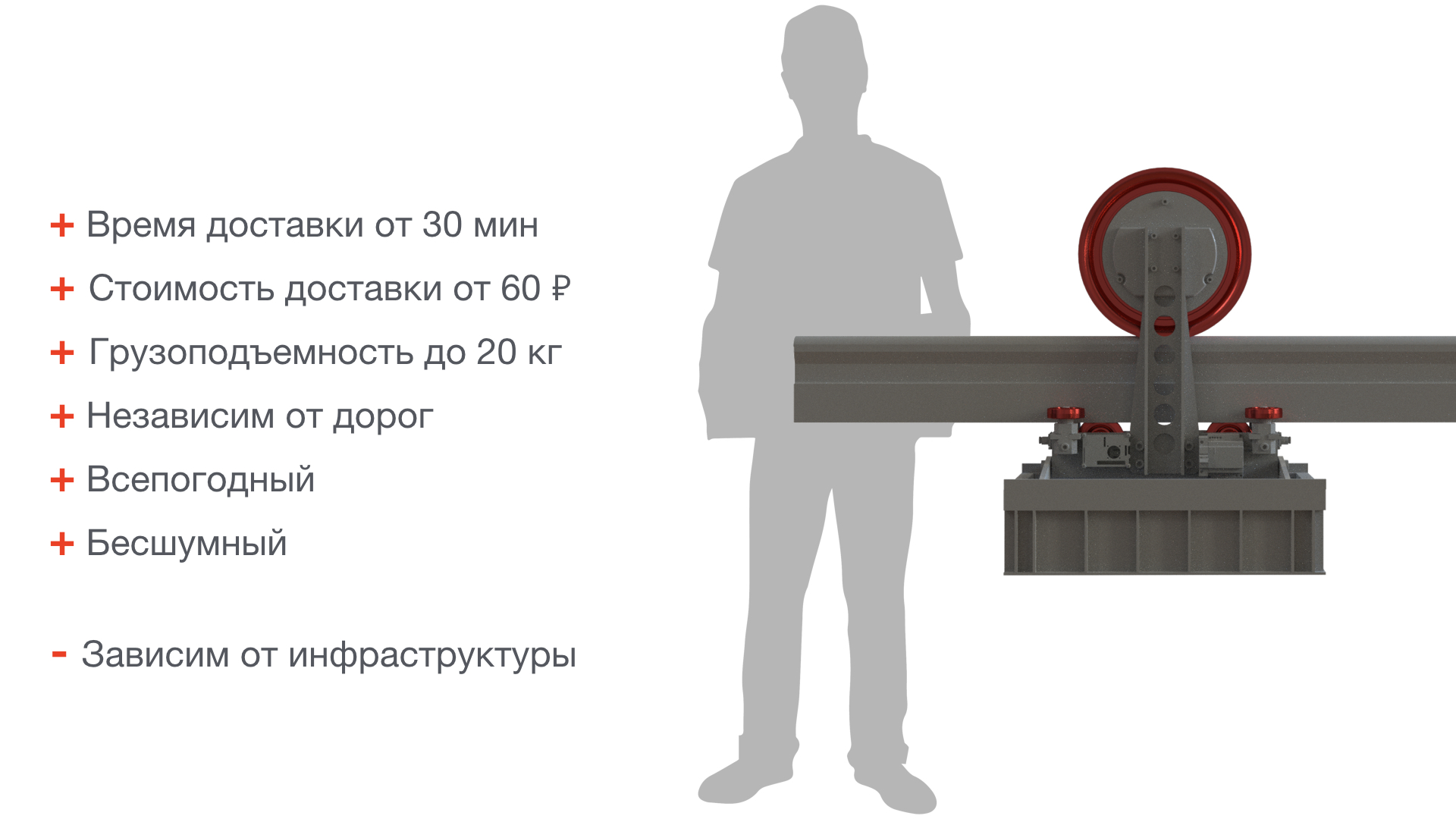

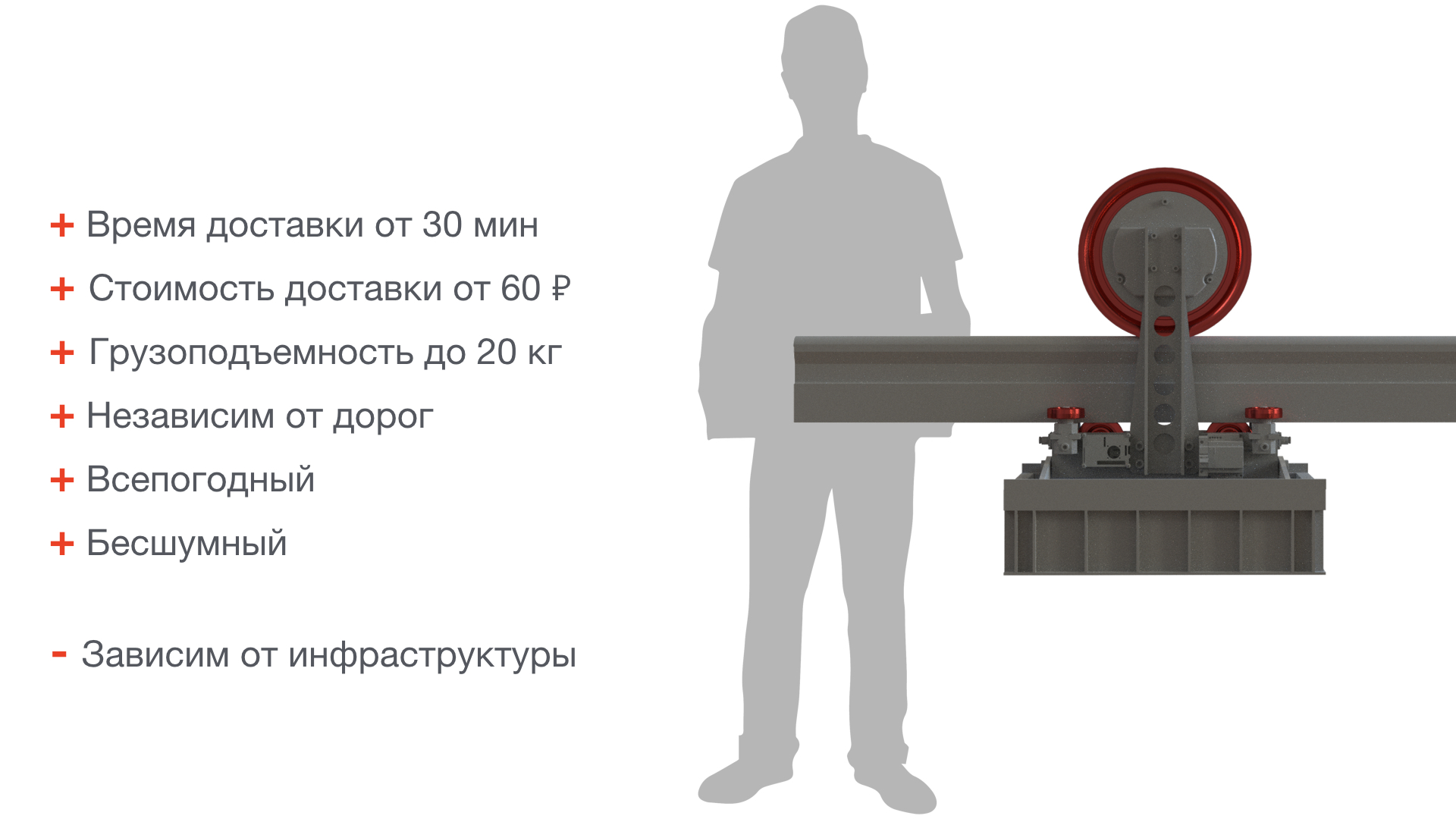

Monorail

We also propose a different solution to the problem - laying the infrastructure over the already existing roads in the form of a compact monorail and rolling stock (shuttles), capable of moving cargo in weight and dimensions covering 90% of the daily need for delivery.

Of course, the infrastructure includes quarterly postamats and specialized depots on the side of warehouses that accept cargo for shipment. And such a system does not involve the participation of a person - from the moment of the click on the store’s site until the moment the package is collected.

Compare analogues:

Despite the fact that “The last mile report 2017” by Barclays belongs to the British audience, a survey of residents of Moscow and the Moscow region indicates similar results. People are not ready all day to wait for the parcel, not knowing what time it will arrive and in rare cases are ready to overpay for the speed of delivery.

It can be assumed that in the next 10 years the situation will change and people will need instant delivery for impulsive everyday purchases, for example, this has already become popular in some US cities, where delivery takes place in an hour , thanks to the coordinated work of warehouse staff, robots and Amazon courier . The distance to the client at the same time is no more than a couple of kilometers.

The advantages of the monorail

- unlike ground-based unmanned solutions, the monorail does not freeze in traffic jams, does not stop at intersections of roads - which affects the speed of delivery;

- the carrying capacity of such a solution is limited only by the strength characteristics of the shuttle and the track;

- It is much easier to predict the time of arrival of the cargo, in relation to the existing analogues - it is important to know that the package will be on time and not have to wait;

- autopilot for one-dimensional task has already been created, which means the project does not apply to games in R & D;

- the decision will be silent - good news for those who are tired of the noise outside the window;

- All-weather is an indisputable advantage over what flies or moves on the ground (in any case, if we are talking about the climate that is characteristic of northern latitudes).

Monorail Disadvantages

- the cost of infrastructure - the current task, to obtain the technology of production, assembly and installation of the track, the cost of which is to strive to a minimum

- the cost of maintaining the track and rolling stock - minimizing due to the robotization of production;

- Coordinating the laying of infrastructure in a city or suburb is a predictable obstacle at the level of the city and municipalities. The mechanism is not as transparent as we would like, but we believe that it will be no more difficult than agreeing on, say, a trolleybus line and we are not talking about the center of the city.

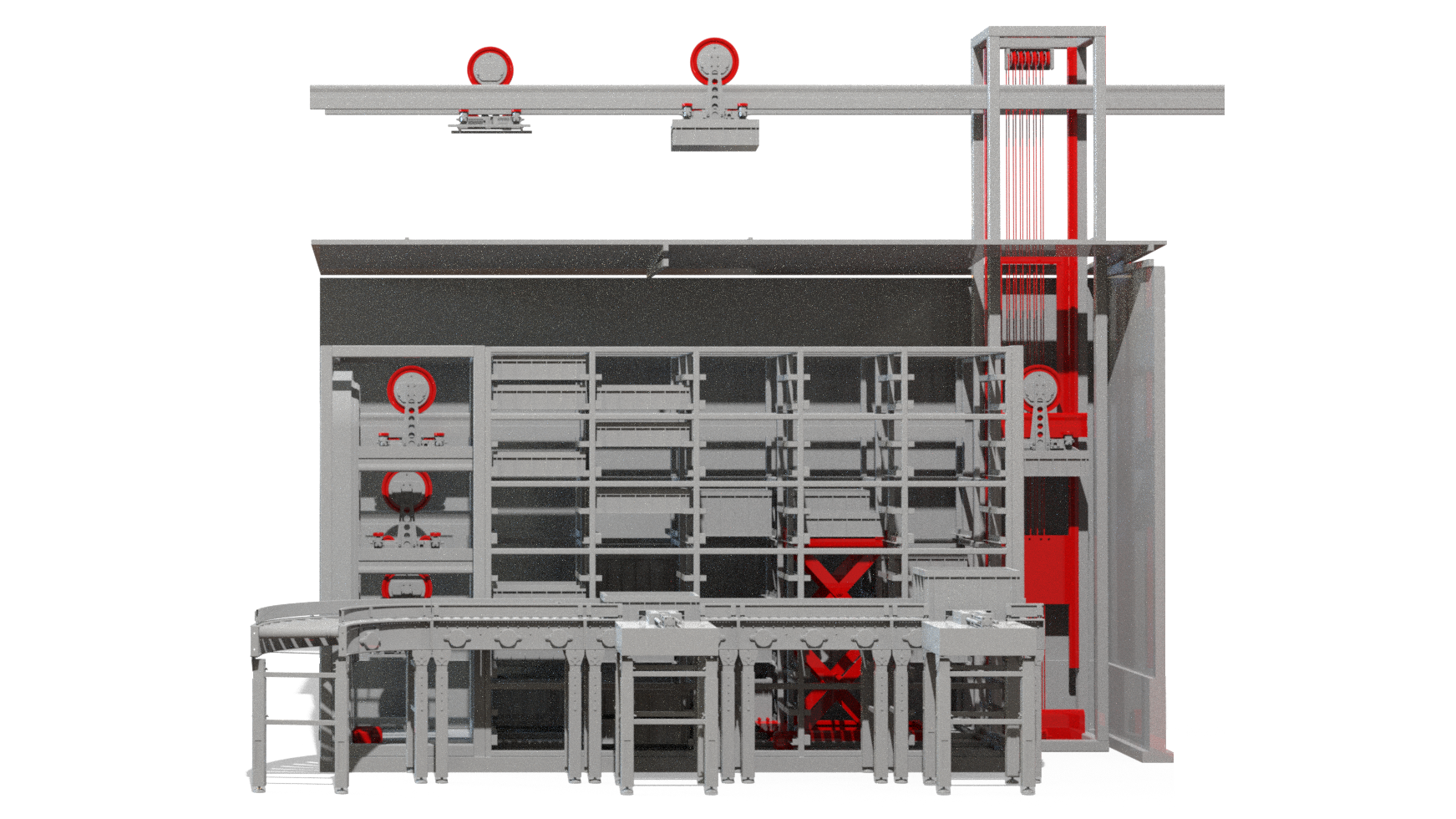

Monorail Ecosystem

Postamat

Postamat in the neighborhood - around the clock accepts and stores the goods on demand. If you do not want to go to him on foot - the local courier will do this part of the work for you. Due to short distances, he, as a postman, will serve up to 30 addresses per day, which means one-time service will be five times cheaper than a courier from the city.

Warehouse depot

Warehouse depot - an automatic terminal for shipping goods on the warehouse side is integrated into the internal logistics, and its own fleet of shuttles ensures no delays in the shipment.

Rolling stock

- rolling stock - compact automatic shuttles combine the reliability of rail transport with the mobility of the drone;

- speed of 45-60 km / h - delivery at a distance of 12 km, together with the process of processing and assembling cargo takes 30 minutes;

- height of the monorail - 4-6 meters.

Track structure

At the first stage of the network development, it encircles the city along the Moscow Ring Road and connects all the warehouses located in the kilometer zone. Suburban branches are built over the existing road infrastructure, over the dividing lane of the highway or along the railway tracks.

Postamats are located near the concentration of traffic of residents with the maximum coverage of the audience.

Monorail economy

This is the topic of a separate article with detailed calculations (if I’m going to publish the interest of the audience), I’ll therefore mention the key figures: the capital cost of building a 1 km highway is $ 420,000.

Thus, equipping the Moscow and Moscow region agglomeration with a monorail network for the Moscow Ring Road will cost $ 129,756,000.

Based on the fact that each user brings $ 12, and the active audience will be 1,866,400, the return on investment will be in the 5th year.

We will consider such an assessment optimistic.

What can go wrong or risks

- the costs of coordinating the construction of infrastructure may be higher — it depends on the level of support for the project at the level of the Moscow government;

- audience assessment and involvement may be overstated;

- The estimate of capital costs in infrastructure may be underestimated.

About the way

After we reviewed the possible rolling stock composition options, the task fell apart into two possible solutions: the active shuttle is a passive path, the active path is a passive shuttle (this is about changing the direction of motion at intersections).

So on the railways, the traditional monorail and in the workshop logistics, this problem is solved by the arrows, who transfer rolling stock from one direction to another. This solution has a number of indisputable advantages: rolling stock is simple to manufacture and it has high reliability. All decisions about the direction are made by the system, which means there is no need to equip the shuttle itself with brains.

disadvantages

The arrows must be maintained, in the cold season to warm up, so as not to freeze the moving parts. And with the growth of traffic, they will also be a limitation of the bandwidth of the system, since they will have to constantly switch to a particularly active fork. And it will affect the resource arrows.

Alternative

The path with passive transitions, when the decision of where to move takes the shuttle and itself moves from track to track. Analogues of such a solution are already less common, where it comes to heavy traffic.

pros

The ease of track maintenance, traffic density, and traffic range is limited only by the ability of the shuttle to move from track to track.

Minuses

The complication of the design of the shuttle, the increase in cost with a simultaneous drop in reliability and the shuttle must be made smarter.

Without giving us an unequivocal answer, we decided to conduct experiments and start from the passive shuttle - the active path.

Rail form

Always choose between simplicity of design and its functionality. From simple metal cable harnesses and a whole system of two or more rails that hold the rolling stock in the required position. In addition, the rail must contain a pair of contact wires, if it is not a battery solution.

About the shuttle

- cost price of $ 800 (for mass production), otherwise problems with the economy begin;

- carrying capacity up to 20 kg together with a tare container, with a weight of the shuttle up to 25 kg;

- speed: 45-60 km / h on a straight line without slopes with a load of 20 kg.

What should be included in the design of the shuttle:

- current collection unit or battery;

- the mechanism of removing the shuttle from the monorail in a manual safe manner;

- solution of automatic fastening of the container with the load;

- all-weather solution (protection of nodes from exposure to the atmosphere);

- automatic shuttle control system;

- precise positioning system at a distance;

- system of protection against collision with interference on the way: at the local level, it must decide itself if it is an obstacle or a neighbor in the direction of travel (and the sensitivity distance must be sufficient to make a decision and completely stop the rolling stock).

You can also paint the process of organizing the movement, protection from vandalism, the process of cleaning the path from soot, dirt, ice and droppings, but risking to tire the reader. However, if necessary, I am ready to tell about everything in details in one of the following posts.

And in conclusion

The problem of the last mile requires a solution that fits into the reality of a weighted economy and the presence of corresponding demand in the market, and its maturity is still an open answer; and the USA.

The economy of the decision looks well off, but with the full support of the cities. At the same time, it gives the city itself a relative unloading of peripheral roads and highways from local logistics transport, a proportional reduction in CO2 emissions and an improved environmental situation.

The parity of technologies was formed around the two-dimensional and three-dimensional transport control tasks, but the one-dimensional task is a monorail, belongs to the category of solved, and, therefore, it is not necessary to test the technical hypothesis. It remains to confirm the consistency of the economic model on the cargo flow and establish a reasonable payback period, by reducing capital costs in infrastructure and rolling stock. Under equal conditions in the market, the solution will have an advantage, which will begin to scale first and an easy monorail claims to this role.

The following posts will be devoted to the prototype of the shuttle and the postamat, the device of the monorail overpass.

All Articles