The acoustic future of nanotubes: the new life of thermoacoustics

It is known that traditional electrodynamic loudspeakers along with a mass of advantages also have tangible disadvantages, for example, a certain limit of fidelity. To achieve high levels of sound quality, the electromechanical principle of operation of traditional speakers requires a lot of tweaks, seriously limits the capabilities of developers, leads to significant costs and, accordingly, increases their cost. In addition, traditional materials used for speaker membranes, as is known, have a “ceiling” at the lowest possible level of distortion, are massive enough, and permanent magnets introduce additional distortion.

In previous posts we have already described several well-known alternatives to speakers, such as electrostatic, iso / orthodynamic emitters and ionophones. In this material we will talk about, perhaps, the most high-tech and original replacement for the dynamic drivers we are used to — the radiators created on the basis of nanotubes.

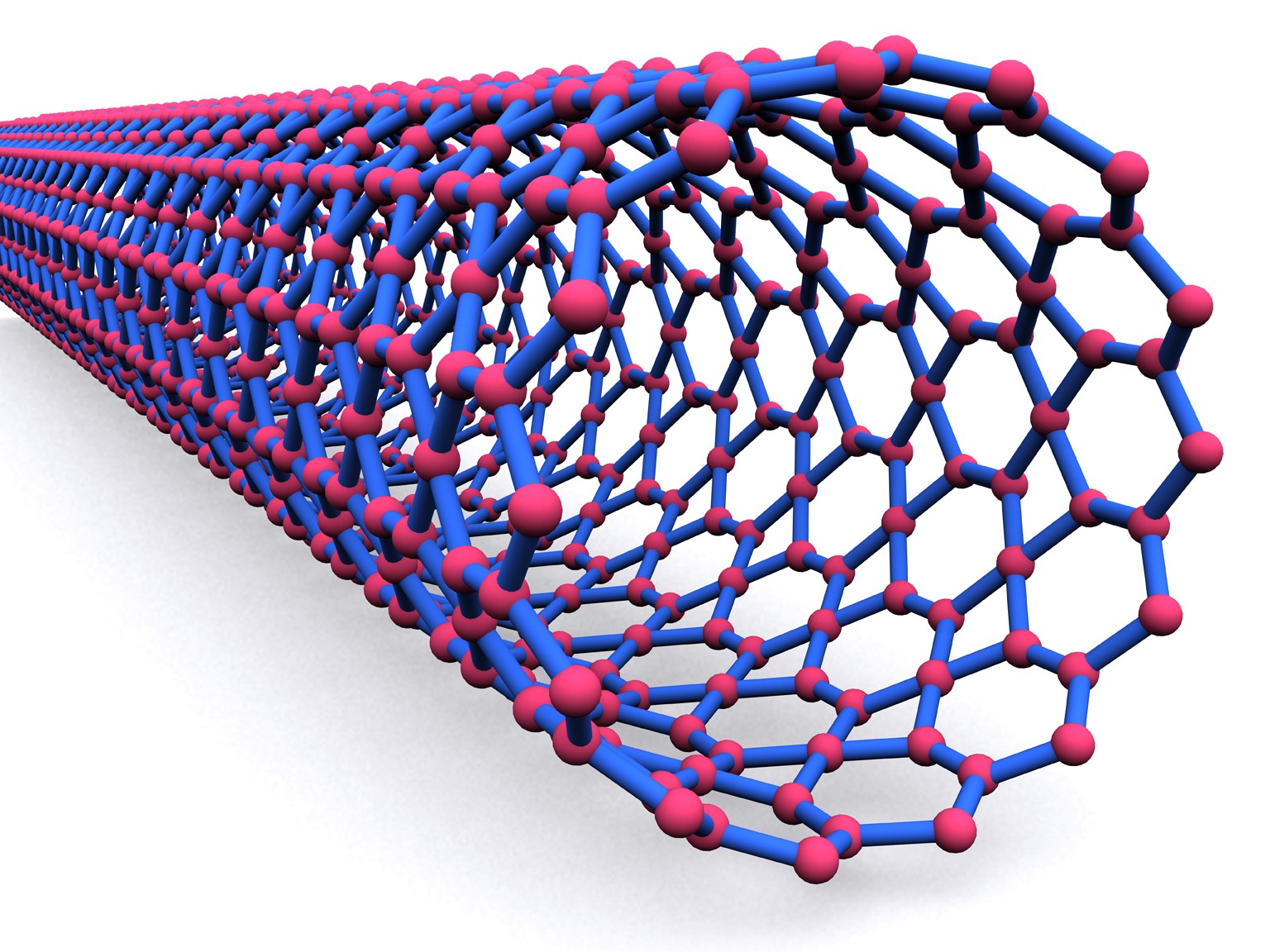

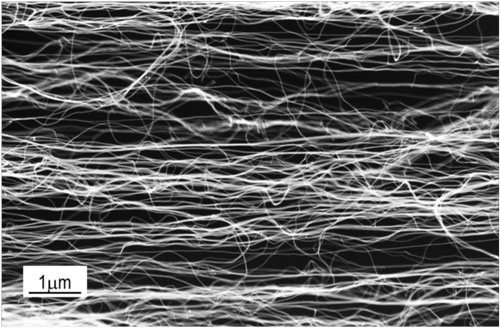

Carbon nanotubes are allotropic modification of carbon in the form of graphene hollow cylindrical structures and with a diameter of tenths to several nanometers. Simply put - it is a huge molecule consisting of millions of carbon atoms located at the vertices of the structural elements of regular hexagonal shape.

As a material, carbon nanotubes have an extremely high ratio of strength to density. The strength coefficient of the tubes is from 1 to 100 GPa (the strength coefficient of steel is 500–3000 MPa), and the density of the material is slightly higher than the density of water - 1.35 g / cu. see. At the moment, the nanotube fiber is the thinnest known, the thickness of this fiber is 30,000 times smaller than the average thickness of a human hair. Another important (especially for acoustic use) feature of nanotubes is their rapid heating under the influence of alternating electric current and low heat capacity.

Due to their properties, nanotubes have found practical application in a huge number of areas. I will cite only a small part: heavy-duty threads, nanobalance, gas detection sensors, medicine in general, and surgery in particular, energy generators and engines, artificial muscles, current sources, and more. etc. One of the most ambitious projects related to nanotubes is a cable for a space elevator. Although, in a number of publications, such their use is questioned, due to a significant loss of strength during fiber creation.

Unlike the space elevator, there is no doubt about the effectiveness of using nanotubes to create acoustic emitters of high fidelity. Prototypes of such speakers have already been created for experimental purposes. But efficiency is one thing, serial production is another.

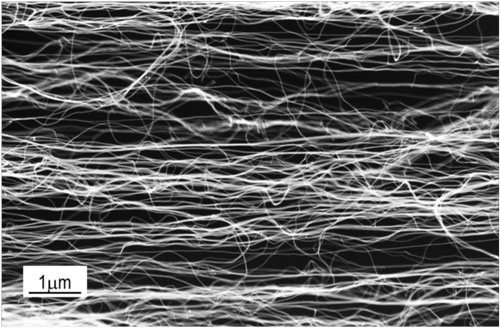

The key point for using the acoustic properties of nanotubes was the year 1991, when they managed to create several types (single-layer and multi-layer) of transparent carbon films.

It should be noted that the acoustic properties of carbon nanotubes were discovered by chance. Numerous experiments with a relatively new material led to the conclusion that nanotube sheets can emit sound waves under the influence of alternating current.

In 2008, Chinese researchers under the general leadership of Kaili Jiang (Kaili Jiang) noticed that a sheet of nanotubes makes a sound under the influence of alternating current. After that, they applied a modulated music signal and realized that the sheet was capable of reproducing sound. Having sent a laser vibrometer (Polytech PSV 300-F) to a sheet, the scientists were surprised that the film used as a radiator did not move. Later it was found out that the sound appeared as a result of the rapid heating of the sheet, i.e. thermoacoustic process.

Interestingly, the very phenomenon of thermoacoustic effect is known from the end of the 19th century. His first detailed description was made by American scientists HD Arnold and IB Crandall in the article “The Thermophone as a Precision Source of Sound” published on July 1, 1917. At that time there were no materials with the help of which it would be at all useful to apply the thermoacoustic principle in practice.

The results of the Kylie Jiang team's research were published in the journal Nano Letters "Flexible, Stretchable, Transparent Carbon Nanotube Thin Film Loudspeakers." In the article, scientists described devices that successfully reproduced the music signal and sound from a microphone using a thermo-acoustic effect.

The maximum temperature of the sheet when the signal with a nominal power of 12 W (8 Ohms) was applied was 80 degrees Celsius. According to Kylie Jiang, it is possible to create similar loudspeakers with a less high temperature, but this was not implemented as part of the experiment. In this case, the radiators had a number of unique characteristics.

The publication of Chinese researchers was quoted for some time by the media. Media even predicted the imminent death of traditional speakers, but soon the innovation was safely forgotten. No known attempts to create serial drivers followed.

Despite the obvious advantages of nanotubes, as a material for membranes of acoustic emitters and thermoacoustic effects, this approach is not without drawbacks. The main problem is the cost of the nanotubes themselves.

Current wholesale prices for Chinese-made single-layer nanotubes range from $ 30 to $ 90 per gram. According to the claims of potential producers of acoustic products from this material, the existing prices deprive of the meaning of the release of budget products with their use.

Regarding the high end of the market, where the price could justify the "prestigious cost" of products is still more difficult. There already exist active electrostatic and orthodynamic emitters close and identical to the fiber of the nanotubes on the acoustic properties. At the same time, technological processes and equipment, which allow producing such acoustics, have been tested and have fully calculated economic efficiency. To introduce nanotubes, it is necessary to invest heavily in equipment, development, planning, without any commercial guarantees.

There are also technical nuances associated with the use of this type of emitters. First of all, there are still no published studies on reducing the temperature of the radiator's surface, although Kylie Jiang mentioned this possibility. On the other hand, if we compare the temperature of the film with the temperature of the plasma in ionophones (which are already being produced in series), even experienced prototypes of drivers with nanotubes look much safer.

American researcher of Russian origin Mikhail Kozlov from the University of Texas at Dallas in 2014 published a report on the creation of a prototype of the original hybrid emitter. Using nanotube films as a membrane, he developed a loudspeaker that used a thermo-acoustic effect and the traditional principle of a dynamic driver. According to the plan of the researcher, this approach will allow to solve some of the problems described above.

I sincerely hope that thermophones will appear on the mass market and will be mass-produced. From the studies of Jiang and Kozlov, it becomes clear that technology has a promising future, if it is brought to mind. The implementation problems described above are undoubtedly serious and complex. Meanwhile, 10 years have passed since the first publication about the appearance of the working prototype of the emitter Kylie Jiang, and during this time they could probably be solved.

I believe that there are other, less objective and less obvious reasons why they are not in a hurry to introduce this technology. These reasons include the reluctance of some market participants (with sufficient capacity to produce classic speakers) to lose ground in their segment. Unfortunately, contrary to popular beliefs, innovations are not always useful for business, especially if a lot of money is invested in archaic technology.

Jeans

In our catalog is presented A wide range of high fidelity speaker systems .

Photo content used:

www.nanowerk.com

pubs.acs.org

aip.scitation.org

In previous posts we have already described several well-known alternatives to speakers, such as electrostatic, iso / orthodynamic emitters and ionophones. In this material we will talk about, perhaps, the most high-tech and original replacement for the dynamic drivers we are used to — the radiators created on the basis of nanotubes.

Something about nanotubes

Carbon nanotubes are allotropic modification of carbon in the form of graphene hollow cylindrical structures and with a diameter of tenths to several nanometers. Simply put - it is a huge molecule consisting of millions of carbon atoms located at the vertices of the structural elements of regular hexagonal shape.

As a material, carbon nanotubes have an extremely high ratio of strength to density. The strength coefficient of the tubes is from 1 to 100 GPa (the strength coefficient of steel is 500–3000 MPa), and the density of the material is slightly higher than the density of water - 1.35 g / cu. see. At the moment, the nanotube fiber is the thinnest known, the thickness of this fiber is 30,000 times smaller than the average thickness of a human hair. Another important (especially for acoustic use) feature of nanotubes is their rapid heating under the influence of alternating electric current and low heat capacity.

Due to their properties, nanotubes have found practical application in a huge number of areas. I will cite only a small part: heavy-duty threads, nanobalance, gas detection sensors, medicine in general, and surgery in particular, energy generators and engines, artificial muscles, current sources, and more. etc. One of the most ambitious projects related to nanotubes is a cable for a space elevator. Although, in a number of publications, such their use is questioned, due to a significant loss of strength during fiber creation.

Unlike the space elevator, there is no doubt about the effectiveness of using nanotubes to create acoustic emitters of high fidelity. Prototypes of such speakers have already been created for experimental purposes. But efficiency is one thing, serial production is another.

The key point for using the acoustic properties of nanotubes was the year 1991, when they managed to create several types (single-layer and multi-layer) of transparent carbon films.

Thermoacoustic emitters with a nanotube membrane

It should be noted that the acoustic properties of carbon nanotubes were discovered by chance. Numerous experiments with a relatively new material led to the conclusion that nanotube sheets can emit sound waves under the influence of alternating current.

In 2008, Chinese researchers under the general leadership of Kaili Jiang (Kaili Jiang) noticed that a sheet of nanotubes makes a sound under the influence of alternating current. After that, they applied a modulated music signal and realized that the sheet was capable of reproducing sound. Having sent a laser vibrometer (Polytech PSV 300-F) to a sheet, the scientists were surprised that the film used as a radiator did not move. Later it was found out that the sound appeared as a result of the rapid heating of the sheet, i.e. thermoacoustic process.

Interestingly, the very phenomenon of thermoacoustic effect is known from the end of the 19th century. His first detailed description was made by American scientists HD Arnold and IB Crandall in the article “The Thermophone as a Precision Source of Sound” published on July 1, 1917. At that time there were no materials with the help of which it would be at all useful to apply the thermoacoustic principle in practice.

The results of the Kylie Jiang team's research were published in the journal Nano Letters "Flexible, Stretchable, Transparent Carbon Nanotube Thin Film Loudspeakers." In the article, scientists described devices that successfully reproduced the music signal and sound from a microphone using a thermo-acoustic effect.

The maximum temperature of the sheet when the signal with a nominal power of 12 W (8 Ohms) was applied was 80 degrees Celsius. According to Kylie Jiang, it is possible to create similar loudspeakers with a less high temperature, but this was not implemented as part of the experiment. In this case, the radiators had a number of unique characteristics.

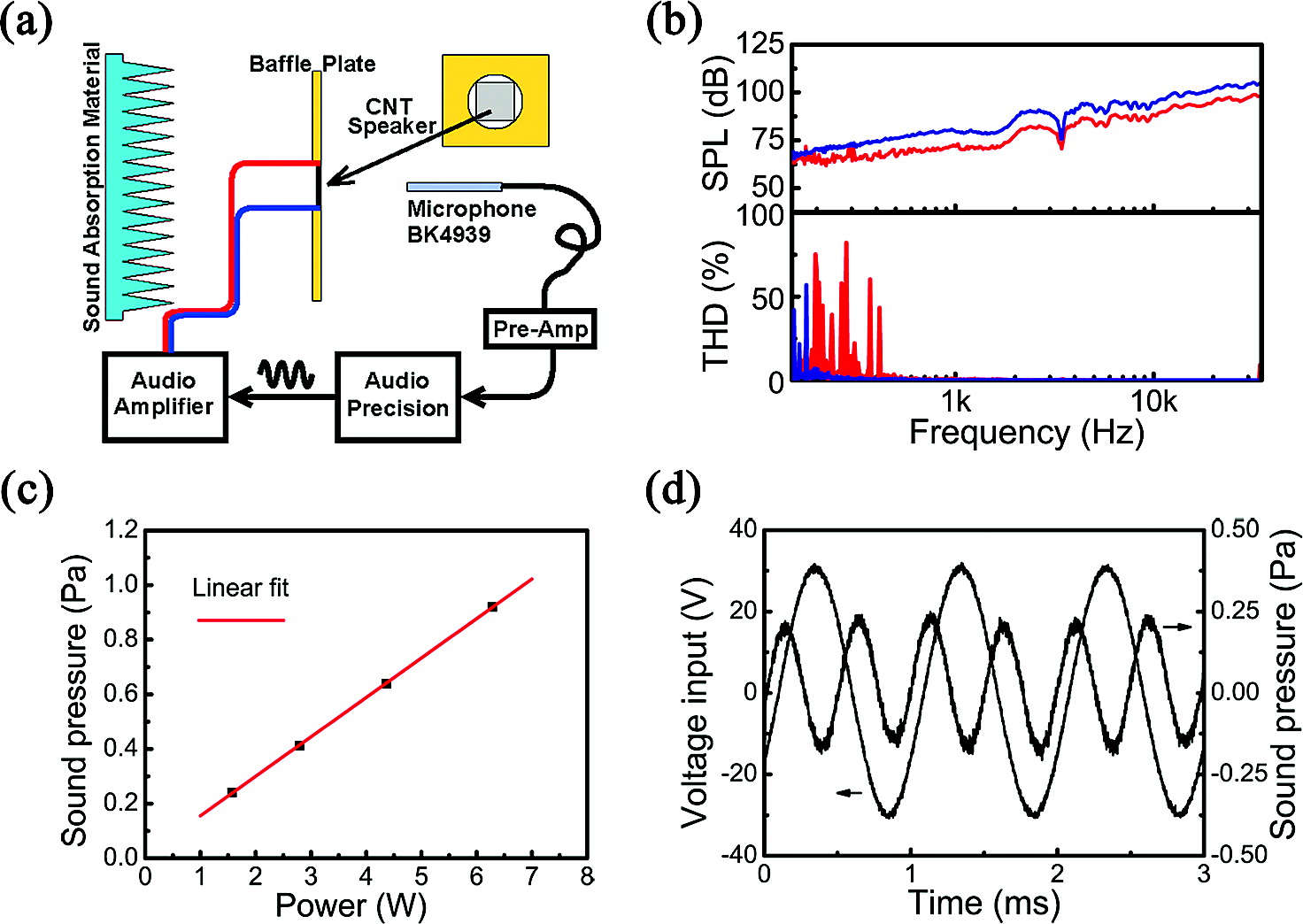

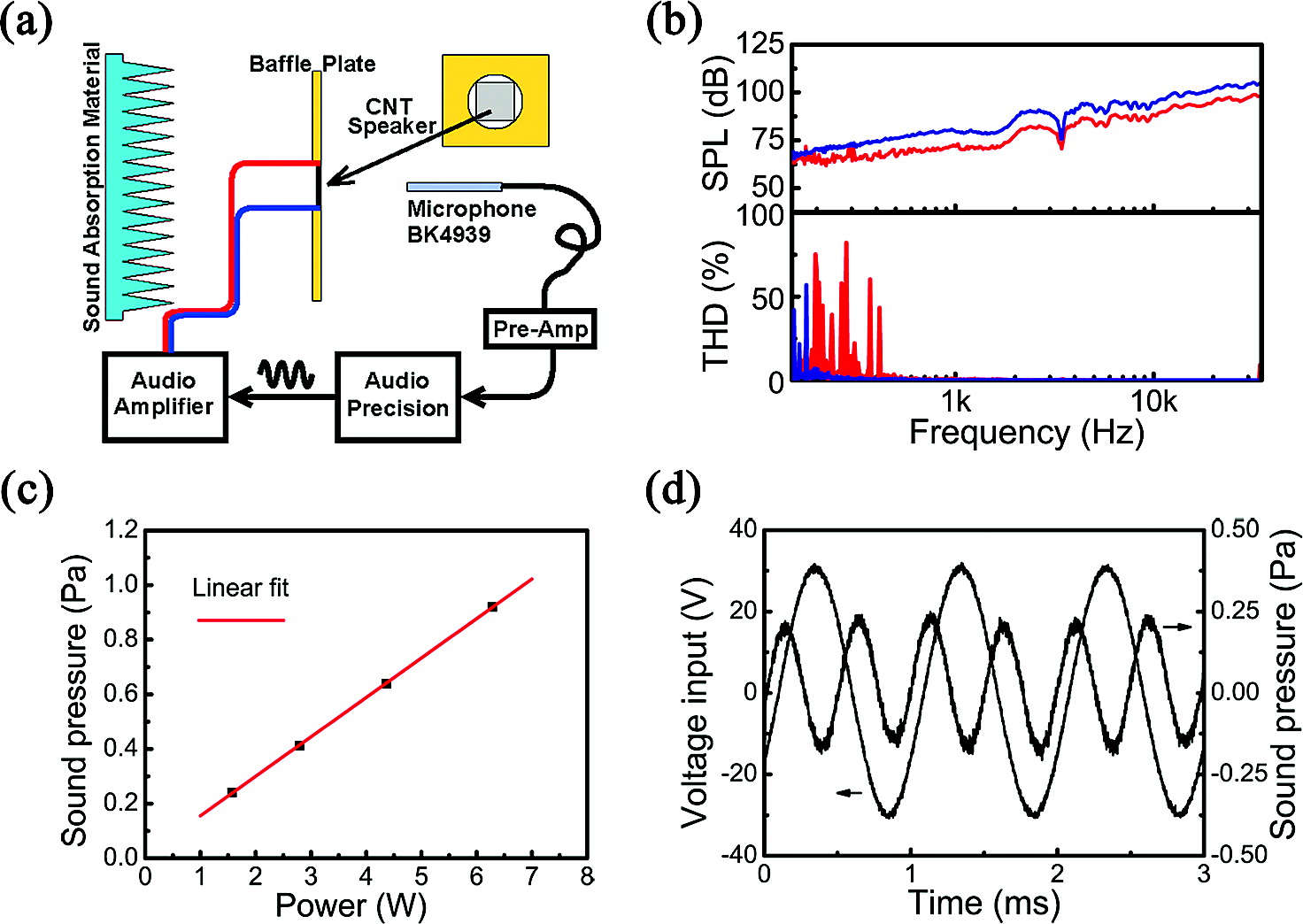

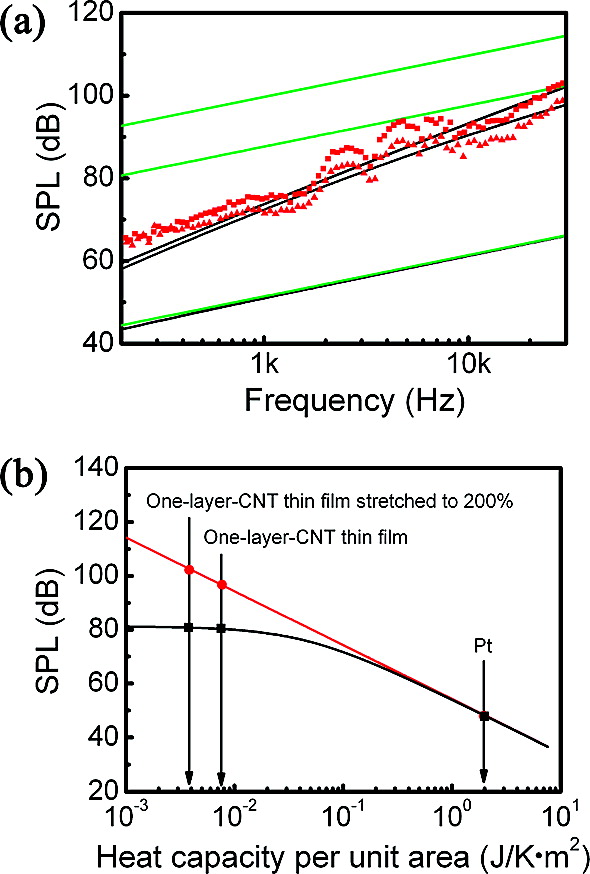

Photo 2 Testing the acoustic characteristics of a CNT thin-film speaker. (a) Schematic illustration of an experimental setup. (b) The sound pressure level (in dB) and the total harmonic distortion of the single-layer (red) and four-layer (blue) CNT loudspeakers at a distance of 5 cm between the loudspeaker and the microphone. Input power is 3 watts and 12 watts for single-layer and four-layer loudspeakers, respectively. © Sound pressure generated by a four-layer CNT loudspeaker, depending on the input power, indicating a linear relationship. Black squares represent the experimental results, and the red line represents the appropriate result. (d) Real-time signals for the input voltage of a four-layer CNT thin-film loudspeaker and output sound pressure from a microphone, indicating that the sound pressure frequency doubles the frequency of the input voltage. (C) Nano LettersIn the course of the experiments described, it was recorded that the emitter allows generating sound with a frequency range and a sound pressure level (SPL) sufficient for use in modern portable and stationary acoustic technology. In addition, the prototype had an impressively low level of harmonic distortion (THD).

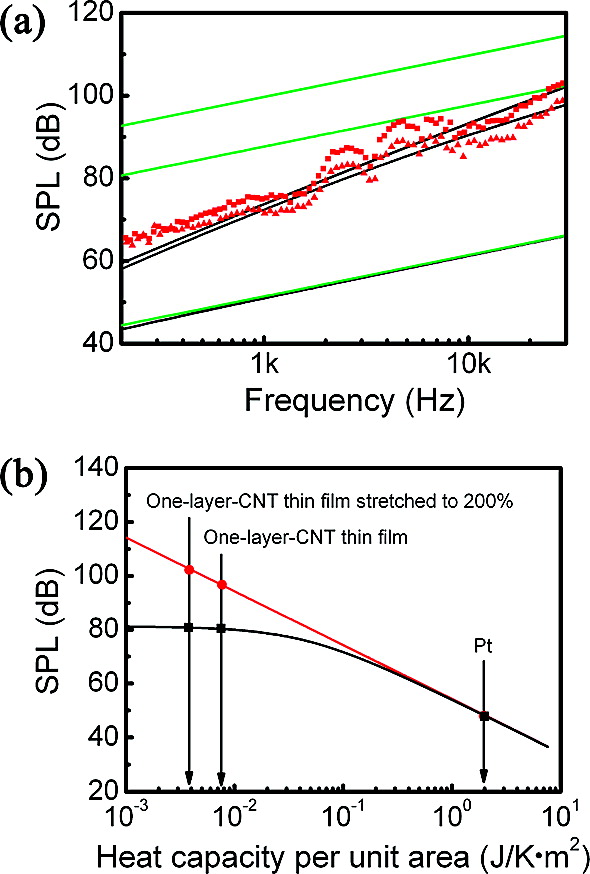

Theoretical and experimental data for thermo-acoustic thin-film loudspeakers. (a) Theoretical and experimental results of SPL compared with the operator of thermo-acoustic thin-film loudspeakers. The experimental data are represented by red solid squares and triangles for single-layer and four-layer thin films of CNT, respectively. Green lines and black lines - SPL, calculated according to the theory of Arnold and Krendall (eq. 1) and our theories (eq. 2), respectively, for single-layer (upper) and four-layer (middle) loudspeakers CNT and thickness of 700 nm Pt thermophone (lower). Input power is 4.5 watts. (B) The dependence of the SPL (at 10 kHz with an input power of 1 W) on HCPUAC s is calculated according to the theory of Arnold and Crandall (eq 1, red line) and our theory (eq., 2, black line), respectively. (C) Nano LettersThe article noted that the sheet used as a membrane is transparent and flexible. Kylie Jiang mentioned that it can be deformed without significant damage to the quality of the sound. It was also found that a film of nanotubes placed on a cylindrical frame, allows you to emit sound of equal intensity in all directions. An interesting feature that refutes some of the conclusions of Arnold and Krendel, is that when the film is stretched (200% of the original area), the signal remains almost unchanged.

The publication of Chinese researchers was quoted for some time by the media. Media even predicted the imminent death of traditional speakers, but soon the innovation was safely forgotten. No known attempts to create serial drivers followed.

Problems introducing thermophones

Despite the obvious advantages of nanotubes, as a material for membranes of acoustic emitters and thermoacoustic effects, this approach is not without drawbacks. The main problem is the cost of the nanotubes themselves.

Current wholesale prices for Chinese-made single-layer nanotubes range from $ 30 to $ 90 per gram. According to the claims of potential producers of acoustic products from this material, the existing prices deprive of the meaning of the release of budget products with their use.

Regarding the high end of the market, where the price could justify the "prestigious cost" of products is still more difficult. There already exist active electrostatic and orthodynamic emitters close and identical to the fiber of the nanotubes on the acoustic properties. At the same time, technological processes and equipment, which allow producing such acoustics, have been tested and have fully calculated economic efficiency. To introduce nanotubes, it is necessary to invest heavily in equipment, development, planning, without any commercial guarantees.

There are also technical nuances associated with the use of this type of emitters. First of all, there are still no published studies on reducing the temperature of the radiator's surface, although Kylie Jiang mentioned this possibility. On the other hand, if we compare the temperature of the film with the temperature of the plasma in ionophones (which are already being produced in series), even experienced prototypes of drivers with nanotubes look much safer.

Kozlov hybrids

American researcher of Russian origin Mikhail Kozlov from the University of Texas at Dallas in 2014 published a report on the creation of a prototype of the original hybrid emitter. Using nanotube films as a membrane, he developed a loudspeaker that used a thermo-acoustic effect and the traditional principle of a dynamic driver. According to the plan of the researcher, this approach will allow to solve some of the problems described above.

image of a multi-layered sheet of carbon nanotubes used for a thermomagnetic sound transducer. (Image: Mikhail Kozlov, University of Texas at Dallas).According to the scientist, he managed to combine the advantages of thermo-acoustic and dynamic drivers. The idea proposed by Kozlov is the placement of a carbon nanotube sheet between conductive rods next to a permanent magnet. When electrically excited, the thermal response of the material is combined with sheet vibrations caused by the electromagnetic action of the Lorentz force. As a result, the design allows to obtain hybrid thermomagnetic radiation of sound waves, with a relatively low level of distortion and impressive amplitude characteristics that are superior to the Chinese thermophones described above.

Total

I sincerely hope that thermophones will appear on the mass market and will be mass-produced. From the studies of Jiang and Kozlov, it becomes clear that technology has a promising future, if it is brought to mind. The implementation problems described above are undoubtedly serious and complex. Meanwhile, 10 years have passed since the first publication about the appearance of the working prototype of the emitter Kylie Jiang, and during this time they could probably be solved.

I believe that there are other, less objective and less obvious reasons why they are not in a hurry to introduce this technology. These reasons include the reluctance of some market participants (with sufficient capacity to produce classic speakers) to lose ground in their segment. Unfortunately, contrary to popular beliefs, innovations are not always useful for business, especially if a lot of money is invested in archaic technology.

Jeans

In our catalog is presented A wide range of high fidelity speaker systems .

Photo content used:

www.nanowerk.com

pubs.acs.org

aip.scitation.org

All Articles