It is easy to choose DSU monitoring! .. Or not?

Alas, the answer is ambiguous - both yes and no. Of course, it’s easy to choose something, but getting confused is even easier. So, about how not to get confused, and will be discussed.

DGU you or other equipment - a universal solution for remote monitoring and control, which is suitable for everyone, can do everything and is cheap, does not exist. There are always restrictions. One option offers a meager set of functions, but for pennies, the other way around - requires a high price, but for great features. And between them there will be countless variations that combine functionality and price in different proportions. And it seems that one can easily get lost in this sea of solutions. Although…

But in fact, everything is simpler, because there are only 3 possible solutions , and they can be sorted out.

Before we talk about the promised three solutions, we should look back at the tasks that we solve, i.e. on the reasons why we all decided to start it all. After all, the correct sequence, from the point of view of causal relationships (ie, logic), is to select monitoring for a specific situation, and not to adjust to any monitoring system yourself. Therefore, the choice of a remote monitoring system ( RMON ) will always depend on the equipment you need to monitor and control, as well as what data you want to monitor, and what parameters you want to remotely control.

Why did we spend the time on the previous paragraph? Yes, because it is a very common mistake.

So - first we analyze our tasks and our equipment. Speaking about the monitoring of the DSU, we will most likely talk about one of the following sets of equipment:

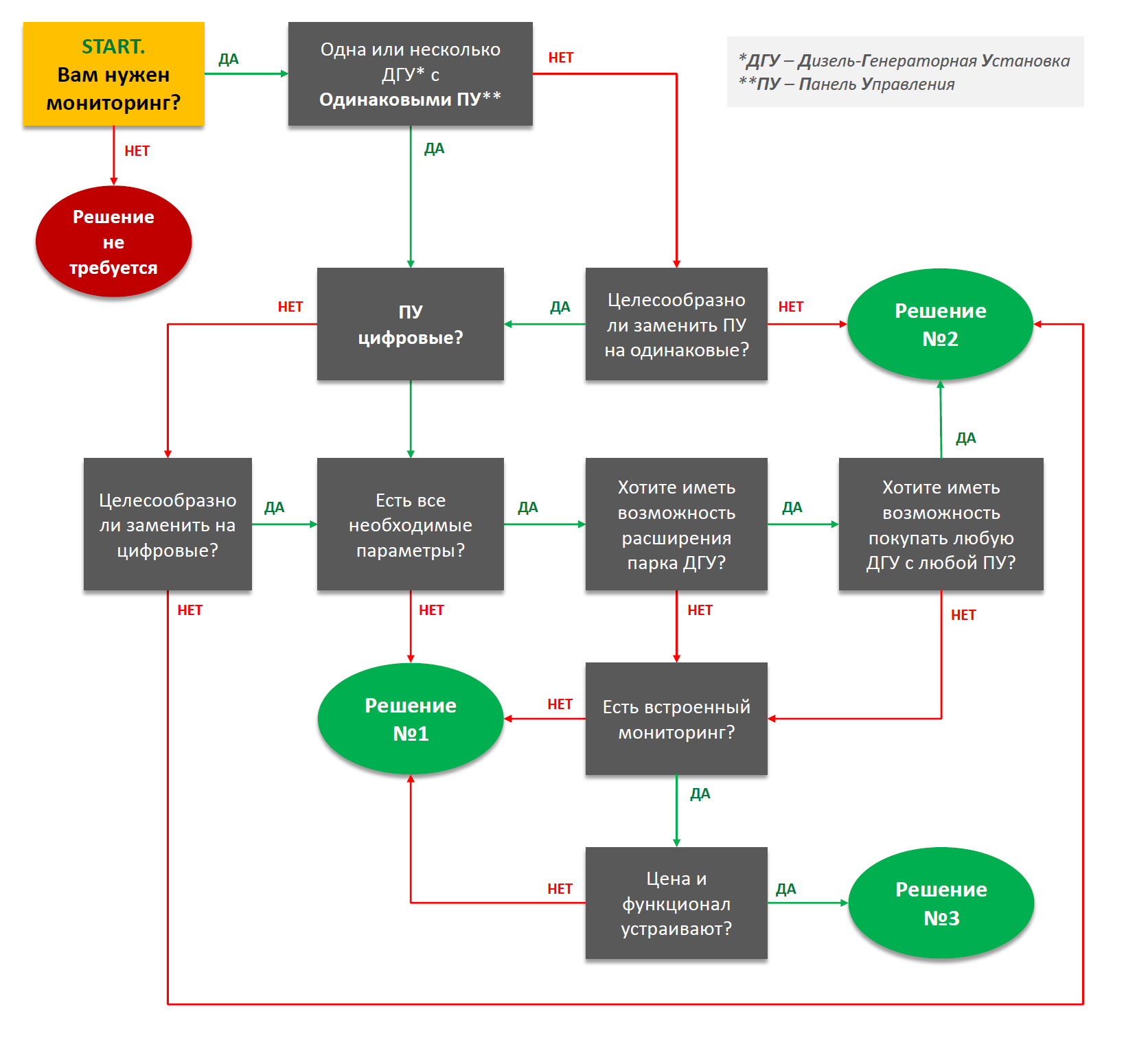

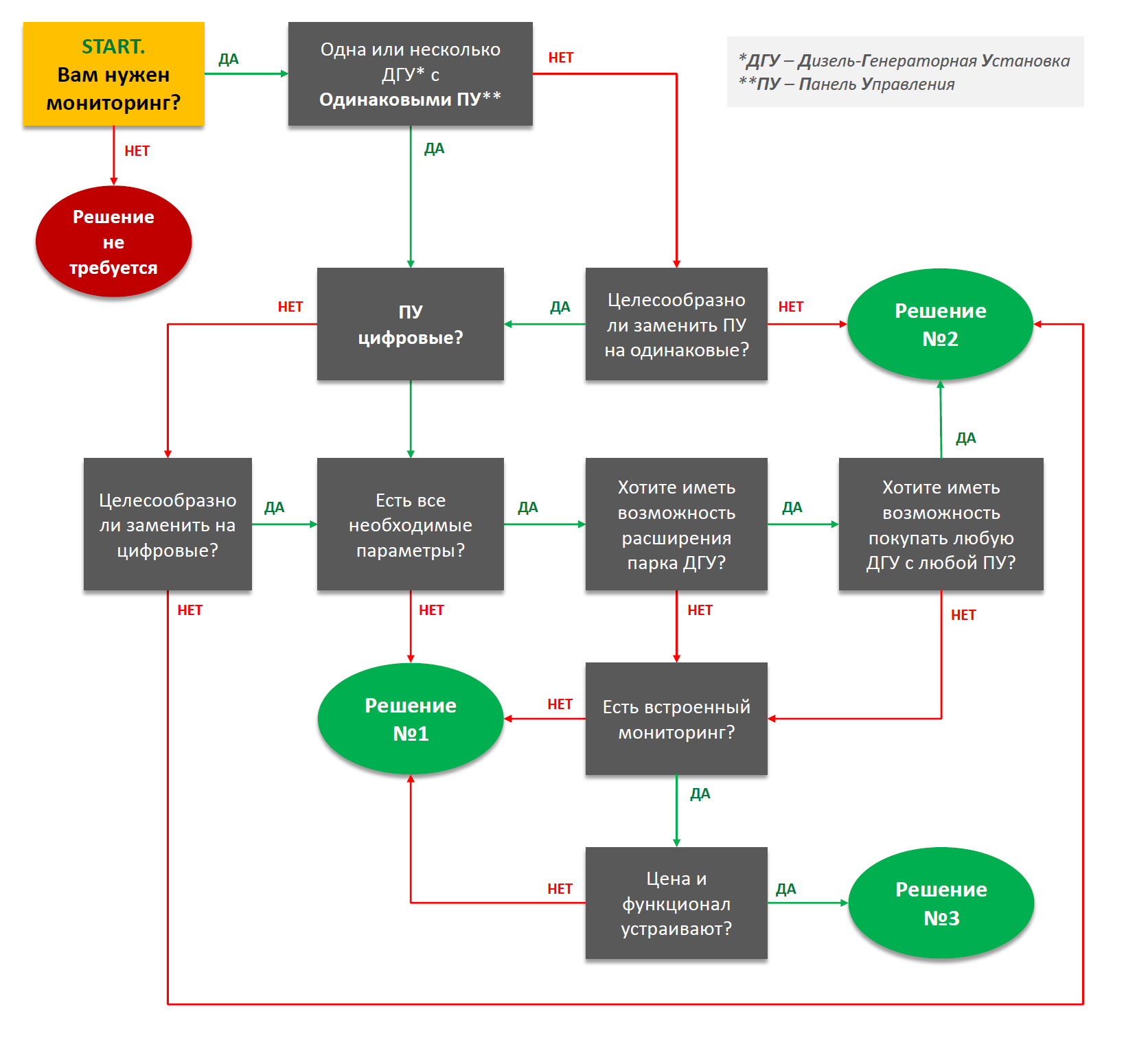

For each of the sets of equipment there are different approaches to the organization of monitoring, which can be summarized in one scheme of 3 solutions:

In cases when you have 1 DGU or several identical DGS, and the use of the built-in monitoring system is impossible or impractical, third-party automation controllers OWEN, Moxa, Wiren Board, Wago, and the like are in a hurry. If the PU is analog, then you will need another set of additional sensors and transducers to get the necessary digital signals from the necessary system nodes. But the controller, sensors, and other "hardware" of the lower level cannot solve the monitoring problem - you need to either find a programmer who will connect the controller with the operator's post, with other systems, configure the interface and upload data, etc.

Or you can immediately pick up a simple typical solution, based on possibly the same controllers, where everything you need to monitor and control the same digital PUs will already be included. For DGU, such companies as Axitech, Svyaz Engineering M, Hited , ICBcom, etc. are engaged in such ready-made model variants. By and large, this is already becoming one of the special cases of Decision No. 2, therefore in case something more is needed than by monitoring the state of a DGS state, in some cases, one can consider both solutions, and then stop at one of them.

Versatile options that can work with any power plants and with any control panels, both analog and digital. These solutions were originally created for the parks of equipment from different manufacturers, taking into account the need to make friends with each other different brands, different types of PU. They combine hardware and software of both the lower level (controllers, sensors, communication devices, processing programs and data coding) and the upper level (server, processing programs and information output, databases, user interfaces, mobile applications, etc.) .

In this direction, whole software and hardware complexes are offered, for example, ComAp, Netbiter, RedPine , Aries, etc. Such monitoring systems are often called “turnkey solutions”, and they can be typical (base + options), and can be developed individually for specific projects. One of the important advantages of these systems, besides their universality, should be the possibility of scaling and modernization. The larger and more diverse the fleet of equipment, the more convenient and more profitable to use such monitoring systems.

In this case, you can use the built-in monitoring already installed in the electronic PU from the manufacturer of the DGS itself (for example, Cummins, SDMO, FG Wilson), or from the manufacturer of the PU (for example, ComAp, Datakom, SmartGen). Sometimes it is really beneficial, especially when it comes to the fact that we need simple monitoring of one or two identical stations standing nearby. But the more stations and the more parameters you need to keep track of, the less convenient and profitable this option becomes - here you have to carefully count and compare everything before making a decision.

Separately, it should be mentioned that the use of embedded monitoring systems limits the user in purchasing a new station (expanding or replacing the current one) - he will have to choose the same equipment to continue using the monitoring system, i.e. This is an additional factor binding the user to the brand, which is very unprofitable in the future.

There is no initially bad or good solution - each of them may be optimal for various different tasks. But there is a wrong choice of the type of solution, and here the main thing is not to confuse, but instead of simplifying life, it will only become more difficult. Therefore, it is extremely undesirable to confuse and compare among themselves the options of the various types of solutions directly, without regard to the peculiarities of each particular case. For example, if any “expert”, without analyzing the problem, says that in any case it is necessary to choose an automation controller just because it is cheaper than a ready-made monitoring complex (where the same controller is just a node), then smile, carefully agree and nod, politely say goodbye, and then appeal to those who really understand the subject.

Perhaps this article will not help to finally select the appropriate monitoring option, but it certainly will help someone to understand the solutions offered by the market. If you look at the proposals of various companies involved in the sale of monitoring systems, you may get the impression that everyone offers some kind of unique solution. In fact, these are special cases of those 3 decisions that we talked about, flavored with juggling with terms, a desire to stand out among competitors and other marketing tricks.

To make life easier

It seems that this is some kind of banal truth, known to everyone? Alas, in real conditions, many people confuse the cause with the effect and start not by analyzing their task, but by comparing different types of solutions among themselves, comparing products from different types of solutions (controller and hardware-software complex), forgetting why all this is necessary, confusing really important things with unnecessary tinsel. As a result, the most correct option can be discarded at the initial stage, and the average or frankly bad one can become your new headache for many years.

DGU you or other equipment - a universal solution for remote monitoring and control, which is suitable for everyone, can do everything and is cheap, does not exist. There are always restrictions. One option offers a meager set of functions, but for pennies, the other way around - requires a high price, but for great features. And between them there will be countless variations that combine functionality and price in different proportions. And it seems that one can easily get lost in this sea of solutions. Although…

But in fact, everything is simpler, because there are only 3 possible solutions , and they can be sorted out.

Cause and investigation

Before we talk about the promised three solutions, we should look back at the tasks that we solve, i.e. on the reasons why we all decided to start it all. After all, the correct sequence, from the point of view of causal relationships (ie, logic), is to select monitoring for a specific situation, and not to adjust to any monitoring system yourself. Therefore, the choice of a remote monitoring system ( RMON ) will always depend on the equipment you need to monitor and control, as well as what data you want to monitor, and what parameters you want to remotely control.

Why did we spend the time on the previous paragraph? Yes, because it is a very common mistake.

So - first we analyze our tasks and our equipment. Speaking about the monitoring of the DSU, we will most likely talk about one of the following sets of equipment:

- One diesel generator with analog or digital control panel

- Several DGS with the same control panels (the same model)

- Several DGUs with different control panels (different brands, types, models)

3 promised decisions

For each of the sets of equipment there are different approaches to the organization of monitoring, which can be summarized in one scheme of 3 solutions:

Decision number 1

In cases when you have 1 DGU or several identical DGS, and the use of the built-in monitoring system is impossible or impractical, third-party automation controllers OWEN, Moxa, Wiren Board, Wago, and the like are in a hurry. If the PU is analog, then you will need another set of additional sensors and transducers to get the necessary digital signals from the necessary system nodes. But the controller, sensors, and other "hardware" of the lower level cannot solve the monitoring problem - you need to either find a programmer who will connect the controller with the operator's post, with other systems, configure the interface and upload data, etc.

Or you can immediately pick up a simple typical solution, based on possibly the same controllers, where everything you need to monitor and control the same digital PUs will already be included. For DGU, such companies as Axitech, Svyaz Engineering M, Hited , ICBcom, etc. are engaged in such ready-made model variants. By and large, this is already becoming one of the special cases of Decision No. 2, therefore in case something more is needed than by monitoring the state of a DGS state, in some cases, one can consider both solutions, and then stop at one of them.

Decision number 2

Versatile options that can work with any power plants and with any control panels, both analog and digital. These solutions were originally created for the parks of equipment from different manufacturers, taking into account the need to make friends with each other different brands, different types of PU. They combine hardware and software of both the lower level (controllers, sensors, communication devices, processing programs and data coding) and the upper level (server, processing programs and information output, databases, user interfaces, mobile applications, etc.) .

In this direction, whole software and hardware complexes are offered, for example, ComAp, Netbiter, RedPine , Aries, etc. Such monitoring systems are often called “turnkey solutions”, and they can be typical (base + options), and can be developed individually for specific projects. One of the important advantages of these systems, besides their universality, should be the possibility of scaling and modernization. The larger and more diverse the fleet of equipment, the more convenient and more profitable to use such monitoring systems.

Decision number 3

In this case, you can use the built-in monitoring already installed in the electronic PU from the manufacturer of the DGS itself (for example, Cummins, SDMO, FG Wilson), or from the manufacturer of the PU (for example, ComAp, Datakom, SmartGen). Sometimes it is really beneficial, especially when it comes to the fact that we need simple monitoring of one or two identical stations standing nearby. But the more stations and the more parameters you need to keep track of, the less convenient and profitable this option becomes - here you have to carefully count and compare everything before making a decision.

Separately, it should be mentioned that the use of embedded monitoring systems limits the user in purchasing a new station (expanding or replacing the current one) - he will have to choose the same equipment to continue using the monitoring system, i.e. This is an additional factor binding the user to the brand, which is very unprofitable in the future.

The main thing is not to confuse!

There is no initially bad or good solution - each of them may be optimal for various different tasks. But there is a wrong choice of the type of solution, and here the main thing is not to confuse, but instead of simplifying life, it will only become more difficult. Therefore, it is extremely undesirable to confuse and compare among themselves the options of the various types of solutions directly, without regard to the peculiarities of each particular case. For example, if any “expert”, without analyzing the problem, says that in any case it is necessary to choose an automation controller just because it is cheaper than a ready-made monitoring complex (where the same controller is just a node), then smile, carefully agree and nod, politely say goodbye, and then appeal to those who really understand the subject.

What is the result?

Perhaps this article will not help to finally select the appropriate monitoring option, but it certainly will help someone to understand the solutions offered by the market. If you look at the proposals of various companies involved in the sale of monitoring systems, you may get the impression that everyone offers some kind of unique solution. In fact, these are special cases of those 3 decisions that we talked about, flavored with juggling with terms, a desire to stand out among competitors and other marketing tricks.

To make life easier

- Always proceed from your task, your needs, your wishes.

- Then choose the type of solution that can solve all your tasks as accurately as possible and fulfill all your wishes.

- And only then choose the product within the chosen solution for functionality, price, conditions.

It seems that this is some kind of banal truth, known to everyone? Alas, in real conditions, many people confuse the cause with the effect and start not by analyzing their task, but by comparing different types of solutions among themselves, comparing products from different types of solutions (controller and hardware-software complex), forgetting why all this is necessary, confusing really important things with unnecessary tinsel. As a result, the most correct option can be discarded at the initial stage, and the average or frankly bad one can become your new headache for many years.

All Articles