Biogas from biomass. Part II

Almost three years ago I was doing an article about biogas research that we conducted in Tomsk. The article at that time caused considerable interest, and even now I receive emails asking for more details about this technology and the prospects for its practical implementation. We did not abandon the development of this topic, a lot of interesting thoughts and news have accumulated, which I would like to tell about, therefore we are interested in mercy, please, under cat.

Almost three years ago I was doing an article about biogas research that we conducted in Tomsk. The article at that time caused considerable interest, and even now I receive emails asking for more details about this technology and the prospects for its practical implementation. We did not abandon the development of this topic, a lot of interesting thoughts and news have accumulated, which I would like to tell about, therefore we are interested in mercy, please, under cat.

What's new?

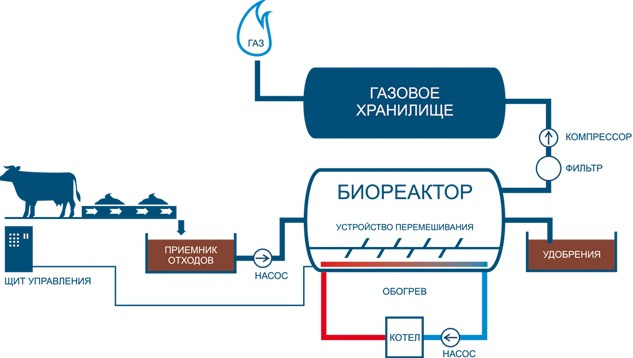

The most important news - the topic is still alive. The idea of recycling waste into something useful and even beneficial in itself warms the soul. I recall that biogas technologies allow the processing of organic waste (manure, sewage, etc.) into combustible gas and bio-fertilizer.

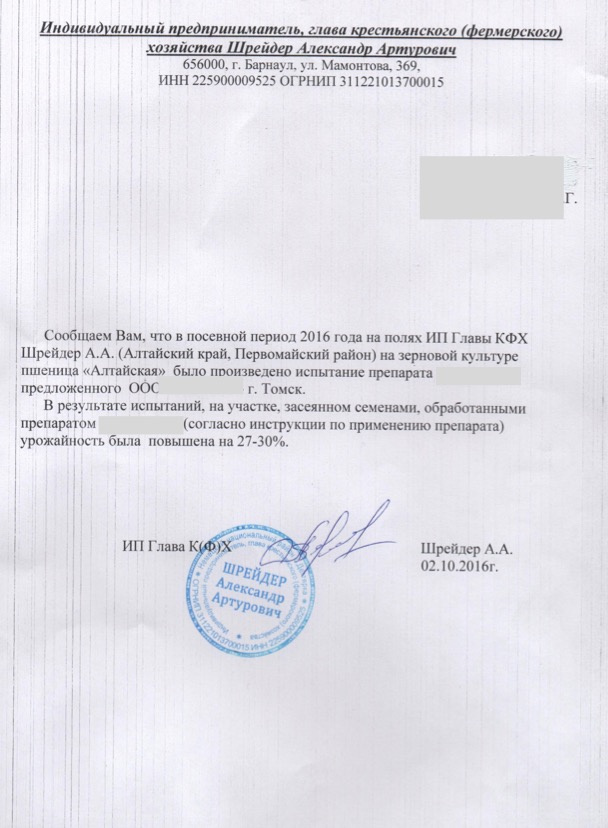

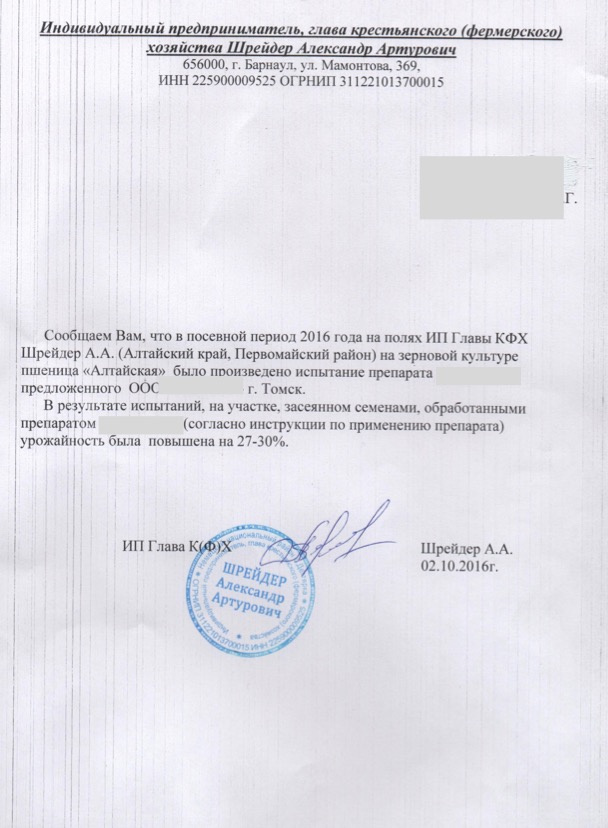

The resulting fertilizer can be used to increase the yield of almost any plant. For example, the increase in wheat yield, which was recorded in independent trials in Altai compared to the control plots where the fertilizer was not used, was about 30 percent.

Note

On the third! At the same time, the cost of fertilizers amounted to no more than 10 percent of the amount of additionally received profit, which in itself is an excellent result.

Recently, patents on the technology of accelerating the production of biogas have appeared, however, it is not yet possible to apply them in real installations, but the fact that development continues in this area is certainly pleasing. The most successful (in our opinion) is the technology described in another patent , the essence of which is to add plain water at different stages of the process, but with a modified redox potential. The authors are great that thoroughly understood the biological essence of the process.

Biogas or bio-fertilizers?

As before, I remain a supporter of the fact that biogas technologies are difficult to position as exclusively energy. First of all, these technologies are good for alleviating the ecological situation associated with the disposal of biological waste, which accumulates around agricultural enterprises a huge amount. This is a real problem, which in addition to environmental harm is often a catalyst for outbreaks of dangerous infections.

Of course, in the process of processing a large amount of biogas is released, but it requires thorough cleaning, drainage, compression, and with it more trouble than benefits. This is primarily associated with the production of electricity from biogas, which requires huge costs. Therefore, it is most reasonable, especially in Russia, to utilize biogas to heat, which can be used to maintain the biogas process itself and to heat buildings and structures. We are a cold country and warmth will always be necessary. If you do not use biogas to generate electricity, the construction of the biogas stations themselves becomes more profitable.

Research facility

It so happened that in the course of our research we needed manure in the amount of 40-50 kg per day for an experimental installation. We live in the city, we don’t have cows, we considered ourselves as a last resort as a source of biomass and we began to look for a supplier of manure. I had to carry manure from the suburbs. We come to the village and find a farmstead with cows. Winter. We knock on the door, the owner opens, and we ask him for manure. Astonishment in the eyes. Why do you guys need it? We say, they say, scientists, we do experiments. It is necessary. Go, says grandfather, for good on health. And if we buy? For 50 rubles for a bucket? After some time, legends began to circulate in a village near Tomsk that eccentrics driving out of town who paid money for ... Well, you understood. But problems with raw materials are solved.

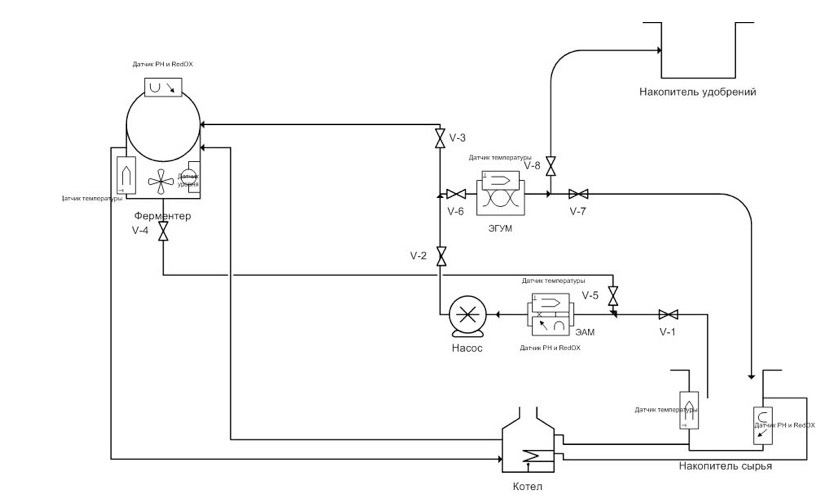

The installation consists of three specialized tanks, connected by pipelines to shut-off (controlled) valves (gate valves). The basis of the installation is a specialized tank of a certain volume, called a fermenter, and the installation also contains a tank for the sample preparation of raw materials, a process control and automation system. Automation and installation management system - proprietary. There is nothing particularly difficult in it.

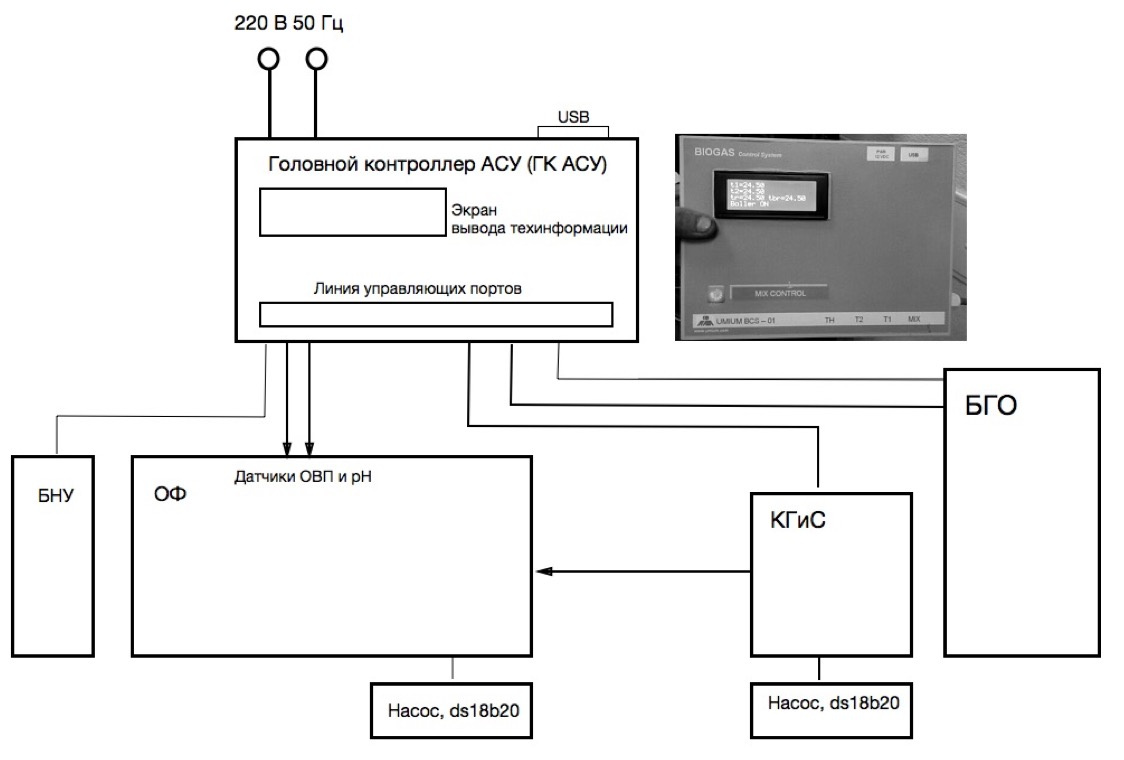

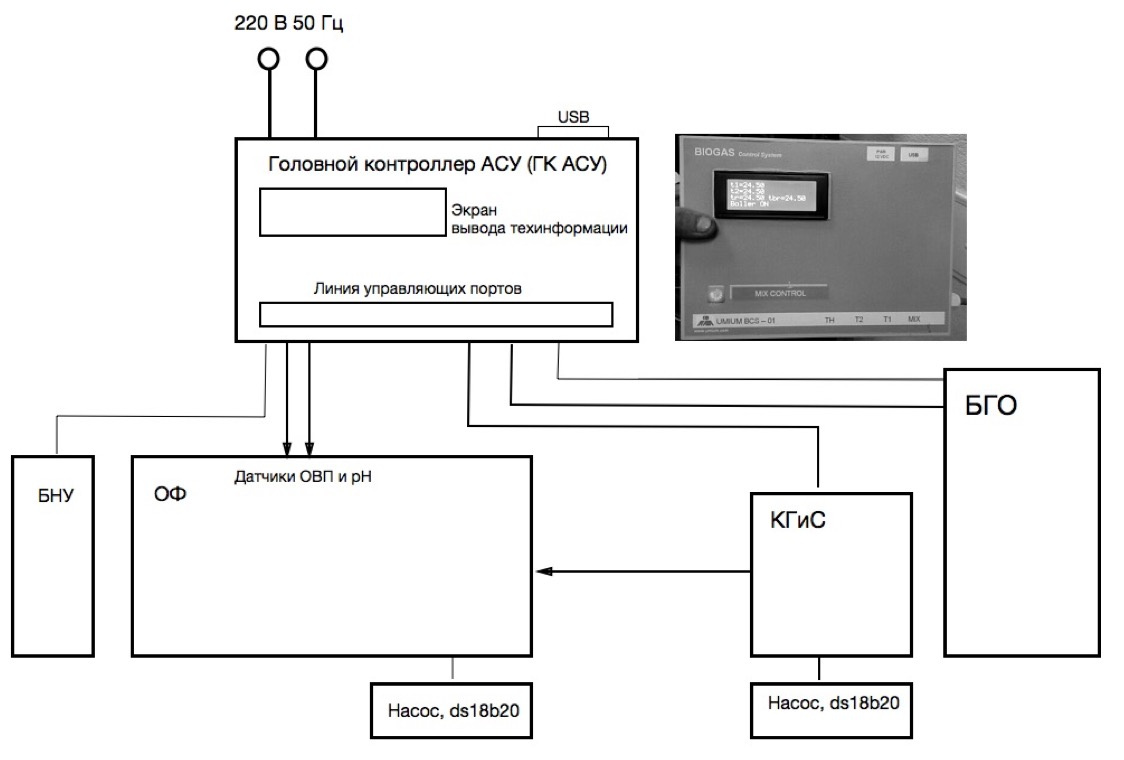

More about the controller

The process is controlled by the head controller of the ACS control panel, which has a screen for outputting technical information and all the necessary telemetry for normal operation of the equipment. GC ASU connects all the units through a serial asymmetric data bus. The ACS carries out continuous telemetry and control of the biogas treatment unit (BSU), including the following data captures:

- The temperature of the processed biomass in the homogenization chamber and sterilization CHG (limit 55 gr. C)

- Manages pumps for mixing and supplying biomass to the main fermenter OF

- Controls the temperature of the flow of a biological process of anaerobic fermentation in the limit of 39 degrees C (unit heating unit BNU contains electric boiler, solid-state relay 40 A and temperature sensor DS18B20 with an acceptable temperature of the boiler not more than 85 g. C)

- Collects data from conductivity sensors, redox potential and pH (RedOx potential no more than -100 mV, pH of the anaerobic stage of the process - 6.2)

- Logs all data

- Has a button for forced mixing of biomass, if necessary.

- It has a methane leak sensor and a system for emergency shutdown of equipment under various scenarios of developments, for example, from short-term power outages or loss of reliable grounding, surge voltage in the network, etc.

The process is controlled by the head controller of the ACS control panel, which has a screen for outputting technical information and all the necessary telemetry for normal operation of the equipment. GC ASU connects all the units through a serial asymmetric data bus. The ACS carries out continuous telemetry and control of the biogas treatment unit (BSU), including the following data captures:

- The temperature of the processed biomass in the homogenization chamber and sterilization CHG (limit 55 gr. C)

- Manages pumps for mixing and supplying biomass to the main fermenter OF

- Controls the temperature of the flow of a biological process of anaerobic fermentation in the limit of 39 degrees C (unit heating unit BNU contains electric boiler, solid-state relay 40 A and temperature sensor DS18B20 with an acceptable temperature of the boiler not more than 85 g. C)

- Collects data from conductivity sensors, redox potential and pH (RedOx potential no more than -100 mV, pH of the anaerobic stage of the process - 6.2)

- Logs all data

- Has a button for forced mixing of biomass, if necessary.

- It has a methane leak sensor and a system for emergency shutdown of equipment under various scenarios of developments, for example, from short-term power outages or loss of reliable grounding, surge voltage in the network, etc.

Fermenters are subject to installation and insulation for maximum conservation of thermal energy, especially if the installation will be further operated in an open area. The most important thing is to make a correct calculation of the volume of the main fermenter (of course, with some reserve).

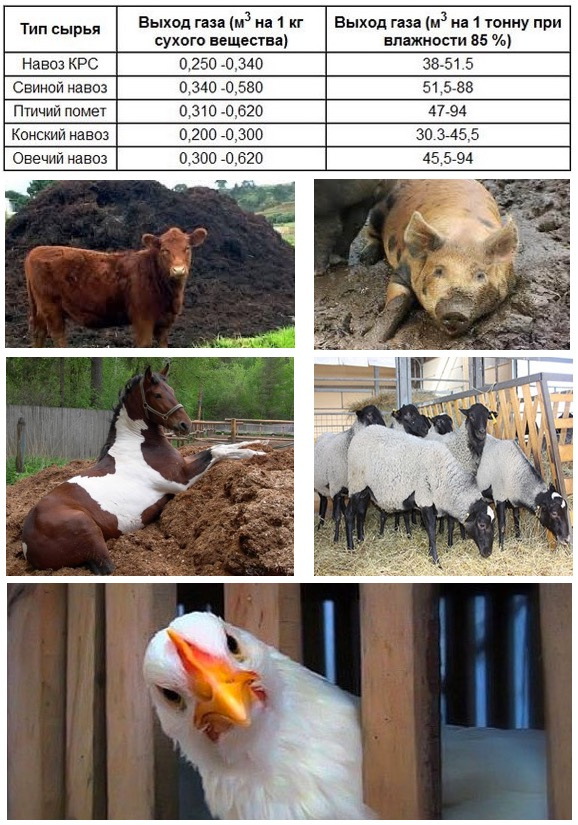

Of course, the output of biogas depends on the quality of the feedstock, if the term “quality” can be applied to the manure. But in fact, raw materials are essential. It is best of all that the raw material is free from impurities, extraneous contamination, free from mold and surfactants. The main law of a biogas plant is that the path of raw materials to loading should be as short as possible. The output of biogas from the manure of various animals, of course, is different. It depends on the characteristics of digestion, which determines the composition and structure of the waste.

Other organic waste may be added to the biogas station, such as cleaning vegetables, fruits, fresh grass, waste water, etc. It is even better that the raw materials for the station be a mixture of various wastes. This improves the processing process, makes it more stable, and the output of biogas is greater. At the same time on the same type of raw materials, for example, on clean pork drains or chicken manure, the process can stop altogether, since these substrates are highly toxic and they must be diluted with other wastes, providing buffering of the raw materials.

The gas coming out of the installation is called biogas. This is a combustible gas of complex composition. It contains two thirds of methane, the rest is carbon dioxide, hydrogen sulfide, impurities of hydrogen, ammonia, water vapor. The gas accumulates in a special gas-tight soft bag - gas-holder.

If the accumulated gas is cleared of carbon dioxide and other dangerous impurities, we obtain biomethane - a complete analogue of natural gas. However, biogas purification is an expensive procedure and is aimed, first of all, in order to get electricity or fill cars. If this task is not worth it, then biogas can be used without special purification to produce heat and hot water. For these purposes (in our opinion) it is most expedient to use biogas plants in our conditions.

Prospects for biogas technology

For Russia. And, of course, this is my personal opinion. For a start, I would divide this question into two parts. Industrial use of biogas technology and various private practices.

Industrial use of biogas technologies is developing poorly, in principle, due to the practical absence of good-quality technologies, legal vacuum in legislation and the most severe corruption. Of course, without the budget leverage, such technologies can not be adequately developed, but I don’t know how to turn around the corruption schemes of various actors from innovations under the brand of biogas development. There remains the direction of the use of biogas stations by private owners. Here we observe a certain Russian phenomenon, about which I would like to talk particularly. First of all, in the nature of our man, the principle is laid wherever possible never to pay for anything. At least substantial money. And the best freebie! This property is used by all kinds of crooks who have filled up Internet videos and sites with offers for three kopecks to build a biogas station, to get biogas in unlimited volumes and forget about all the problems. Such figures have discredited the very topic of biogas in Russia, which, by the way, is very actively developing now all over the world. Especially in China . Biogas plant can not be cheap.

This is all the same biotechnology, which has a number of features, requires modern controlling, a certain qualification of operators, etc. This is not a shed technology, it requires a new understanding of the essence of agricultural production, the principle of the continuity of all processes - from the preparation of raw materials, transportation, veterinary manipulation, manure removal, and ending with the marketing of bio-fertilizers and energy audit of production. Only in this case, biogas technology will give the desired effect. What is the point of enclosing biogas stations in old barns and agricultural enterprises of the last century? Why not make new projects of large livestock farms with the integration of all the most promising and interesting technologies that exist? After all, it is obvious that this is where the future success lies. Again - this is my opinion.

Fist effect

On the one hand, we see a large number of homemade biogas stations, on the other - a different phenomenon is observed. Fist effect What I mean? There are people who are engaged in farming. Such are the modern fists. Economic and responsible on the one hand, but independent on the other.

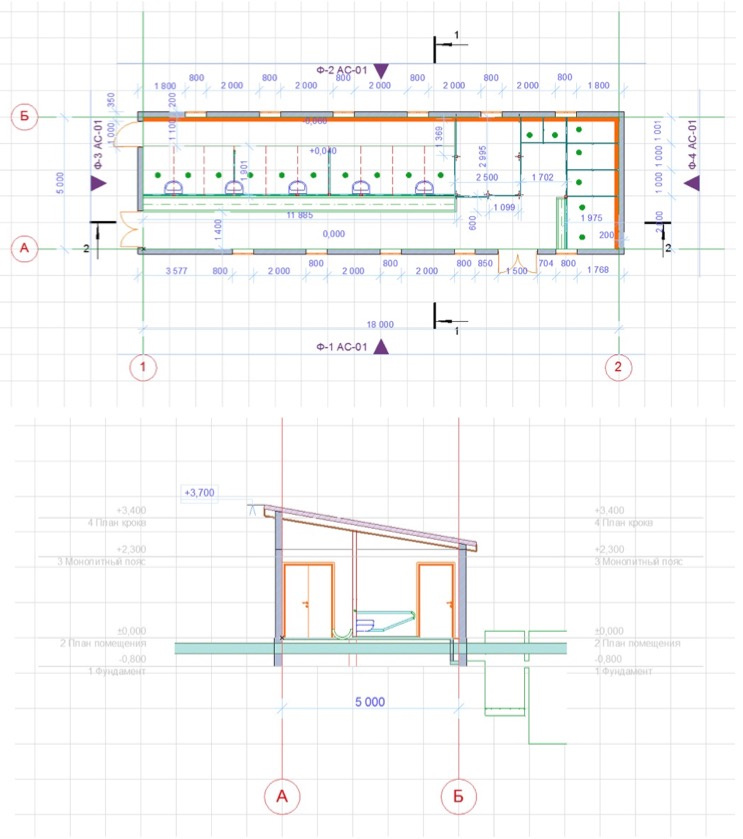

Such people give another request. They want to gain independence through a biogas plant. Gas for yourself, do not bow to anyone in the legs. Such people are willing to buy a good quality installation and expensive. It is on this unusual segment of consumers should pay special attention. In this regard, our group is now focused on creating a comprehensive solution - a mini-farm for a private farmer with a biogas plant for 500-600 m 3 of gas per month. To solve this problem, a dozen milk cows will suffice. The project of the barn itself is already there, it remains to associate it with a biogas plant, register and give a clear technical and legal status of this animal breeding complex.

Why such an approach? I explain. The station is designed for independent heating of the farmer’s estate (up to 200m 3 ) and providing hot water both at home and at work. Electricity from biogas is not provided - expensive. The project support (besides biogas) is the use of bio-fertilizer. Both for themselves and for sale under a single trade brand, which is gaining momentum now.

This helps to formally pay for the installation in two to three years. Not for two or three months, as in advertising on the Internet or on YouTube, but for a couple of years. In order to bring the project of such a mini-farm to mind, we need electronics engineers, industrial automation specialists, light designers of buildings and structures, fire safety experts, people who are well aware of the specifics of technical regulations, any GOST, SNIPOV, need a good lawyer (just in case ), marketer, patent specialist, designers. We make this project open, those who wish can offer their competencies. So often it happened that only the whole world can do something. Something worthwhile. Email me asmtomsk@gmail.com if you are interested in this topic and (or) have your own ideas.

All Articles