The inscription is visible even if the train is standing at a high platform, so do not miss it.

On this car - Ammendorf, which has undergone a major overhaul (CWR), an air distributor (VR) is installed. No. 242 passenger type. It is now being installed on all new and “rejected” cars, in exchange for the earlier 292nd BP. Here about these devices belonging to the family of braking devices we will talk today.

1. Heirs of Westinghouse

Passenger-type air distributors operated on 1520 mm gauge railways are a kind of compromise between the simplicity of the design inherited from the Westinghouse triple valve and traffic safety requirements. They did not follow such a long and dramatic path of development as their cargo counterparts.

Currently, two models are used: air diffuser conv. No. 292 and rapidly replacing it (at least in the wagon fleet of Russian Railways) air distributor conv. No. 242.

These devices differ in design, but are almost identical in their operational properties. Both devices operate at a difference of two pressures - in the brake line (TM) and the spare reservoir (ZR). Both provide additional discharge of the brake line during braking: the 292nd discharges the TM into a special closed chamber (additional discharge chamber) with a volume of 1 liter, and the 242nd - directly into the atmosphere. Both devices are equipped with an emergency braking accelerator. Both devices do not have step-by-step tempering - they are released immediately when the pressure in the TM is increased above the pressure in the air discharge set there after the last braking, as they say - they have a “soft” tempering.

The absence of step-by-step tempering is compensated by the fact that both devices do not work alone on the car (although they can), and together with an electric air distributor condition. No. 305, which introduces electric brake control, and a working chamber with pneumatic relays, providing the possibility of step-by-step tempering.

As an example, consider BP 242 as a more modern, as well as EVR 305.

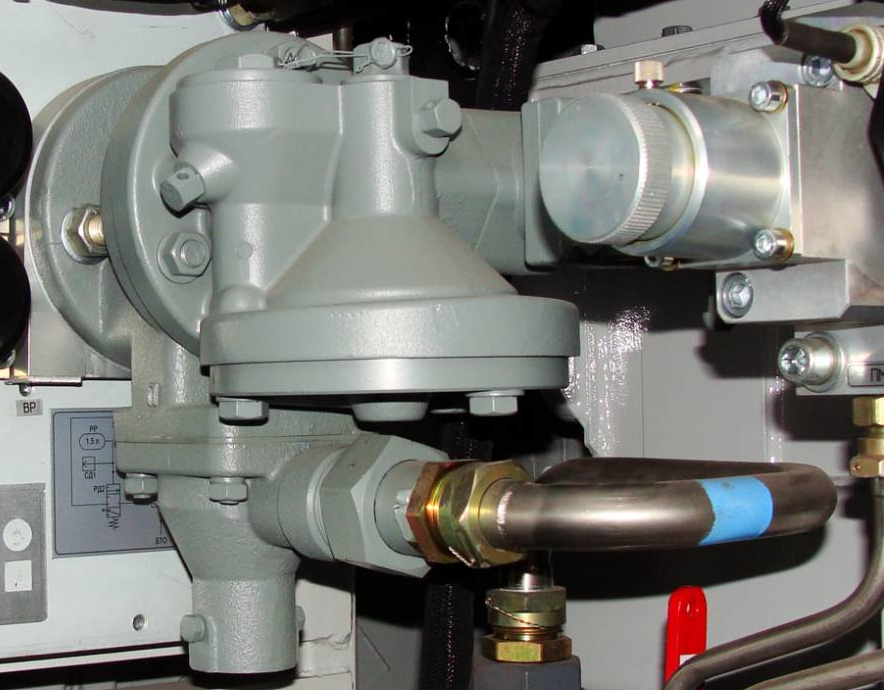

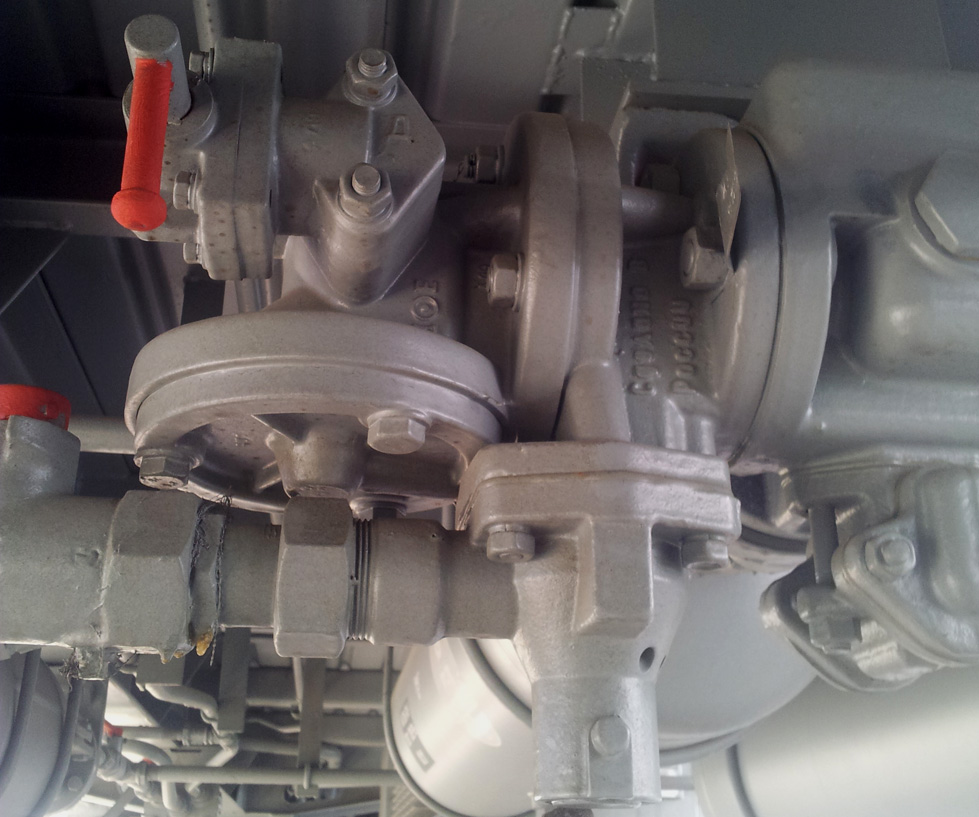

Brand new BP 242 on a pneumatic panel in the engine room of an electric locomotive EP20

He installed on a passenger car

We now turn to the device and the principle of operation of this device.

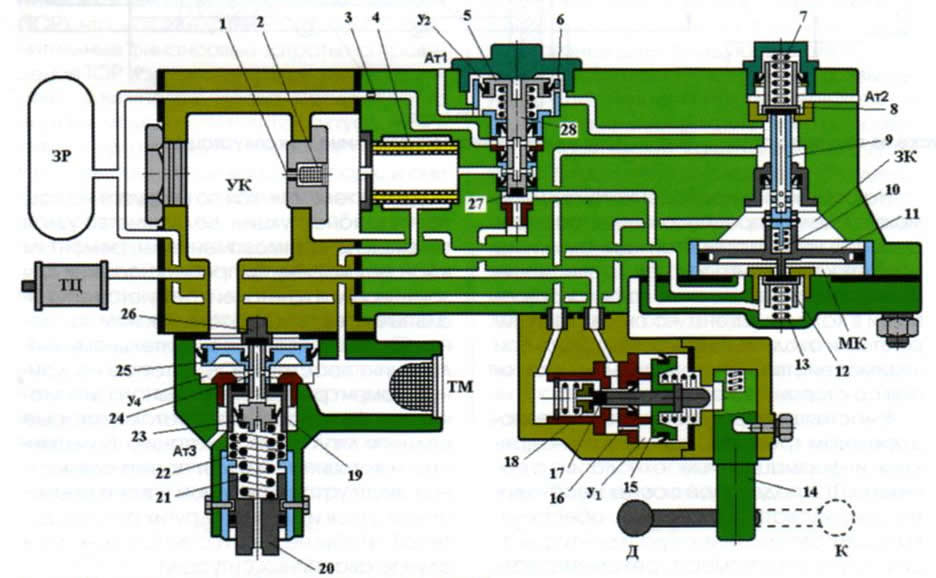

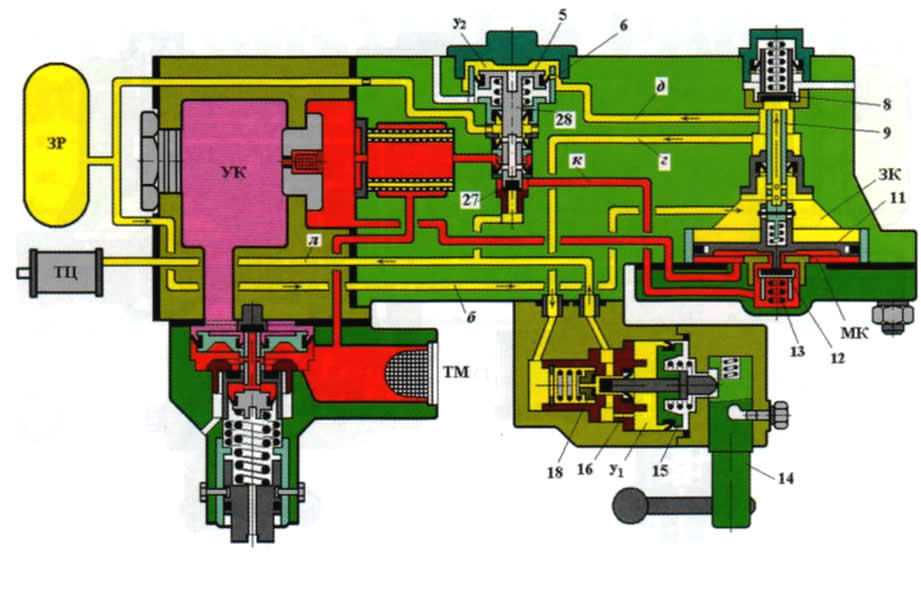

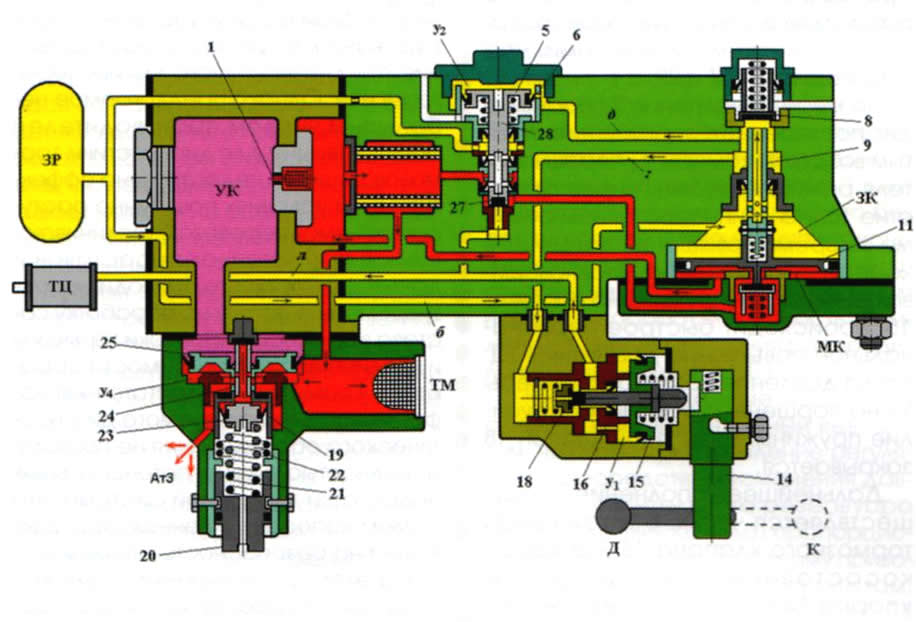

The diagram explaining the device BP 242: 1, 3, 6, 16 — calibrated holes; 2.4 - filters; 5 - piston limiter additional discharge TM;

7, 10, 13, 21, 22 - springs; 8 - exhaust valve; 9 - hollow rod; 11 - the main piston; 12 - valve additional discharge; 14 - prop switch mode; 15 - piston of the mode switch; 17.28 - stocks; 18 - brake valve; 19 - a stall valve; 20 - prop switch emergency braking; 23, 26 - valves; 24 - hole; 25 - piston of an emergency braking accelerator; 27 - valve for limiting additional discharge; UK - accelerating chamber; ZK - spool chamber; MK - trunk camera; - brake line, - reserve tank; TC - brake cylinder

How does the air diffuser start? It begins with charging, that is, filling the chambers of the air distributor itself and the spare tank with compressed air from the brake line. These processes occur when the locomotive is launched in the depot, when it is without air, as well as on all cars, when they are attached to the locomotive, and the end crane is opened - the train is taken “into the air”. Consider this process in more detail.

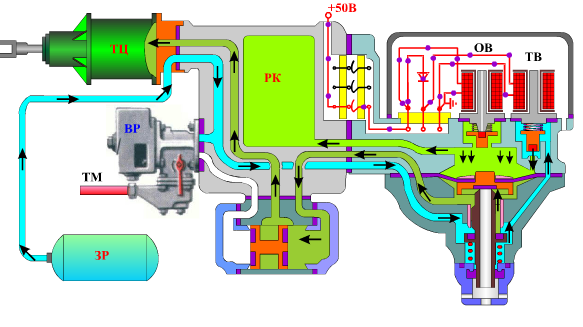

BP 242 action when charging

So, air from the brake line, under a pressure of 0.5 MPa, rushes into the device, filling the chamber U4 under the accelerating piston, then goes up the channel (shown in red), through filter 4, through channel A to the main chamber (MK) propping up from below the main piston 11, it rises, with its hollow stem 9 opens the exhaust valve 8, which communicates the cavity of the brake cylinder with the atmosphere. At the same time, the air from the filter, through the axial channel of the rod 28, through the calibrated hole 3 goes into the spare tank (shown in yellow), and from there through the channel into the spool chamber (ZK) above the main piston 11.

This process continues until the pressure in the spare tank, main and spool chamber is equal to the charging pressure in the brake line. The main piston will return to neutral by closing the exhaust valve. The air distributor is ready for action.

I will write again - the pressure in the TM is unstable, there are leaks in it, small leaks, but they always exist. That is, the pressure in the TM can decrease. If the pressure decrease is at a rate less than the service rate, then the air from the spool chamber manages to flow into the main chamber through the throttle 3, the main piston remains in place and braking does not occur.

With a decrease in pressure in the brake line at the rate of service braking, the pressure in the MK decreases rapidly enough so that the main piston has time to move down, under the action of more pressure in the spool chamber. Moving down, it opens the valve additional discharge 12.

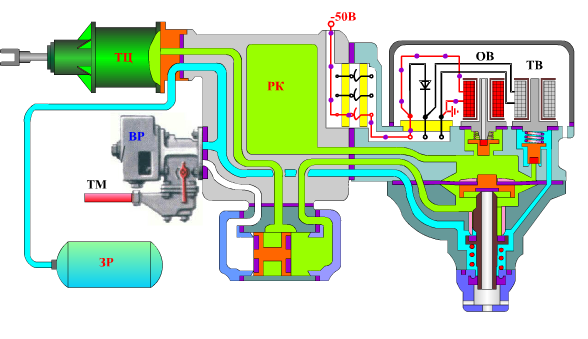

Effect of BP 242 during braking: TM additional discharge phase

Air from the main chamber, through the valve 12 through the channel K, through the axial channel of the rod 28 enters the atmosphere. The pressure in the brake line and the main chamber is reduced even more fun and the piston 11 continues its downward movement.

BP 242 braking action: initial filling of the brake cylinder

The hollow rod of the main piston 9 moves away from the seal on the exhaust valve, thereby opening the way for air from the reserve tank, which rushes through the channel B to the spool chamber, the axial channel of the rod 9, channel G and the mode switch passes into the brake cylinder through channel L. At the same time the same air passes through the channel D into the chamber U2, presses on the piston 6, which cuts off the channel of additional discharge from the atmosphere. Additional discharge stops. At the same time, the rod 28 of the piston 6 drops down, the radial channels in it are blocked by rubber cuffs, which leads to the separation of the main and spool chambers. This increases the sensitivity of the air distributor to braking - now lowering the pressure in the brake line at any rate will lead to lowering of the main piston and filling of the brake cylinder.

BP 242 action during braking: switching the filling rate of the shopping center

At the beginning, the brake cylinder is filled quickly, with a wide channel, through the open brake valve 18. As the brake cylinder is filled, the mode switch chamber U1 is also filled through the calibrated hole 16. When the pressure becomes sufficient to compress the spring under the piston 15, the brake valve closes, and the TC is filled through a calibrated hole in the brake valve at a slower pace. This happens if the handle of the mode switch 14 is turned to the position "D" (long). This mode is applied if the number of cars in the train exceeds 15. This is done in order to slow down the filling of the shopping center on the cars, providing greater uniformity in the response of the brakes in composition.

In short trains, the handle 14 is placed in the "K" position (short). At the same time, it mechanically opens the brake valve 18, and filling the shopping center with a fast pace occurs all the time.

When the driver puts the crane in the shutoff position, the pressure drop in the brake line stops. The filling of the brake cylinder will take place until the pressure in the spare tank, and therefore in the spool chamber, has reached the pressure in the main chamber, and therefore in the brake line, due to the air flow, filling. The main piston will return to neutral. The filling of the shopping center ceases, overlapping occurs.

To release the brakes, the driver puts the crane handle in I position. Air from the main tanks rushes into the brake line, significantly increasing the pressure in it (up to 0.7 - 0.9 MPa, depending on the length of the train). The pressure in the BP main chamber also increases, which leads to the main piston moving upward, opening the exhaust valve 8, through which air from the brake cylinders, as well as from the U2 chamber, enters the atmosphere. The pressure drop in the chamber U2 causes the piston 6 and the rod 28 to rise, the brake line and the spare reservoir are again communicated through the throttle 3 - the spare reservoir is charged.

When the charging pressure in the equalization tank (SD) is equal to the charging one, the driver puts the crane in position II (train). The pressure in the TM is quickly restored to the pressure level in the SD. At the same time, due to the throttle 3, the pressure in the spare tank still does not have time to grow up to the charging one, charging of the air defense continues, but at a slower rate. Gradually, the pressure in the spare tank, main and spool chambers is set equal to the charging. Then the air distributor is again ready for new braking.

From the point of view of the driver, the described processes look something like this:

A separate element of BP 242 is an emergency braking accelerator; in the diagram it is located on the left side of the device. When charging, along with filling the main part of the air distributor, the accelerator is charged - the cavity under the piston 25 is filled with air, and the cavity above the piston through the accelerator chamber (CC). The brake line and the accelerator chamber communicate through the throttle hole 1, the diameter of which is such that during service braking the pressure of the accelerator chamber has time to compare with the pressure of the brake line and the accelerator does not work.

Emergency Brake Assist

However, when the pressure drops at an emergency pace - the air leaves the brake line in 3 to 4 seconds, they do not have time to compare, the air from the accelerator chamber presses on the piston 25, and it opens the stall valve 19, opening a wide hole in the brake line, from which air goes into the atmosphere, exacerbating the process. Thus, during emergency braking, during operation of the accelerator on each car, a window opens in the brake line.

To turn off the accelerator (for example, if it malfunctions), use the special key to turn the stop 20, which blocks the accelerating piston in the upper position.

Despite the many written words and letters, in fact, this device has a fairly simple and reliable design. Compared with its predecessor, BP 292, this one does not contain spools, which are still quite capricious in operation, needing to be rubbed to the mirror and lubricated, and also subject to wear.

The air distributor 242 is a stand-alone device, it can work without assistants. In fact, on passenger cars and locomotives, it acts in conjunction with another device called

2. Electric air distributor (EVR) conv. №305

This device is designed to work in an electro-pneumatic brake system on passenger rolling stock. It is installed on wagons and locomotives together with BP 242 or BP 292. This is how the block of brake equipment on a passenger car looks like

In the foreground is the brake cylinder. A bit further, the working chamber of the EVR 305 is bolted to the rear wall of the shopping center. The electric part of the EVR is connected to the left with a pressure switch, and to the right is the air distributor 292. To it, through the disconnecting tap, an outlet from the brake line is connected (painted red)

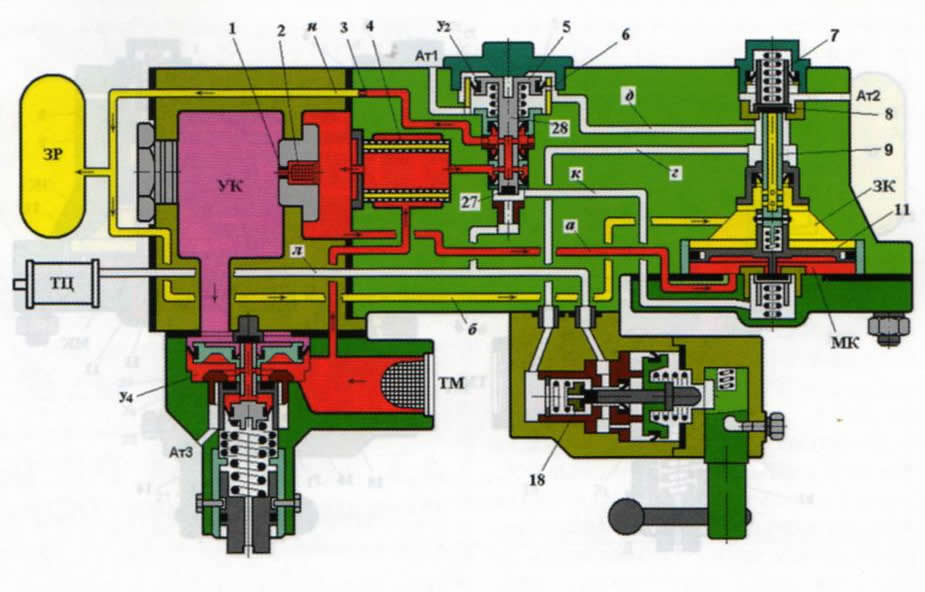

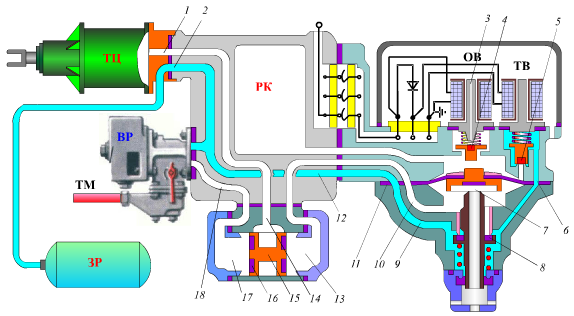

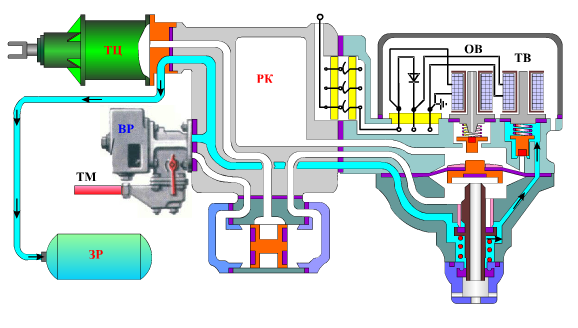

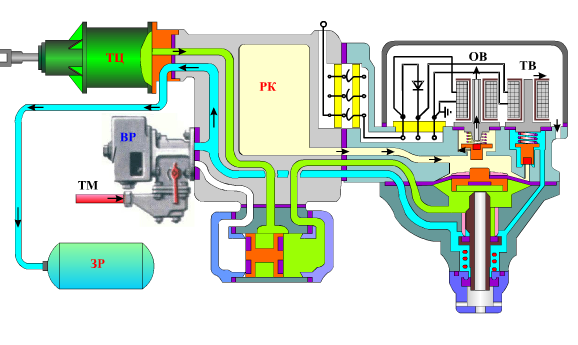

EVR 305 device: 1, 2, 3, 6, 9, 10, 11, 12, 14, 18 - air channels; 4 - valve release valve; 5 - valve of the brake valve; 7 - atmospheric valve; 8 - feed valve; 11 - aperture; 13, 17 - cavity of the switching valve; 15 - switching valve; 16 - sealing valve switch; TC - brake cylinder; RK - working chamber; OV - release valve; TV - brake valve; - reserve tank; BP - air distributor

EVR 305 consists of three main parts: a working chamber (PK), a switching valve (PC) and a pressure switch (RD). In the case of the pressure switch, there are installed holiday 4 and brake valves 5 controlled by electromagnets.

When charging, power to the valves is not supplied, the release valve communicates the cavity of the working chamber with the atmosphere, the brake valve is closed. The air from the brake line, through the air distributor through the channels inside the EVR, passes into the spare tank, charging it, but does not go anywhere else, since the closed brake valve blocks the path of the pressure switch to the cavity above the diaphragm.

The action of the EVR 305 when charging

When the driver’s crane is in position Va, a positive (relative to the rail) potential is applied to the EPT wire and both valves receive power. The exhaust valve isolates the working chamber from the atmosphere, while the brake valve opens the air path into the cavity above the taxiway diaphragm and further into the working chamber.

The action of the EVR 305 when braking

The pressure in the working chamber and in the cavity above the diaphragm increases, the diaphragm bends down, opening the supply valve 8, through which air from the reserve tank first enters the right cavity of the switching valve. The valve plug moves to the left, opening air to the brake cylinder.

When the driver’s crane is placed in the ceiling, the voltage supplied to the EPT wire changes polarity, the diode through which the brake valve is powered is locked, the brake valve loses power, and the brake valve closes. The increase in pressure in the working chamber stops, and the filling of the brake cylinder occurs until the pressure in it is equal to the pressure in the working chamber. After that, the membrane returns to the neutral position, the feed valve closes. There is a ceiling.

The action of EVR 305 when overlapping

The release valve continues to receive power by holding the release valve in the closed position, preventing air from escaping from the working chamber.

For vacation, the driver puts the crane handle in the I position for a full vacation, and in II - for a step. In both cases, the valves lose power, the release valve opens, discharging air from the working chamber into the atmosphere. The diaphragm, supported from below by pressure in the brake cylinder, moves upward, opening the exhaust valve, through which air exits the brake cylinder

The action of EVR 305 on vacation

If, when the second position is released, the handle is again blocked, the air will no longer flow out of the working chamber, and the shopping center will be emptied until the pressure in it is equal to the pressure remaining in the working chamber. This achieves the possibility of stepwise vacation.

Such an electro-pneumatic brake has a number of features. Firstly, when the EPT line breaks, the brakes release. In this case, the driver, after a series of mandatory, prescribed by the instructions, moves to the use of an air brake. That is, EPT is not an automatic brake. This is a flaw in this system.

Secondly, during EPT operation, the conventional air distributor is in the released position, not ceasing to absorb leaks from the spare tank. This is a plus, as it provides the inexhaustibility of the electro-pneumatic brake.

Thirdly, this design does not interfere with the operation of a conventional air distributor. If the EPT is off, then BP, filling the brake cylinder, will first fill the left cavity of the switching valve, moving the plug in it to the right, opening the air from the spare tank to the brake cylinder.

This is how the described systems work from the driver’s cab:

Conclusion

I wanted to squeeze cargo braking devices into the same article, but no, this topic requires a separate discussion, since cargo BPs are much more complicated, use much more sophisticated technical solutions and tricks due to the specifics of operating freight rolling stock.

As for the passenger brake, its relationship with the Westinghouse brake is compensated by additional technical solutions, which on the domestic rolling stock gives acceptable performance indicators, the level of safety and the manufacturability of maintenance and repair. It will be interesting to compare with the “how they have it” abroad. Compare, but a little later. Thanks for attention!

PS: My thanks to Roman Biryukov for the photo material, as well as to the site www.pomogala.ru , from which illustrative material was taken.