I began to develop this kit in 2014 - it took me to pick up some spectacular experiments for a television show and “Soluble Spoon” was among them.

Rather, it was not a spoon, but simply gallium metal. A feature of gallium is its low melting point, below 30 ° C. It can be melted right in the palm of your body heat. It was this metal that replaced mercury in classic thermometers: it is safe and melts easily.

Then, in the filming, this experience was not used and was postponed “for later”. About a year later, I again had to get it from my “bank of ideas”. This time it was required to come up with a spectacular scientific set. But again, instead of a “spoon”, another idea passed, and the set “Quantum Levitation” turned out.

Now he did not begin to remove the idea of the “spoon” and gradually began to work it out.

The essence of the focus: the spoon melts perfectly in a glass of warm water, although the viewer thinks that the spoon is dissolved:

Recruitment Development Process

Gallium metal

It was necessary to study it and understand all its subtleties. It turned out, in addition to being easy to melt, it also curiously reacts with aluminum. It became clear that they should not be together in one set.

WIKIPEDIA : The chemical properties of gallium are similar to those of aluminum, but metal gallium reactions tend to be much slower due to less chemical activity. An oxide film formed on the surface of a metal in air protects gallium from further oxidation. In relation to aluminum and its alloys, gallium is a powerful strength reducer.

About 97% of global gallium production goes to various semiconductor compounds.

It also turned out that Gallium in the molten state can be drawn into the syringe directly through the needle, like ordinary water. I decided to use this fact in the set. But more on that later.

Mold for filling

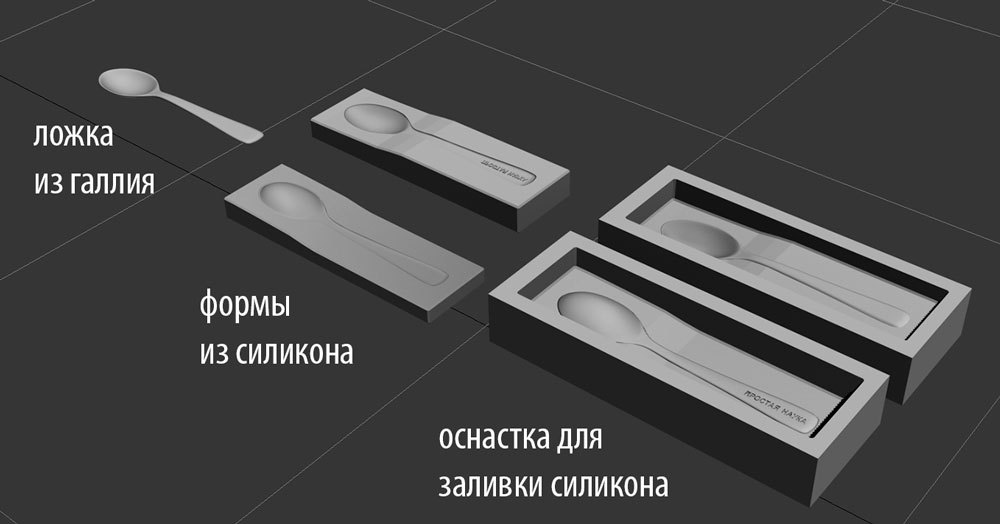

How to make metal take the shape of a spoon? You need to melt it, pour it into a specially made form in the form of a spoon and cool. It is not a problem to melt and cool, but I had to tinker with the form. This turned out to be the most difficult.

First, the mold was made of gypsum. Thanks for the help to Vadim Nesterov . At that time, he was actively experimenting with ceramics and, right away, in 15 minutes he made a mold for a spoon. Of course, this form was not perfect, but the spoon was excellent.

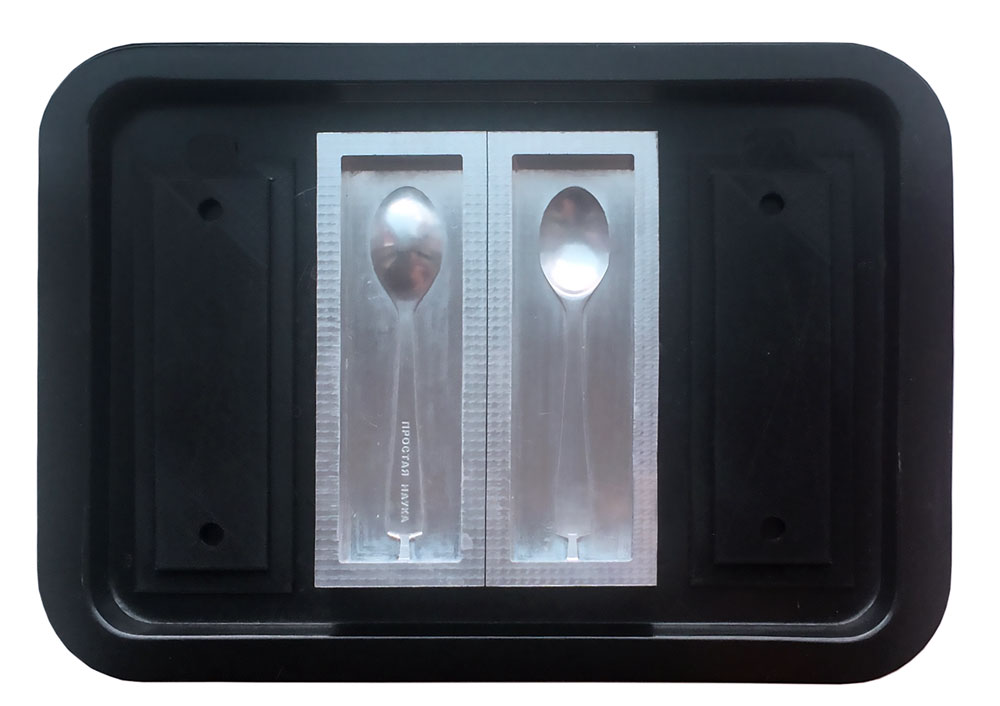

It became clear that the form can be made, but gypsum does not fit. Mostly because it crumbles. He began to google and found a similar set on one American site. There, the mold was made of translucent silicone.

I decided to try their method and ordered a similar silicone from the states. A parcel arrived, consisting of 2 jars: large and small. Silicone is obtained by mixing two reagents.

It remains to decide how to make a snap into which this silicone is poured. To begin with, I asked Ksenia Minakova to build a 3D model of all stages. At that time, she worked as a designer for me and learned to model in 3D MAX. The result was excellent.

Now it was necessary to make equipment for these models. We found guys and made tooling on a CNC machine from large aluminum briquettes. Yes, I said that gallium and aluminum are not friendly. But in this case it is not important, because silicone will not be poured into the equipment, not gallium.

Poured the purchased silicone into molds. It freezes over the course of a day. This is an important fact that will directly affect the speed of production and, consequently, the cost. Remember this.

Gallium container

Remember, I said that Gallium can be drawn into a syringe like water? As a container for metal, I use a disposable syringe.

We take a syringe with metal from the set and put it in warm water for several minutes. The metal will quickly melt and become liquid. We put on a needle and inject gallium into a silicone mold through a special hole.

To prevent the spoon from “spreading” ahead of time, the metal must be cooled. It is enough to place the form filled with gallium in the refrigerator - it stably holds + 5 ° C. I noticed that it takes more than half an hour to cool before the spoon is ready for use.

After the focus, directly from the glass I draw the molten metal into the syringe through the needle. The kit is ready to use again.

Packaging

In the photo from the Internet, two sheets of transparent plastic and screws were used to press together the two parts of the silicone mold. Without this, it will be inconvenient to use the kit. Still need to solve the issue with packaging.

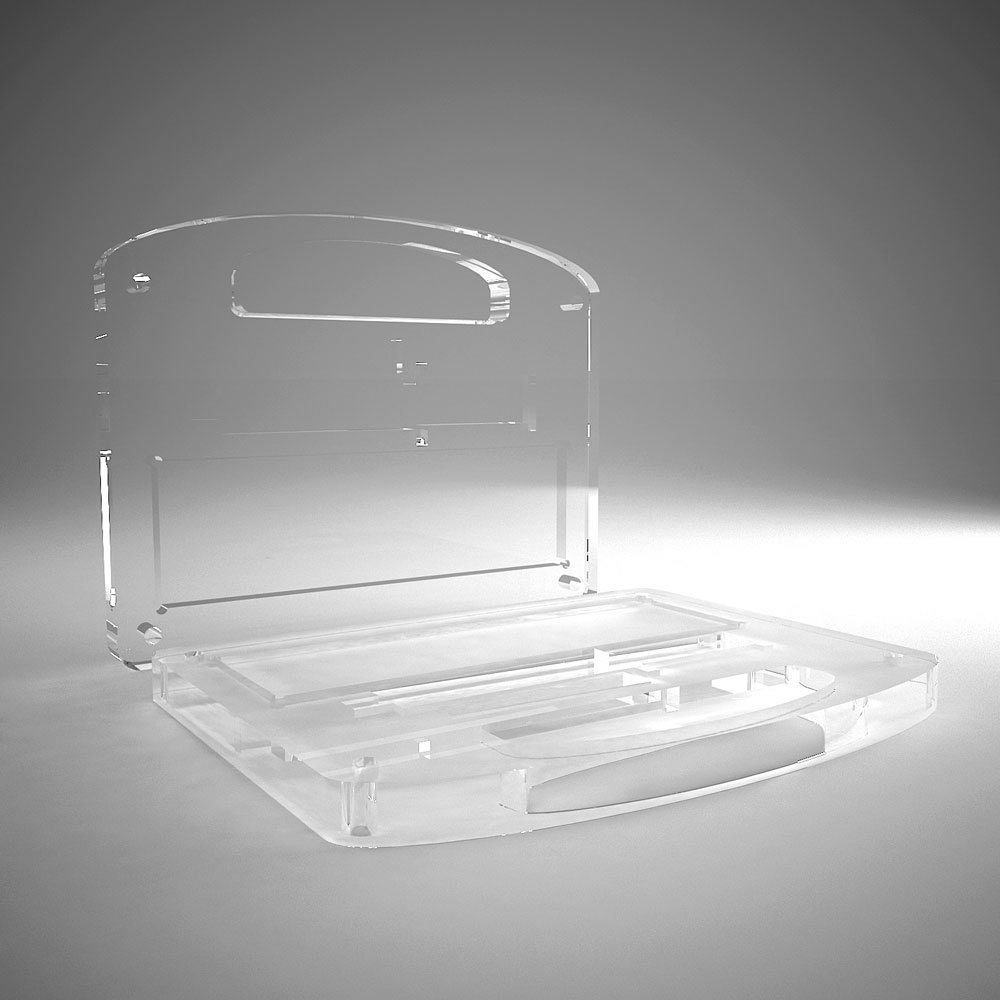

It seems that I was able to find an elegant solution: a case in which all parts of the set will be stored and with the help of it, silicone molds are pressed against each other during gallium filling. As usual, first the 3D model:

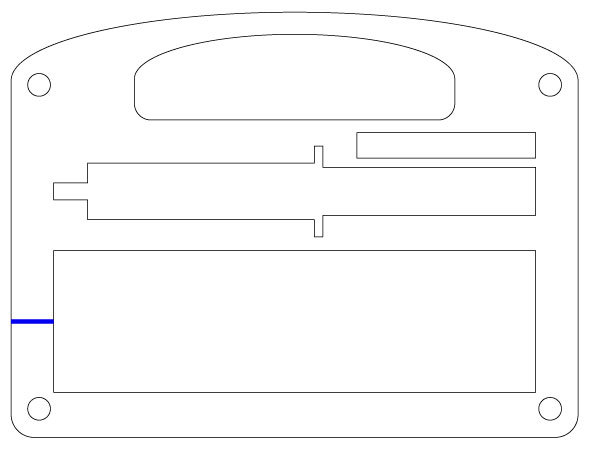

Made a drawing for cutting on CNC:

For fastening, I decided to use furniture ties, they fit perfectly in size:

And you can spin them with a coin. I use it as a chip!

Part of the case was cut on a milling machine, part on a laser. It is better to use a laser, the ends remain transparent:

Case is ready:

What are the ideas for selling this kit?

- on your website;

- on OZONe and Wildberries

- shops for geeks;

- expensive gift shops.

For sale through your website, you don’t really need anything, but for delivery to other stores you need a certificate. These will have to worry. I will describe the process of obtaining in the following posts.

If you have any ideas how and where you can sell this kit, write in the comments. Any useful information and ideas will be very useful for me.