We are on the verge of the fourth industrial revolution. In developed and developing countries, in every corner of the planet, there will come complete automation of production.

We are moving forward with incredible speed. Ten years ago there were about 500 million devices connected to the network. Today there are already about 10-20 billion of them.

Industry 4.0 will lead to ultra-automation of production processes, increased labor productivity, economic growth and enterprise competitiveness.

With the development of information technology, the world is changing dramatically. If earlier it took several weeks, a dozen specialists and financial investments to monitor and obtain information from the objects surrounding us, now one platform and a couple of “mouse clicks” are enough.

IoT technologies open up fantastic business opportunities and change the very nature of the product.

What is the Internet of things?

The Internet of Things (Internet of Things, abbreviated IoT) is a concept by which devices are combined into one network and interact with each other. This helps make devices “smart”: they collect information on their own, share it and make decisions.

You can monitor and manage the status from a computer or phone. The Internet of things is used in manufacturing, agriculture, medicine, the urban environment and in everyday life.

The main phenomena of the Internet of things:

- Devices that enter the network and communicate with each other

- connection method - M2M - that is, machines - for - machines, without human intervention;

- work with a large amount of data. Application of Big Data technologies.

The data obtained are the basis for analysis, drawing up a business model and improving production efficiency.

“If in the twentieth century, data entered the computer only from a person who used additional devices to enter them, then in the twenty-first century we are already dealing with gadgets that can collect and send data themselves. This is the essence of the Internet of things. Data is collected, processed and transmitted by devices without human intervention ”The main difference between the Internet of things and conventional automated control systems (APCS) in the amount of processed data. Hundreds of thousands of signals are sent to the server every second and processed immediately. Thanks to this, the user in real time sees the operation of the equipment.

Kevin Ashton is the inventor of the concept and term Internet of Things (IoT).

A regular SQL database cannot handle this amount of information. Processing takes too much time and data is no longer relevant. Non-relational (NoSQL) databases are used for IoT technology. They do not aggregate the information that comes from the devices, but store it in its original form, which allows you to accumulate terabytes of signals for any period of time. Since the data is not aggregated, it is possible to make a slice according to any parameter and apply the new algorithm to historical signals, which allows you to quickly and flexibly work with information.

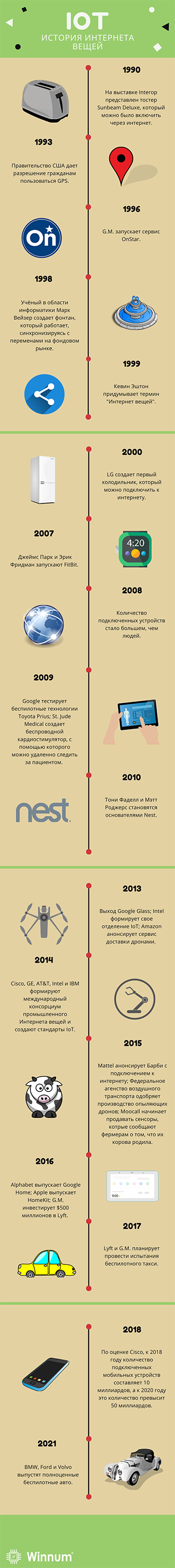

How did it all start?

The very idea that devices can exchange information with each other without human intervention appeared in the late 70s. However, it took 20 years to connect the first device to the network and another 9 years to formulate the very definition of the Internet of things.

Below is an infographic with key points in the development of the Internet of things.

Today, all forms of communication come down to either a person-person or person-device scheme. IoT technologies offer a "step" into the future, in which communications are presented in the form of a machine - machine (M2M). This unique technology is able to combine the physical objects surrounding us into a single system, and this system into a system of systems. It makes it possible to manage objects, receive information from them and anticipate errors.

“IoT connects the objects around us into a system, and this system into a system of systems. They exchange information with each other and work without human intervention in real time. "The Internet of Things provides organizations with completely new ways to manage and monitor remotely performed operations. It allows you to fully control remotely located objects and constantly transfers information to the data warehouse.

How to work with data and manage equipment?

Users work in the IoT platform. This is a special environment in which you can receive analytics, build reports, configure alerts and manage devices. In the platform, you can work with ready-made solutions for specific tasks: monitoring machines, managing drones, tracking the location of objects. And you can create your own solutions. To do this, some platforms provide SDK libraries for various programming languages with which you can write an application for your tasks.

“Prevention is always cheaper than repair”A nice bonus will be the presence of a digital 3D double. This is a three-dimensional model of the enterprise sites that are connected to the IoT. The double clearly demonstrates the operation of devices: their statuses and states, moving around the site.

Depending on the platform, logging in is carried out through a special application or through a web interface. The second option is more convenient, since it allows you to work from any device that has a browser.

The Internet of Things in Mechanical Production

Consider the benefits of introducing the Internet of things with an automobile manufacturing company as an example. To make the car body, you need to process metal, weld parts to each other, paint the entire structure. Milling and turning machines, welding machines and spray booths work in production. Only 100 pieces of equipment. The company decided to apply IoT technology to improve production. All equipment was connected to a single enterprise network, where each of the 100 machines sends 100 signals per second. The entire amount of data is automatically sent to the internal server of the company. Access to this information was granted to the shop manager, process engineer, and repair service engineer.

The shop manager monitors the operation of the equipment through the application in his phone. He sees which machine is sharpening the part now, which is on and just standing, and which is completely off. Each hour of the machine costs 3,500 rubles. The enterprise loses the same amount of money for every hour of equipment downtime. Each part must be produced using a certain technology, in certain modes, otherwise it may turn out to be defective or even worse - the machine will break. Thus, the shop manager constantly monitors the progress of production, finds bottlenecks and increases work efficiency.

The process engineer also monitors the production from his office. But he is interested in other things: how much time each part is made, how quickly the tool is spent. He sees that equipment can work more efficiently and produce more parts. The technologist gives the command to rewrite the control program, according to which the machine operates. Now the part is processed 30% faster, which means the machine will manufacture more products.

The repair engineer set up an alert for himself. In the event of an accident, he will receive a message and will be able to quickly solve the problem. If the cause of the failure is unknown, the specialist will study the history of signals from the equipment and conduct an investigation of the accident.

Internet of things in the near future

IndustryARC estimates that by 2021, the IoT market will reach $ 123 billion. In the context of fierce competition, more and more industrial and manufacturing companies will begin to implement Internet of things technologies.

The idea of the Internet of things can dramatically affect the development of the modern world, since it will allow many production processes to take place without human intervention.

In the near future, the Internet of things will significantly transform the business and even entire industries. This system will help to solve a number of global problems of modern production.