That sensor that on the left I already touched on the pages of Habr, so today we’ll talk about his younger brothers.

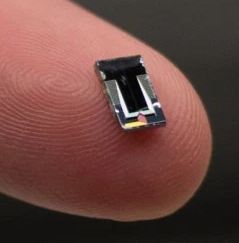

When you think of a new startup, sometimes it seems that in the field of electronic devices everything has already been invented before us and the scope of creativity has narrowed today. In fact, this is far from the case. Over the past few years, revolutionary changes have occurred in the world of electronic components, which continue to this day. The chips depicted on the background of the coin were unthinkable 5 years ago, but during this year only their family received several replenishment.

Modern electronic components can not only create new, but also expand the functionality of long-existing devices. The devices developed with their use become smaller, cheaper, more functional and easier to use than their predecessors. But the main thing is that they are easier to integrate into our digital world, which means they scale well. This is one of the main reasons why tech startups are gaining popularity with investors today.

About modern microcontrollers and techniques that simplify the process of "inventing" new products, you can read in my previous articles. Today, the turn has come to the sensors. It is impossible to grasp the immensity, so I made a brief and purely subjective review of integrated sensors, which, in my personal experience, may be most useful, both when designing completely new devices and during modifications, in order to give new qualities to long-released devices, so distinguish them from a number of competitors. I gave advantages to those whose advantages I managed to evaluate in my projects.

General trends

In order to function, your device must communicate with the outside world, receiving information. A person uses the senses for this, and a device under the control of a microcontroller uses sensors. Over the years, sensors are becoming smaller, smarter and, more importantly, cheaper. Analog interfaces give way to digital. The sensors learned to make a sequence of measurements autonomously and put them in their own buffer memory. Preprocessors are built into them for primary processing and analysis of measurement results. The number of registers for setting operating modes and data processing sometimes exceeds one hundred. The presence of self-calibration procedures and tabular functions make it possible to bring the result closer to a linear dependence in a wide range of external conditions (temperature, humidity, etc.). Sensors are increasingly using MEMS (microelectromechanical) technology. They learned how to independently conduct lengthy measurement processes and give signals when parameters go beyond the permissible range. Modern technologies have reduced the energy consumption of many types of sensors to such a level that they can operate on a single small battery for years.

Inertial sensors

The most useful for expanding the functionality of the device by far are “inertial sensors” made according to MEMS technology. Today, six-axis sensors containing a three-axis accelerometer and gyroscope are the most popular. At the service of those who want to get even more information about the orientation in space of 9 axial sensors, in

which are added magnetometer. Inertial sensors provide great opportunities for improving old and creating new devices due to the fact that they have hundreds of applications that are not quite obvious at first glance.

which are added magnetometer. Inertial sensors provide great opportunities for improving old and creating new devices due to the fact that they have hundreds of applications that are not quite obvious at first glance.

Among this triad, the accelerometer certainly plays a major role. When operating at polling frequencies of the order of several tens of hertz, it has an exceptionally low current consumption - tens of microamps. Modern inertial sensor chips include data processing preprocessors. They are capable of autonomously producing very complex primary processing of the obtained data using analog and digital filters with programmable parameters. Thanks to the FIFO memory buffer, they can accumulate the obtained results, analyze them and send a signal to awaken the microcontroller only after the boundary conditions recorded in the memory are reached. As boundary conditions, not only such simple ones as exceeding the level of acceleration, but, for example, a change in the rhythm of walking, can act. Yes, yes, based on the accelerometer readings, the sensors learned to independently recognize the nature of the movement and even its individual parameters. At the right time, the sensor awakens the microcontroller and transfers the accumulated data from the FIFO buffer to it. The microcontroller conducts a more serious analysis, if necessary, performs the response and again goes into sleep. This algorithm is best suited for high-performance, low-power ARM MCUs.

Having dimensions of several millimeters, such sensors are the best suited for security applications, tamper sensors, power switches of sealed devices. Based on them, it is convenient to implement button-less controls for devices in anti-vandal performance and / or harsh operating conditions. It is possible to track the relative position of parts of a person’s body or a complex structure, determine the nature of movement (distinguish walking from running or climbing stairs, record moments of immobility, turning or “moving away” from a car, etc.), determine when dangerous engine vibration turbines, give a signal that the slope is out of range and much more!

Surprisingly, even 9 channel sensors did not really learn how to solve the problem for which it would seem that they were originally intended. They are able to track the trajectory of movement with acceptable accuracy only within the limits of movements over short distances and short periods of time. Using them to replace GPS navigation indoors is not possible - measurement errors accumulate too quickly. In addition, depending on time and temperature, the gyro readings “float”, and the magnetometer requires preliminary calibration. Remember these annoying requirements to describe the eight with your phone for orientation in space? This is from that opera ...

Surprisingly, even 9 channel sensors did not really learn how to solve the problem for which it would seem that they were originally intended. They are able to track the trajectory of movement with acceptable accuracy only within the limits of movements over short distances and short periods of time. Using them to replace GPS navigation indoors is not possible - measurement errors accumulate too quickly. In addition, depending on time and temperature, the gyro readings “float”, and the magnetometer requires preliminary calibration. Remember these annoying requirements to describe the eight with your phone for orientation in space? This is from that opera ...

Sensors for measuring movements and distances

Extremely large galaxy of devices with different operating principles and sizes.

One of the most popular applications is the definition of small displacements.

The optimal solution to the measurement problem depends on the material of moving objects. Reed switches are the cheapest and easiest to roughly determine the position of magnetized objects, but there are much more advanced integrated solutions based on the Hall effect. Induction sensors have very limited use, but capacitive sensors are used much more often, due to the simplicity of microminiaturization.

Sensors based on optocouplers have their advantages; they are used for a long time and widely. I will not dwell on ultrasonic distance sensors, which are extremely popular due to their widespread use as modules for Arduino.

Undeservedly rare, in the developed devices, sensors based on “miniature cameras” and lasers are used. In my opinion, it’s in vain, because thanks to the widespread use in mouse-type manipulators, the price of these devices is at a very low level.

Undeservedly rare, in the developed devices, sensors based on “miniature cameras” and lasers are used. In my opinion, it’s in vain, because thanks to the widespread use in mouse-type manipulators, the price of these devices is at a very low level.

Since the PAN3101 sensor is based on a camera with a resolution of up to 800 dpi, you can buy cheaper from the Chinese one and a half dollars apiece.

I myself had to use the VL6180XV0 laser sensor. It costs around two and a half dollars and is suitable for measuring distances up to 10 cm. I tried to replace it with an ultrasonic sensor in order to increase the accuracy of determining the distance in the pusher that ejects cigarette packs, but for this I needed a slightly longer range. A thorough study of datasheets, in which it was possible to find a mention of a poorly documented feature, the ability to switch the range of measured distances, helped. As a result, I was able to increase it to 30 cm. Unfortunately, this negatively affected the accuracy of measurements. The loss had to be compensated by the introduction of digital filtering and a complex algorithm for determining the position, taking into account previous states.

I myself had to use the VL6180XV0 laser sensor. It costs around two and a half dollars and is suitable for measuring distances up to 10 cm. I tried to replace it with an ultrasonic sensor in order to increase the accuracy of determining the distance in the pusher that ejects cigarette packs, but for this I needed a slightly longer range. A thorough study of datasheets, in which it was possible to find a mention of a poorly documented feature, the ability to switch the range of measured distances, helped. As a result, I was able to increase it to 30 cm. Unfortunately, this negatively affected the accuracy of measurements. The loss had to be compensated by the introduction of digital filtering and a complex algorithm for determining the position, taking into account previous states.

I cannot but say a few words about lidars - solid-state devices based on lasers, often containing a system of moving mirrors used to measure distances to an object.

They are most widely used in unmanned vehicles, 3D-cartography, drone control systems ... The latest developments are monolithic chips based on gallium nitride (GaN) and occupy an area on the board of less than four square millimeters!

They are most widely used in unmanned vehicles, 3D-cartography, drone control systems ... The latest developments are monolithic chips based on gallium nitride (GaN) and occupy an area on the board of less than four square millimeters!

Touch sensors

The most widely used today are capacitive sensors, which are used in a variety of control elements, displacing from there solutions based on mechanics. Capacitive sensors today successfully replace buttons. Their diversity is huge. There are ready-made panels with controllers that work like a laptop’s touchscreen.

To form finger-sensitive elements - buttons and scroll bars, possibly on a board made of foil-coated PCB, and use either specialized microcircuits or integrated solutions built into some microcontrollers to service them. The solution price is often lower than the mechanical version, so TTP223 touch-button controllers can be bought for five cents apiece

To form finger-sensitive elements - buttons and scroll bars, possibly on a board made of foil-coated PCB, and use either specialized microcircuits or integrated solutions built into some microcontrollers to service them. The solution price is often lower than the mechanical version, so TTP223 touch-button controllers can be bought for five cents apiece

In cases where tightness and anti-vandal performance are required, it is worth considering the option of using piezo buttons. As you might guess, the principle of their work is based on the piezoelectric effect. An additional advantage of this kind of buttons is reliable and long-term operation in a wide range of temperatures and humidity.

In cases where tightness and anti-vandal performance are required, it is worth considering the option of using piezo buttons. As you might guess, the principle of their work is based on the piezoelectric effect. An additional advantage of this kind of buttons is reliable and long-term operation in a wide range of temperatures and humidity.

Often, buttons on field-effect transistors are integrated into the button, as well as protection elements against overcurrent, voltage, and incorrect polarity connection.

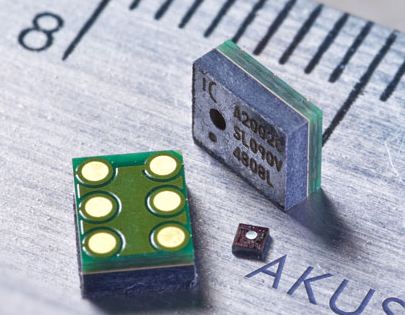

MEMS microphones

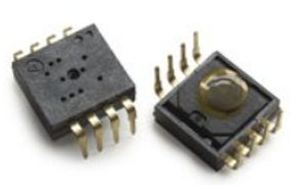

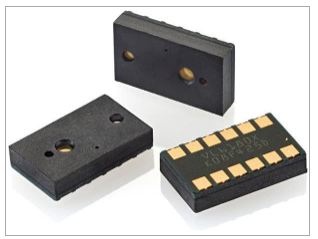

These are small-sized products with low energy consumption. The photo shows an ultra-miniature microphone in a 1 x 1 mm case with its “older” brothers. In addition to microphones with analog output, there are digital ones. They include an analog signal amplification path and an ADC. Their application allows us to simplify and reduce the cost of matching with the microcontroller, to reduce power consumption, noise level, and in some cases non-linear distortions.

These are small-sized products with low energy consumption. The photo shows an ultra-miniature microphone in a 1 x 1 mm case with its “older” brothers. In addition to microphones with analog output, there are digital ones. They include an analog signal amplification path and an ADC. Their application allows us to simplify and reduce the cost of matching with the microcontroller, to reduce power consumption, noise level, and in some cases non-linear distortions.

In my project of a universal medical device, a microphone was required that could perceive the low-frequency sounds of human organs. Most MEMS microphones have a rather high lower cut-off frequency, however, after quite a long search we managed to find a good option, though with an analog output. The baby with the unpronounceable name SPW0442HR5H-1 manufactured by Knowles in the size 3.1 mm x 2.5 mm x 1 mm can work in the range from 10 Hz to 10 KHz and costs around half a euro.

In my project of a universal medical device, a microphone was required that could perceive the low-frequency sounds of human organs. Most MEMS microphones have a rather high lower cut-off frequency, however, after quite a long search we managed to find a good option, though with an analog output. The baby with the unpronounceable name SPW0442HR5H-1 manufactured by Knowles in the size 3.1 mm x 2.5 mm x 1 mm can work in the range from 10 Hz to 10 KHz and costs around half a euro.

Pressure, humidity and temperature sensors

Sensors of pressure, humidity and temperature will not surprise anyone for a long time. Depending on the tasks being solved and the project budget, you can choose components capable of making precision measurements, or having an extremely low cost - a combined Chinese humidity and temperature sensor can be found for half a dollar.

In one of my articles, I already talked about the experience of writing drivers for the combined temperature and pressure sensor HTS221. In conclusion, I just want to note one feature that is often paid attention too late - to obtain relevant values for parameters such as humidity and temperature, their correct installation is necessary. Otherwise, a situation will arise when you are measuring not at all what is required.

In one of my articles, I already talked about the experience of writing drivers for the combined temperature and pressure sensor HTS221. In conclusion, I just want to note one feature that is often paid attention too late - to obtain relevant values for parameters such as humidity and temperature, their correct installation is necessary. Otherwise, a situation will arise when you are measuring not at all what is required.

And of course, if you need to transfer the measurement results in analog form over relatively large distances (for example, when measuring high temperatures using thermocouples), special attention should be paid to the transmission and signal matching lines.

Specialized sensors for medical applications

Recently, both start-ups and leading manufacturers of electronic components working in this field have paid most direct attention to the development and production of highly integrated circuits that combine sensors and complex signal processing circuits.

Integrated components and devices for telemedicine are a big and interesting topic, but due to the restrictions on place and time, at the end of the article, I will briefly mention only one such sensor, which I am directly dealing with right now, during the project to develop a universal medical device.

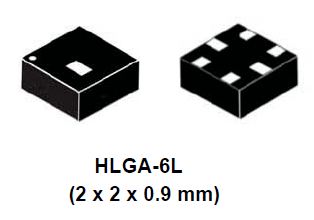

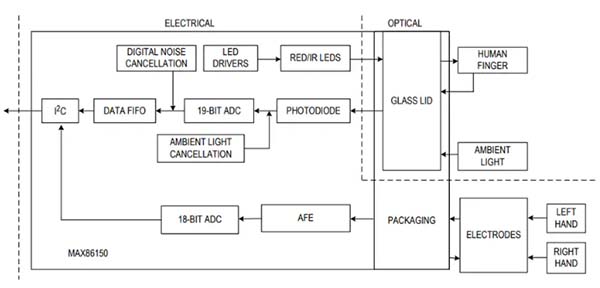

This is a microcircuit manufactured by Maxim Integrated MAX86150, it is its body that is depicted on the post splash screen while maintaining the proportions next to the coin. She can measure the heart rate, the level of oxygen saturation of the muscles, and most importantly, shoot a single-channel electrocardiogram.

Inside the case, with a size of only 3.3 X 5.6 X 1.3 mm, there is a 19-bit ADC, red and green LEDs with built-in drivers, a photodiode and a data processing channel - nodes for noise suppression, removal of external photodiode light, FIFO buffer, digital and analog filters. The microcircuit's supply voltage is only 1.8 volts, and the power consumption for unused LED drivers is less than 100 microamps in active mode and about one microampere in sleep mode.

Such impressive functions at a price well below $ 10 in retail allow us to develop, for example, small-sized medical equipment to detect cardiac abnormalities in the early stages of the disease. It is possible to create extremely compact fully autonomous devices for long-term monitoring of the patient's condition at home and at moments of physical exertion.

This family of chips is constantly expanding, literally several times a year, its new representatives appear. Most leading manufacturers of electronic components are also developing developments in many areas in the field of medicine - from ultra-miniature cameras to integrated sensors for ultrasound.

Great prospects in this area are opened by the joint use of devices on the latest elemental base and artificial intelligence for the diagnosis of diseases. But more about that next time ...