In a previous publication, we talked about how buses and protocols work in industrial automation. This time we focus on modern working solutions: let's see what protocols are used in systems around the world. Consider the technology of German companies Beckhoff and Siemens, Austrian B&R, American Rockwell Automation and Russian Fastwel. And also we will study universal solutions that are not tied to a specific manufacturer, such as EtherCAT and CAN.

At the end of the article there will be a comparative table with the characteristics of the EtherCAT, POWERLINK, PROFINET, EtherNet / IP and ModbusTCP protocols.

We did not include the protocols PRP, HSR, OPC UA and others, as on them on Habré there are already excellent articles of our fellow engineers who are engaged in the development of industrial automation systems. For example, Protocols of seamless redundancy of PRP and HSR and Gateways of industrial exchange protocols for Linux. Build it yourself . "

To begin with, we define the terminology: Industrial Ethernet = industrial network, Fieldbus = field bus. In Russian industrial automation, confusion occurs in terms of fieldbus and low-level industrial network. Often these terms are combined into a single vague concept of "lower level", which is called both the field bus and the lower level bus, although this may not be a bus at all.

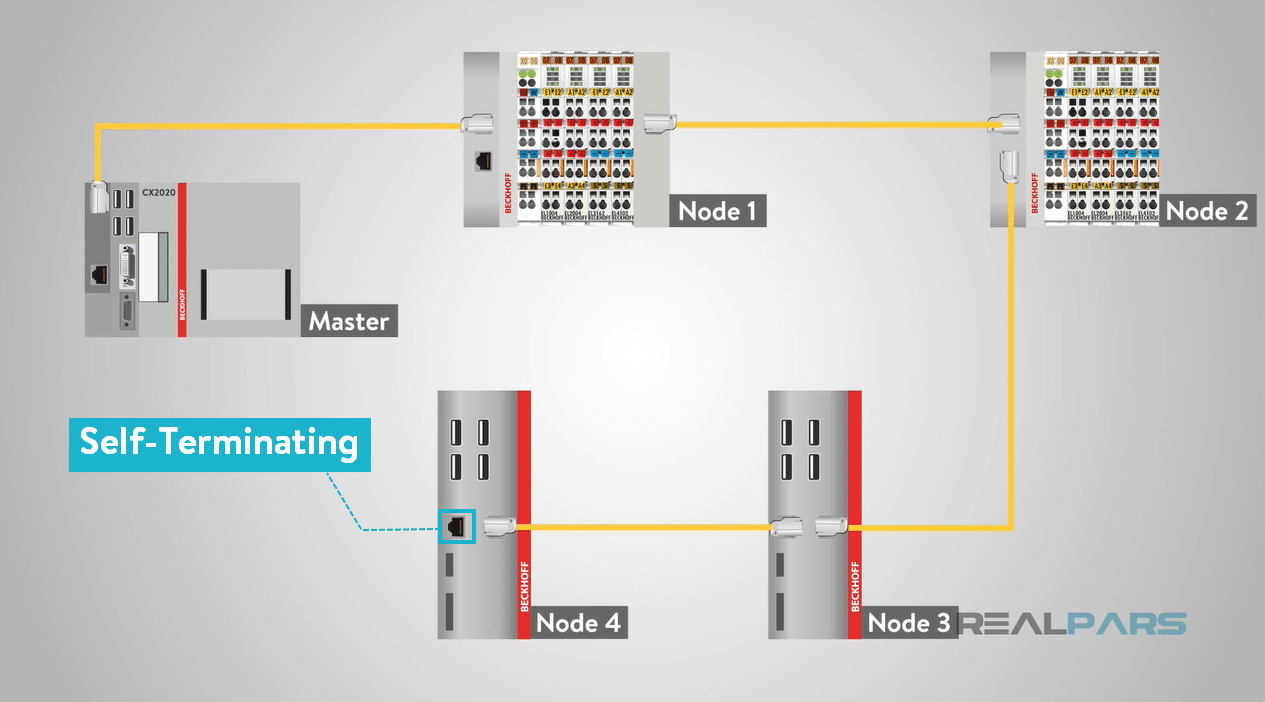

EtherCAT Industrial Network Standard, developed by Beckhoff

The EtherCAT protocol and industrial network is perhaps one of the fastest data transfer methods in automation systems today. The EtherCAT network has been successfully used in distributed automation systems, where the interacting nodes are spaced over a long distance.

EtherCAT protocol uses standard Ethernet frames for transmitting its telegrams, therefore compatibility with any standard Ethernet equipment is maintained and, in fact, data reception and transmission can be arranged on any Ethernet controller, if the corresponding software is available.

Beckhoff controller with a set of I / O modules. Source: www.beckhoff.de

The protocol specification is open and accessible, but only within the framework of the development association - EtherCAT Technology Group.

Here's how EtherCAT works (the sight is mesmerizing, like the Zuma Inca game):

The high exchange rate in this protocol — and we can talk about units of microseconds — is realized due to the fact that the developers refused to exchange using telegrams sent directly to a specific device. Instead, one telegram is sent to the EtherCAT network, addressed to all devices at the same time, each of the subordinate nodes for collecting and transmitting information (they are also often called USO - a communication device with an object) picks up from it on-the-fly the data that was intended for it and inserts it in a telegram the data that he is ready to provide for exchange. After this, the telegram is sent to the next subordinate node, where the same operation takes place. After passing all the ODR, the telegram is returned to the main controller, which, on the basis of the data received from the slave devices, implements the control logic, again interacting by means of a telegram with the slave nodes that issue a control signal to the equipment.

An EtherCAT network can have any topology, but in fact it will always be a ring - due to the use of full duplex mode and two Ethernet connectors. Thus, the telegram will always be transmitted sequentially to each device on the bus.

Schematic diagram of an Ethercat network with multiple nodes. Source: realpars.com

By the way, the EtherCAT specification does not contain limitations of the physical layer 100Base-TX, therefore, the implementation of the protocol is possible on the basis of gigabit and optical lines.

Siemens Open Industrial Networks and Standards PROFIBUS / NET

The German concern Siemens has long been known for its programmable logic controllers (PLCs), which are used around the world.

Data exchange between nodes of an automated system under the control of Siemens equipment is implemented both via a field bus called PROFIBUS and in the PROFINET industrial network.

The PROFIBUS bus uses a special two-wire cable with DB-9 connectors. At Siemens it is purple, but in practice we have met others :). To connect several nodes, the connector can connect two cables. It also has a switch for a terminal resistor. The terminal resistor must be turned on at the end devices of the network, thus it is reported that this is the first or last device, and after it there is nothing, only darkness and emptiness (all rs485 work like that). If you turn on the resistor on the intermediate connector, then the section following it will be disconnected.

PROFIBUS cable with connectors. Source: VIPA ControlsAmerica

The PROFINET network uses an analogue of a twisted pair cable, usually with RJ-45 connectors, the cable is painted green. If the PROFIBUS topology is a bus, then the topology of the PROFINET network can be anything: even a ring, even a star, even a tree, even taken together.

Siemens controller with connected PROFINET cable. Source: w3.siemens.com

There are several communication protocols on the PROFIBUS bus and on the PROFINET network.

For PROFIBUS:

- PROFIBUS DP - the implementation of this protocol implies communication with remote slaves, in the case of PROFINET this protocol corresponds to the PROFINET IO protocol.

- PROFIBUS PA - is essentially the same PROFIBUS DP, only used for explosion-proof versions of data transfer and power supply (analogue of PROFIBUS DP with other physical properties). For PROFINET, an explosion-proof protocol by analogy with PROFIBUS does not yet exist.

- PROFIBUS FMS - designed to exchange data with systems of other manufacturers that cannot use PROFIBUS DP. The equivalent of PROFIBUS FMS in the PROFINET network is the PROFINET CBA protocol.

For PROFINET:

- PROFINET IO;

- PROFINET CBA.

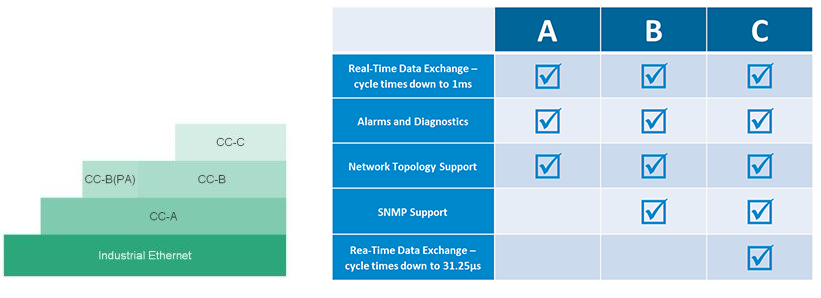

The PROFINET IO protocol is divided into several classes:

- PROFINET NRT (no real time) - used in applications where time parameters are not critical. It uses Ethernet TCP / IP as well as UDP / IP.

- PROFINET RT (real time) - here the input / output data exchange is implemented using Ethernet frames, but the diagnostic and communication data are still transmitted via UDP / IP.

- PROFINET IRT (isochronous real time) - This protocol was developed specifically for motion control applications and includes the isochronous phase of data transfer.

As for the implementation of the PROFINET IRT hard real-time protocol, two communication channels are allocated in it for communication with remote devices: isochronous and asynchronous. An isochronous channel with a fixed time exchange cycle length uses clock synchronization and transmits time-critical data; second-level telegrams are used for transmission. The transmission duration in the isochronous channel does not exceed 1 millisecond.

In the asynchronous channel, the so-called real-time data is transmitted, which is also addressed via the MAC address. Additionally, various diagnostic and auxiliary information is already transmitted over TCP / IP. Neither real-time data, much less other information, of course, cannot interrupt the isochronous cycle.

An expanded set of PROFINET IO functions is not needed for every industrial automation system, therefore this protocol is scaled for a specific project, taking into account the conformance classes or conformance classes: CC-A, CC-B, CC-CC. Compliance classes allow you to select field devices and trunk components with the minimum required functionality.

Source: PROFINET university lesson

The second PROFINET exchange protocol - PROFINET CBA - is used to organize industrial communication between equipment from different manufacturers. The main production unit in CBA systems is a certain entity called a component. This component is usually a combination of the mechanical, electrical and electronic parts of a device or installation, as well as the corresponding application software. For each component, a software module is selected that contains a complete description of the interface of this component according to the requirements of the PROFINET standard. Then these software modules are used to exchange data with devices.

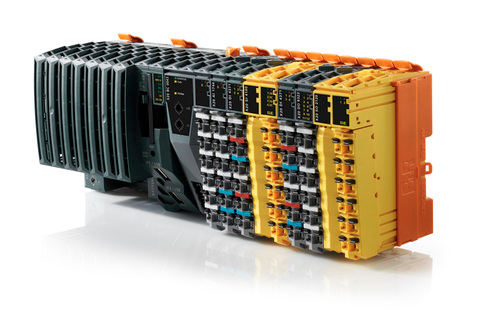

B&R Ethernet POWERLINK Protocol

The Powerlink protocol was developed by the Austrian company B&R in the early 2000s. This is another implementation of the real-time protocol over Ethernet. The protocol specification is available and distributed freely.

Powerlink technology uses the mechanism of the so-called mixed poll, when all the interaction between devices is divided into several phases. Particularly critical data is transmitted in the isochronous phase of exchange, for which the required response time is configured, the rest of the data will be transferred as far as possible in the asynchronous phase.

B&R controller with a set of I / O modules. Source: br-automation.com

Initially, the protocol was implemented on top of the 100Base-TX physical layer, but a gigabit implementation was later developed.

The Powerlink protocol uses an exchange planning mechanism. A certain token or control message is sent to the network, with the help of it it is determined which of the devices currently has permission to exchange data. Only one device can have access to the exchange at any time.

Schematic representation of an Ethernet POWERLINK network with multiple nodes.

In the isochronous phase, the polling controller sequentially sends a request to each node from which critical data must be received.

The isochronous phase is carried out, as already mentioned, with an adjustable cycle time. In the asynchronous phase of the exchange, the IP protocol stack is used, the controller requests non-critical data from all nodes that send a response as they gain access to the transmission to the network. The time ratio between the isochronous and asynchronous phases can be adjusted manually.

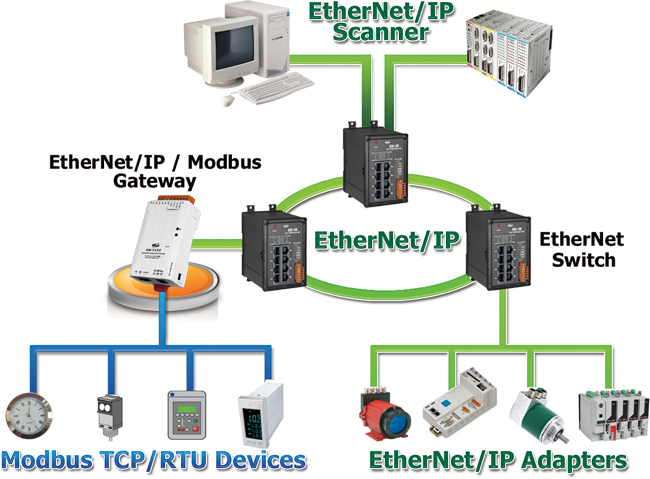

Rockwell Automation Ethernet / IP Protocol

EtherNet / IP was developed with the active participation of Rockwell Automation in 2000. It uses the TCP and UDP IP stack, and expands it for use in industrial automation. The second part of the name, contrary to popular belief, does not mean Internet Protocol, but Industrial Protocol. UDP IP uses the CIP (Common Interface Protocol) communication stack, which is also used on ControlNet / DeviceNet networks and is implemented over TCP / IP.

The EtherNet / IP specification is public and free. The Ethernet / IP network topology can be arbitrary and include a ring, star, tree, or bus.

In addition to the standard functions of the HTTP, FTP, SMTP, EtherNet / IP protocols, it implements the transfer of time-critical data between the polling controller and I / O devices. Transmission of time-critical data is provided by TCP packets, and time-critical delivery of cyclic control data is via UDP.

For time synchronization in distributed systems, EtherNet / IP uses the CIPsync protocol, which is an extension of the CIP communication protocol.

Schematic illustration of an Ethernet / IP network with multiple nodes and Modbus devices. Source: www.icpdas.com.tw

To simplify EtherNet / IP network setup, most standard automation devices come with predefined configuration files.

Fastwel FBUS Implementation

They thought for a long time whether to include the Russian company Fastwel with its domestic implementation of the industrial protocol FBUS in this list, but then they decided to write a couple of paragraphs to better understand the realities of import substitution.

There are two physical implementations of FBUS. One of them is a bus in which the FBUS protocol runs on top of the RS485 standard. In addition, there is an implementation of FBUS in an industrial Ethernet network.

It is difficult to call FBUS a high-speed protocol, the response time greatly depends on the number of input-output modules on the bus and on the exchange parameters, usually it varies between 0.5-10 milliseconds. One FBUS slave can contain only 64 I / O modules. For a fieldbus, the cable length cannot exceed 1 meter, therefore, we are not talking about distributed systems. Rather, it goes, but only when using an industrial FBUS network over TCP / IP, which means an increase in the polling time by several times. Bus extenders can be used to connect the modules, which allows you to conveniently place the modules in the automation cabinet.

Fastwel controller with connected I / O modules. Source: Control Engineering Russia

Total: how all this is used in practice in ACS TP

Naturally, the species diversity of modern industrial data transfer protocols is much larger than we described in this article. Some are tied to a specific manufacturer, some, on the contrary, are universal. When developing automated process control systems (APCS), the engineer selects the optimal protocols, taking into account specific tasks and limitations (technical and budget).

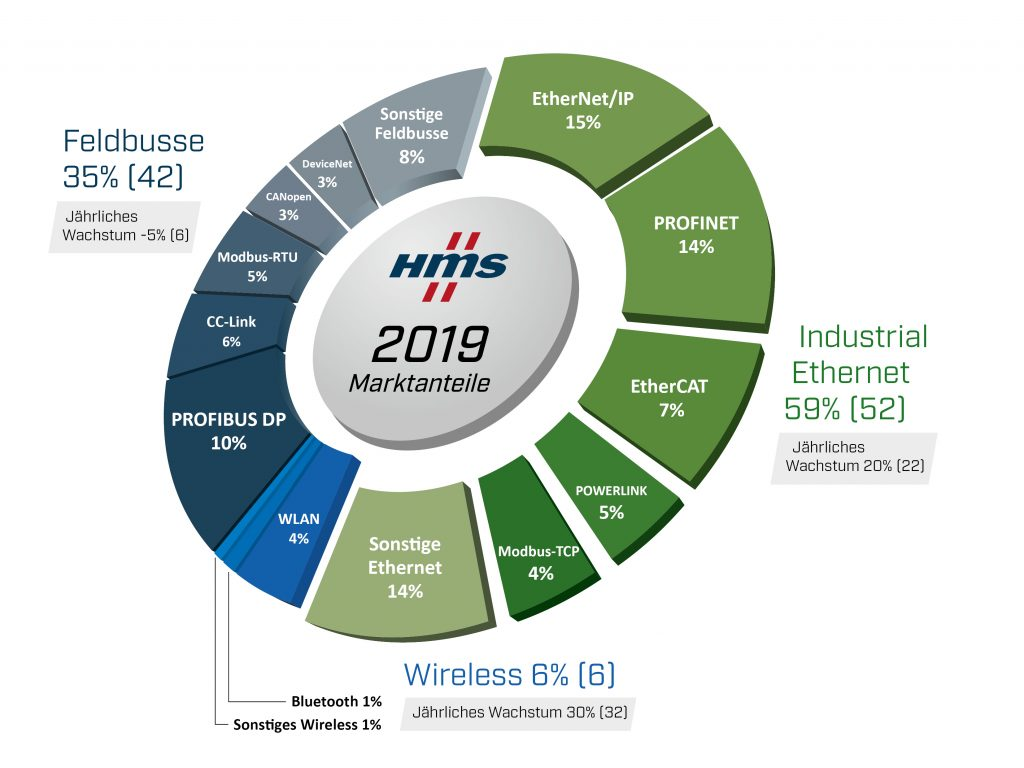

If we talk about the prevalence of a particular exchange protocol, we can cite the chart of HMS Networks AB , which illustrates the market share of various exchange technologies in industrial networks.

Source: HMS Networks AB

As can be seen in the diagram, PRONET and PROFIBUS from Siemens occupy a leading position.

Interestingly, 6 years ago, PROFINET and Ethernet / IP protocols occupied 60% of the market .

The table below summarizes the described exchange protocols. Some parameters, for example, performance are expressed in abstract terms: high / low. Numerical equivalents can be found in performance analysis articles.

|

| EtherCAT | Powerlink | PROFINET | EtherNet / IP | ModbusTCP |

Physical level | 100/1000 BASE-TX | 100/1000 BASE-TX | 100/1000 BASE-TX | 100/1000 BASE-TX | 100/1000 BASE-TX |

Data rate | Channel (Ethernet frames) | Channel (Ethernet frames) | Channel (Ethernet frames), Network / transport (TCP / IP) | Network / Transport (TCP / IP) | Network / Transport (TCP / IP) |

Real time support | Yes | Yes | Yes | Yes | Not |

Performance | High | High | IRT - high, RT - medium | Average | Low |

Cable length between nodes | 100m | 100m / 2km | 100m | 100m | 100m |

Transfer phases | Not | Isochronous + Asynchronous | IRT - isochronous + asynchronous, RT - asynchronous | Not | Not |

Number of nodes | 65535 | 240 | TCP / IP Network Limitation | TCP / IP Network Limitation | TCP / IP Network Limitation |

Collision Resolution | Ring topology | Clock synchronization, transmission phases | Ring topology, transmission phases | Switches, Star Topology | Switches, Star Topology |

Hot swap | Not | Yes | Yes | Yes | Depends on implementation |

Cost of equipment | Low | Low | High | Average | Low |

The applications of the described communication protocols, field buses and industrial networks are very diverse. From the chemical and automotive industries to aerospace technology and electronics. High-speed communication protocols are in demand in real-time positioning systems of various devices and in robotics.

What protocols did you work with and where did you use it? Share your experiences in the comments. :)