Collaboration in the design of electrical systems products.

Electrical equipment is the basis of modern products

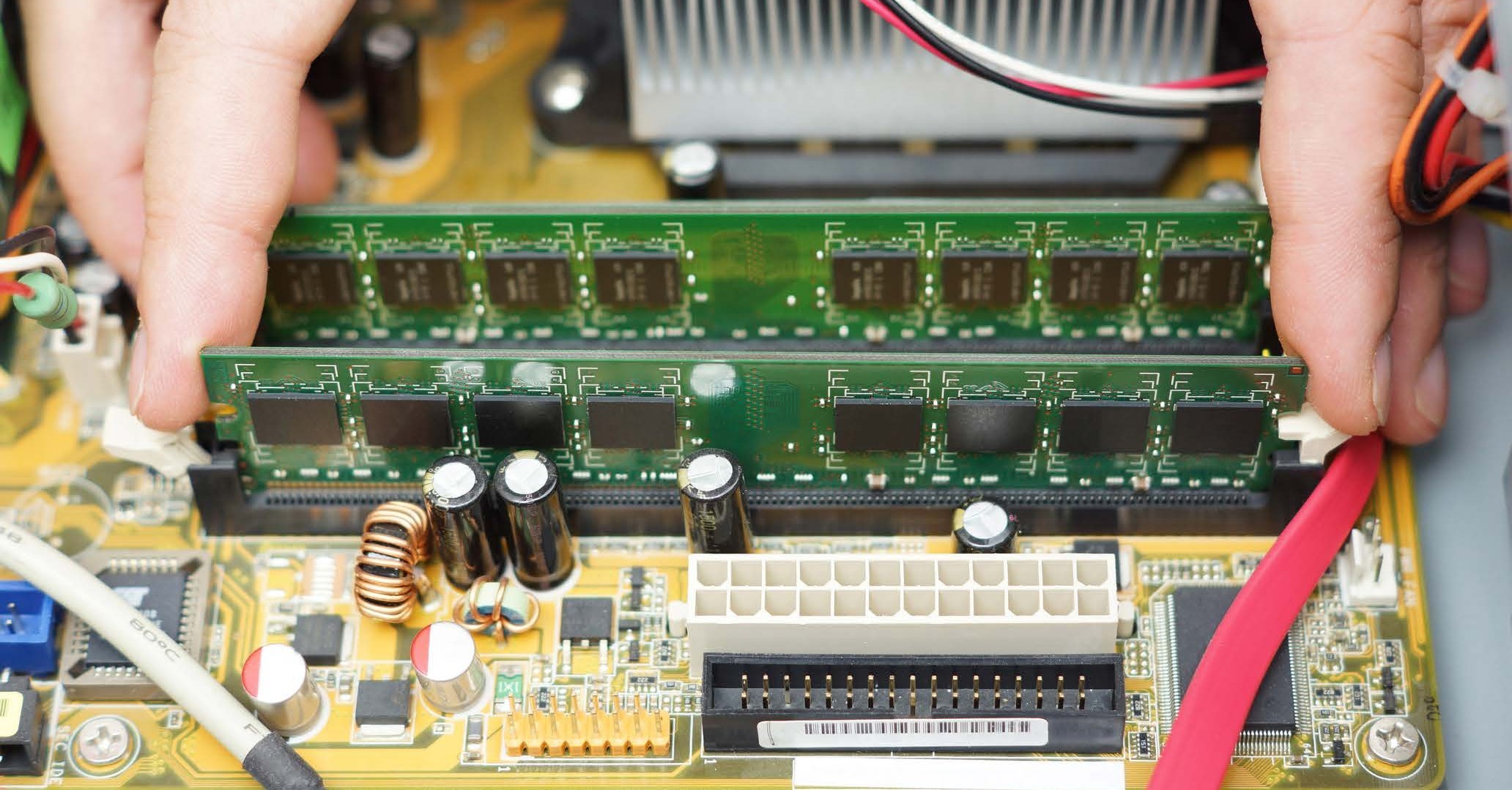

Today, most products are simply stuffed with electronics. Electronic systems perceive the environment and control the operation of equipment. Processors, printed circuit boards and embedded software enable machines to intelligently respond to and act on the environment with motors and drives. Electronic components communicate with IoT devices. In addition, electronics is integrated with electrical equipment, which has become a kind of "nervous system" of modern products.

Therefore, today the design of electrical systems is the most important stage of product development. If there is a lack of electric power, the electronics will start to malfunction, and if there is an excess of it, either the fuse or the electronic components themselves will burn. Too low network bandwidth leads to packet loss, which destroys the control system or does not allow the results of analytical processing of data from Internet of things devices to be applied. Without reliable electrical systems, modern products simply become inoperative.

Joint and step-by-step development process

Designing electrical systems is a very time-consuming task. And not only circuit engineers solve it. Mechanical engineers also make a big contribution. They develop routes for wiring through the mechanical components of the product, often combining wires into bundles. Typically, the process is as follows:

Electrical design: circuit engineers develop a functional and logical design of the electrical system. They choose the types of electrical elements and connectors. Elements are connected by conductors. Then, the control of design decisions is carried out to make sure that the scheme functions exactly as intended. At this stage, a complete description of the electrical system is obtained, indicating all the elements, connectors, and conductors connecting them.

Tracing electrical wiring through mechanical components: Based on the design of the electrical system, mechanical engineers begin to lay wiring through mechanical components. At the same time, they follow the documentation prepared by circuit engineers. It indicates which elements each wire connects. In order not to create chaos, the mechanical engineer combines the wires into bundles and finds the optimal trajectory of their trace, ensuring the implementation of all electrical connections.

Iterative design and troubleshooting:

On the tracing of wiring harnesses on the mechanical components of the product, the design does not end. There are always problems requiring identification and elimination. In particular, if the wire is too long, an excessive signal attenuation occurs.

If the power cable is laid next to the control cable, interference may occur. Circuit engineers and mechanical engineers must work together and iteratively to identify and fix problems. At this last stage, circuit designers and mechanics need to constantly exchange information. To check the quality of signal transmission, electricians need to know the initial lengths of the conductors and the lengths after making the changes. Mechanics need to know about all the changes that electronics engineers make to wiring and connectors. Therefore, the importance of sharing information and working together can hardly be overestimated.

Three-minute demonstration of creating, routing, and arranging wires, cables, and bundles in a Solid Edge assembly environment:

Another point - in some cases, circuit engineers and mechanics need to solve problems together. To do this, you need to clearly understand the relative position of electrical elements, wiring, and mechanical components, which will allow you to successfully identify and eliminate inconsistencies.

Primitive, fragmented systems

Given the growing demand for smart, connecting to the network products and devices of the Internet of things, most companies require simple and effective design systems (best if they already exist in the organization). These include:

- A universal application for the development of electrical circuits , in which the design of electrical systems is performed;

- 2D computer-aided design (CAD) systems used for laying wires and bundles along the mechanical components of the product;

- spreadsheets for the preparation of specifications and calculations;

Purely technically, this set of tools is enough for the design of electrical systems. However, the main disadvantages are hidden in the methods of interaction of mechanical engineers and electricians, which creates risks for the entire product development process; - Lack of automation: these three applications are in no way integrated with each other, which does not allow automating the processes of information transfer from the design stage of electrical equipment to the stage of tracing electrical wiring on mechanical components. Mechanical engineers have to manually deal with the documentation for the electrical system to find out where and which wires need to be laid;

- Lack of associativity in the iterative design process: As noted above, the development of electrical systems is an information process. The listed tools are not connected in any way. Any changes made must be manually evaluated and discussed with colleagues. This not only spends valuable time, but also leads to errors due to the human factor;

- Lack of interactivity: Scattered tools do not allow you to find the same wire both on the electrical circuit and on the drawing of the mechanical assembly. Applications are not related. They lack the intellectual representation of the elements of electrical equipment and wiring. Because of this, engineers spend a lot of time identifying problems, and there is a danger of making mistakes.

These shortcomings do not just create inconvenience in work. They can lead to much bigger problems. Failure to quickly eliminate inconsistencies leads to a breakdown in design time. Lack of tools to support the collaboration of engineers devalues their efforts. There is a high probability that a design error will proceed to the next stages, which will cause a complete disorganization of the entire development process.

Solid Edge Wiring and Harness Design Modules

Fortunately, new design tools have emerged that address these risks. In order to meet market demand and maintain a high level of quality, you need to find the best way to integrate mechanical and electrical design solutions. Solid Edge modules for the design of electrical systems are characterized by ease of use, wide functionality and high efficiency, which will be appreciated by customers.

Solid Edge : a package of affordable and convenient tools that solve all the problems of product development. In relation to the design of electromechanical systems, Solid Edge performs 3D modeling of mechanical components along which bundles and wires are laid.

Solid Edge Wiring and Harness Design modules are designed to develop wiring diagrams and work together with mechanical engineers to optimize the overall design of the product. The modules support data integrity at all stages - from the construction of wiring diagrams to the design of wiring harnesses. As a result, making the wrong design decision becomes simply impossible.

Solid Edge Electrical Routing Module : A specialized environment for efficient wiring design, wire routing and bundling them into bundles and cables when working with assemblies in Solid Edge.

All modules not only have wide functionality, but are also fully integrated with each other, which gives a number of significant advantages.

Automated information transfer: thanks to close integration, information on electrical systems is comprehensively transferred to the stage of development of mechanical components. Mechanical engineers get a clear list of wires to be laid.

All changes made are bi-directionally transmitted between the electrical and mechanical parts of the project. As a result, the design process is automated, and productivity increases dramatically.

Intellectual associativity of project documentation: when adding elements to one document, they are appropriately added to other documents. For example, if you put a new element on the wiring diagram, it will appear in the 3D assembly of the corresponding mechanical assembly, as well as in the design specification, and the color change of the wire on the 3D assembly of the mechanical assembly is displayed on the wiring diagram and in the specification. In other words, one change applies to all documents. As a result, the human factor is eliminated and the probability of making mistakes is minimized.

Interactive object selection: The modules in question are connected in real time to the Solid Edge Electrical Routing module. This makes collaboration possible when selecting an item in one application makes it stand out in another. For example, when an electrical engineer selects a wire on a wiring diagram, the same wire is highlighted on a 3D model of a mechanical assembly. And vice versa: when selecting a wire of a 3D model of a mechanical unit, the same wire is highlighted on the wiring diagram. This feature facilitates discussion when identifying and resolving interdisciplinary discrepancies.

The modules form an integrated solution that increases the productivity of both electrical engineers and mechanical engineers. Specialists jointly find problems in electrical systems and fix them. As a result, projects are completed on time and on budget.

Chad Jackson, chief analyst at Lifecycle Insights:

“One of the biggest difficulties in developing intelligent and network-connected products is solving the problems of integrating electronic, electrical and mechanical systems. Convenient bi-directional transmission of information between electrical engineers and mechanical developers allows them to work only with current versions of the project, eliminates problems associated with the increasing complexity of the project, and also simplifies collaboration if problems are identified. The use of Solid Edge Wiring and Harness Design modules, tightly integrated with the traditional Solid Edge engineering environment, is a step in the right direction. ”

Special Price for Solid Edge Electrical Design

Nanosoft announces special prices for software for the development of the electrical part of the project:

Until December 20, there is a 40% discount on the Solid Edge Electrical Design + Solid Edge kit , and for Solid Edge users, a 40% discount on Solid Edge Electrical Design .