The decrease in the cost of access to space and the emergence of humanity the possibility of the colonization of Mars were declared by Elon Musk as the goal of the existence of SpaceX since the founding of the company in May 2002. However, such ambitious plans could not be realized with the initial investment of Mask, which amounted to about $ 100 million, so SpaceX began their work with the development of a rather modest launch vehicle “Falcon 1”, capable of putting only 420 kg into low Earth orbit.

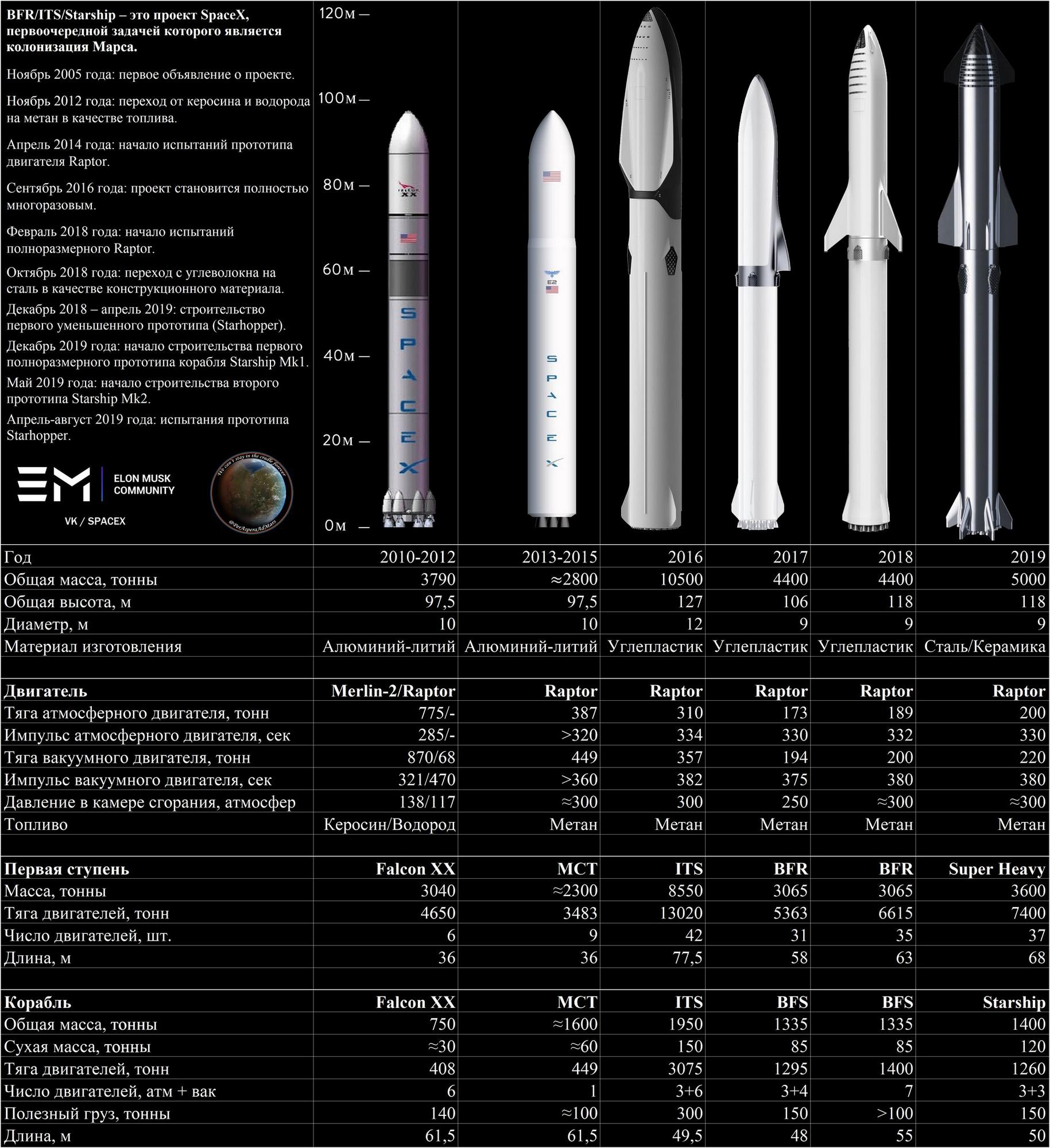

However, already in November 2005 , before the launch of his first rocket, when the entire company had only about 160 employees, he announced plans to create an extra-heavy rocket for flying to Mars capable of delivering 100 tons of payload into orbit. The project was called "BFR", which later became officially decrypted as Big Falcon Rocket, and the original unofficial name was translated as "damn big rocket." At its first stage, there should have been an enlarged version of the Merlin 2 oxygen-kerosene engine, in which they planned to replace the ablation cooling of the combustion chamber with regenerative cooling (in the first case, special material is used on the walls of the chamber to cool the chamber, which gradually evaporates, and in the second case, pumping fuel or an oxidizing agent through many thin tubes in the walls is used for this). In terms of thrust, this engine should have yielded only to the RD-170, and the Raptor oxygen-hydrogen engine should have stood at the 2nd stage.

But the first 3 unsuccessful launches of Falcon 1 by the end of 2008 put the company on the brink of ruin, so strategic plans had to be temporarily put aside in favor of finding funds for the implementation of ongoing projects. Nevertheless, already on July 30, 2010, Tom Markusic presented at the AIAA Joint Propulsion presentation the technical details of the project.

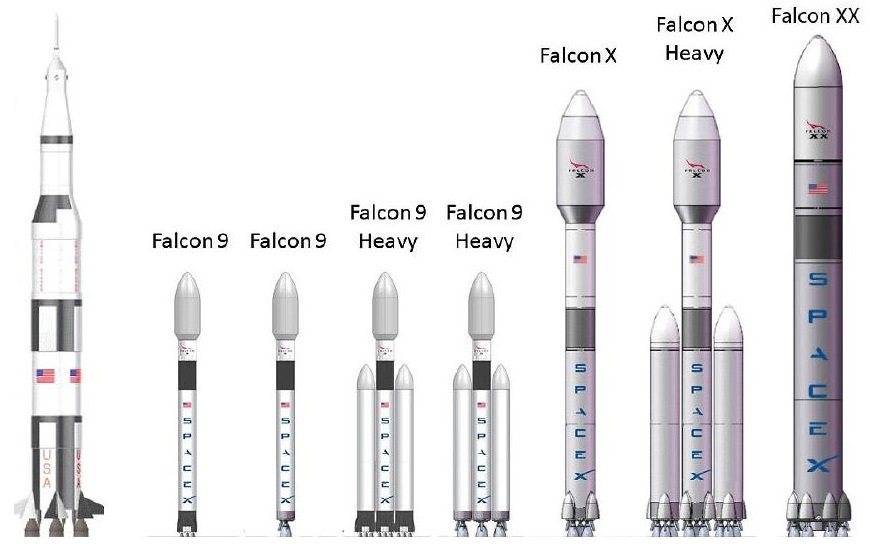

At that time, the missile was an enlarged Falcon 9, having 3 versions: Falcon X / Falcon X Heavy with a diameter of 6 m and Falcon XX with a diameter of 10 m. A pair of engines was provided for them: the first stage was to be driven by kerosene engines "Merlin 2" with a thrust of 770 ton-forces and an impulse of 285 seconds at sea level and 870 tons and 321 seconds in vacuum, with a pressure in the combustion chamber of 138 atmospheres in both cases. The second stage was supposed to install a Raptor hydrogen-oxygen engine with a thrust of 68 tons and an impulse of 470 seconds, at a pressure of 117 atmospheres. The launch vehicles were to launch 38, 125 and 140 tons of payload into low Earth orbit, respectively.

Comparison of the sizes of the new line of missiles with Falcon 9 and Saturn-5 (left).

However, almost immediately it turned out that obviously it would not be possible to make a system having 2 types of fuel, one of which is also hydrogen. And since one of the key approaches in the work of SpaceX, Elon Musk announced the rejection of expensive solutions, it was decided to abandon this option almost immediately. In November 2012, Musk publicly announced that methane-oxygen engines would be installed on their new rocket. A little later he announced her mysterious abbreviation “MCT”, which turned out to be an abbreviation for the name “Mars Colonial Transport”, which was supposed to transport 100 people to Mars at a time.

In the second quarter of 2013, Musk announced that SpaceX would not conduct an IPO (public offering of stocks) until regular MCT flights to Mars began. He called the reason for this that exchange investors are not interested in projects that are so long in implementation that, as a result, could lead to conflicts in the management of the company.

Also at this time it was announced that the thrust of the Raptor will be increased to 300 tons. And on February 19, 2014, at a conference in Santa Barbara, California, SpaceX's vice president of engine manufacturing Thomas Muller announced that the Raptor will have a complete gasification scheme for fuel components. At that time, there were only two such engines in the world - the Soviet 640-ton RD-270 and the American 112-ton IPD - the tests of both for various reasons were never completed.

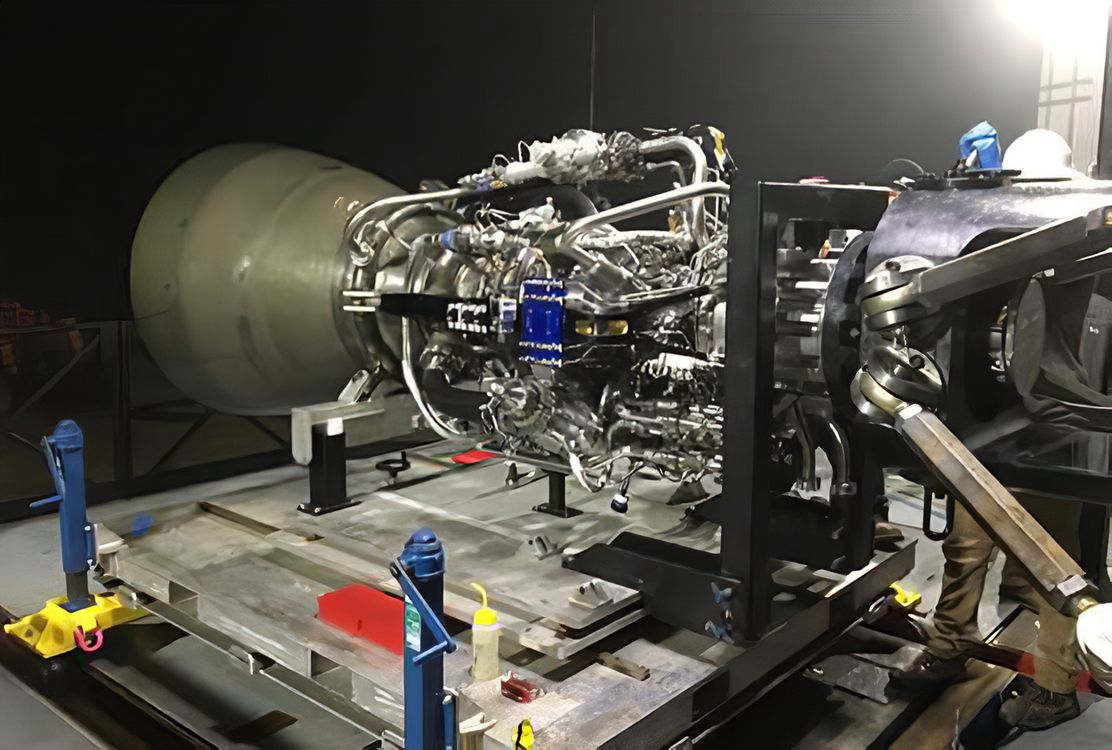

Due to the fact that IPD developments were carried out under the auspices of NASA, and thus belonged to all US citizens at once, SpaceX took advantage of them, also gained access to the equipment and even lured some of the specialists working on it, since this project did not continue. Testing of the Raptor gas generator began in May 2014, and by April 21 at the Stennis Space Center (Mississippi), a test bench for testing all engine subsystems was completed. Shortly thereafter, tests began on a smaller version of the engine, with a thrust of about 100 tons.

On September 28, 2016, at the International Congress of Astronautics, Ilon Musk first personally presented the Martian transport project, which was supposed to have truly insane characteristics. Having 12 meters in diameter and 122 meters in height, this 2-stage ITS booster rocket (stands for Interplanetary Transport System) was supposed to have a total mass of 10.5 thousand tons, develop an engine thrust of 13 thousand tons and put into orbit 300 and 550 tons of cargo in reusable / disposable versions. In terms of these indicators, ITS should have exceeded at least 3.5 times all previous launch vehicles that have ever been created.

The Raptor engine at that time was supposed to develop 310 tons of sill thrust with an impulse of 334 seconds in the atmospheric version, and in the vacuum - 357 tons of forces and 382 seconds of impulse. The pressure in the combustion chamber of the engine also had to exceed all the analogues that existed at that time, reaching 300 atmospheres.

The first stage was supposed to have a dry mass of only 275 tons, with a total mass of the stage of 6975 tons, and have 42 atmospheric Raptor. The ship and the tanker had to have a dry weight of 150/90 tons, a payload of 300/380 tons and a total weight of 1950/2500 tons, respectively. They should have been installed on 3 atmospheric and 6 vacuum versions of the engine, and their length would be 49.5 meters. At the same time, it was planned to achieve a launch cost of only $ 43 million for the ship and $ 8 million for the tanker, which, given the dispatch of 100 passengers at a time on the ship, gave a ticket price of only $ 140 thousand per person.

In order to understand how crazy the indicators were laid into this system, it is enough to look at its mass perfection (the ratio of the mass of empty rocket stages to the total mass of refueled ones): for the first stage, it should have been 0.039, and for the tanker, it should be 0.036. For comparison, in the Russian-Ukrainian Zenit-3MS rocket, this figure is only 0.079 for the 1st stage and 0.094 for the 2nd, and for the Falcon 9 Block 5 launch vehicle, these values are 0.065 and 0.04, respectively. SpaceX planned to achieve all this due to the widespread use of carbon fiber as a structural material.

It is not at all surprising in this situation that the project is faced with serious technical problems. At the next International Congress of Astronautics on September 29, 2017, Elon Musk again presented a project that has undergone major changes downward. The total weight of the system was reduced to 4,400 tons, with 5,400 tons of traction and 31 engines at the 1st stage. The dimensions of the system also decreased: the diameter began to be 9 meters, and the total height - 106 meters. There are 3 atmospheric and 4 vacuum engines left on the ship, with a total mass of the structure of 1335 tons and a length of 48 meters. The characteristics of the Raptors also decreased: to a pressure of 250 atmospheres, 173 tons of traction at an impulse of 330/356 seconds in the atmosphere / vacuum for the atmospheric version, and 194 tons of traction at an impulse of 375 seconds for the vacuum version.

However, there was good news: by this time, the ≈100 ton-thrust version of the Raptor had already passed 42 tests, with a total duration of more than 20 minutes. At the same time, the pressure in the combustion chamber was raised to 200 atmospheres.

In 2018, the presentation of changes to the system was combined with the presentation of the first passenger of the ship - billionaire Yusaku Maedzawa - so the technical part turned out to be rather meager. Perhaps the main changes Musk announced in this presentation on September 17, 2018, were an increase in the length of the ship to 55 meters and the installation of 7 Raptor engines on it only in the atmospheric version. The reason for such changes was the desire to quickly switch to commercial operation of the system.

In October 2018, Musk decided to transfer the reusable system to steel as a structural material, which he later called the best design solution for this system, since steel costs only 2% of the cost of carbon fiber ($ 3 against almost $ 200 per 1 kg), and also has great strength at cryogenic and high temperatures.

In early December 2018, at the private SpaceX cosmodrome in Boca Chica (Texas), the assembly of an unusual vehicle began, which finally took its form by January 10. This device turned out to be Starhopper - a 39-meter reduced version of the Starship, designed for the first flight tests of the engine, manufacturing technologies for cryogenic tanks and their refueling.

To test Starhopper , tanks with a volume of 432 m 3 for liquid oxygen and 364 m 3 for liquid methane were installed in Boca Chica, which were refueled in advance by gas carrier trucks. Work inside and on the surface of Starhopper continued for several months, and for ease of access inside, its nose was not firmly fixed, due to which a storm wind broke off and damaged the fairing on January 23 at a speed of 80 km / h. They decided not to restore it, but to cover the Starhopper with a hemispherical lid.

However, in the morning of February 3, good news about the project appeared again: at the test site in McGregor (Texas), the first tests of the full-sized Raptor began, which immediately began to go at a very aggressive pace.

By February 7, Raptor had developed 172 tons of thrust at a pressure in the combustion chamber of 257 atmospheres on “warm” fuel, which was higher than the required threshold of 170 ton-forces for using it on a launch vehicle and ship. On February 10, a pressure of 268.9 atmospheres was achieved, which corresponded to approximately 180 tons of thrust. And by February 21, engine No. 1 was planned to be damaged in a test to develop the highest possible pressure.

Starhopper transported to launch site March 8, 2019 in Boca Chica, Texas.

On April 3, Starhopper completed the first burn with engine # 2, followed by a small jump on the “leash” on April 5, to a height of about 1 meter.

In May, the Starship Mk1 ship was laid in Boca Chica, and at the same time, in the Coco town (Florida), the parallel laying of the Starship Mk2 started! The teams building the prototypes applied different construction methods, thus competing among themselves, for which they were given the name: the Mk1 in Boca Chica was built by the “red” team, and the team that built the Mk2 in Coco became “blue”. This paid off, since the blue team from Cocoa from the very beginning managed to advance in construction much faster, although they started construction a little later. But in order to complete the construction of the Mk1 by the time of the presentation, part of their team was temporarily transferred to Boca Chica.

At the same time, the tests of Starhopper continued: on July 22, he made a full flight lasting 22 seconds and a height of 18 meters.

However, the engine tests did not go quite smoothly: engines No. 3 and 4 were lost in the fight against technical problems, and No. 5, due to design flaws, displaced the stator of the oxygen turbine, which was why they also decided to disassemble it for spare parts.

All this, together with the problems of dangerous vibrations at a frequency of 600 Hz, was able to defeat Raptor No. 6. And although he still had the risk of damage with a thrust of about 40% , this nevertheless did not interfere with the lengthy tests of Starhopper, since at the same time the thrust should not fall below 50%.

On August 27, the final flight of Starhopper took place with an engine number 6 to a height of 150 meters, lasting about 57 seconds. After that, it was decided to use it only for test burns of engines.

It is worth noting that such a large expenditure of engines in the testing process is quite common: so on the RD-270 tests, 22 pieces were used, while for the complete completion of the tests they required as many as 200 pieces.

Nevertheless, problems with throttling the engine led on June 28, Ilona Mask to the idea of creating a simplified version of the engine for a constant thrust of 250 tons . Also in June, it became known that the success of the Starship trials convinced 3 telecommunications companies to choose this carrier as a means of delivering their satellites into orbit in 2021.

According to current data, the prototype of the Starship Mk1 ship weighs ≈200 tons at a height of 50 meters , but by the 4th or 5th ship it is planned to reduce the mass to 120 tons. The mass of the ship will have to reach 1400 tons, and the total mass of the system - as much as 5000 tons.

At the moment, SpaceX has already submitted an application to the FAA for a Starship Mk1 test flight, which, according to SpaceX National Security Contract Director Gary Henry, should take place in about 2 months. And according to Musk, Starship can enter the orbit for the first time already in 2020, which implies the assembly at this point also of the 1st stage - Super Heavy.

Raptor

Recently, Musk has also provided some details about the engine design. Its combustion chamber and nozzle have a cooling jacket from milled copper channels, the loads from which are transferred to the casing from inconel. And for efficient mixing of fuel components, many coaxial centrifugal nozzles are used . It is also noteworthy that the capacity of the turbines in one Raptor is as much as 74 megawatts .

Musk also said that by the end of the year it is planned to reach a production speed of 500 Raptor per year. According to his estimates, mass production will reduce their cost by more than 10 times. In future versions, it is planned to achieve a Raptor mass of 1.5 tons with a thrust-weight ratio of more than 170. Also, according to environmental analysis , the characteristics of the Raptor nozzle became known:

| Characteristic | Critical Section Radius | Fillet radius | Touch angle | Nozzle outlet diameter | Nozzle length |

|---|---|---|---|---|---|

| Value | 0.111 m | 0.033 m | 32 ° | 1.3 m | 1.53 m |