The birth of new technologies in traditionally manufactured business processes

I haven’t picked up a pen for a long time ...

Last year, he described several technical Trouble Shooting projects. I want to continue with this article.

The uniqueness is that I post the project, not because it was not accepted or paid, but because the customer gave permission, although with some restrictions.

Some time later, after the publication of an article on a 3D metal printer , one entrepreneur approached me with a proposal for cooperation. As often happens, the task was to invent a bicycle, i.e. what was needed has long been needed. Therefore, instead of cooperation, I just gave the person a tip on the manufacturer and forgot for a while. But, the boomerang of good always returns. A year later, this entrepreneur addressed a new task that we have worked out and which I will talk about today.

To design a fully automated apparatus for the production of seals and stamps, with a production speed of no more than 5 minutes per 1 standard print.

I start any project with a detailed analysis. The analysis is: the problem, the market, the customer, the customer’s customer, competitors, analogues, solutions in related industries, etc.

An autopsy showed that there are several technologies for the production of seals and stamps, including:

We disassembled these technologies by processes, in order to identify the most expensive, from the point of view of automation:

Further, the technologies were analyzed in terms of the quality of the result.

I will not give a comparison table, I can only say that flash technology won, because:

As a result, it was decided to automate flash technology.

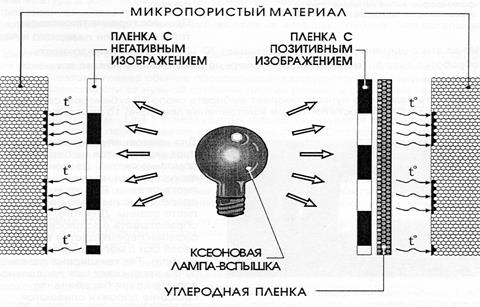

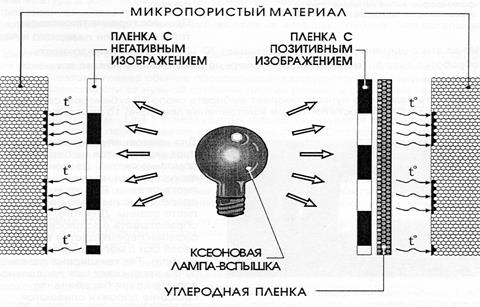

Flash technology stamp manufacturing scheme

The simplest solution would be to make a mini production line. When, in the technology itself, nothing changes, but intermediate devices are added. Or a robot (following the trends).

But this approach is alien to us and this is what we came up with:

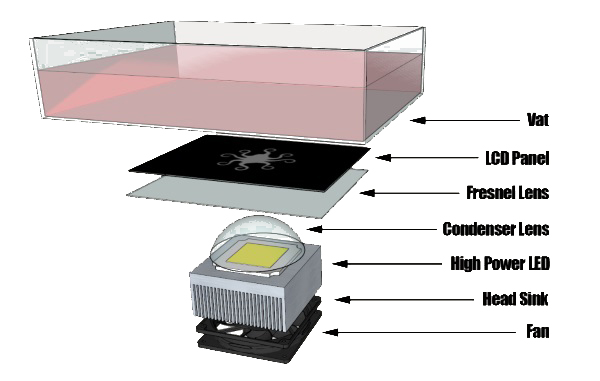

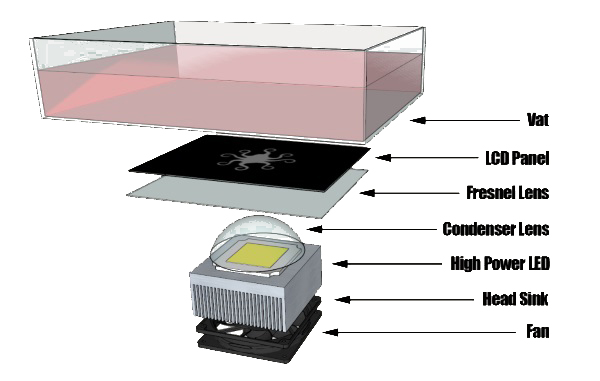

Option 1. Instead of the template printed on the printer (stencil), we will use the matrix from the phone. This principle is applied in 3D printers (LCD SLA UV technology). This will allow us not to move the template, but to form it directly in the working area of the device, which will increase speed and reduce the cost of the design.

The scheme of using a phone screen matrix for UV exposure

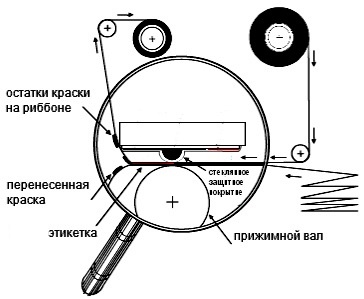

Option 2. Instead of a flash lamp, for spot sintering of pores of microporous rubber, we will use a thermal head from a thermal printer (receipt printer). Those. a template is not needed at all.

Thermal Printer Operation Scheme

Option 3. To use cheaper options for the source material, we will not bake the pores, but clog them. For this we use:

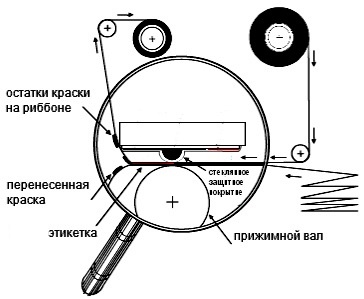

Option 3a. thermal printer with ribbon (thermal transfer ribbon).

Ribbon thermal transfer scheme

Option 3b. Laser printer.

Options 1, 2 and 3a are tested in practice and work fine. Of course, it was necessary to select the optimal modes (for example, the temperature of the thermal head, speed, etc.), the optimal materials (both main and auxiliary).

Option 3b. Although it is theoretically the most promising, it still requires the selection of a porous heat-resistant material, and perhaps a slightly different approach (for example, printing on a micro grid and then using it as a stencil).

As a result, we have developed as many as 4 options for new printing technologies. All of them have a speed much higher than required and the cost is lower than existing.

Last year, he described several technical Trouble Shooting projects. I want to continue with this article.

The uniqueness is that I post the project, not because it was not accepted or paid, but because the customer gave permission, although with some restrictions.

Background

Some time later, after the publication of an article on a 3D metal printer , one entrepreneur approached me with a proposal for cooperation. As often happens, the task was to invent a bicycle, i.e. what was needed has long been needed. Therefore, instead of cooperation, I just gave the person a tip on the manufacturer and forgot for a while. But, the boomerang of good always returns. A year later, this entrepreneur addressed a new task that we have worked out and which I will talk about today.

A task

To design a fully automated apparatus for the production of seals and stamps, with a production speed of no more than 5 minutes per 1 standard print.

Analysis

I start any project with a detailed analysis. The analysis is: the problem, the market, the customer, the customer’s customer, competitors, analogues, solutions in related industries, etc.

An autopsy showed that there are several technologies for the production of seals and stamps, including:

- Photopolymer technology. The simplest and most common technology to date. The technology consists in exposing, through the template, a polymer resin sensitive to UV rays (approximately, just like the photoresist is illuminated in the manufacture of printed circuit boards).

- Laser engraving. Here, I think the explanation is superfluous.

- Flash technology. For the manufacture of seals, this technology uses a special microporous rubber, the pores of which are sintered by the action of temperature. For spot sintering, a flash lamp and a stencil are used.

- Mechanical engraving. Rarely used.

- Printing on a 3D printer. Exotic option.

We disassembled these technologies by processes, in order to identify the most expensive, from the point of view of automation:

- In photopolymer technology, it is a washing of clichés from an uncured photopolymer.

- In laser technology, this is the periodic calibration of the laser and the removal of the smell of burnt rubber.

- In flash technology, the processes are simple, but the material itself is expensive (microporous rubber).

- Mechanical engraving is time.

- 3D printing - maintenance.

Further, the technologies were analyzed in terms of the quality of the result.

I will not give a comparison table, I can only say that flash technology won, because:

- High resolution

- May be multicolor,

- Moisture resistance

- Ease of use (paint filled),

- Big cycle between gas stations.

As a result, it was decided to automate flash technology.

Flash technology stamp manufacturing scheme

Decision

The simplest solution would be to make a mini production line. When, in the technology itself, nothing changes, but intermediate devices are added. Or a robot (following the trends).

But this approach is alien to us and this is what we came up with:

Option 1. Instead of the template printed on the printer (stencil), we will use the matrix from the phone. This principle is applied in 3D printers (LCD SLA UV technology). This will allow us not to move the template, but to form it directly in the working area of the device, which will increase speed and reduce the cost of the design.

The scheme of using a phone screen matrix for UV exposure

Option 2. Instead of a flash lamp, for spot sintering of pores of microporous rubber, we will use a thermal head from a thermal printer (receipt printer). Those. a template is not needed at all.

Thermal Printer Operation Scheme

Option 3. To use cheaper options for the source material, we will not bake the pores, but clog them. For this we use:

Option 3a. thermal printer with ribbon (thermal transfer ribbon).

Ribbon thermal transfer scheme

Option 3b. Laser printer.

Options 1, 2 and 3a are tested in practice and work fine. Of course, it was necessary to select the optimal modes (for example, the temperature of the thermal head, speed, etc.), the optimal materials (both main and auxiliary).

Option 3b. Although it is theoretically the most promising, it still requires the selection of a porous heat-resistant material, and perhaps a slightly different approach (for example, printing on a micro grid and then using it as a stencil).

Result

As a result, we have developed as many as 4 options for new printing technologies. All of them have a speed much higher than required and the cost is lower than existing.

All Articles