Prototyping fixtures using 3D printers

Prototyping is one of the most popular uses for 3D printers. And this is quite understandable. 3D printing helps in a short time to get a lot of product samples without resorting to the services of outsourcing companies. As a result, we get solid pluses: reduced labor costs, often for materials and reduced prototype manufacturing time. The big mistake is that only industrial 3D printers costing over a million will help optimize the production process. CENTRSVET GROUP, which has been using 3D printing for prototyping for more than a year, is proof of that.

CENTRSVET has been developing and producing premium class lamps since 2005. The design of the lamps is designed in the style of functionalism and has a special conceptual and concise character. The main value of the company - the right light.

Due to its attention not only to design, but also to the quality of light, the company has won many prestigious awards, is a regular partner of well-known television projects and has earned the respect of customers in the b2b and b2c segments.

Below are some team projects:

Special project - Groza chandelier by order of the Museum of Moscow City

Selection of lighting fixtures for K. Orbakaite’s apartment (“Perfect Repair” TV program)

The right light for the "World Class" in Sochi

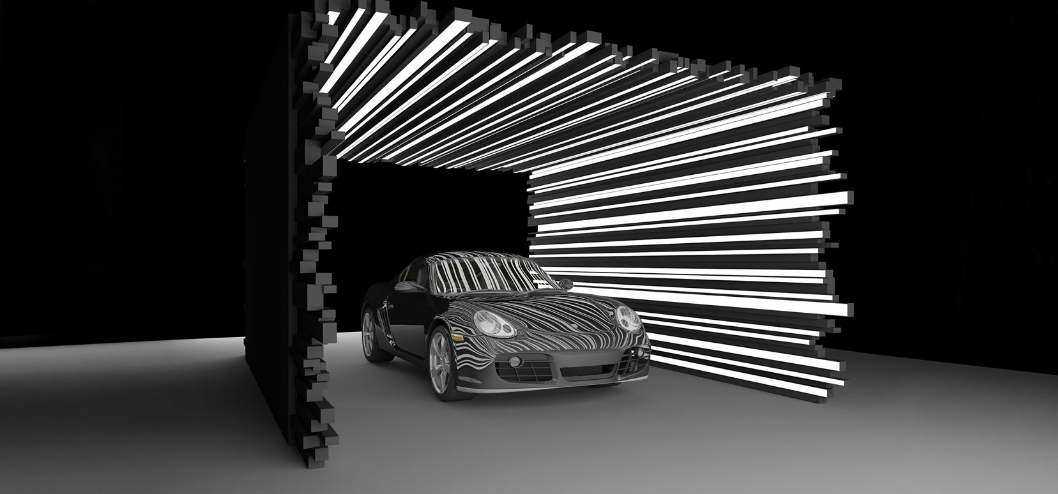

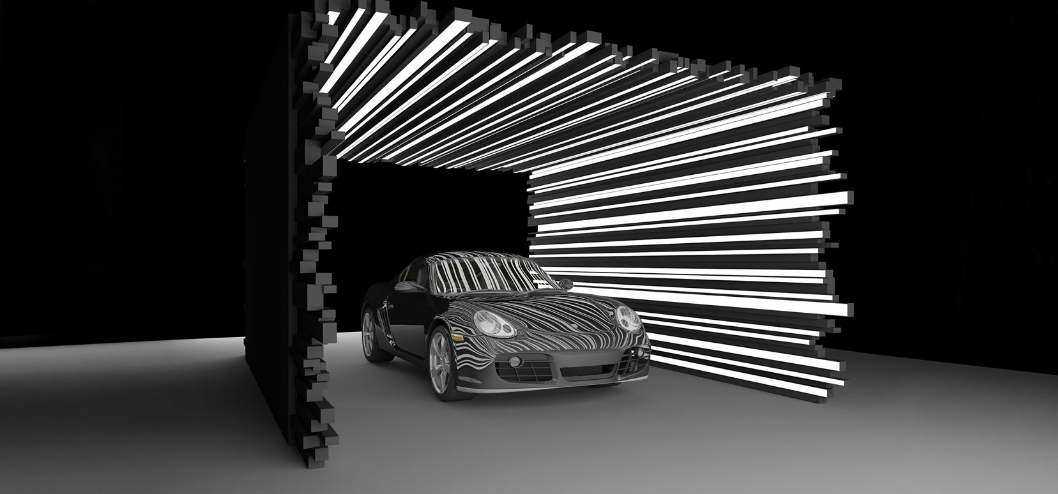

Light installation for the presentation of the Porsche 911 GTS

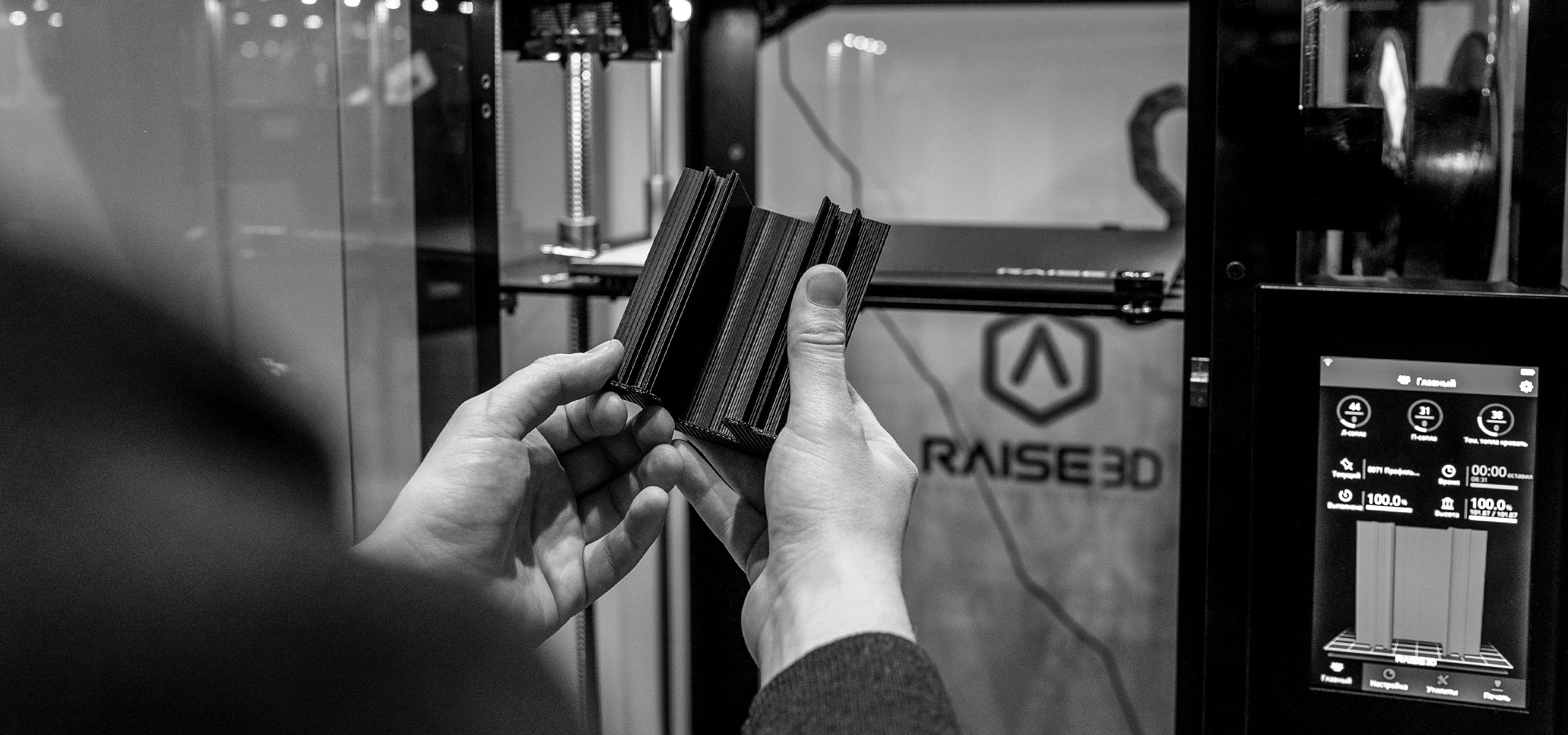

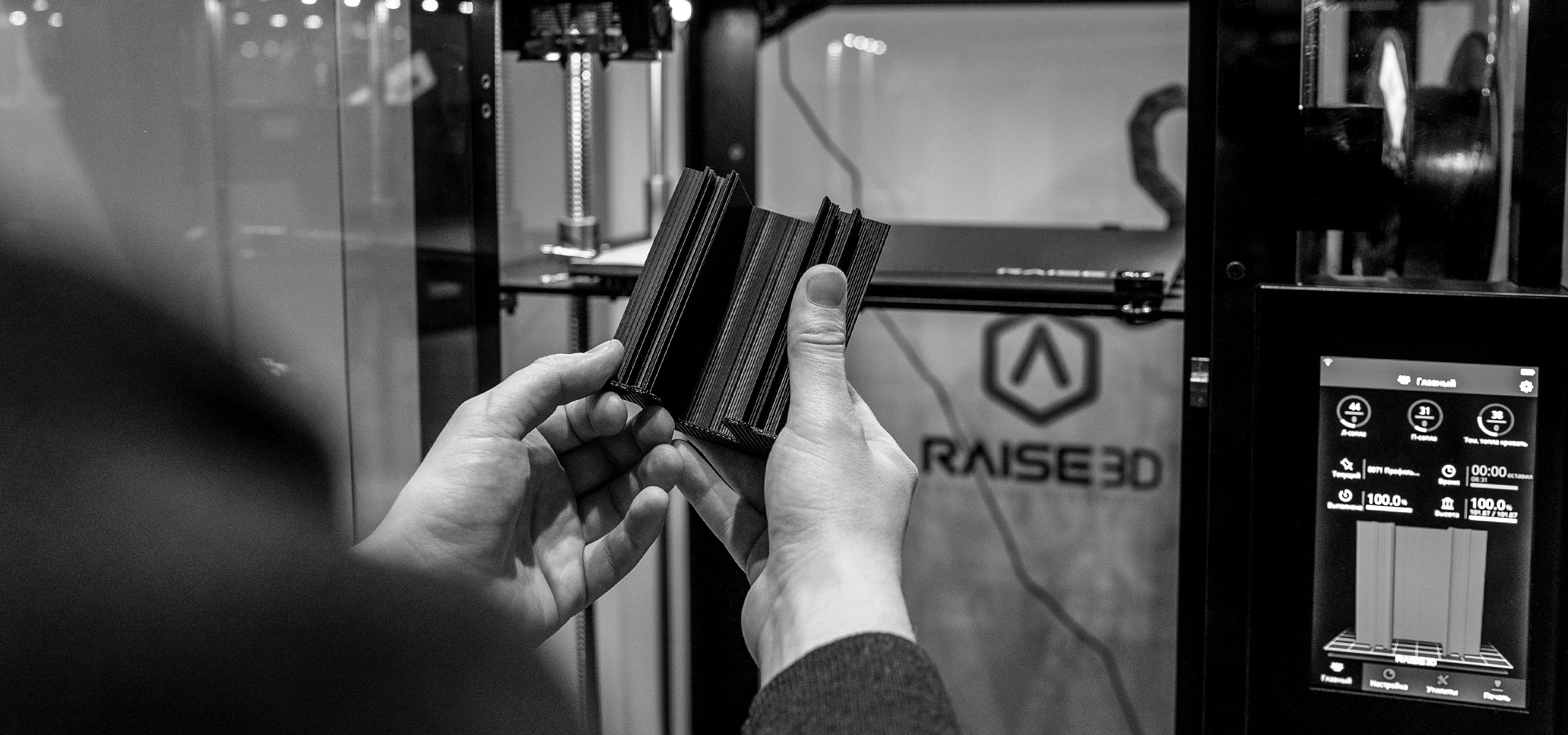

In order to create an ideal in every sense of the product, more than one prototype has to be made. For this purpose, 2 assistants appeared in CENTRSVET - a 3D Raise3D N2 Plus printer.

Alexander, an engineer working with printers, shared his impressions of Raise3D and explained why they decided to use 3D printing in their production. Raise3D is not the first 3D printers in the company. CENTRSVET has been using additive technologies for a long time.

“The most important thing that we focused on when choosing a 3D printer was the construction area, printing accuracy, reliability and minimal maintenance time. Raise3D N2 Plus approached in all respects, and after starting work with Raise3D, we were only convinced of the correctness of our choice. ”

Alexander said that at the moment prototypes of absolutely all products are printed on 3D printers, from small lamps to large global objects. Each prototype is agreed by the commission, changes and adjustments are recorded that need to be made.

Most often, each product has to create several prototypes with regard to the changes that are made, step by step until the ideal result is achieved.

Estimated not only the appearance of the printed housing fixtures, but also the location of the electronics inside.

Alexander says that given the very large range of companies, it is difficult to imagine how the coordination would take place when creating samples for outsourcing. The time spent on the production of the product would increase significantly.

For a couple of months from the moment of purchase, the Raise3D printers proved to be like real workaholics, working almost without interruptions. Alexander said that since the first launch, printing time was more than 600 hours. For comparison, before the company used 2 MakerBot printers, which have accumulated 1200 hours in 2 years.

If Raise3D keeps to its current rhythm, in 2 years the figure will be 7200 hours. But, something suggests that the pace will increase with each month =)

Join us in the social. networks to keep abreast of the latest developments:

VKontakte Raise3D Club Russia - Raise3D owners club in Russia:

VKontakte | Facebook | YouTube

The team of the company Color World

CENTRSVET has been developing and producing premium class lamps since 2005. The design of the lamps is designed in the style of functionalism and has a special conceptual and concise character. The main value of the company - the right light.

Due to its attention not only to design, but also to the quality of light, the company has won many prestigious awards, is a regular partner of well-known television projects and has earned the respect of customers in the b2b and b2c segments.

Below are some team projects:

Special project - Groza chandelier by order of the Museum of Moscow City

Selection of lighting fixtures for K. Orbakaite’s apartment (“Perfect Repair” TV program)

The right light for the "World Class" in Sochi

Light installation for the presentation of the Porsche 911 GTS

In order to create an ideal in every sense of the product, more than one prototype has to be made. For this purpose, 2 assistants appeared in CENTRSVET - a 3D Raise3D N2 Plus printer.

Alexander, an engineer working with printers, shared his impressions of Raise3D and explained why they decided to use 3D printing in their production. Raise3D is not the first 3D printers in the company. CENTRSVET has been using additive technologies for a long time.

“The most important thing that we focused on when choosing a 3D printer was the construction area, printing accuracy, reliability and minimal maintenance time. Raise3D N2 Plus approached in all respects, and after starting work with Raise3D, we were only convinced of the correctness of our choice. ”

Alexander said that at the moment prototypes of absolutely all products are printed on 3D printers, from small lamps to large global objects. Each prototype is agreed by the commission, changes and adjustments are recorded that need to be made.

Most often, each product has to create several prototypes with regard to the changes that are made, step by step until the ideal result is achieved.

Estimated not only the appearance of the printed housing fixtures, but also the location of the electronics inside.

Alexander says that given the very large range of companies, it is difficult to imagine how the coordination would take place when creating samples for outsourcing. The time spent on the production of the product would increase significantly.

For a couple of months from the moment of purchase, the Raise3D printers proved to be like real workaholics, working almost without interruptions. Alexander said that since the first launch, printing time was more than 600 hours. For comparison, before the company used 2 MakerBot printers, which have accumulated 1200 hours in 2 years.

If Raise3D keeps to its current rhythm, in 2 years the figure will be 7200 hours. But, something suggests that the pace will increase with each month =)

Join us in the social. networks to keep abreast of the latest developments:

VKontakte Raise3D Club Russia - Raise3D owners club in Russia:

VKontakte | Facebook | YouTube

The team of the company Color World

All Articles