Printed items access the Internet of Things without electronics on board.

The Internet of Things is becoming an increasingly common technology. Many users of gadgets related to this area do not even know how it all works. In most cases, systems of this type are equipped with special chips that allow cameras, refrigerators and even teapots to enter the network. Without such chips, the devices would cost much less. But is it possible to imagine the possibility of interaction with the network without the necessary electronic components?

It turns out, yes. According to some experts, even a regular bottle with a laundry softener used for washing can provide information on how much liquid is left in the bottle, and whether it is time to run to the store for a new softener. All that is needed to create a module capable of transmitting information about the amount of a substance (or many other parameters) is a 3D printer.

New technology was developed at the University of Washington. Specialists who participated in the project achieved the ability to create plastic objects and sensors that are able to collect and transmit information to network devices. CAD-models of these systems, the developers have already posted on the network. Using models, volume print enthusiasts will be able to develop various products on their own, putting them on sale. For example, it can be a volume control without a battery and a WiFi chip, a button for automatically ordering goods from Amazon or Ebay, a security sensor warning the user that a pipe has burst in the house.

“Our goal was to create something that you can print on a printer at home and connect to a wireless network,” says one of the participants. “But the greatest success was the fact that this can be done without wireless communication modules, all devices created are made of plastic. This is something that did not exist before. ”

The principle of operation of the system is described in an article published as early as November 30, 2017, following the results of a report made at the SIGGRAPH conference (Conference and Exhibition on Computer Graphics and Interactive Techniques in Asia) .

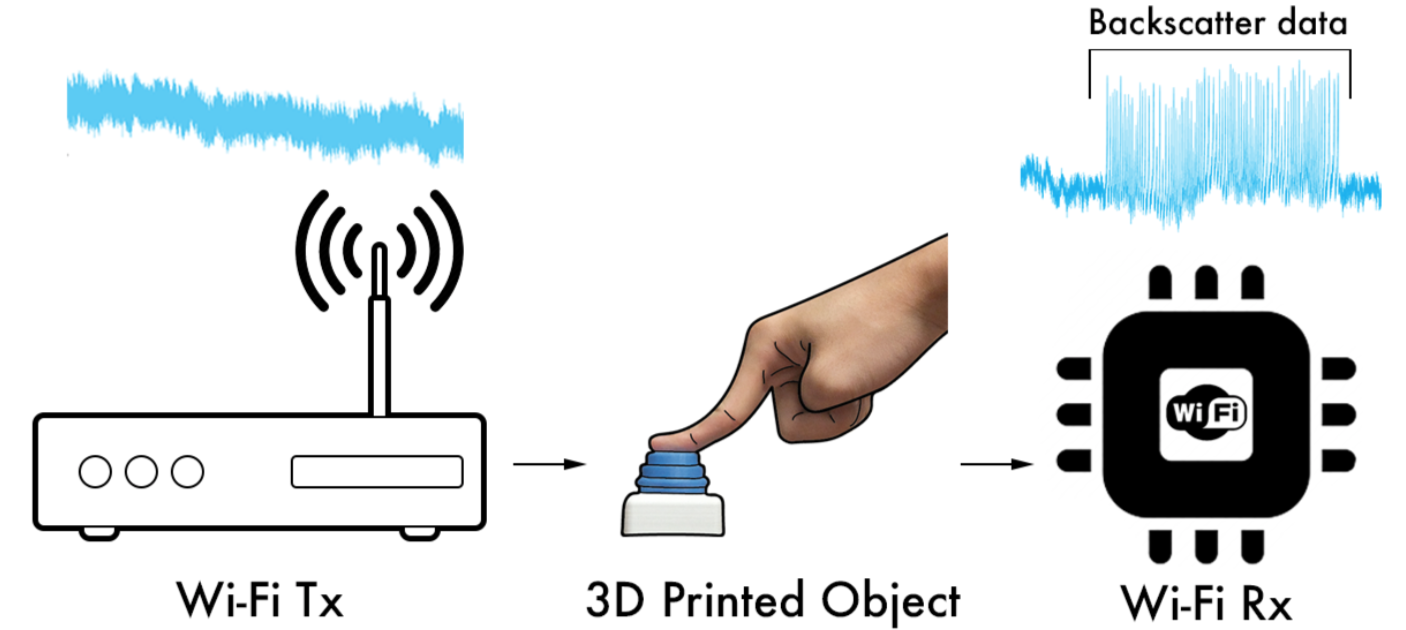

There is nothing fantastic here. Experts have created technology, using the method of backscattering . It allows devices to share information. In the project in question, the team replaced some electronic components with conventional plastic. These systems use plastic springs and gears for operation. All of them can be easily printed on a 3D printer.

In backscatter systems, an antenna is used to transmit data. This data is reflected by the WiFi router (or other device) radio emission, which changes in a certain way and is reflected again. Changes made to the radiation are of a specific nature, which allows decoding the information embedded in the reflected radiation. The antenna itself embedded in a plastic device is a conductive plastic fiber or copper particles “embedded” in plastic.

In the case of a plastic system of a certain work (pressing a button, turning a gear or a spring), the conductivity of the system changes, and the radio emission reflected by it carries with it certain changes. They, as mentioned above, are decrypted by a wireless electronic device.

The information that is embedded in the radiation is digital, that is, it is a common binary system of ones and zeros. The developers managed to achieve this with the help of special gears with teeth of various configurations. The sharp prong is zero, blunted - one. A working device transmits a system of ones and zeros to the wireless network, which is decoded if there is special software (in this case there is nothing complicated).

If you go back to the same bottle with a softener, then in order for the smart home system to track the amount of substance in it, you just need to put a module with a small wheel with blades on the neck. Turning, the system transmits a signal that catches special software that monitors the amount of substance in the bottle. “When the volume of the softener reaches a critical level, the system understands this and can send an order to Amazon to receive the same bottle of softener. Thus, the user does not have to go to the store himself and waste his time. ”

The university team, with the support of UW Networks & Mobile Systems Lab, has printed several work systems that are able to monitor certain processes and transmit information to wireless devices. Plastic systems that scientists have printed out are not too complicated, but indicative. This is an anemometer, a measure of the speed of fluid movement through pipes and scales. Among other scientists, they created a module that monitors the level of the liquid in the bottle (it was this device that was mentioned above).

More scientists have created all sorts of switches, knobs and plastic buttons, with which they were able to control smart devices in the office.

This technology can also be used as a radio tag, which does not require electronic components, a bar code and other identification systems. "They all look like ordinary objects printed on a printer, but their peculiarity is that they change the configuration of the surrounding radio emission and / or magnetic field."

The study was funded by the National Science Foundation, the Sloan Foundation and Google.

All Articles