Need for vinyl. We are talking about eco-solvent printing and car vrapping

Many of you already know that Epson produces printers for printing on T-shirts, photo printers for printing gallery and exhibition works, sublimation printers that print on thermal transfer paper, but we have not told about eco-solvent yet.

The time is right to correct, because at the recent past championship on vinyl styling - Russian Wrap Masters up 2017 - all works for pasting were printed on an Epsol SureColor SC-S80610 eco-solvent printer .

In this post we will tell and show how the printing and pasting of cars, as well as what materials are suitable for such tasks.

Russian Wrap Masters Cup

At the end of September in Moscow, the annual Russian Car Wrap Masking Championship was held - Russian Wrap Masters Cup 2017 (by the way, the qualifying round of the World Cup). The best master pastors from all over the country fought for the title of champion of Russia and the right to represent the country at the World Championships. The work of the masters was evaluated by an international judging panel led by vice-world champion Colin Skaberes.

Of course, pasting, like airbrushing, is not a cheap pleasure. And prices vary considerably. Much depends on the materials and area of the glued surfaces. The larger and bold the area, the more expensive a square meter. A meter of high-quality premium cast film with a real lamination and printing will cost about 50-60 dollars. Of course, you can choose a more budget option, varying materials and print quality. The cost of car pasting will cost from $ 1000 to $ 6000. What is surprising is that even at this threshold of entry, there are craftsmen who can turn this operation in their garage (having an imprint in their hands, of course), but most likely the result will be far from perfect.

But we still talk about the professional approach.

Airbrush and Vinyl

So, you decided to make your horse unique - it's time to decide: airbrush or vinilography ?

Airbrush | Vinilography |

| Benefits:

1. Excellent anti-theft tool, the car is noticeable and remembered. 2. Lifetime is much longer than the film. 3. Airbrushing is the work of an artist, i.e. you get a picture, only written not on a canvas, but on a car body. | Benefits:

1. Usually, a more affordable solution for the price than airbrush (depending on the area of coverage). 2. Pasting of the whole car can be made in a few days. 3. If the vinyl gets bored, it can be painlessly removed or replaced. 4. Reliable protection of the vehicle against minor scratches and chips. 5. Always know the final result, which can be seen first on the monitor, and then exactly the same in the details on his horse. |

| Disadvantages:

1. The quality of airbrushing depends only on the professionalism of the master. You can get a very mediocre picture that is difficult to fix. 2. A very long process (sketching on paper, discussion of the sketch takes about 2-3 months). 3. If the drawing gets tired, it will be very difficult to get rid of it. Is that stick vinyl :-) 4. It is not easy to sell a car with airbrushing. 5. And, of course, the price: professionals charge about $ 300-500 for a small idea that does not go beyond one part; if this is a high-quality, traced to the smallest detail picture, then 700-1000 dollars. For the hood is usually double the price because of its large area. | Disadvantages:

1. Term of use - up to 7 years, in some cases - up to 10. 2. Burnout. If the vinyl was, for example, only on the wing, then after removing the paint color, which was under the vinyl, will slightly differ in tone (slightly lighter or darker) from the color on the car body (often solved by light polishing). Minus is noticeable if a part of the element is glued. For example, a circle on the hood, the door. |

Suppose that having considered all the pros and cons, you chose vinyl . What's next?

- We determine the pattern and detail on which we want to apply it.

- We choose a film (with the involvement of professionals), because not only the cost depends on its type, but also how much our masterpiece will delight the owner and those around him.

Film maker

For auto styling used vinyl films. Vinyl is a popular name. In fact, this is all PVC - polyvinyl chloride.

Depending on the type of production, the films are calendered and cast .

Calendered, in turn, are divided into monomeric and polymeric, depending on the type of vinyl used in production. Polymer or monomeric vinyl raw paint, heat, pass through an extruder (from the Latin extrudo - "push") - a machine for softening materials and giving them shape by pushing through a profiling tool. Then repeatedly rolled through a series of heated shafts, calenders. As a result, the material is literally stretched to the required thickness and a thin film is obtained. Since the material undergoes constant tension in the direction of motion when creating calendered films (the film is actually pulled through the machine), when exposed to temperature and time, they tend to return to their original state as much as possible.

Monomeric calendered film is primarily a budget solution for printing. Very often you can find advertising signs in cracks or traces of glue around the work schedule on the doors of the bank. This happens when they try to save money and use the budget film for longer than expected.

For professional autovinyl, monomer films are not used. But the polymeric calendered film can already be used on slightly curved surfaces and is used for autovinyl for short-term solutions, also for advertising on public transport.

Casting

It is cast films used for so-called. "Wrapping" (wrapping), that is, covering / pasting cars. In injection molding technology, polymer vinyl raw material is dissolved in solvents and poured onto a special substrate. After several additional technological cycles, a very thin film is obtained, and the casting method makes it possible to achieve not only the small thickness of the material, but also its equal thickness throughout the entire area.

In cast films there is no residual stress, and accordingly, there is no shrinkage. Such a film is exceptionally stable and stable and is characterized by minimal internal stresses.

In most cases, the components of the raw material mixture for casting, which ensure the quality of the finished films, are more expensive than those used in calendering. But durability and easy formability justify higher costs when buying cast films.

| Indicator | Calendered | Molded |

| Life time | 1–7 years old | up to 10 years |

| Minimum thickness | 60 microns | 40 microns |

| Cuddling | there is | not |

| Temperature resistance | up to 90 ° C | up to 115 ° C |

| Cold stretching | with heat treatment | without heat treatment |

| Curved base film adhesion | only with heat treatment | without heat treatment |

Little about the printing process

Of course, as a customer, you won’t worry much about which printer your picture is printed on, the main thing is the result. But we offer printers, so we can not share what we are proud of - a series of large-format printers for outdoor printing . Briefly tell about the technology and the printers themselves.

What kind of ecosolvent and why is it needed?

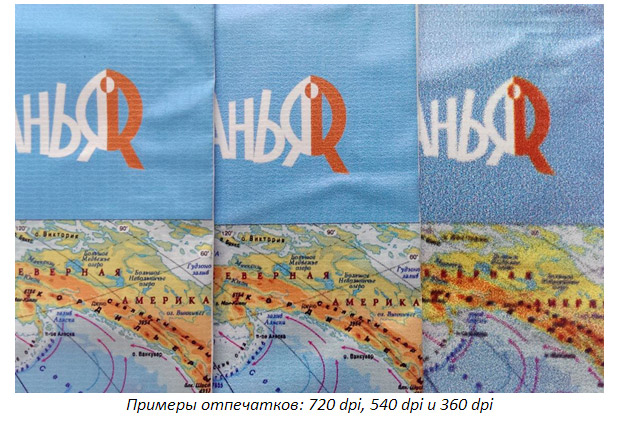

In the beginning was the solvent. Solvent ink is extremely aggressive and in fact eats into the media (most often it is banner fabric). Due to this, the seal is the most resistant to external influences - rain, sun and mechanical damage. Cyclohexanone contained in solvent inks has been found to be quite harmful for the environment and human health. The premises where solvent machines operate must be equipped with forced-air ventilation. In addition, a low print resolution (360 dpi) and a rather large drop size (40–80 pl) limit the use of such printers by external printing of wide and extra-wide formats. That is, upon closer inspection, the graininess will be visible.

One of the key principles of production for Epson is the environmentally friendly products, so even for creating works for outdoor use, we produce only eco- solvent printers. What's the Difference?

Eco-solvent inks are sufficiently resistant for external printing, while they are suitable for printing interior works, as they are the safest inks in the whole group of solvent-based inks. The shelf life of the print when used in the external design - up to 3 years without lamination.

In addition, eco-solvent printers of the SureColor SC-S series have a resolution of 1440 dpi, and the minimum droplet size is only 4.2 square meters. Epson UltraChrome GS3 ink is practically odorless and does not contain nickel; therefore, it does not require additional ventilation systems, which makes it possible to use Epson SureColor SC-S printers in ordinary office premises.

Printers for eco-solvent printing are usually used for printing advertising, for example, luxury brands, vinyl stickers for pasting cars, that is, when you need high quality (detail) and durability.

Epson eco-solvent printers have three models: Epson SureColor SC-S40610 , Epson SureColor SC-S60610 and Epson SureColor SC-S80610 .

The maximum print width of all models is 64 inches (1624 mm), and they differ in color and print speed:

- Epson SureColor SC-S40610 is the youngest model in the line, uses 4 colors (CMYK) for printing.

- Epson SureColor SC-S60610 is the same four-color model, with only two print heads and 8 slots for cartridges (CMYK + CMYK). Thanks to two print heads, it can reach speeds of up to 95.3 square meters. at one o'clock.

- Epson SureColor SC-S80610 is the flagship model with 8 and 10 colors, including white and metallic inks, so you can even print on transparencies.

All works for the participants of the Russian Wrap Masters Cup were printed on Epson SureColor SC-S80610.

Andrei Lobov , organizer of the Russian Wrap Masters Cup 2017, an Orafol technician, explains why an Epson eco-solvent printer was chosen for printing participants' works:

“The quality of work and durability of the result, first of all, depend on the material and skills of the master pastor. But the quality of the picture itself is certainly the merit of the printer. We noticed the Epson SureColor SC-S80610 printer back in 2016 at the Druppa exhibition in 2016. Then a bright and juicy imprint attracted the attention: we had never seen such color and brightness of colors, especially red. Everyone who glues vinylography is celebrated. ”

How to glue car vinyl tape

We, of course, recommend to contact the experts to do everything correctly and get the desired result. Professionals know the principle of working with the film, the sequence of actions and have in place all the required materials and equipment.

The whole process involves working with reagents and chemically active substances, therefore safety precautions must be followed:

- clean room with good ventilation;

- temperature not below +22 degrees;

- low humidity, and then the film may begin to peel off;

- If, when pasting, trash gets under the cover, it can lead to material deformation.

Methods and stages of pasting

The two main methods are dry or wet .

Pasting on a dry surface is faster than on a wet one. However, with dry gluing, it is impossible to correct the location of the material, if the vinyl is already applied to the surface of the car.

The wet method is more practical - the sticker can be slightly moved, unfolded and smoothed.

Stages pasting

First you need to conduct training.

- Degrease the body / details of the car, which will be attached to the film.

- Fitting. It is necessary to carefully calculate the position of the film on the surface of the machine.

- It is necessary to detach the film from the paper base, which covers the adhesive part, and take the spray with a solution of water and detergent.

- It is necessary to make special channels for the exhaust of air so that you can easily eliminate the bubbles that have appeared. Such air vents are made of squeegee, if dry vinyl pasting is carried out, or distillation, which is suitable for the wet method.

The last step is lamination .

For printed films, correct lamination is required. Unfortunately, it is often laminated with the same, but transparent material. This is fundamentally not true. It is necessary to use a film for lamination. First, it should be the same level as the printed film, for example cast. In addition to mechanical protection, the correct laminate will provide protection against UV radiation and the seal will not fade in a year, and in five, too. In addition, applying a film with lamination will be more convenient and easier.

Beauty! .. Strange?

As an afterword, we will share an interesting fact: in Japan every year an event called “ Itasha ” takes place. 痛 車 - literally “Machine, pain”, i.e. at the same time, for which it is shamefully painful, and “pain for the wallet” because of the high cost of turning the car into something described below. In principle, the term was originally applied to the overly expensive Italian cars of Japanese nouveau riche. Then he migrated to vinilografiyu with anime. By the way, it was the itasha-design that was used at the first championship of Russia.

Car owners and fans of manga and anime gather at the event and demonstrate their ... works of art in the form of cars, covered with film / painted with images of favorite cartoon characters and comics. And not only the exterior is estimated, but also the car interior . Easier to show than to tell:

Jalopnik has a posting with a bunch of photos and a delivering discussion (in English). You, most importantly, breathe evenly and calmly when you look at the photos =)

In addition, the event at the time told Danny Chu. There is a photo essay , as well as an excerpt from the author's program “Culture Japan”, dedicated to this event:

By the way, the transfer is excellent. Anyone who is interested in Japan (and owns any kind of English), we recommend for viewing.

Playlist with all the episodes on the author's channel . (Caution! Tightens for a long time!)

We thank the company VIOC for technical advice in preparing the post.

All Articles