Why the appearance of electricity did not immediately change the industry?

The increase in productivity, expected due to the emergence of electric dynamos, was late in appearance

For investors who have invested in Boo.com, WebVan and eToys, the end of the dot-com bubble has been a huge shock. Such companies have collected tangible investments under the promise that the world wide web will completely change everything. And then in the spring of 2000, stock markets collapsed.

Some economists were skeptical of bloated computer-related promises right from the start. In 1987, we didn’t have the World Wide Web, but databases and spreadsheets appeared in all workplaces - and this had almost no effect.

boo.com is famous for its collapse in May 2000, which happened after it failed to get additional funding.

A leading growth analyst, Robert Solow, issued a phrase that later became famous: “The computer age has come everywhere except for performance statistics.”

It is difficult to calculate the impact of innovation on the economy. The best measurement method available to us is total factor productivity. Its growth means that the economy is somehow seeking an increase in output with the same investments — such as mechanisms, human labor, and education.

Performance paradox

In the 1980s, when Robert Solow wrote his analytics, productivity grew record-breakingly in many decades — even slower than during the Great Depression. Technology flourished, and productivity stagnated. Economists have called this a performance paradox.

To understand what happened then, you need to rewind time a hundred years ago. Then another great technology disappointed the producers: electricity.

Some corporations invested in dynamos and motors, installed them in the workplace. But the expected surge in performance did not occur.

But the potential of electricity was clearly visible. Thomas Edison and Joseph Swan [and Alexander Nikolaevich Lodygin - approx. transl.] independently invented a usable incandescent lamp in the 1860-1870s. In 1881, Edison built power stations on Pearl Street in Manhattan and on Holborn Street in London.

Pearl Street Station became the first central commercial power plant in the world

Less than a year, as he already sold electricity as a commodity. A year later, the first electric motors fed on the production. And yet, by the year 1900, less than 5% of the energy in America’s factories came from electric motors. The era of steam continued.

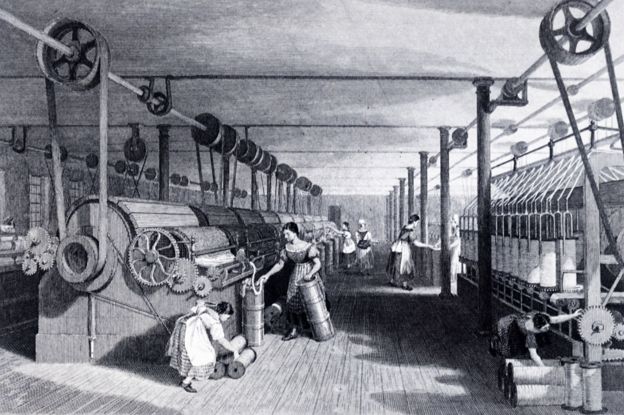

The steam factory was supposed to be very impressive. Mechanical energy came from a single huge steam engine, turning the central steel shaft, running along the entire length of the factory. Sometimes he went outside and continued in the next building.

The steam cotton factory of 1830 was based on a complex design of gears and belts

Auxiliary shafts connected by gears and belts controlled hammers, piercers, presses and weaving machines. Belts could even transfer energy vertically through a hole in the roof to the second or even third floors.

They were closed by complex "belt towers" that protected against the spread of fire through the holes. Hundreds of lubricators constantly greased the whole structure.

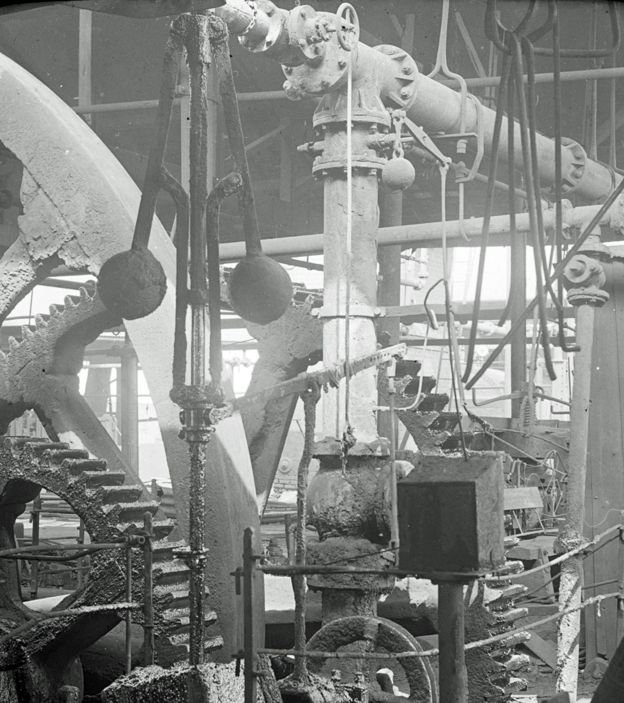

Steam engines rarely stopped. If the factory had to work at least one machine, it was necessary to burn coal in the furnace.

The teeth rustled, the shafts twisted, the belts stirred fat and dust, and there was always a risk that the worker would clamp the sleeve or cord, and he would be dragged into a comprehensive machine that worked tirelessly. But some factory owners replaced steam engines with electric motors, receiving clean and modern energy from the nearest power station.

Revolutionary influence

But because of the need for tangible investments in modernization, they were often dissatisfied with the savings they received. Until about 1910, many entrepreneurs, having familiarized themselves with the electric motor system, chose the good old steam.

Why? To get all the benefits of electricity, factory owners had to change their way of thinking. Of course, they could use an electric motor in the same way that steam engines were used. Then they would fit into the old system.

But electric motors were capable of more. Electricity made it possible to deliver energy exactly when and where it was needed.

Small steam engines were terribly inefficient, but small electric motors worked perfectly. Therefore, the factory could accommodate several small motors, each with its own small shaft.

Electricity made it possible to organize factories and workers according to the logic of the production line.

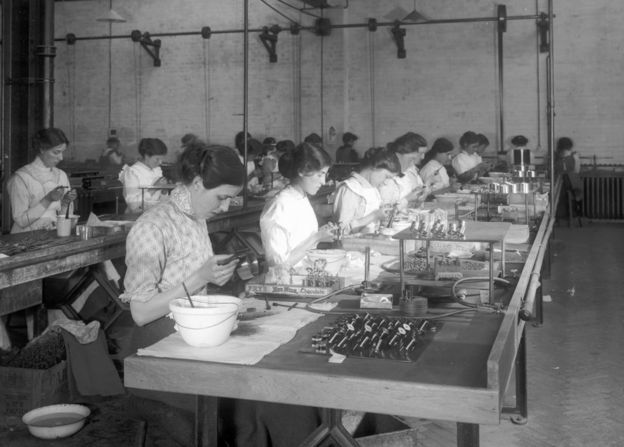

With the development of technology, each workbench could acquire its own car with its own small electric motor. Energy is no longer transmitted through a single massive rotating shaft, it was going through the wires. A steam factory had to be strong enough to withstand huge steel shafts. The electrical factory could be light and airy. Steam factories had to be built according to the logic of the drive shaft. Electricity made it possible to organize factories and workers according to the logic of the production line.

Increase efficiency

The old factories were cramped and dark, everything huddled around the trees. New factories could disperse, their wings and windows could pass light and air. In old factories, steam engines set a common rhythm. Employees could do this on new ones.

Jeweler in 1909 uses the fruits of electric lighting and machine tools

Factories could be cleaner, safer, more efficient, because the machines needed to work only during use. But such results could not be achieved simply by pulling out the steam engine and replacing it with an electric motor. You had to change everything: the architecture and the production process. And, since workers had more autonomy and flexibility, you had to change their hiring, training, and payment procedures.

Factory owners doubted for obvious reasons. They, of course, did not want to waste money. In addition, they did not want to think through all the consequences of the world, which would have to be adapted to the new technology. But as a result of the change occurred, they were inevitable.

Electricity has become cheaper and more reliable. American workers began to cost more because of the laws that limited emigration from Europe, torn by war.

Jump forward

Wages took off and hiring workers moved from quantity to quality. Trained workers could use the autonomy provided by electricity. And the more factory owners realized how to use all the advantages of electric motors, the more production ideas spread between them.

By 1920, the productivity of American industry soared as it did not happen before or after.

The famous automatization of the production of cars from Henry Ford

You might decide that such a leap forward is due to a new technology. But no. Economic historian Paul David attributes most of his success to the fact that manufacturers have finally figured out how to use technology, which at that time was already 50 years old. What constitutes Robert Solow's sarcastic remarks in a new light.

By the year 2000 — about 50 years after the appearance of the first computer program — productivity began to grow slightly. Two economists, Eric Bryndjolfson and Lorin Hitt, published a study showing that many companies invested in computers, having received practically no advantage, while others achieved tangible benefits.

Time and imagination

The difference explained whether companies were ready to reorganize in order to take advantage of what computers could offer. And this often meant decentralization, transferring some business functions or parts of a business process to an independent contractor, choosing the optimal organization of the supply chain and giving more choices to customers. It was impossible to simply take the old system and add improved computers. I had to start doing things differently.

Online giant Amazon continues to exploit new technology, using robots in warehouses and drones for deliveries

And the world wide web is even younger. By the time the dot-com bubble burst, she was about ten years old. When the dynamos were just as young as the web is now, the factory owners still preferred a pair. Real changes were just beginning to appear on the horizon.

The peculiarity of the revolutionary technology is that it changes everything - that's why we call it revolutionary. And to change everything takes time and imagination, as well as courage. And sometimes - a lot of hard work.

All Articles