Automotive electric turbine

The most effective way to increase the engine power of a car is a turbine. However, it has a number of significant drawbacks such as: the presence of the turbo lag, optimal operation in a small range of engine revolutions, low resource, complexity of installation in an unprepared engine for this.

The electric turbine is capable of solving many of these problems. With the electric turbine, the required boost pressure can be created at any time and it is possible to slow down without fear that the pressure will drop. In the electric turbine there is no hot part warmed to a thousand degrees. This has a positive effect on its resource, price and ease of installation.

This article will be devoted to our development in this direction.

Development and design features

At the moment in China you can buy a lot of electric turbines, which are placed directly at the entrance in front of the air filter. However, they are 100% useless. To provide the necessary pressure and large volume of air supplied, the power of the electric motor should be about 4 kW. The Chinese turbines on the strength of several hundred watts.

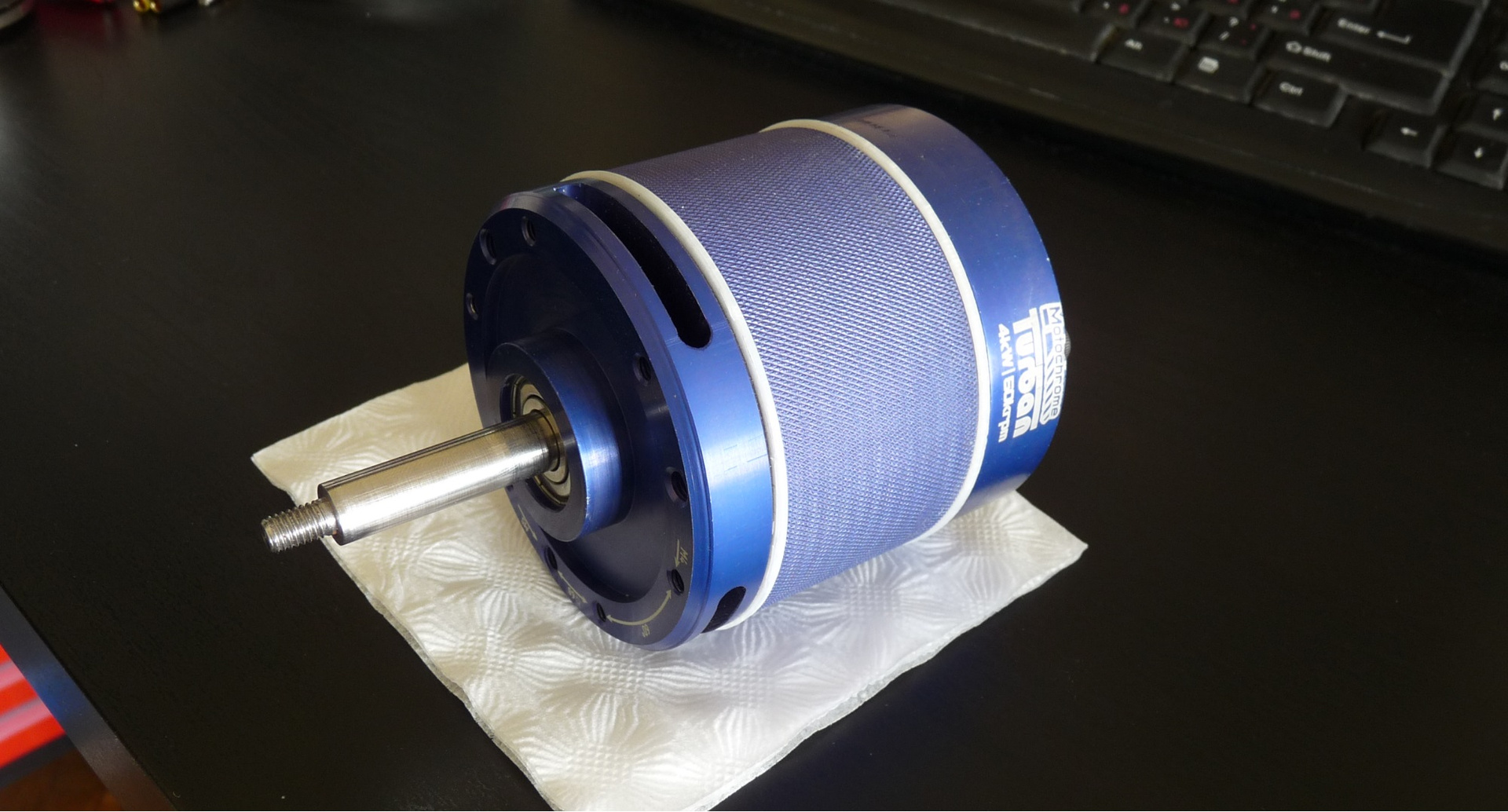

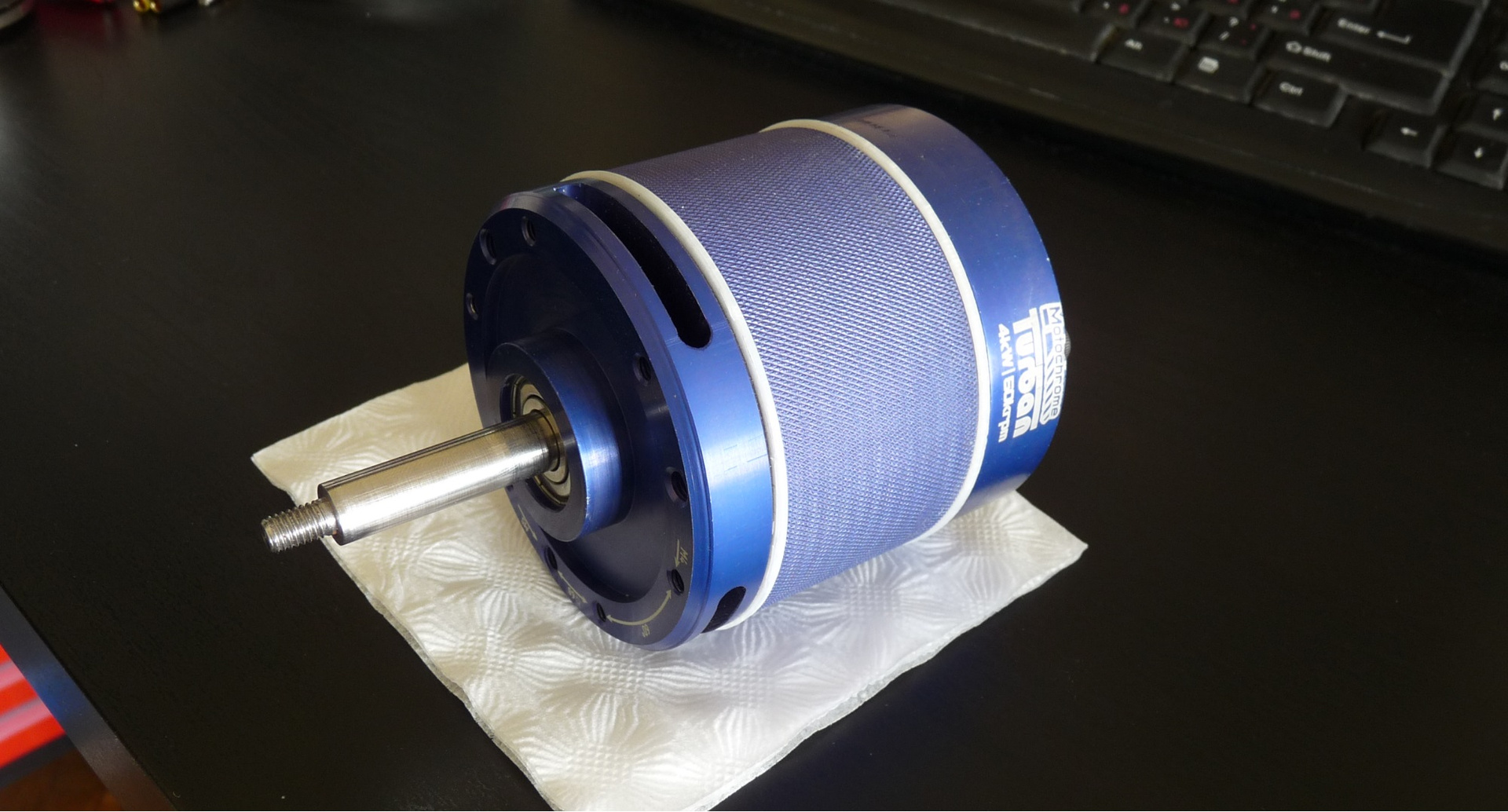

For this task, we specifically designed a brushless electric motor capable of delivering up to 5 kW of power and which can spin the turbine up to 50000RPM. The motor was specially designed so that at full power it gave its maximum efficiency of 93%, then it will emit 350W of heat, which is quite realistic to remove and, in theory, our engine can issue a full boost constantly. More information about the characteristics of our motor can be found at the link .

To power this motor, we decided to use two car batteries. This greatly simplifies the process of operation and the cost of installation. One battery is used regular, the second is connected to it in series. To recharge the second battery, it reconnects to the first through high-precision relay contactors. Lithium batteries would be an order of magnitude more expensive, while they would need special charging and very careful operation while respecting the correct temperature.

However, this solution has a minus. To power the motor at full power, a current in the region of 250A is needed, lead batteries are capable of delivering this, but not for a long time (seconds by 10-30). Then the batteries will need a little “rest.” However, we think this is quite enough, rarely from the engine requires full power for a longer period.

We used this turbine as the turbine itself (its characteristics are also available by reference ).

We removed from it all the excess and squandered under the mount of the motor. All bearings are located directly in the motor and the impeller is put on its shaft, which automatically makes the motor shaft and the impeller aligned. Since the turbine will rotate at very high speeds, we picked up Italian high-speed SKF bearings in the motor.

For the operation of a brushless motor, a controller is needed and for such a large current it is quite expensive. However, we specifically selected currents and voltages so that the most powerful of the cheap controller costs 1500 rubles for this task. This controller is enough on the verge of full power and at the same time it requires very good cooling. More powerful controllers already cost more than 10,000 rubles.

Result

Measurements of our motor at a power of up to 1000W showed that the characteristics of our motor (consumption, rpm, Kv) are quite close to those calculated in the simulation. A large amount of stator and copper wire could provide high efficiency and low heat. With proper power turbine with him accelerates to the desired speed. But unfortunately we have not been able to conduct full-fledged tests at full power. When powered from two batteries, 2 seconds after a set of full revolutions, the controller burned down due to the lack of adequate cooling. We ordered a new controller and plan to put it in a container with transformer oil, which should provide the best cooling.

Conclusion

As a result, we managed to create a working electric turbine, which has a low cost and is quite simple to install. Further tests will be held on a real car.

Approximate cost of necessary components:

The total cost of the turbine set will be around 50000r.

PS

The author of this idea is Frimen3 (frimen3@gmail.com). He has long been engaged in the study of this issue geektimes.ru/post/252076 and he just ordered from us the development of the motor for this task.

The electric turbine is capable of solving many of these problems. With the electric turbine, the required boost pressure can be created at any time and it is possible to slow down without fear that the pressure will drop. In the electric turbine there is no hot part warmed to a thousand degrees. This has a positive effect on its resource, price and ease of installation.

This article will be devoted to our development in this direction.

Development and design features

At the moment in China you can buy a lot of electric turbines, which are placed directly at the entrance in front of the air filter. However, they are 100% useless. To provide the necessary pressure and large volume of air supplied, the power of the electric motor should be about 4 kW. The Chinese turbines on the strength of several hundred watts.

For this task, we specifically designed a brushless electric motor capable of delivering up to 5 kW of power and which can spin the turbine up to 50000RPM. The motor was specially designed so that at full power it gave its maximum efficiency of 93%, then it will emit 350W of heat, which is quite realistic to remove and, in theory, our engine can issue a full boost constantly. More information about the characteristics of our motor can be found at the link .

To power this motor, we decided to use two car batteries. This greatly simplifies the process of operation and the cost of installation. One battery is used regular, the second is connected to it in series. To recharge the second battery, it reconnects to the first through high-precision relay contactors. Lithium batteries would be an order of magnitude more expensive, while they would need special charging and very careful operation while respecting the correct temperature.

However, this solution has a minus. To power the motor at full power, a current in the region of 250A is needed, lead batteries are capable of delivering this, but not for a long time (seconds by 10-30). Then the batteries will need a little “rest.” However, we think this is quite enough, rarely from the engine requires full power for a longer period.

We used this turbine as the turbine itself (its characteristics are also available by reference ).

We removed from it all the excess and squandered under the mount of the motor. All bearings are located directly in the motor and the impeller is put on its shaft, which automatically makes the motor shaft and the impeller aligned. Since the turbine will rotate at very high speeds, we picked up Italian high-speed SKF bearings in the motor.

For the operation of a brushless motor, a controller is needed and for such a large current it is quite expensive. However, we specifically selected currents and voltages so that the most powerful of the cheap controller costs 1500 rubles for this task. This controller is enough on the verge of full power and at the same time it requires very good cooling. More powerful controllers already cost more than 10,000 rubles.

Result

Measurements of our motor at a power of up to 1000W showed that the characteristics of our motor (consumption, rpm, Kv) are quite close to those calculated in the simulation. A large amount of stator and copper wire could provide high efficiency and low heat. With proper power turbine with him accelerates to the desired speed. But unfortunately we have not been able to conduct full-fledged tests at full power. When powered from two batteries, 2 seconds after a set of full revolutions, the controller burned down due to the lack of adequate cooling. We ordered a new controller and plan to put it in a container with transformer oil, which should provide the best cooling.

Video tests of the turbine with a power of 600 and 1000 watts

Conclusion

As a result, we managed to create a working electric turbine, which has a low cost and is quite simple to install. Further tests will be held on a real car.

Approximate cost of necessary components:

- Motor -17000r

- Turbine -20000r

- Battery-3000r

- 4 relays -3000r

- Additional electronics, pipes, air ducts -5000r

The total cost of the turbine set will be around 50000r.

PS

The author of this idea is Frimen3 (frimen3@gmail.com). He has long been engaged in the study of this issue geektimes.ru/post/252076 and he just ordered from us the development of the motor for this task.

All Articles