MIT has developed a robot to search for leaks in pipes

Access to clean, safe water is one of the pressing needs worldwide. However, modern water supply systems lose on average 20% of water due to leaks. They not only degrade the quality of water supply, but can also cause serious damage to buildings and roads, eroding foundations. Leak detection systems are expensive and slow to work: they do poorly where wood, clay or plastic pipes are used, which make up most of the world's water supply systems.

Researchers at the Massachusetts Institute of Technology (MIT) are trying to solve this problem. According to scientists, the new system is able to quickly and cheaply look for even tiny leaks, regardless of the material from which the pipes are made. It took nine years to develop and test such a system — a professor of mechanical engineering Kamal Youcef Toumi and his team PipeGuard worked on it all the time. Scientists are ready to present the results of their work at the upcoming IEEE / RSJ International Conference on Intelligent Robots and Systems ( IROS ) in September.

In the summer of 2017, the team conducts tests on 12-inch concrete water distribution pipes in the city of Monterrey, Mexico. In this city, the administration allowed to test not by chance - every year Monterrey loses about 40% of the water due to leaks, and damage in the form of lost profits is estimated at about $ 80 million. At the same time, leaks lead to general water pollution, as leaked water sometimes returns to distribution pipes.

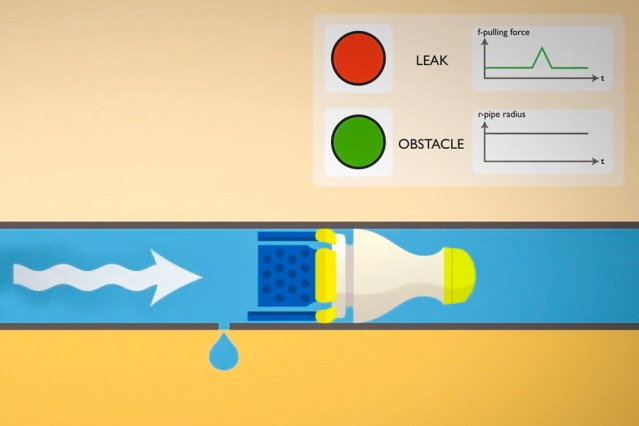

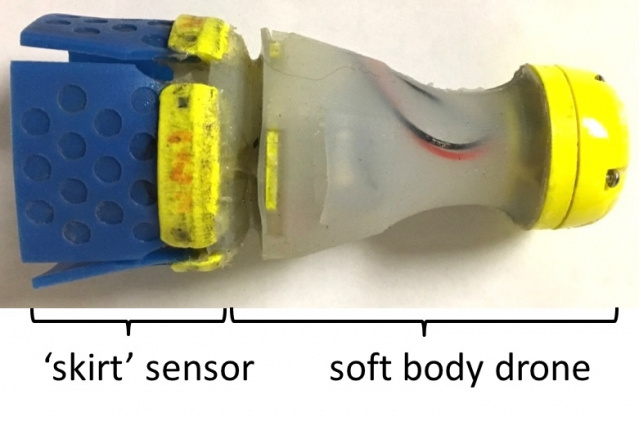

The system uses a small rubber robot that looks like a badminton shuttle. The device can be embedded in the water supply system through any fire hydrant. There it passively goes with the flow, registering its location as it moves. In parallel, the robot detects even small changes in pressure, measuring its value with the help of a rubber “skirt”, which fills the diameter of the pipe.

Then the device is removed by the network from another hydrant, the data is analyzed. There is no need to dig anything or even interrupt the water supply. In addition to the passive robot, which moves through the pipe, drawn by the power of water, a team of scientists has developed an active version that can control their own movement.

PipeGuard intends to commercialize its robotic leak detection system to reduce overall losses. For example, in Saudi Arabia, where most of the drinking water comes from expensive desalination plants, about 33% is lost due to leakage. And the first field tests at the beginning of 2017 took place exactly there.

Pipetech LLS, which serves the pipelines in Al-Khobar, provided a rusty pipe section about 1.6 km long and 2 inches in diameter for the experiment. This pipeline system is often used to verify and certify new technologies. Testing robots in pipes with bends and T-shaped joints suggested the creation of an artificial leak to demonstrate the capabilities of the system.

During this experiment, the robot successfully detected leaks and distinguished them from spurious signals caused by changes in pressure or pipe size, roughness or orientation of the pipe in space. The tests were carried out 14 times over three days, and each time, according to a member of the PipeGuard team, a graduate student Yu Wu (You Wu), were successful. Moreover, the robot found a tiny leak that was about 3.5 liters (gallons) per minute, which is one tenth less than the minimum size that standard detection methods can determine on average.

After field testing in Monterrey, the team plans to create a more flexible, foldable version of its robot, which can quickly adapt to pipes of different diameters. For example, the Boston pipeline system is a mix of 6-, 8-, and 12-inch pipes. Many of them were installed so long ago that the city does not have accurate data on their exact location. The new version of the robot will be able to unfold as an umbrella, and work in pipes of different diameters.

According to the researchers, the value of the robot is not only to reduce water losses, but also to provide a safer and more reliable water supply. The ability of the robotic system to detect the smallest leaks will allow for timely repair work long before a truly serious accident. Moreover, robots can be used both in water pipes and in other distribution systems, for example, natural gas.

Such pipes are also often old and not marked on the maps. They can accumulate gas, which leads to serious explosions. However, leaks in a gas pipeline are usually difficult to detect until they are large enough so that a person can smell the added odorants. In fact, the MIT system was originally designed to detect these leaks, and subsequently adapted for plumbing.

PipeGuard hopes that in the end, the robot will not only look for leaks, but also get a special mechanism by which small leaks can be repaired on site.

All Articles