How do Russian registrars develop AdvoCam

Hello, dear readers Geektimes! With you, Alexander Shub, one of the most reputable (and I am also modest, isn’t it?) In our country journalists working in the field of portable automotive electronics, in particular, DVRs. For the sixth year, I have been working on the subject of these devices, and the number of models that have been in my hands managed to pass well over two hundred. Over the past two years, I have put a lot of effort into explaining to consumers the specifics of the DVR market and debunk established stereotypes. Let me remind you that at the end of 2015 I explained in detail why the AdvoCam-FD Sport action camera is not a clone and generally has little in common with the popular Chinese SJCAM SJ4000. Along the way, various aspects of the process of creating new cameras, the reasons for making certain decisions on the model were touched upon.

Then, in the editorial material specifically for Mobile-Review.com, I thoroughly studied the question of why even with the same components, recorders can work and shoot video in completely different ways.

Only one remained undisclosed, but the most interesting question is how does the development of DVRs occur? I started searching for an answer together with LJ-blogger Aslan (the original material was published here ) and engineers of the Russian brand AdvoCam.

It is considered that good consumer electronics in Russia cannot be developed. It is impossible in principle. In part, it is difficult to disagree - the same project YotaPhone has long become a household name .

However, in certain areas, Russian products compete on an equal footing with foreign developments for the wallets of domestic consumers. One such example is the market for household automotive recorders.

Of course, not everything is so simple. Most registrar brands in Russia prefer to either buy ready-made devices from Chinese factories, or order turn-key development from Asians. In the second case, as practice shows, the result leaves much to be desired. Too shamelessly the Chinese factories use the fact that the Russian customers in the bulk do not understand anything in technology and are not even able to draw up a competent technical task for eliminating errors.

Brand AdvoCam - a pleasant exception. This is a real Russian automotive black box developer, a manufacturer with its own staff of engineers and programmers. By the way, following the results of 2016, AdvoCam won the first place among the brands of video recorders in Russia, if we consider by the volume of devices sold.

Our path lies to the northeast of Moscow. An hour and a half on the road - and we drive up to the usual three-storey building at first glance. Behind its walls lies the real Mecca of video surveillance. The development center is owned by Videomax. Experts of the organization for almost two decades engaged in the creation of video systems, including software platforms for managing single networks of video cameras. That is why the creation in 2011 of the AdvoCam brand, which specializes only in home car DVRs, was quite a logical step. This material will deal directly with the camera development center for cars, and here you can read a detailed report from the AdvoCam pilot production in the city of Alexandrov, Vladimir region.

How does the development of consumer DVR begin? With such a thing called "debug board."

The “heart” of any registrar is the central processor. The manufacturer of the "stone" produces a debugging board, which reveals all the possibilities of its creation. No registrar in the world can be created without this seemingly strange device.

The easiest to understand the essence of such a board comparison is clay crafts. From the same piece of clay, the master can mold completely different products: from an elegant jug to a rough souvenir in the form of a small figurine. So with the help of a debug board, engineers put a starting point in creating a car recorder, a stationary surveillance camera, or even a camera. Therefore, you can see an abundance of various connectors, even for a wired connection to the network. Such a fee can only be purchased directly from the processor manufacturer, the price can go up to $ 2,000. But the largest registrar brands usually get it for free, as a “compliment” from the processor developers. Why take money from the brand of autocameras, which already stably provides the plant for the production of processors with the demand for tens of thousands of components every month?

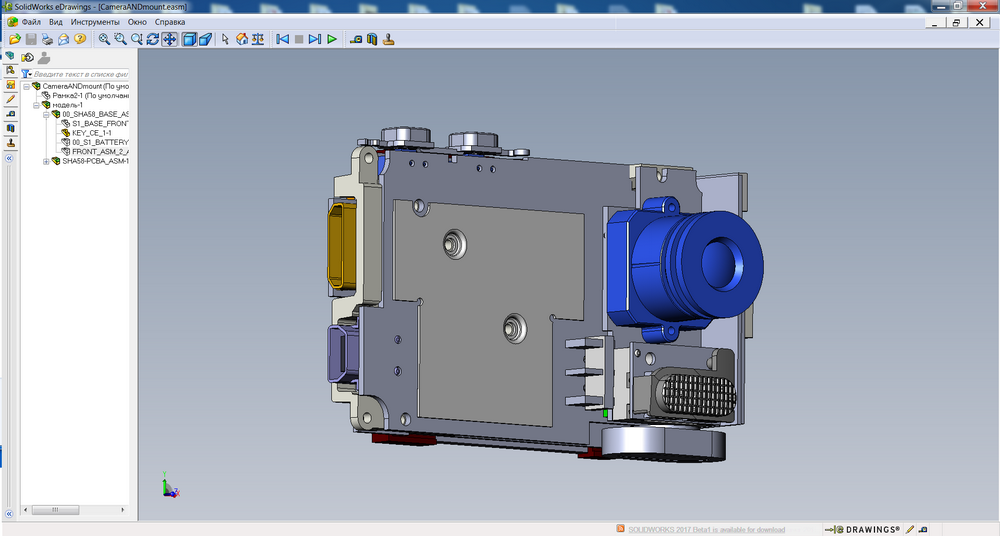

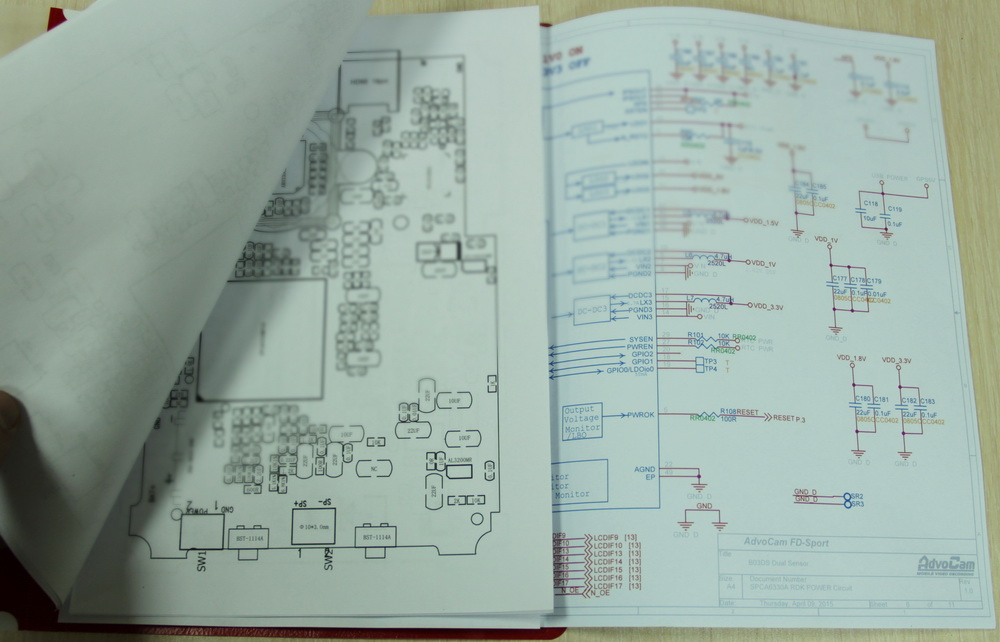

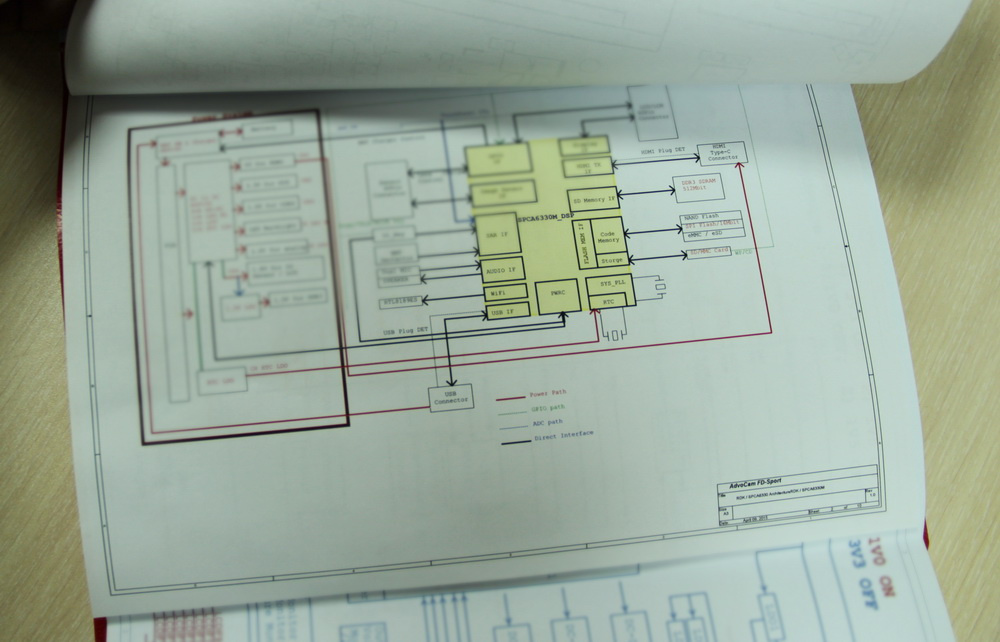

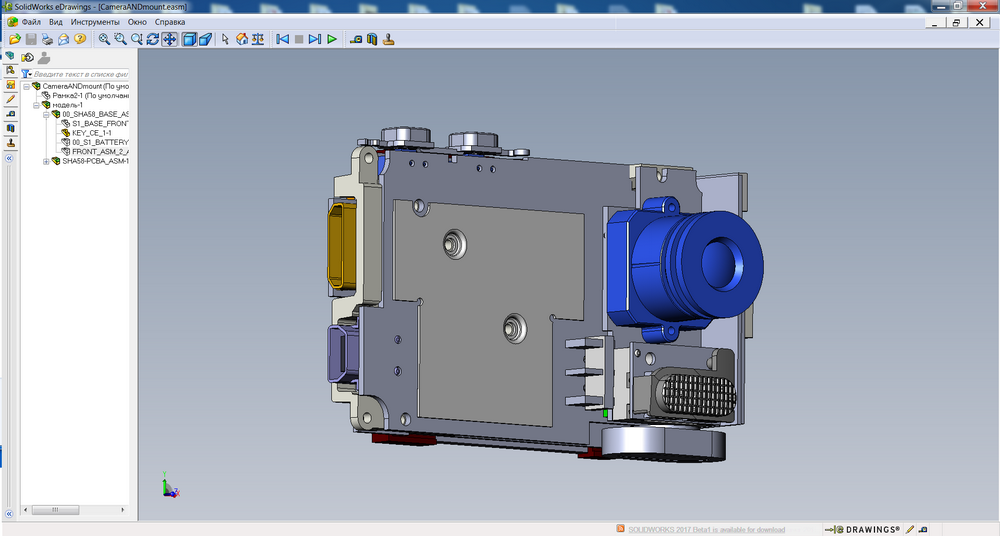

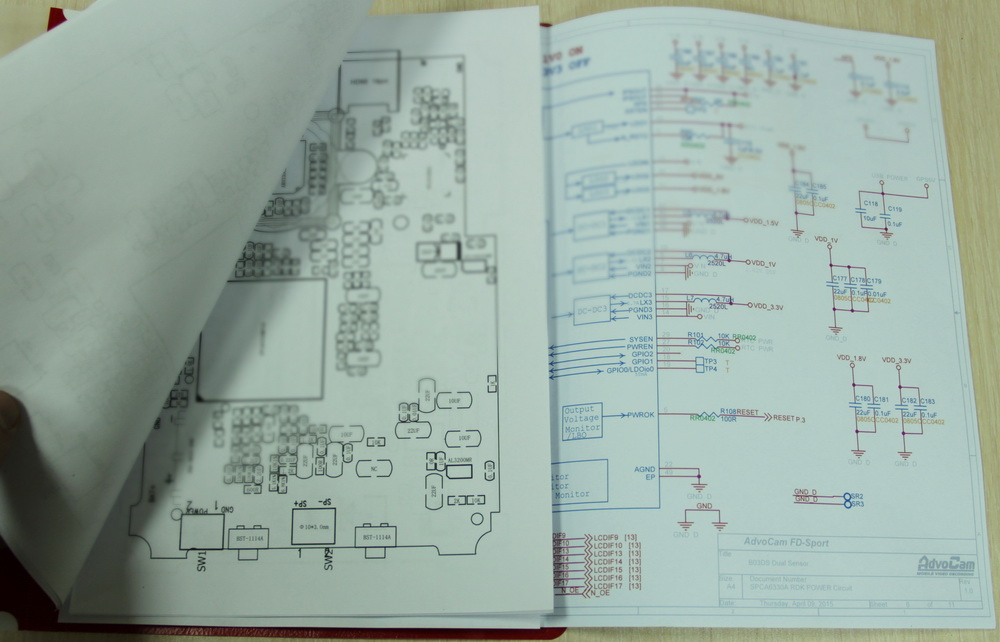

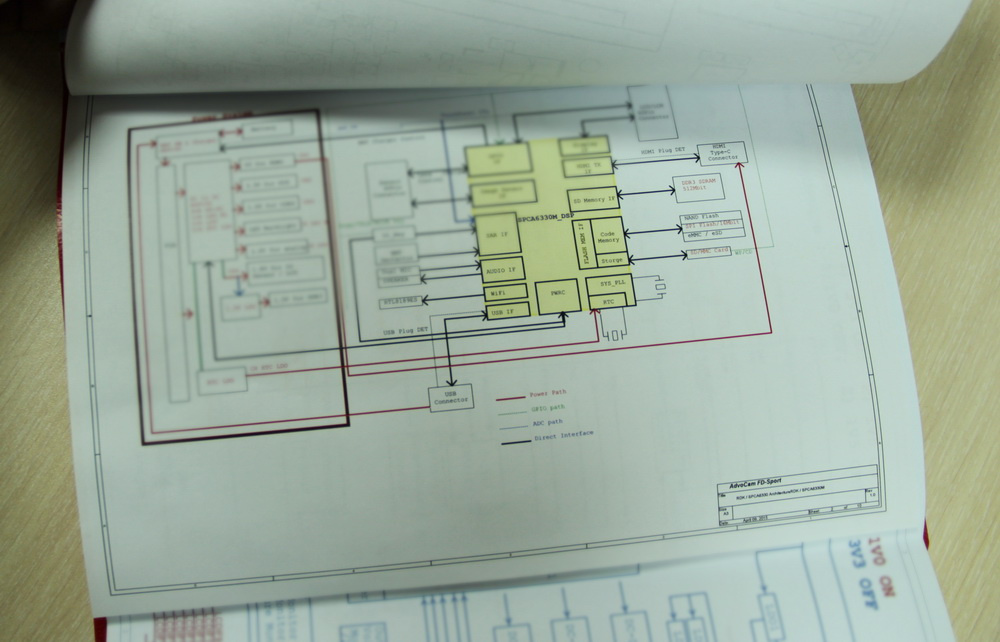

Russian developers AdvoCam conduct various tests of the debug board, study its software and gradually form the design documentation. It reflects in which dimensions of the case it is possible to “shrink” the motherboard with the components on it. How to perform a rewiring is to properly arrange all the necessary components on the motherboard and connect them together. The more miniature the registrar model is required to make, the more difficult and longer this stage of development of the final product takes.

The documentation for AdvoCam-FD Sport for 7,600 rubles is an inexpensive hybrid recorder and action camera with the maximum number of complete accessories on the market.

AdvoCam-FD Sport and its mega-wide equipment

Then it is time to deal with the appearance of the device, there are two possible options. The first is the cheapest, it is the use of the so-called "open design". That is, the housing, which is freely available and can easily be used by any manufacturer.

In the AdvoCam FD-Sport model, a free “open design” was used to obtain an extremely low retail price. Otherwise, the price tag of the device would “fly away” far beyond 10,000 rubles.

Please note that very often users consider - they say, if the two models of different brands have the same “exterior”, then the “filling” is the same. So, you need to buy a cheaper copy. This is a gross misconception. Let the filling be identical, but you can make it work in a completely different way . Stable high-quality video is the result of not cheap labor of not only hardware engineers, but also programmers. Which, in fact, enliven the piece of iron and “squeeze” video quality software out of it. But for any layouts, a buggy recorder that removes any image whatsoever, with constant freezes, frame drops and galloping frame brightness, does not require any special expenses. In other words, the lower price of the model may be a consequence of the manufacturer’s banal unwillingness to spend money on obtaining a reliable quality device.

The second option is an independent development of the hull design from scratch. Such an event, depending on the complexity of the case, costs from $ 15,000 to $ 60,000. Let me give you a little arithmetic. On average, the volume of the first test batch of recorders in Russia is 2,000–3,000 units. For this very test batch, the brand assesses the demand for the model by the market and decides whether to release the device further or not. Thus, even the minimum $ 15,000 for the development of the original case means $ 7.5 in cost per device. And this is the cost price, and when the model reaches the store shelf, all taxes and surcharges are added, $ 7.5 can be easily multiplied by two. Total - plus $ 15, or almost one thousand rubles, you pay only for the exclusive design of the device. For the fact that the design of the case of your device will not be repeated in any other registrar. How do you like that? Not really? That's the same thing!

In the case of the flagships, the original design for the extra 1,000 rubles of the price tag can still be somehow justified: the need to pay 12,000 rubles instead of 11,000 rubles is unlikely to be a big tragedy for the consumer.

The four models of the AdvoCam FD8 line used the same unique body, the differences consisted only in the color of the front lining. In this case, the costs of creating your own unique design were covered by using it simultaneously in many different brand devices that were essentially offered in the same package.

But among state employees at the price of up to 6,000–7,000 rubles, we are already talking about a price increase of almost a quarter, or even more. Only a few of the largest international brands can afford to create a design of state employees from scratch. The calculation is made on the credibility of the brand (the consumer is willing to overpay a little for a model of a well-known brand) and the scale of sales - the bigger they are, the smaller the proportion of body costs in the overall final price of a registrar.

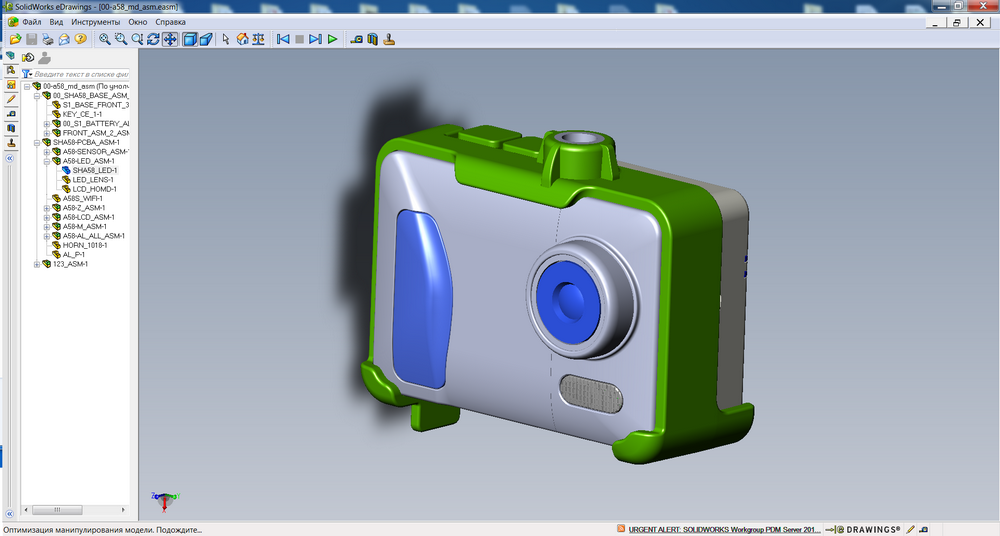

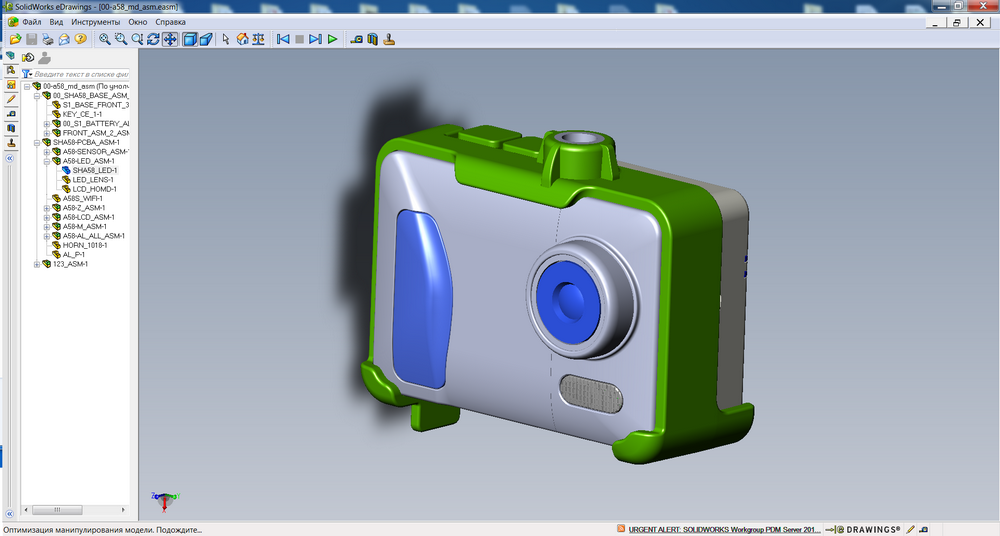

Creation of the case occurs on the computer, in the case of AdvoCam - in SolidWorks. This is a software package for 3D modeling, creating industrial design, and even conducting engineering analysis, such as virtual tests of strength and heat transfer.

Development of the design of the hybrid of the registrar and the action camera AdvoCam-FD2 mini that has not been released into production

As soon as the design is ready, the body is printed on a 3D printer. Yes, on the "domestic", albeit an expensive 3D-printer. Costing almost 100,000 rubles. An assessment is made of the color in which the model will look better - for this, most ordinary paint cylinders for automobiles are bought.

However, the printer gives a rather rough model and is not able to fully display the small details of the case. Therefore, as an option, an expensive silicone casting can be ordered, which will 100% convey what the developer sees on the computer screen. Again, this operation will not be done for low-cost, low-cost models. However, if we are talking about a flagship and you need everything to be perfectly adjusted, you can not do without silicone forms.

When the hands have the final version of the case, the final touches are made on the layout of the system board of the device, then the “motherboards” are ordered in small batches of 10-20 pieces from one of the Russian enterprises. The logical question is - why and for mass batches of the final production “motherboards” are not produced in Russia? The answer is trivial - expensive, the price of the board increases three to five times, and the end device on the store shelf will increase in price by 25-30%. And instead of some good state employees for 6,000 rubles, we will get quite an average price segment from 8,000 rubles. But for the most part, alas, the consumer doesn’t care where the motherboard is made: in Shenzhen or in some Yekaterinburg. The price difference between 6,000 and 8,000 rubles fully justifies the greater confidence in the Chinese manufacturer as compared with the domestic one.

AdvoCam engineers manually wiring components on the board, then the staff of the assembly shop, sorry for the tautology, assemble the models. In fact, this is already a pre-production test assembly, which, among other things, makes it possible to identify potential problems in a subsequent mass production and eliminate them before mass production is commissioned by AdvoCam at any affiliate contract factory in China.

I note that you can order test boards in China, it will cost ten times cheaper. But if a domestic enterprise fulfills an order in one week, then the Chinese can take up to two or three weeks. Therefore, in the case of just the first test instances, it is more logical to overpay. Just in order to quickly get the first prototypes of the new model.

By the way, when the model has already gone to the series and the registrar is sold in stores, it is on the serial device board that you can easily determine whether the model is a unique development of the company or is it another Chinese for branding by hundreds of different customers around the world. In the case of a proprietary model, the name of the brand or its parent company will be indicated. If only the name of the factory is given - most likely, the machine can be ordered by any “manufacturer”. Either the fee was made exclusively for the customer, but then it turns out in some way fraud - you buy a camera from a famous Taiwanese manufacturer, but in fact - the same Chinese apprentices.

The motherboard of the Taiwanese Mio MiVue 518 indicates that the device was developed by a third-party Chinese factory commissioned by Mio

For comparison: the board looks like the model AdvoCam-FD One (4,400 rubles), the most thoughtful budget recorder of the beginning of 2017. In which there is a 2 megapixel webcam function and a powerful battery. This unit shows a record for autonomous shooting, a record for recorders with a price tag below 5,000 rubles, as much as 40 minutes from a single battery charge.

In addition to indicating the brand, the board also shows the name of the model for which it was made. So we have a) a 100% development of AdvoCam specialists specifically b) specifically for AdvoCam-FD One

In the meantime, the most difficult and long stage of the creation of a registrar begins in production in China - the preparation of molds for casting model parts. It is this process that “absorbs” the lion's share of the budget for creating a design. Work is carried out only in the Chinese factory, where there is all the necessary equipment at the cost of hundreds of thousands of dollars. And here are two options. Either an experienced Russian technologist will follow the work of the Chinese and control the obtaining of the ideal mold. Or, in the absence of a controller, Asian performers are able to save their time (and money) and, albeit uncritically, but still to cheat. As a rule, this concerns laziness in eliminating minor defects of the inner side of the case. For example, plastic floated here and there, the tracks of sprues were not completely trimmed and the tracks were cleaned (what it is - it will be said below). A typical Russian brand customer who does not understand the topic will not notice anything. Or for all the claims, the Chinese will find a hundred reasons why everything should be like that.

At first glance, there is nothing complicated. There is a hollow mold, where liquid plastic is fed under pressure through sprue tubes. Then liquid cooling is poured through separate tubes, the part cools down. In the final it remains only to remove the mold cover (in the language of professionals - “slam”) and cut off the sprues. In fact, there is a huge amount of nuances - such that the preparation of the mold itself takes about three months, and with a complex case with a large number of parts comes up to six months.

Unfortunately, shooting on the production of AdvoCam molds is prohibited, but the Discovery Channel at one time was shown an excellent movie about how to make molds

Take even the most banal - cooling. Half body - a part with walls of different thickness, bends, roundness. And you need to submit antifreeze (as a rule, it is used) so that literally every square millimeter of the part cools evenly and simultaneously. A little bit somewhere "brought" the plot later - write disappeared, the plastic will float. So that you understand, the whole operation from plastic filling to “slamming” takes no more than a few seconds. Therefore, the creation of the mold requires surgical precision. Any "jamb" puts an end to the possibility of launching the model into mass production.

When developers get a properly molded case, they install all the “hardware” of the recorder into it and begin final testing and troubleshooting from both a software and hardware point of view. From laboratory tests, tests are carried out on shakers and in temperature chambers.

DVRs AdvoCam after a day in the temperature chamber at -35 ° C - turn on and work as if nothing had happened

So the models are adapted for the Russian operating conditions - this ensures that the recorder will not fly away on the next bump. Plus, the camera will not be afraid of frost, it will turn on and will shoot even at -35 ° C. Or it will not melt in hot summer at +40 ° C under the scorching rays of the sun.

Practical field tests consist in the fact that each developer installs two and sometimes more recorders in his car and starts their everyday use. It may be that the board overheats in a certain place, condensate gets inside when temperature drops, and so on and so forth.

Parallel to the “field” testing of “hardware”, a great deal of work is being done on software firmware. Since the software is mostly responsible for the fact that your camera does not become a glitch, all functions will be performed properly.

The original firmware gives the manufacturer of the processor. Almost always, this is prohibitively “raw” software, which requires persistent, lengthy, painstaking and, as already mentioned, completely expensive revision by Russian professionals from AdvoCam. The firmware is not less than the matrix or lens is responsible for the final quality of the shooting. It is not enough to fix the matrix and the lens on the motherboard, the most important thing is to force the processor to correctly control the “orchestra” - adjust the color rendition, sharpness, exposure (brightness) and other parameters.

Mass mass production of recorders occurs in China - whatever one may say, but it is much cheaper than trying to establish similar processes in Russia. Even a “screwdriver” assembly of prefabricated components (when in fact it remains only to fix the lens and a pair of components on the board and install everything into the case) increases the cost of the device by about 20-30%. , - . - , .

, AdvoCam-FD8 Gold GPS 10 000 13 000 . , – « » AdvoCam. , Apple GoPro.

: « » ( ) . . , « » , , .

,

, , AdvoCam , , . , Apple Samsung. . , , - .

. – , . , « »? , - (, «» ) . - – , . ( ).

, AdvoCam , . – 2-3 40% «». ? «» – . , – «, ».

But back to the work that AdvoCam is doing on new models after they go on sale. In addition to the hardware, corrections and improvements are introduced to the program part of the recorder, namely, to the firmware. However, absolutely any change in the firmware can lead to the most unexpected consequences. It is like a butterfly effect: the flapping of its wings will cause a hurricane on the other side of the Earth. After all, in the recorder, even a small adjustment of the menu font can cause, for example, glitches of shooting in HDR mode. Therefore, each new firmware needs scrupulous, slow and thorough comprehensive testing.

At the moment, there are only six registrars in the AdvoCam lineup, not counting their versions with different configurations.

: «» - . «» – , , . . AdvoCam – , . , AdvoCam , .

– . , , . - «». . - 30-40%. . ( , , – !).

«» «» . - , . – .

« » – : . «» . , «.» 176 «» . , . 238 , 60%, , . ! , . 176 «» 15 (3,6% !) , .

AdvoCam, , ( 2016 ). , ! , , . AdvoCam « » , « », – , . , , , . .

PS – schub.alexandr@yandex.ru.

Then, in the editorial material specifically for Mobile-Review.com, I thoroughly studied the question of why even with the same components, recorders can work and shoot video in completely different ways.

Only one remained undisclosed, but the most interesting question is how does the development of DVRs occur? I started searching for an answer together with LJ-blogger Aslan (the original material was published here ) and engineers of the Russian brand AdvoCam.

It is considered that good consumer electronics in Russia cannot be developed. It is impossible in principle. In part, it is difficult to disagree - the same project YotaPhone has long become a household name .

However, in certain areas, Russian products compete on an equal footing with foreign developments for the wallets of domestic consumers. One such example is the market for household automotive recorders.

Of course, not everything is so simple. Most registrar brands in Russia prefer to either buy ready-made devices from Chinese factories, or order turn-key development from Asians. In the second case, as practice shows, the result leaves much to be desired. Too shamelessly the Chinese factories use the fact that the Russian customers in the bulk do not understand anything in technology and are not even able to draw up a competent technical task for eliminating errors.

Brand AdvoCam - a pleasant exception. This is a real Russian automotive black box developer, a manufacturer with its own staff of engineers and programmers. By the way, following the results of 2016, AdvoCam won the first place among the brands of video recorders in Russia, if we consider by the volume of devices sold.

Our path lies to the northeast of Moscow. An hour and a half on the road - and we drive up to the usual three-storey building at first glance. Behind its walls lies the real Mecca of video surveillance. The development center is owned by Videomax. Experts of the organization for almost two decades engaged in the creation of video systems, including software platforms for managing single networks of video cameras. That is why the creation in 2011 of the AdvoCam brand, which specializes only in home car DVRs, was quite a logical step. This material will deal directly with the camera development center for cars, and here you can read a detailed report from the AdvoCam pilot production in the city of Alexandrov, Vladimir region.

How does the development of consumer DVR begin? With such a thing called "debug board."

The “heart” of any registrar is the central processor. The manufacturer of the "stone" produces a debugging board, which reveals all the possibilities of its creation. No registrar in the world can be created without this seemingly strange device.

The easiest to understand the essence of such a board comparison is clay crafts. From the same piece of clay, the master can mold completely different products: from an elegant jug to a rough souvenir in the form of a small figurine. So with the help of a debug board, engineers put a starting point in creating a car recorder, a stationary surveillance camera, or even a camera. Therefore, you can see an abundance of various connectors, even for a wired connection to the network. Such a fee can only be purchased directly from the processor manufacturer, the price can go up to $ 2,000. But the largest registrar brands usually get it for free, as a “compliment” from the processor developers. Why take money from the brand of autocameras, which already stably provides the plant for the production of processors with the demand for tens of thousands of components every month?

Russian developers AdvoCam conduct various tests of the debug board, study its software and gradually form the design documentation. It reflects in which dimensions of the case it is possible to “shrink” the motherboard with the components on it. How to perform a rewiring is to properly arrange all the necessary components on the motherboard and connect them together. The more miniature the registrar model is required to make, the more difficult and longer this stage of development of the final product takes.

The documentation for AdvoCam-FD Sport for 7,600 rubles is an inexpensive hybrid recorder and action camera with the maximum number of complete accessories on the market.

AdvoCam-FD Sport and its mega-wide equipment

Then it is time to deal with the appearance of the device, there are two possible options. The first is the cheapest, it is the use of the so-called "open design". That is, the housing, which is freely available and can easily be used by any manufacturer.

In the AdvoCam FD-Sport model, a free “open design” was used to obtain an extremely low retail price. Otherwise, the price tag of the device would “fly away” far beyond 10,000 rubles.

Please note that very often users consider - they say, if the two models of different brands have the same “exterior”, then the “filling” is the same. So, you need to buy a cheaper copy. This is a gross misconception. Let the filling be identical, but you can make it work in a completely different way . Stable high-quality video is the result of not cheap labor of not only hardware engineers, but also programmers. Which, in fact, enliven the piece of iron and “squeeze” video quality software out of it. But for any layouts, a buggy recorder that removes any image whatsoever, with constant freezes, frame drops and galloping frame brightness, does not require any special expenses. In other words, the lower price of the model may be a consequence of the manufacturer’s banal unwillingness to spend money on obtaining a reliable quality device.

The second option is an independent development of the hull design from scratch. Such an event, depending on the complexity of the case, costs from $ 15,000 to $ 60,000. Let me give you a little arithmetic. On average, the volume of the first test batch of recorders in Russia is 2,000–3,000 units. For this very test batch, the brand assesses the demand for the model by the market and decides whether to release the device further or not. Thus, even the minimum $ 15,000 for the development of the original case means $ 7.5 in cost per device. And this is the cost price, and when the model reaches the store shelf, all taxes and surcharges are added, $ 7.5 can be easily multiplied by two. Total - plus $ 15, or almost one thousand rubles, you pay only for the exclusive design of the device. For the fact that the design of the case of your device will not be repeated in any other registrar. How do you like that? Not really? That's the same thing!

In the case of the flagships, the original design for the extra 1,000 rubles of the price tag can still be somehow justified: the need to pay 12,000 rubles instead of 11,000 rubles is unlikely to be a big tragedy for the consumer.

The four models of the AdvoCam FD8 line used the same unique body, the differences consisted only in the color of the front lining. In this case, the costs of creating your own unique design were covered by using it simultaneously in many different brand devices that were essentially offered in the same package.

But among state employees at the price of up to 6,000–7,000 rubles, we are already talking about a price increase of almost a quarter, or even more. Only a few of the largest international brands can afford to create a design of state employees from scratch. The calculation is made on the credibility of the brand (the consumer is willing to overpay a little for a model of a well-known brand) and the scale of sales - the bigger they are, the smaller the proportion of body costs in the overall final price of a registrar.

Creation of the case occurs on the computer, in the case of AdvoCam - in SolidWorks. This is a software package for 3D modeling, creating industrial design, and even conducting engineering analysis, such as virtual tests of strength and heat transfer.

Development of the design of the hybrid of the registrar and the action camera AdvoCam-FD2 mini that has not been released into production

As soon as the design is ready, the body is printed on a 3D printer. Yes, on the "domestic", albeit an expensive 3D-printer. Costing almost 100,000 rubles. An assessment is made of the color in which the model will look better - for this, most ordinary paint cylinders for automobiles are bought.

However, the printer gives a rather rough model and is not able to fully display the small details of the case. Therefore, as an option, an expensive silicone casting can be ordered, which will 100% convey what the developer sees on the computer screen. Again, this operation will not be done for low-cost, low-cost models. However, if we are talking about a flagship and you need everything to be perfectly adjusted, you can not do without silicone forms.

When the hands have the final version of the case, the final touches are made on the layout of the system board of the device, then the “motherboards” are ordered in small batches of 10-20 pieces from one of the Russian enterprises. The logical question is - why and for mass batches of the final production “motherboards” are not produced in Russia? The answer is trivial - expensive, the price of the board increases three to five times, and the end device on the store shelf will increase in price by 25-30%. And instead of some good state employees for 6,000 rubles, we will get quite an average price segment from 8,000 rubles. But for the most part, alas, the consumer doesn’t care where the motherboard is made: in Shenzhen or in some Yekaterinburg. The price difference between 6,000 and 8,000 rubles fully justifies the greater confidence in the Chinese manufacturer as compared with the domestic one.

AdvoCam engineers manually wiring components on the board, then the staff of the assembly shop, sorry for the tautology, assemble the models. In fact, this is already a pre-production test assembly, which, among other things, makes it possible to identify potential problems in a subsequent mass production and eliminate them before mass production is commissioned by AdvoCam at any affiliate contract factory in China.

I note that you can order test boards in China, it will cost ten times cheaper. But if a domestic enterprise fulfills an order in one week, then the Chinese can take up to two or three weeks. Therefore, in the case of just the first test instances, it is more logical to overpay. Just in order to quickly get the first prototypes of the new model.

By the way, when the model has already gone to the series and the registrar is sold in stores, it is on the serial device board that you can easily determine whether the model is a unique development of the company or is it another Chinese for branding by hundreds of different customers around the world. In the case of a proprietary model, the name of the brand or its parent company will be indicated. If only the name of the factory is given - most likely, the machine can be ordered by any “manufacturer”. Either the fee was made exclusively for the customer, but then it turns out in some way fraud - you buy a camera from a famous Taiwanese manufacturer, but in fact - the same Chinese apprentices.

The motherboard of the Taiwanese Mio MiVue 518 indicates that the device was developed by a third-party Chinese factory commissioned by Mio

For comparison: the board looks like the model AdvoCam-FD One (4,400 rubles), the most thoughtful budget recorder of the beginning of 2017. In which there is a 2 megapixel webcam function and a powerful battery. This unit shows a record for autonomous shooting, a record for recorders with a price tag below 5,000 rubles, as much as 40 minutes from a single battery charge.

In addition to indicating the brand, the board also shows the name of the model for which it was made. So we have a) a 100% development of AdvoCam specialists specifically b) specifically for AdvoCam-FD One

In the meantime, the most difficult and long stage of the creation of a registrar begins in production in China - the preparation of molds for casting model parts. It is this process that “absorbs” the lion's share of the budget for creating a design. Work is carried out only in the Chinese factory, where there is all the necessary equipment at the cost of hundreds of thousands of dollars. And here are two options. Either an experienced Russian technologist will follow the work of the Chinese and control the obtaining of the ideal mold. Or, in the absence of a controller, Asian performers are able to save their time (and money) and, albeit uncritically, but still to cheat. As a rule, this concerns laziness in eliminating minor defects of the inner side of the case. For example, plastic floated here and there, the tracks of sprues were not completely trimmed and the tracks were cleaned (what it is - it will be said below). A typical Russian brand customer who does not understand the topic will not notice anything. Or for all the claims, the Chinese will find a hundred reasons why everything should be like that.

At first glance, there is nothing complicated. There is a hollow mold, where liquid plastic is fed under pressure through sprue tubes. Then liquid cooling is poured through separate tubes, the part cools down. In the final it remains only to remove the mold cover (in the language of professionals - “slam”) and cut off the sprues. In fact, there is a huge amount of nuances - such that the preparation of the mold itself takes about three months, and with a complex case with a large number of parts comes up to six months.

Unfortunately, shooting on the production of AdvoCam molds is prohibited, but the Discovery Channel at one time was shown an excellent movie about how to make molds

Take even the most banal - cooling. Half body - a part with walls of different thickness, bends, roundness. And you need to submit antifreeze (as a rule, it is used) so that literally every square millimeter of the part cools evenly and simultaneously. A little bit somewhere "brought" the plot later - write disappeared, the plastic will float. So that you understand, the whole operation from plastic filling to “slamming” takes no more than a few seconds. Therefore, the creation of the mold requires surgical precision. Any "jamb" puts an end to the possibility of launching the model into mass production.

When developers get a properly molded case, they install all the “hardware” of the recorder into it and begin final testing and troubleshooting from both a software and hardware point of view. From laboratory tests, tests are carried out on shakers and in temperature chambers.

DVRs AdvoCam after a day in the temperature chamber at -35 ° C - turn on and work as if nothing had happened

So the models are adapted for the Russian operating conditions - this ensures that the recorder will not fly away on the next bump. Plus, the camera will not be afraid of frost, it will turn on and will shoot even at -35 ° C. Or it will not melt in hot summer at +40 ° C under the scorching rays of the sun.

Practical field tests consist in the fact that each developer installs two and sometimes more recorders in his car and starts their everyday use. It may be that the board overheats in a certain place, condensate gets inside when temperature drops, and so on and so forth.

Parallel to the “field” testing of “hardware”, a great deal of work is being done on software firmware. Since the software is mostly responsible for the fact that your camera does not become a glitch, all functions will be performed properly.

The original firmware gives the manufacturer of the processor. Almost always, this is prohibitively “raw” software, which requires persistent, lengthy, painstaking and, as already mentioned, completely expensive revision by Russian professionals from AdvoCam. The firmware is not less than the matrix or lens is responsible for the final quality of the shooting. It is not enough to fix the matrix and the lens on the motherboard, the most important thing is to force the processor to correctly control the “orchestra” - adjust the color rendition, sharpness, exposure (brightness) and other parameters.

Mass mass production of recorders occurs in China - whatever one may say, but it is much cheaper than trying to establish similar processes in Russia. Even a “screwdriver” assembly of prefabricated components (when in fact it remains only to fix the lens and a pair of components on the board and install everything into the case) increases the cost of the device by about 20-30%. , - . - , .

, AdvoCam-FD8 Gold GPS 10 000 13 000 . , – « » AdvoCam. , Apple GoPro.

: « » ( ) . . , « » , , .

,

, , AdvoCam , , . , Apple Samsung. . , , - .

. – , . , « »? , - (, «» ) . - – , . ( ).

, AdvoCam , . – 2-3 40% «». ? «» – . , – «, ».

But back to the work that AdvoCam is doing on new models after they go on sale. In addition to the hardware, corrections and improvements are introduced to the program part of the recorder, namely, to the firmware. However, absolutely any change in the firmware can lead to the most unexpected consequences. It is like a butterfly effect: the flapping of its wings will cause a hurricane on the other side of the Earth. After all, in the recorder, even a small adjustment of the menu font can cause, for example, glitches of shooting in HDR mode. Therefore, each new firmware needs scrupulous, slow and thorough comprehensive testing.

At the moment, there are only six registrars in the AdvoCam lineup, not counting their versions with different configurations.

: «» - . «» – , , . . AdvoCam – , . , AdvoCam , .

– . , , . - «». . - 30-40%. . ( , , – !).

«» «» . - , . – .

« » – : . «» . , «.» 176 «» . , . 238 , 60%, , . ! , . 176 «» 15 (3,6% !) , .

AdvoCam, , ( 2016 ). , ! , , . AdvoCam « » , « », – , . , , , . .

PS – schub.alexandr@yandex.ru.

All Articles