Choosing a 3D printer: 8 nuances that are worth paying attention to

Sooner or later, everyone learns about 3D printing. And only not many lucky people, imbued with the possibilities that 3D printing opens, catch themselves thinking that they want to buy a 3D printer. Desire gradually develops into a serious decision and the search for the desired option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose, among all the variety of 3D printers. We will try to disclose the answer to this question in as much detail as possible.

What to pay attention to and how to make a choice? We want to offer a small checklist, according to the nuances that need to be paid attention to when choosing a 3D printer.

Do you need to decide for yourself what problems you will use this technique for? What capabilities should a 3D printer have to solve your problems?

First of all, you will need to decide on 3D printing technology. There are two main ways.

If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology will suit you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs with a laser beam that illuminates the photopolymer resin. From here and accuracy of production of models.

Vivid representatives of this segment: Form 2 3D printer or B9Creator 3D printer

If you face a wider range of tasks, and more important is functionality, part size, and low manufacturing cost, then an FDM printer will suit you. 3D printing on this equipment involves the layer-by-layer melting of plastic.

If the SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Of course, you always want to get the best of everything and with maximum opportunities. Do you need all this to solve your current tasks?

What can be cited as an example? For example, the size of the work area FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x 100mm). But for the majority of tasks a certain standard has already been formed. This is a print area lying within 200 x 200 x 200 mm. With small variations in size in one direction or another. Most 3D printers have exactly the size of the workspace. This volume is enough to solve 95% of any problems.

But options are possible ...

If you plan to manufacture small parts, then you may be enough and smaller. But if your work is related to the manufacture, for example, a master model for casting, or large prototypes, then only it makes sense to pay attention to the printer with a large print area.

In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say - you have to pay for everything. Therefore, it often makes sense to focus on the “standard” print area. And even if the part you need to print is more than the working area of your 3D printer, you can always cut it in a special editor, and then print out 2 parts of the model and glue them together.

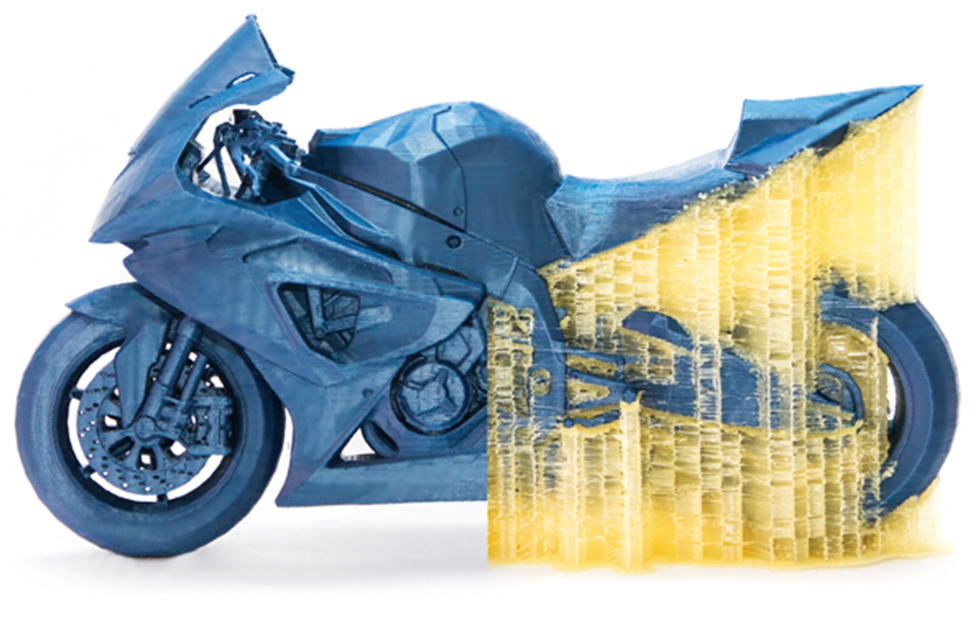

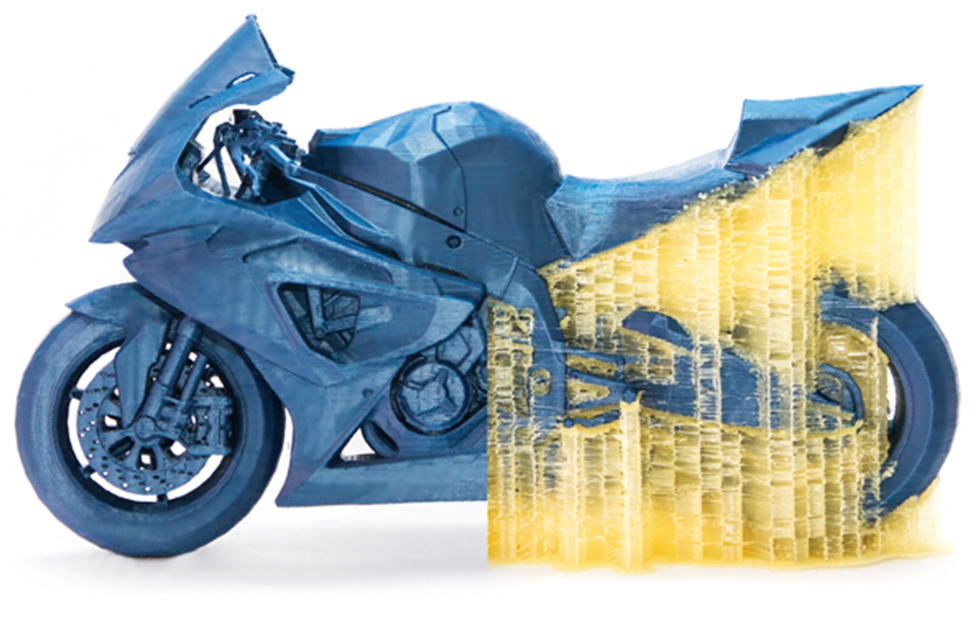

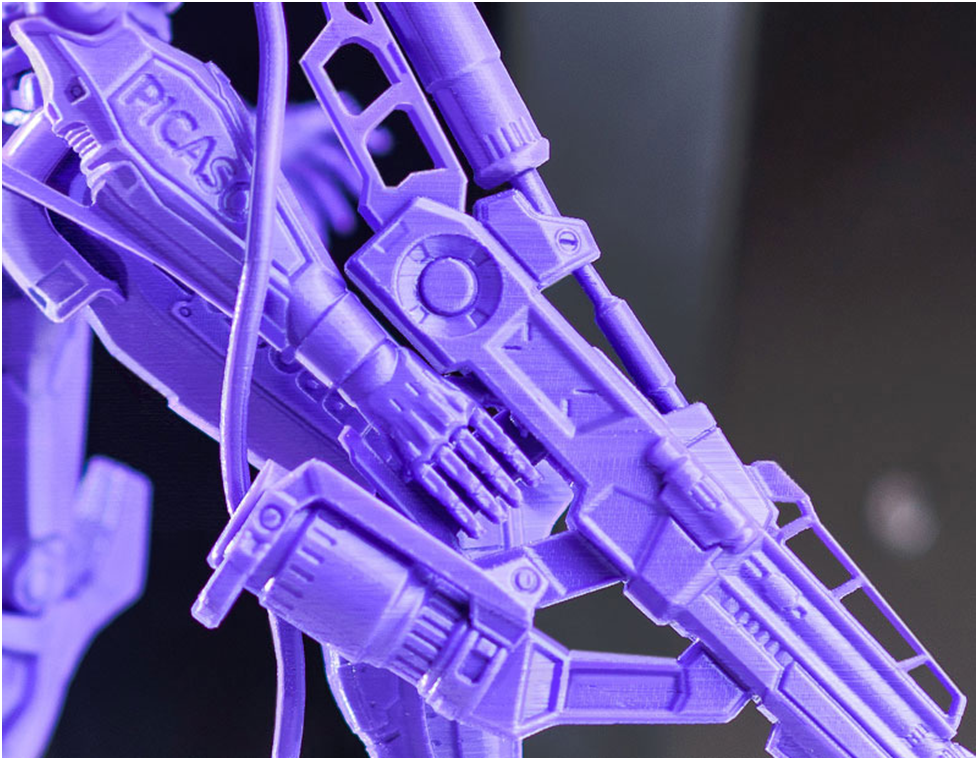

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print support from soluble material. If the models are not the most complex, then you can do with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles greater than 30 degrees.

Another important point. You must immediately determine for yourself a list of possible materials that you are going to print. First of all, this refers to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials it is definitely required that the 3D printer has a heated table. And it is very desirable to have a closed case to provide a thermal circuit around the model.

If you plan to print only PLA plastic. That heated table is not needed.

Still, it is better that the printer had a heated table. Now the difference in the cost of printers with a heated table practically does not differ from the cost without it. But you get a universal solution with which you can perform the full range of tasks before a 3D printer.

One more thing. The ability to print flexible materials.

Quite a large number of 3D printers are faced with the problems of printing flexible materials. Of course, printing various Flexes and Rubbers at first glance is very interesting. But the use of these materials in life is not very common.

Usually for most people this happens like this:

A couple of models are printed, there comes an understanding that this is not a quick and rather complicated process. And on this familiarity with flexible materials ends. Therefore, it makes sense to demand such a possibility from a printer if printing with such materials is very necessary.

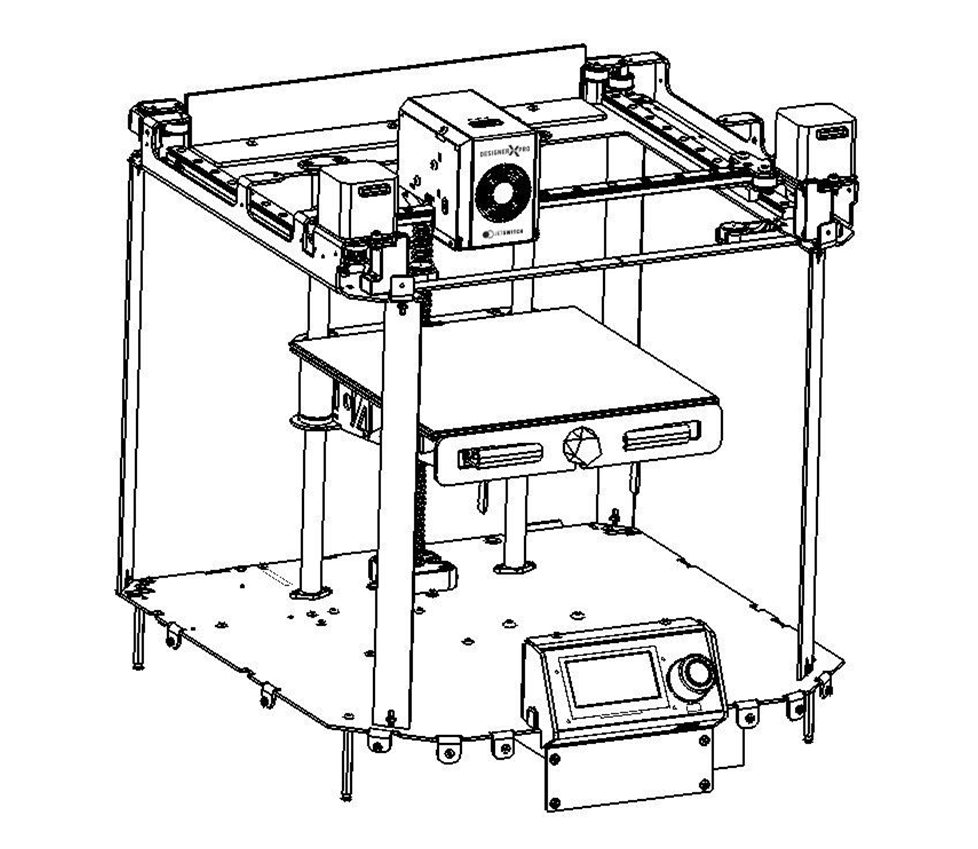

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And the others are closed. As they like to call “cubes” in the Russian-speaking community. What does appearance say?

Printers with an open design, usually have kinematics with a table moving horizontally (based on Prusa 3D printers). This kinematics has some inherent disadvantages. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. This is primarily the so-called wobling.

Also, the lack of a closed case can cause problems with printing quality with high shrinkage plastics (ABS, Nylon).

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by the leading manufacturers in the market. Such printers are built according to the scheme with a lifting table. And they lack most of the shortcomings that are inherent in printers from the previous group. "Cubes" usually have a closed case, which allows the highest quality printing plastic with a high degree of shrinkage.

Printers with a closed casing has a more rigid structure. This allows for better printing.

The kinematics of the print head movement are represented by various designs. They have their pros and cons. But most of them have advantages over the schemes of printers with a moving table.

Most 3D printers on the market come with nozzles with a diameter of 0.3-0.4 mm. This is enough to solve the overwhelming majority of the tasks before a 3D printer.

Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print nozzles with a diameter other than 0.3-0.4 mm occurs very rarely. This mainly concerns either personal experiments or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary.

What do we mean by specific tasks?

This primarily refers to the printing of large products, where it is very important to reduce printing time. This can be achieved using large-diameter nozzles. For example, with a diameter of 0.6-0.8 mm, and even with a diameter of 1 mm. For printers with a large print area, the ability to change nozzles is already a vital necessity.

Therefore, here, as in the case of a heated table, the ability to change the nozzles is a good bonus. It is not required, but very useful if you do not need to pay extra for it.

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimum values, allowing to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print a layer of less than 0.05 mm, and get very high-quality prints. But then there is the problem of a sharp increase in printing time. And if this quality of print is important to you, then it probably makes sense to turn your attention to 3D printers, which we spoke about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Today, there are two main types of extruder. This is a direct extruder in which the bar feed motor is located on the printhead itself. And the so-called Bowden extruder, where the plastic feed engine is located on the body. And the plastic itself is supplied to the extruder through a fluoroplastic tube.

What are the advantages and disadvantages of each type of extruder?

Bowden-extruder, due to the lack of an engine on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects print quality. And a higher speed of movement, which accordingly has a positive effect on the speed of printing. But it has one drawback. Usually on a Bowden extruder it is quite difficult to print with flexible plastics. Such as Rubber or Flex.

All of its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the standard plastic 1.75 mm in diameter. And therefore, users of printers with such plastic are often unable to use new types of materials. Which are primarily produced in the most common form factor 1.75 mm.

A direct extruder usually does not have such big problems with the use of flexible plastics. Easier to set up, but due to the greater mass of the printhead, Bowden-Extruder is inferior in speed and positioning accuracy.

What to prefer? This is already a user choice. We just wanted about the pros and cons of these types of extruders.

Of course, the nuances of choosing a 3D printer are much more. But we think that even our small list will make you look and explore some points that you may not have thought of more closely.

And will save you time and money when choosing a 3D printer.

The company 3Dtool - has extensive experience in the market of 3D equipment. We work with leading Russian and foreign manufacturers, offering high-quality equipment for reasonable money. Our service center is staffed by highly qualified specialists who are able to solve any problem as soon as possible, and all the offered 3D printers are guaranteed for 1 year.

In our assortment you can always find 3D printers for your needs:

1) Low cost 3D printers

2) 3D Printers for Business

3) 3D printers with a large print area

4) 3D printers SLA and DLP

Any questions? Please call: +7 (499) 992-72-23 (Moscow) and 8 (800) 775-86-69 (free of charge in the Russian Federation) or write to mail: sales@3dtool.ru and our staff will gladly give you a detailed advice on any topic of interest.

What to pay attention to and how to make a choice? We want to offer a small checklist, according to the nuances that need to be paid attention to when choosing a 3D printer.

Do you need to decide for yourself what problems you will use this technique for? What capabilities should a 3D printer have to solve your problems?

Nuance 1: Decide on 3D printing technology

First of all, you will need to decide on 3D printing technology. There are two main ways.

If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology will suit you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs with a laser beam that illuminates the photopolymer resin. From here and accuracy of production of models.

Vivid representatives of this segment: Form 2 3D printer or B9Creator 3D printer

If you face a wider range of tasks, and more important is functionality, part size, and low manufacturing cost, then an FDM printer will suit you. 3D printing on this equipment involves the layer-by-layer melting of plastic.

If the SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Soberly assess your needs

Of course, you always want to get the best of everything and with maximum opportunities. Do you need all this to solve your current tasks?

What can be cited as an example? For example, the size of the work area FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x 100mm). But for the majority of tasks a certain standard has already been formed. This is a print area lying within 200 x 200 x 200 mm. With small variations in size in one direction or another. Most 3D printers have exactly the size of the workspace. This volume is enough to solve 95% of any problems.

But options are possible ...

If you plan to manufacture small parts, then you may be enough and smaller. But if your work is related to the manufacture, for example, a master model for casting, or large prototypes, then only it makes sense to pay attention to the printer with a large print area.

In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say - you have to pay for everything. Therefore, it often makes sense to focus on the “standard” print area. And even if the part you need to print is more than the working area of your 3D printer, you can always cut it in a special editor, and then print out 2 parts of the model and glue them together.

Nuance 3: Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print support from soluble material. If the models are not the most complex, then you can do with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles greater than 30 degrees.

Nuance 4: Decide on a list of materials used.

Another important point. You must immediately determine for yourself a list of possible materials that you are going to print. First of all, this refers to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials it is definitely required that the 3D printer has a heated table. And it is very desirable to have a closed case to provide a thermal circuit around the model.

If you plan to print only PLA plastic. That heated table is not needed.

Still, it is better that the printer had a heated table. Now the difference in the cost of printers with a heated table practically does not differ from the cost without it. But you get a universal solution with which you can perform the full range of tasks before a 3D printer.

One more thing. The ability to print flexible materials.

Quite a large number of 3D printers are faced with the problems of printing flexible materials. Of course, printing various Flexes and Rubbers at first glance is very interesting. But the use of these materials in life is not very common.

Usually for most people this happens like this:

A couple of models are printed, there comes an understanding that this is not a quick and rather complicated process. And on this familiarity with flexible materials ends. Therefore, it makes sense to demand such a possibility from a printer if printing with such materials is very necessary.

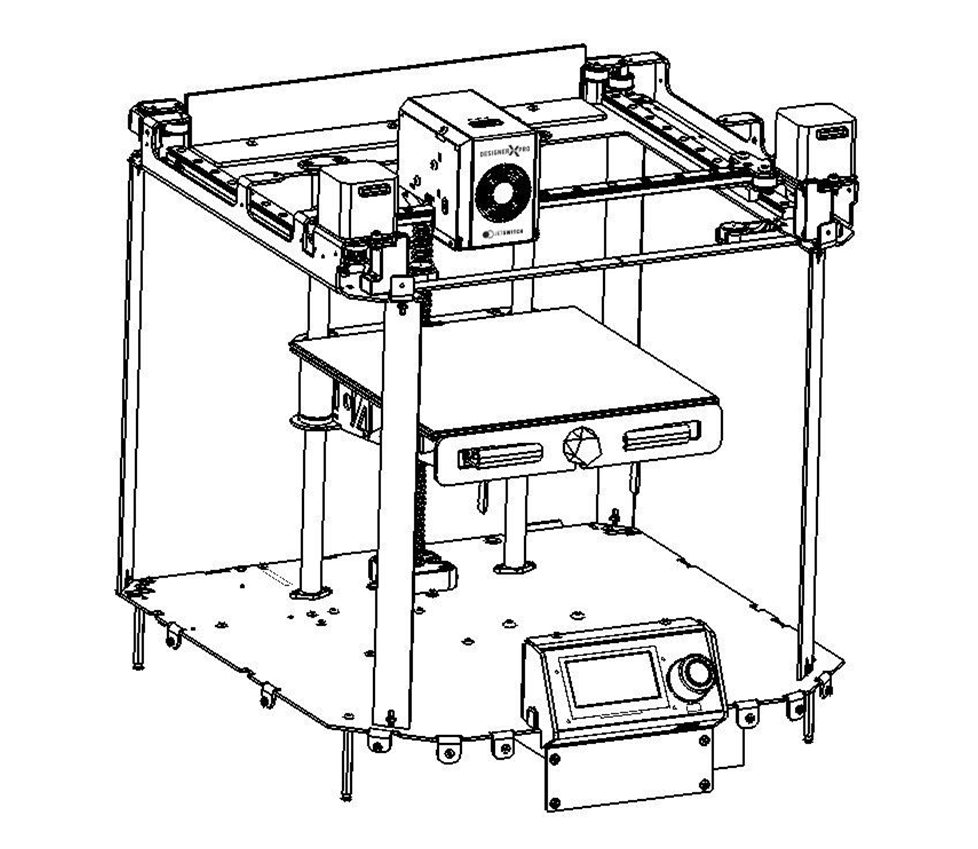

Nuance 5: Construction and Kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And the others are closed. As they like to call “cubes” in the Russian-speaking community. What does appearance say?

Printers with an open design, usually have kinematics with a table moving horizontally (based on Prusa 3D printers). This kinematics has some inherent disadvantages. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. This is primarily the so-called wobling.

Also, the lack of a closed case can cause problems with printing quality with high shrinkage plastics (ABS, Nylon).

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by the leading manufacturers in the market. Such printers are built according to the scheme with a lifting table. And they lack most of the shortcomings that are inherent in printers from the previous group. "Cubes" usually have a closed case, which allows the highest quality printing plastic with a high degree of shrinkage.

Printers with a closed casing has a more rigid structure. This allows for better printing.

The kinematics of the print head movement are represented by various designs. They have their pros and cons. But most of them have advantages over the schemes of printers with a moving table.

Nuance 6: Diameter and the possibility of changing the nozzle

Most 3D printers on the market come with nozzles with a diameter of 0.3-0.4 mm. This is enough to solve the overwhelming majority of the tasks before a 3D printer.

Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print nozzles with a diameter other than 0.3-0.4 mm occurs very rarely. This mainly concerns either personal experiments or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary.

What do we mean by specific tasks?

This primarily refers to the printing of large products, where it is very important to reduce printing time. This can be achieved using large-diameter nozzles. For example, with a diameter of 0.6-0.8 mm, and even with a diameter of 1 mm. For printers with a large print area, the ability to change nozzles is already a vital necessity.

Therefore, here, as in the case of a heated table, the ability to change the nozzles is a good bonus. It is not required, but very useful if you do not need to pay extra for it.

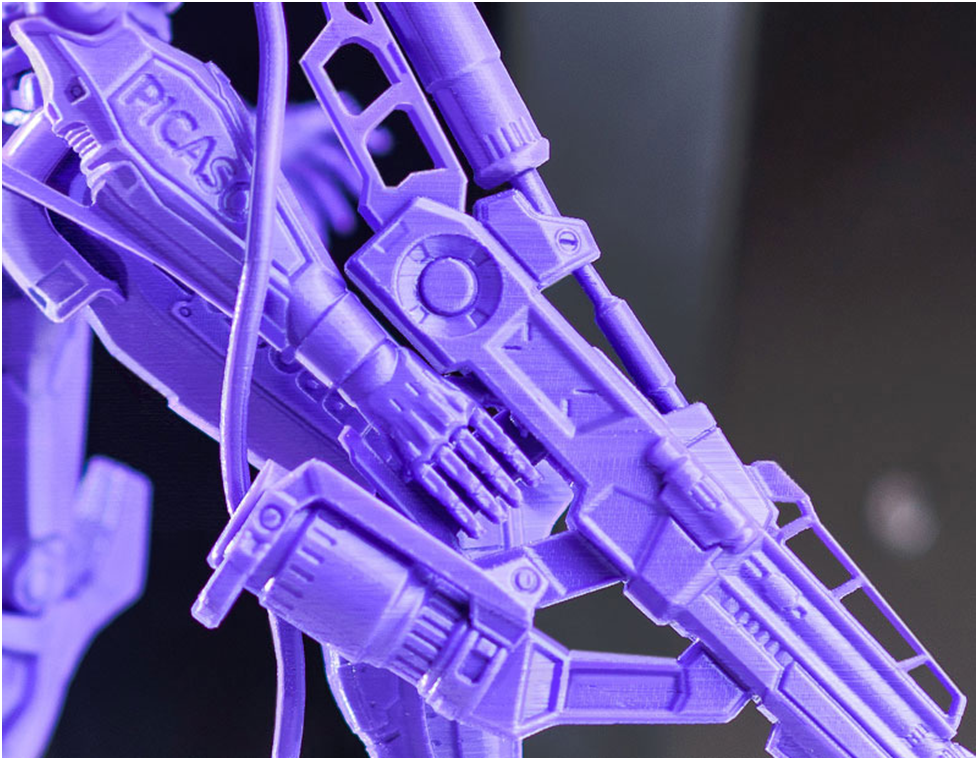

Nuance 7: Print Layer Thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimum values, allowing to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print a layer of less than 0.05 mm, and get very high-quality prints. But then there is the problem of a sharp increase in printing time. And if this quality of print is important to you, then it probably makes sense to turn your attention to 3D printers, which we spoke about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder Type

Today, there are two main types of extruder. This is a direct extruder in which the bar feed motor is located on the printhead itself. And the so-called Bowden extruder, where the plastic feed engine is located on the body. And the plastic itself is supplied to the extruder through a fluoroplastic tube.

What are the advantages and disadvantages of each type of extruder?

Bowden-extruder, due to the lack of an engine on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects print quality. And a higher speed of movement, which accordingly has a positive effect on the speed of printing. But it has one drawback. Usually on a Bowden extruder it is quite difficult to print with flexible plastics. Such as Rubber or Flex.

All of its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the standard plastic 1.75 mm in diameter. And therefore, users of printers with such plastic are often unable to use new types of materials. Which are primarily produced in the most common form factor 1.75 mm.

A direct extruder usually does not have such big problems with the use of flexible plastics. Easier to set up, but due to the greater mass of the printhead, Bowden-Extruder is inferior in speed and positioning accuracy.

What to prefer? This is already a user choice. We just wanted about the pros and cons of these types of extruders.

Of course, the nuances of choosing a 3D printer are much more. But we think that even our small list will make you look and explore some points that you may not have thought of more closely.

And will save you time and money when choosing a 3D printer.

The company 3Dtool - has extensive experience in the market of 3D equipment. We work with leading Russian and foreign manufacturers, offering high-quality equipment for reasonable money. Our service center is staffed by highly qualified specialists who are able to solve any problem as soon as possible, and all the offered 3D printers are guaranteed for 1 year.

In our assortment you can always find 3D printers for your needs:

1) Low cost 3D printers

2) 3D Printers for Business

3) 3D printers with a large print area

4) 3D printers SLA and DLP

Any questions? Please call: +7 (499) 992-72-23 (Moscow) and 8 (800) 775-86-69 (free of charge in the Russian Federation) or write to mail: sales@3dtool.ru and our staff will gladly give you a detailed advice on any topic of interest.

All Articles