More than six million users worldwide SOLIDWORKS can accelerate and improve the product development process - from the conceptual design stage to the manufacture of the final product - and generate added value for their business. Let's take a closer look SOLIDWORKS 2020 is the latest version of the 3D design and engineering software package developed by the Dassault Systèmes research unit based on comments and improvement ideas collected from the SOLIDWORKS community around the world.

So, SOLIDWORKS 2020 helps optimize the development and production of industrial products at all stages. In the new version, improvements focused mainly in three areas:

Productivity increase. Advanced functions for editing drawings, working with assemblies, and performing engineering calculations - all of them significantly speed up the design and analysis of products of any complexity.

Process optimization. Thanks to the advanced design, calculation, engineering data management and production preparation capabilities, the development cycle is shortened, the quality of the products is increased and its cost is reduced.

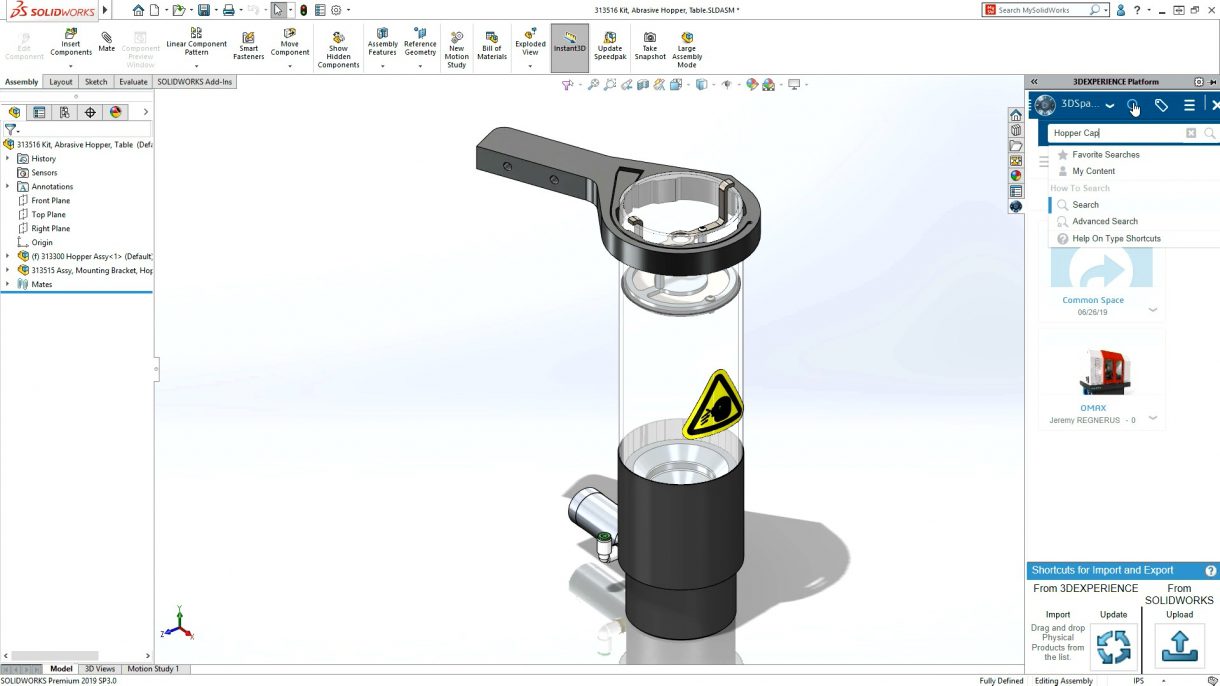

Consistent work in the cloud. With SOLIDWORKS 2020, you can easily connect applications running on the 3D EXPERIENCE platform. This makes it possible to control many aspects of product development, preparation of production and delivery of products, and at any time.

SOLIDWORKS 2020

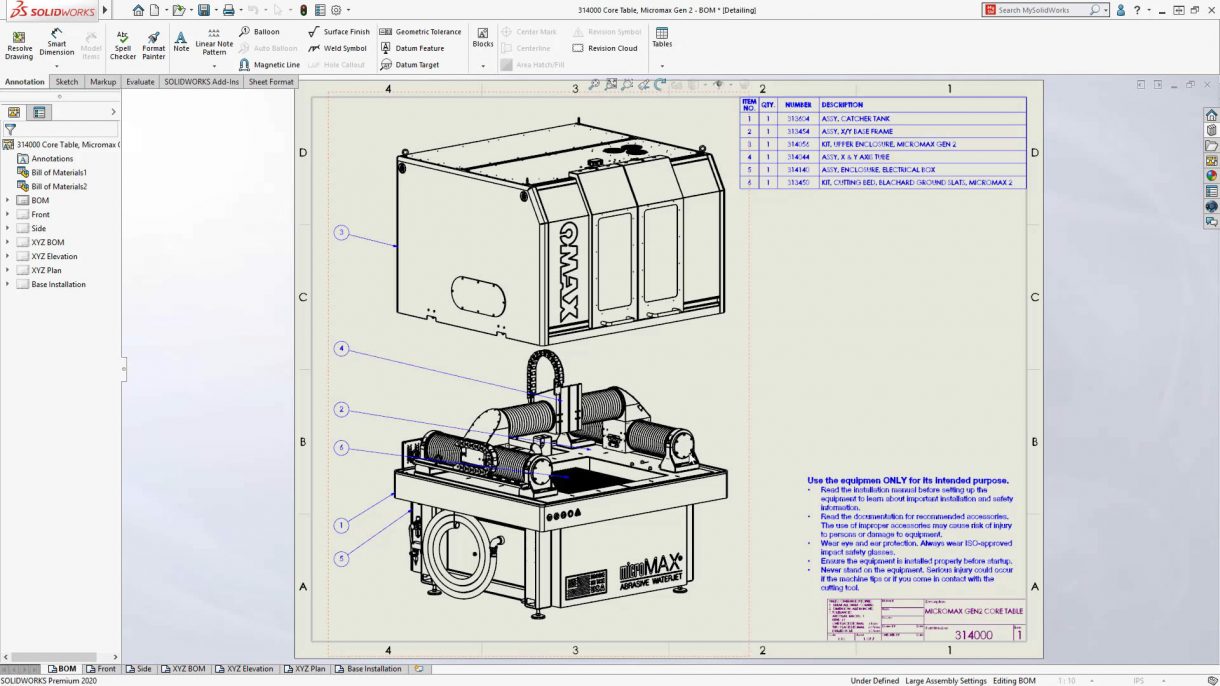

Acceleration of work with drawings of large assemblies. In the new design mode, drawings open in seconds (earlier this took several minutes). You can edit existing signs and notes, put down dimensions, apply signs of deviation of the form, add technical requirements, create new sheets and much more. This mode is especially convenient for making small changes (for example, changing the tolerance of dimensions), for printing drawings, as well as for reviewing and checking projects. Panning and zooming when hardware acceleration is enabled occur smoothly.

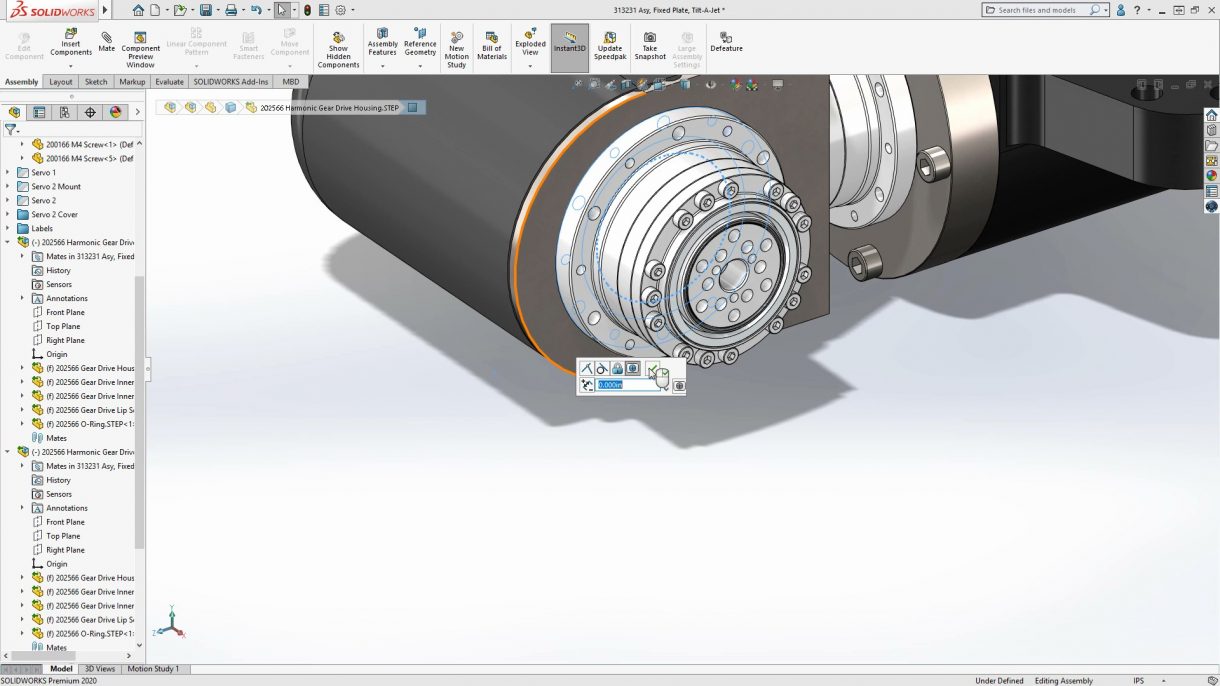

Assembly design. SOLIDWORKS 2020 has expanded the use of envelopes for collaborative work between a design team. The content of the envelopes is not limited to a single assembly: you can select the necessary components at the top level of the assembly. In the large assembly mode, commands are available that allow you to copy, paste, hide, display components on the screen, etc.

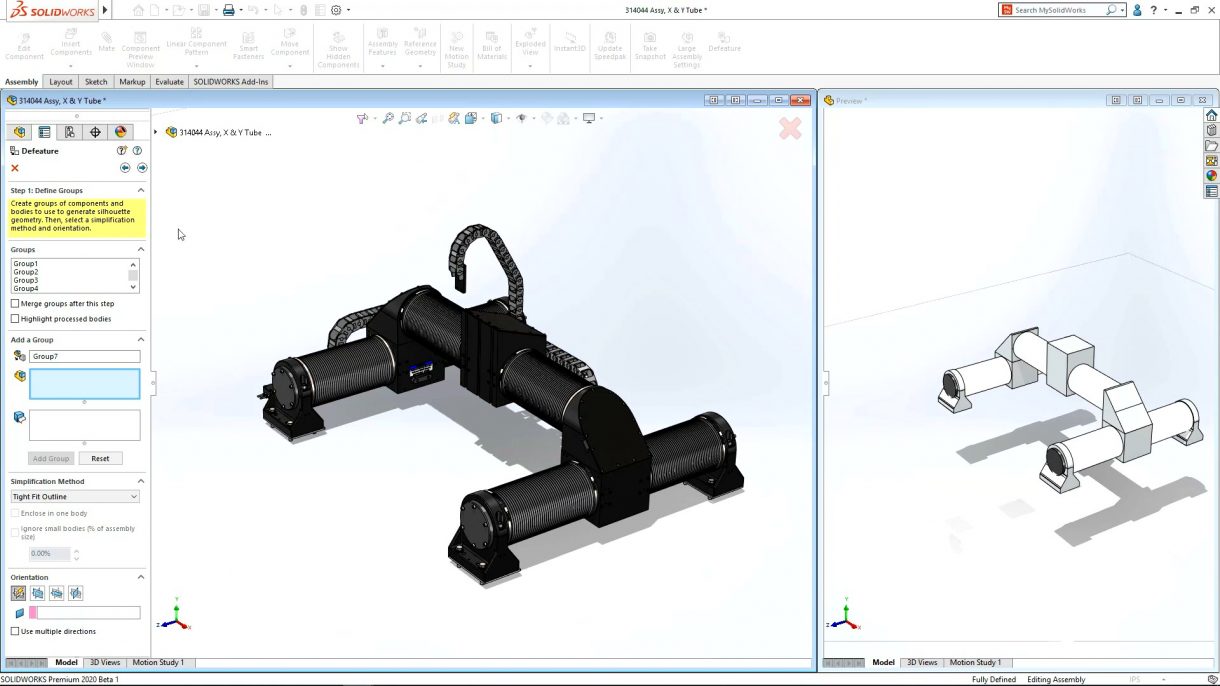

Flexible components. One and the same part inside the assembly can be displayed in different ways: a spring, for example, can be both in a compressed state and in a free state. Several states are also supported for hinges, corrugated tubes, etc. Flexible components eliminate the need to create separate part files or unique configurations, help optimize data management, and increase efficiency.

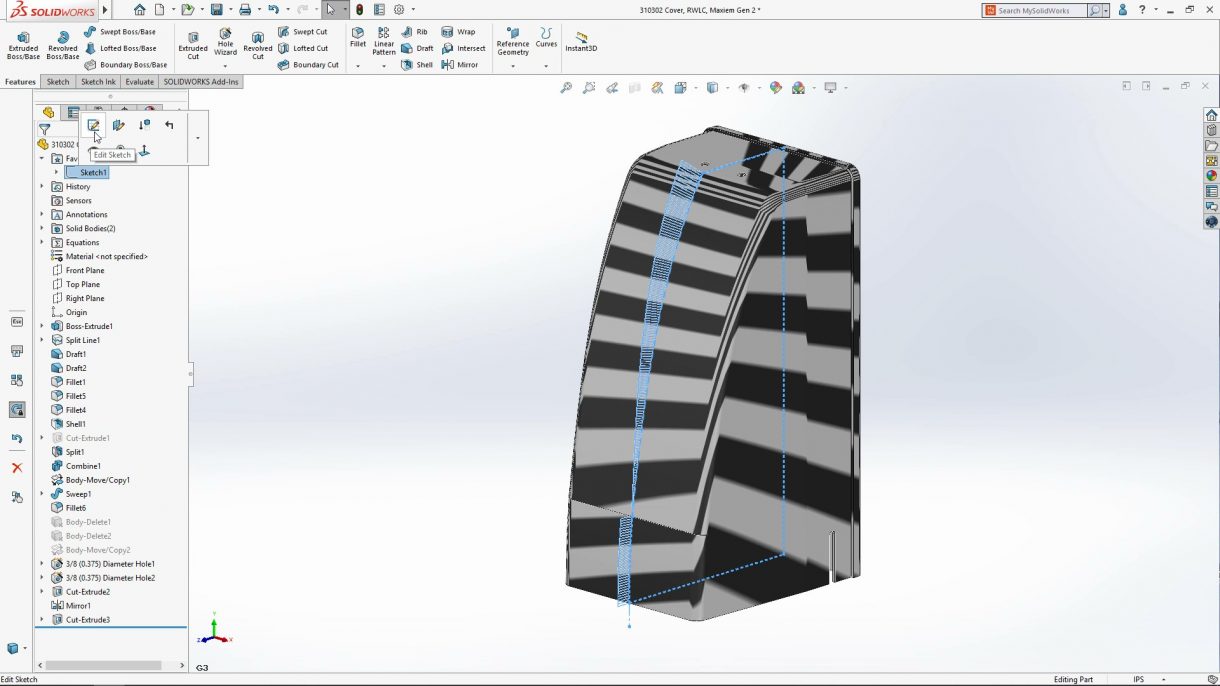

Speeding up sketching. Using silhouette objects, you can create sketches by projecting the contours of a part onto a plane, a kind of shadow of an object. It is possible to build sketch segments with support for G3 continuity. Improvements also touched upon such a function as “repeat the canceled action”: now you will not lose the results of the work, even if as a result of a series of cancellations you accidentally leave the sketching environment.

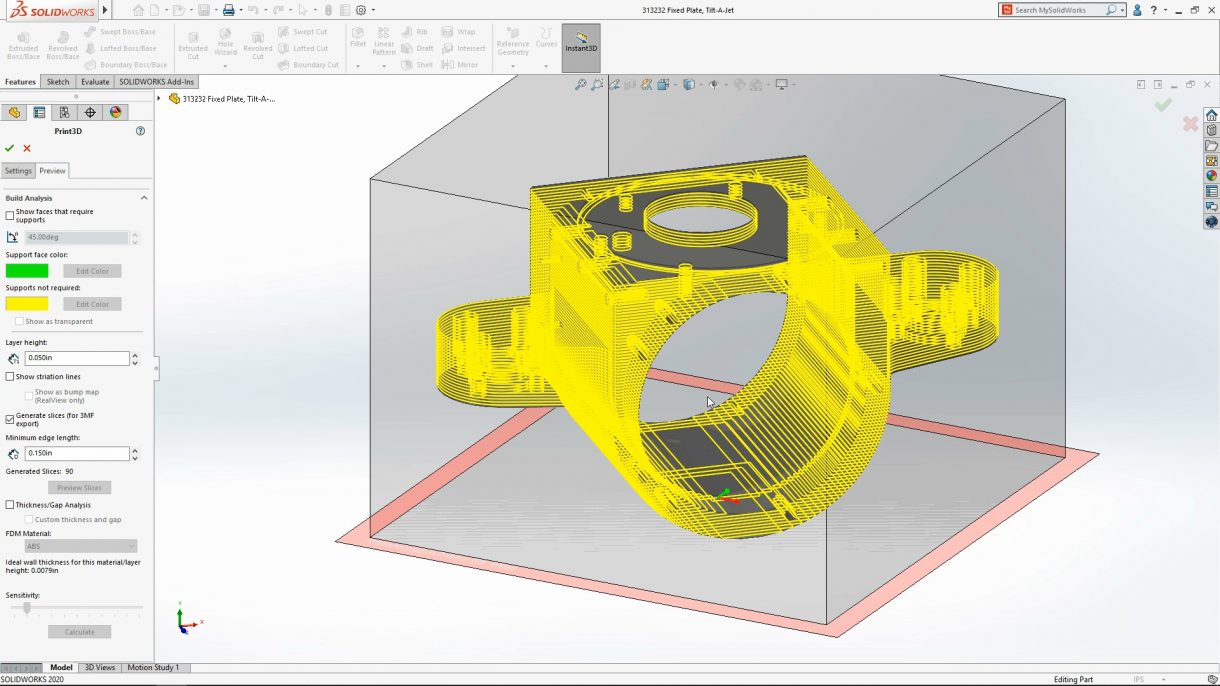

Enhanced 3D printing. The first step to successful 3D printing is to verify that the part or assembly is outside the working area of the printer. To do this, SOLIDWORKS 2020 uses an extensive library of 3D printers with the characteristics of each device. Pre-export to a mesh format (STL, etc.) is no longer needed: slices are formed immediately on the basis of accurate 3D geometry and can be saved in 3MF - an open XML-based format that is specifically designed for additive production and stores not only 3D geometry , but also data on materials, colors, textures and much more. If the company does not have the ability to 3D-print on its own, you can order it at the 3DEXPERIENCE Marketplace by selecting an artist from hundreds of highly qualified service providers.

3D Interconnect technology for advanced data exchange. Now you can drag CAD files exported from other systems directly from Windows Explorer to assemblies - just like any other SOLIDWORKS components. SOLIDWORKS 2020 adds support for new formats: 3D DWG, DXF, and IFC. No file conversion is required for them.

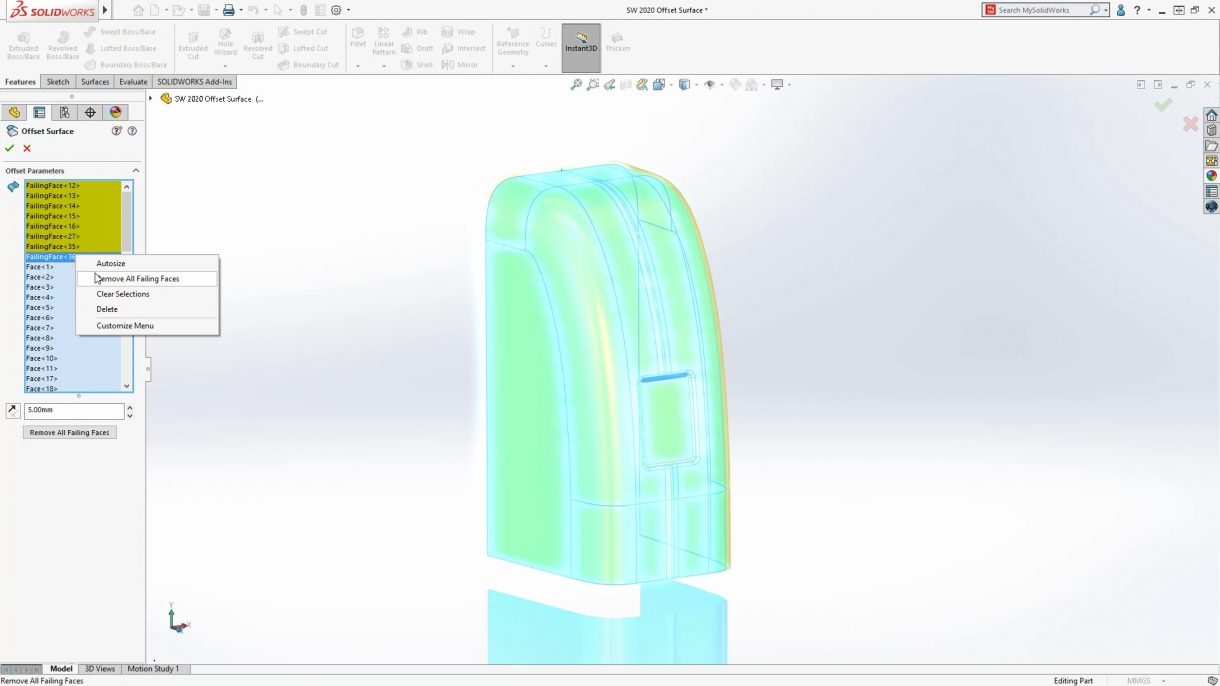

Flexible work with surfaces. Working with imported surfaces and creating equidistant surfaces has always been SOLIDWORKS strengths. However, there were situations when the result of the bias was different from the expected one. SOLIDWORKS 2020 now selects surfaces that cannot be offset, and you can either change the offset parameters or completely remove such surfaces.

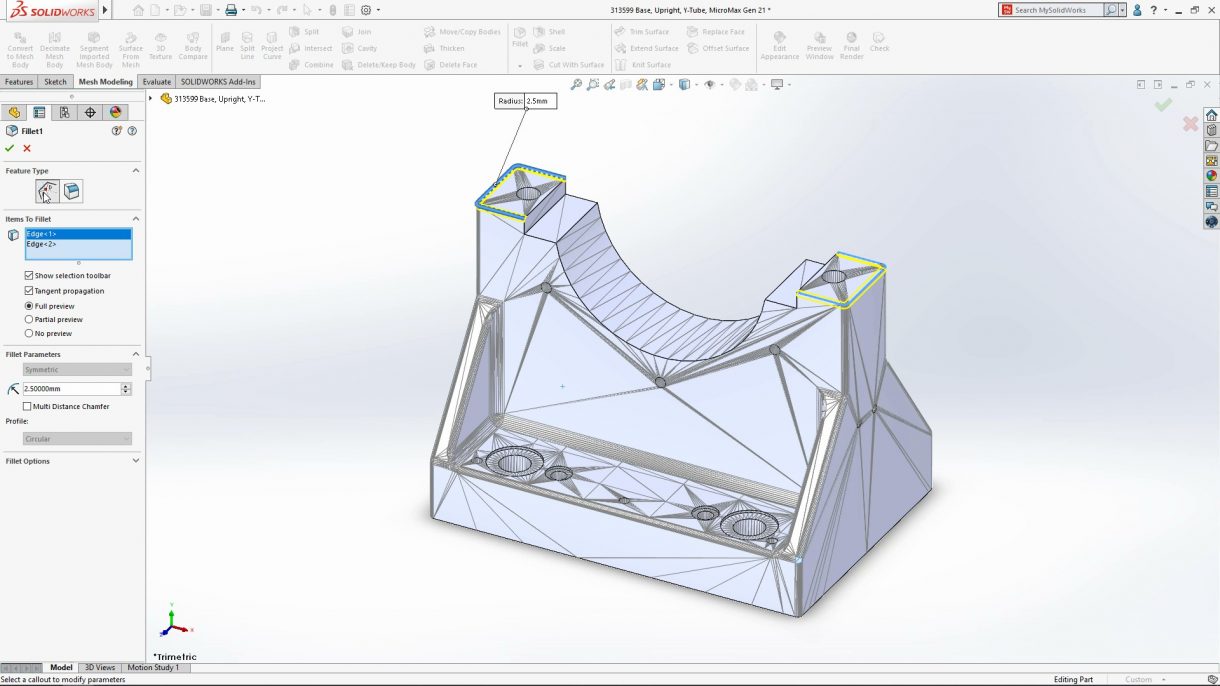

Direct editing of grids. The editing functionality of triangulation models in SOLIDWORKS 2020 continued to expand. In STL files, you can add fillets to the edges using the same methods as for solid-state SOLIDWORKS files. Fillets can be converted to chamfers, and vice versa. Gaps in STL grids are filled using the context menu.

Cloud collaboration in pre-production. SOLIDWORKS 2020 provides convenient data exchange with other necessary tools through the 3DEXPERIENCE cloud platform . Engineers interact in real time, wherever they are and regardless of the devices used. Among the capabilities provided by the cloud, one can note project management, joint work on sketches, sharing models between artists, and product lifecycle management.

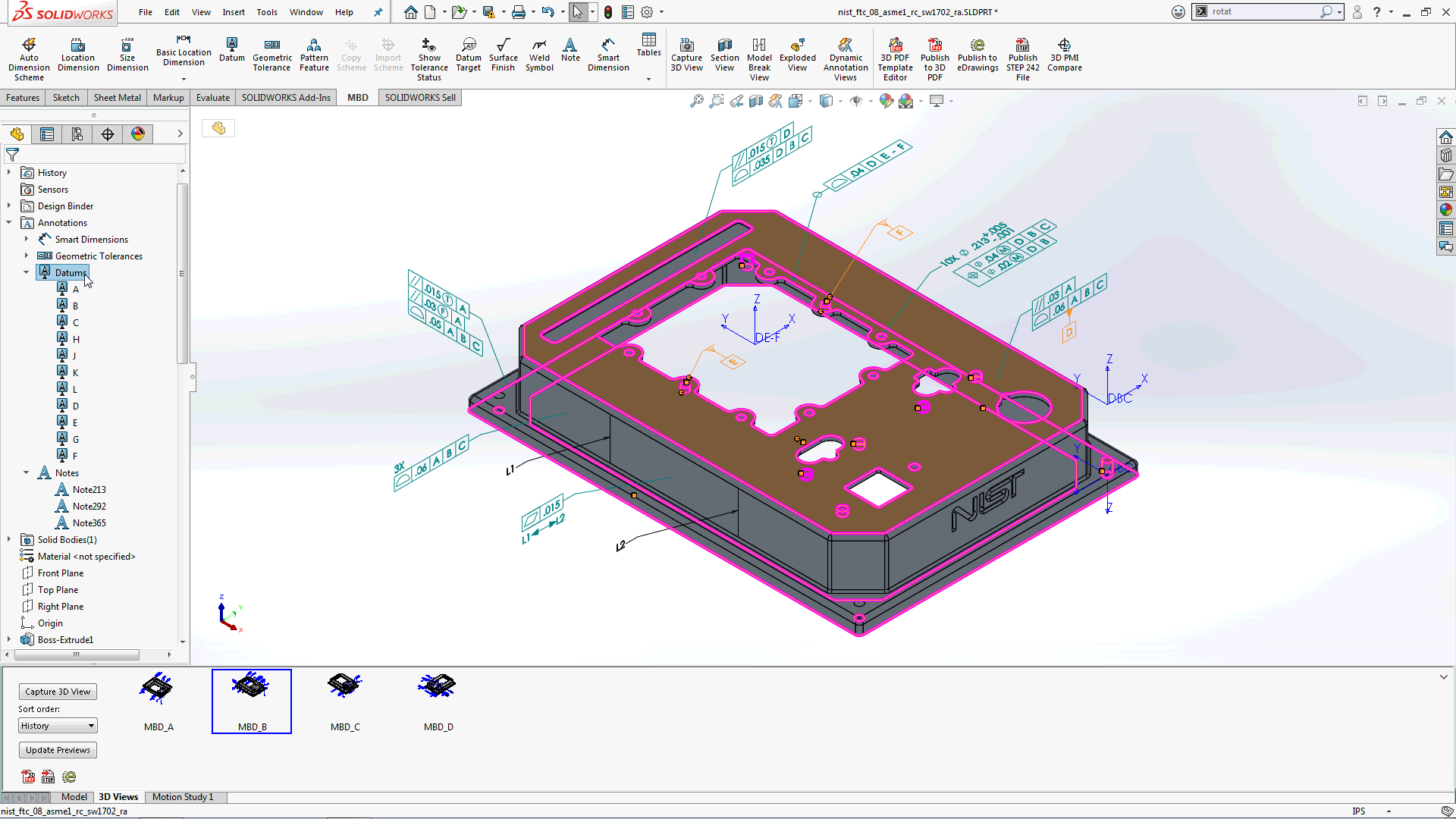

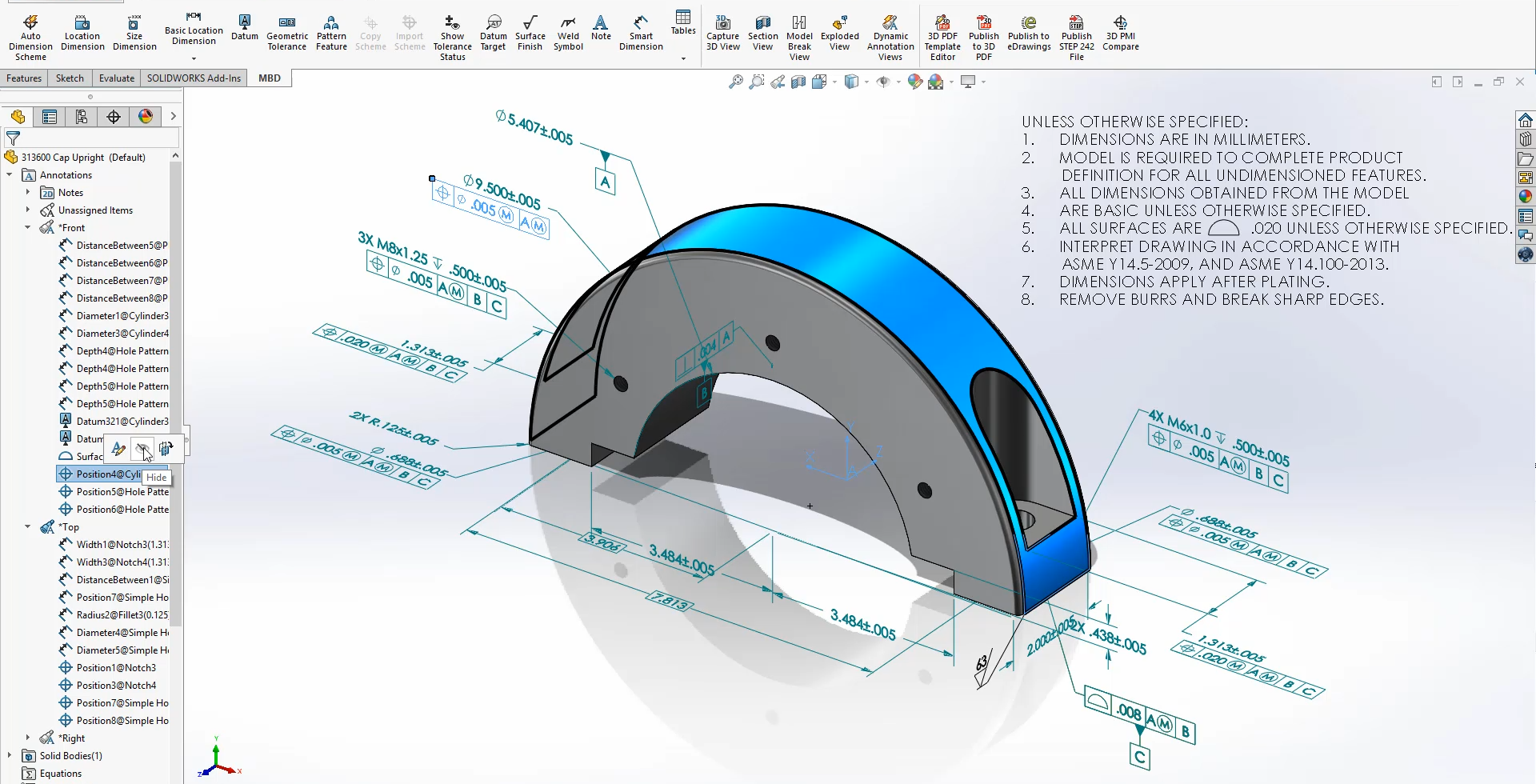

Sort 3D notes by type. Engineers constantly have to search for the necessary design elements or parts. For example, you need to quickly find the sign of the base surface for a linear dimension or designation of roughness, tolerances in shape and location. SOLIDWORKS 2020 provided such an opportunity. By expanding the folder in the tree of elements, you can arrange in the model all sizes, bases, tolerances and other design elements.

Sort 3D notes by type. Notes and conventions can be sorted by type (front, top, etc.). This eliminates the need to include all kinds of annotations to find the item you want. All the necessary information is displayed in a tree where it is possible to search by keywords.

Show and hide each individual note. In order to prevent engineers from constantly having to hide and hide the types of notes completely (and also create their own view for each individual note), in SOLIDWORKS 2020 the ability to control the visibility of conventions in the model through the context menu has been added.

Let us now explain what place 3D-notes occupy in the MBD scheme (definition based on a model). Briefly, it can be expressed with three keywords (three “AND” in this case): integration, intuition, intelligence. Integration is the associativity of notes with the rest of the model. By intuitiveness they mean working with notes in a 3D - world similar to our real one, as well as the opportunity to get acquainted with them on any modern devices. And finally, thanks to its intelligence, information from 3D notes is easily perceived by machines and other product processing devices.

SOLIDWORKS CAM 2020

SOLIDWORKS CAM 2020 is an important component of our pre-production solution. This is a full-featured CAM system that provides 2.5-axis machining.

Testing procedures. They are supported in many modern machines in order to make processing faster, more convenient and error-free. In the manufacture of several parts of the same type, the machine automatically finds the zero point and is installed in it regardless of which operator controls its work. A feature that takes you to a new level of speed and efficiency is only available in SOLIDWORKS CAM Professional .

Creating protrusions for cutting. The function automatically creates protrusions or microconnections based on the part profile, and updates them parametrically with any changes. This helps to avoid production defects, breakdowns of tools and equipment, and therefore - to some extent, insures against unforeseen costs and failure to meet deadlines.

User preferences. We are used to the fact that many things can be customized to your preferences, for example, ringtones on smartphones, screen savers or alerts. SOLIDWORKS CAM takes this trend into account by maintaining a personalized database that stores custom formats and rules. It should be remembered that during the execution of procedures related to settings, the SOLIDWORKS CAD application must be closed.

Tapered threading tool with multiple cutting blades. In the new version, a tool has been added to the library that supports matching the thread angle in conical holes.

Universal Postprocessing Generator (UPG). The new version of the free UPG generator supports the latest SOLIDWORKS CAM features.

SOLIDWORKS Simulation 2020

Increased speed and accuracy of calculations. By combining linear and quadratic elements in one task, the speed and accuracy of SOLIDWORKS Simulation has increased. In threaded and pin joints, deformation of the faces is taken into account. After performing thermal analysis of the model with beams, you can import temperatures into strength calculations.

Everyone who watches the CAD market is aware that Dassault Systèmes has conducted

On October 16, the SOLIDWORKS SUMMIT interactive event presented the updated SOLIDWORKS 2020 design system.

We bring to your attention a recording of the speech of Andrey Vinogradov, technical manager of SOLIDWORKS, Dassault Systèmes in Russia and the CIS, who gave a detailed overview of the key updates and technical advantages of the SOLIDWORKS 2020 software package.

Subscribe to Dassault Systèmes news and stay up to date with innovation and modern technology.

Dassault Systèmes official page

Subscribe to Dassault Systèmes on social networks:

Vkontakte

3DS Blog WordPress

3DS Blog on Render

3DS Blog on Habr