A couple of months before the opening of the WDC at Tver Carriage Building.

A new release of the Orioles was released for the WDC release, now it has version 2.0. Let's show how this train is going, and what interesting has appeared in it. At the same time, we’ll dive a little into the layout features and problems that designers solve. Immediately - the most important thing: the first "Oriole" was already good. The second is the history of improvements and twisting features that were not included in the first release. From the point of view of the chassis, almost nothing has changed.

The body enters the assembly shop in painted form and on temporary trolleys. Here you can see the car separately, the car separately. About how exactly the car is made from sheets of metal and other structures, we already talked about here in this post last year. There are a couple of differences, but about them - a little later.

One of the first steps after assembling a body is laying a heater:

Here you can clearly see the carriage frame. The train now has a new design of ceilings - it is more vibration-resistant, more technological to assemble. One of the difficulties of assembling the ceiling is the question of how to fit it under the rest of the car when “covering” it. Historically, large solid parts were used before. The most modern approach is to assemble from profiles, as a designer, but this requires other machines and other equipment. Now the "Oriole 3.0" is being designed, just profiles for the roof are possible there. And the intermediate solution on the existing equipment is more adjustments on the ceiling, and it is completely span (before it was necessary to adjust three zones of the cabin to each other, that is, three large groups of parts).

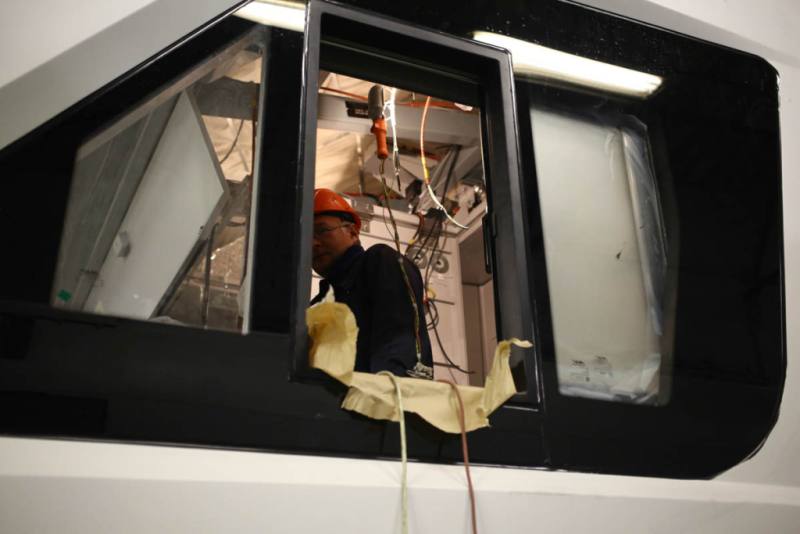

The entrance group has become much more complicated. There were a lot of engineering subsystems because of the appeared displays, trash containers, door lights and other changes. To realize all this, it was necessary to change the arrangement of air ducts.

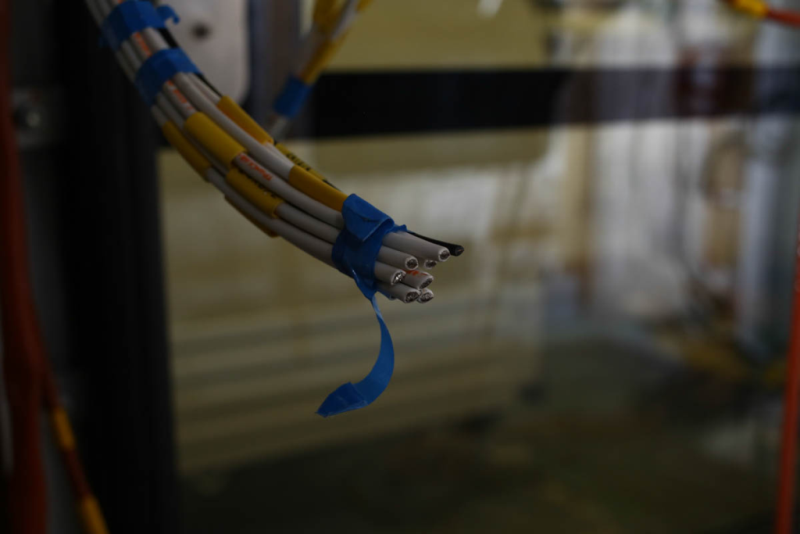

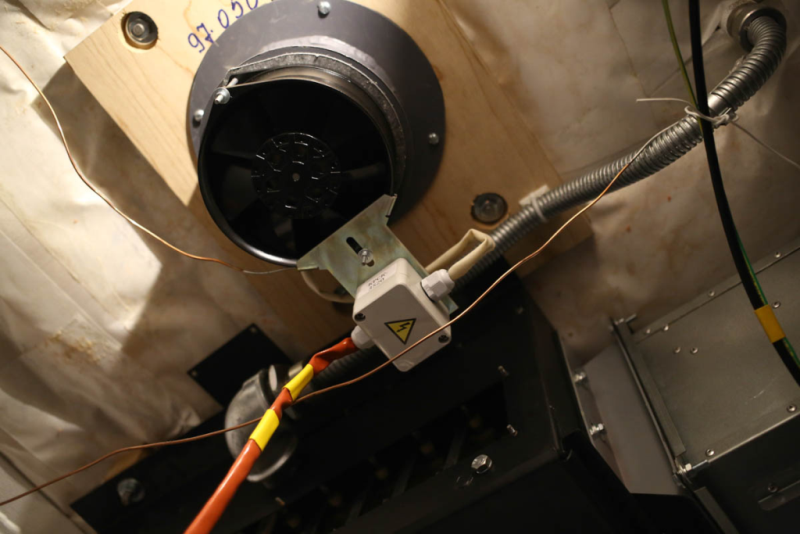

This is not just a pipe, but a water drain (water from the roof of the car). He, too, goes through all this magnificent interweaving of systems. Nearby there is a high-voltage cable from above to the carriage equipment:

A little later it will be seen what happens. In the meantime, look at the following important operation: until the remote control is installed, you need to check for leaks. The cat method is no longer suitable, the cab is checked by sprinkling (in fact, the cat method has never been used):

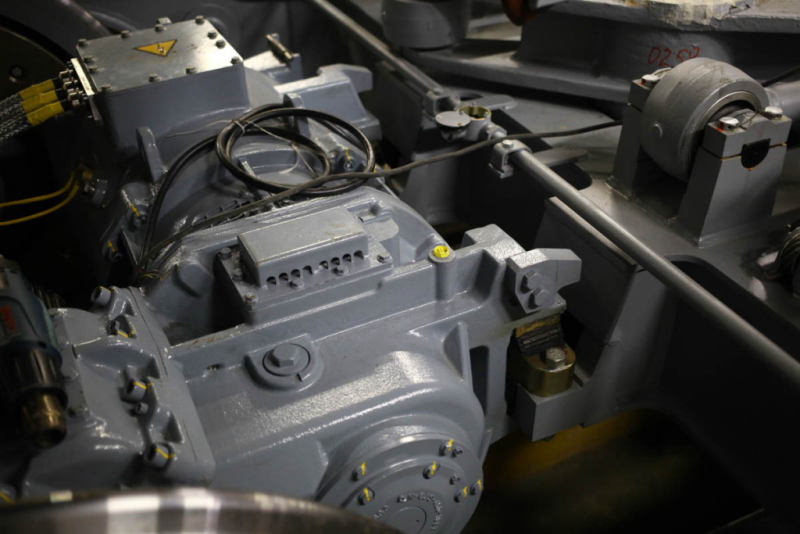

Here is the carriage equipment. "Oriole" is largely domestic. If we consider the Russian divisions of world manufacturers, including: according to some estimates, the percentage of parts reaches 90. Perhaps this is an estimate by mass fraction. One way or another, when important exceptions come from what is produced domestically, I will talk about it. The first important exception is the traction drive.

Installation of partitions:

At the end of the stage it turns out like this:

The "filling" is already waiting in the workshop, distributed over the assembly stages. As the nodes are installed, the carriage is moved further and further. In the end, he finds himself outside the assembly shop in the big real world. But he is ready for this moment.

The car’s sprinkling is done in such an installation (in the photo - not the car of the “Oriole 2.0” electric train, but the other on the assembly in the TVZ):

This carriage is in great need of carts:

And while they are not there, it is raised, and you can mount all the car equipment:

This is how it looks from the outside:

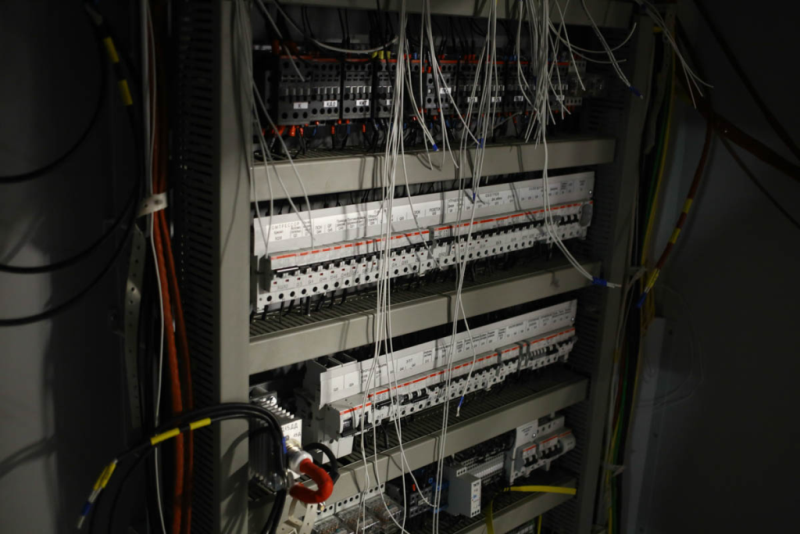

The next stage is electrics:

The equipment is placed both outside and inside:

Here is about this level of difficulty:

Now look at the cabin in front. Here you can see some very interesting nodes:

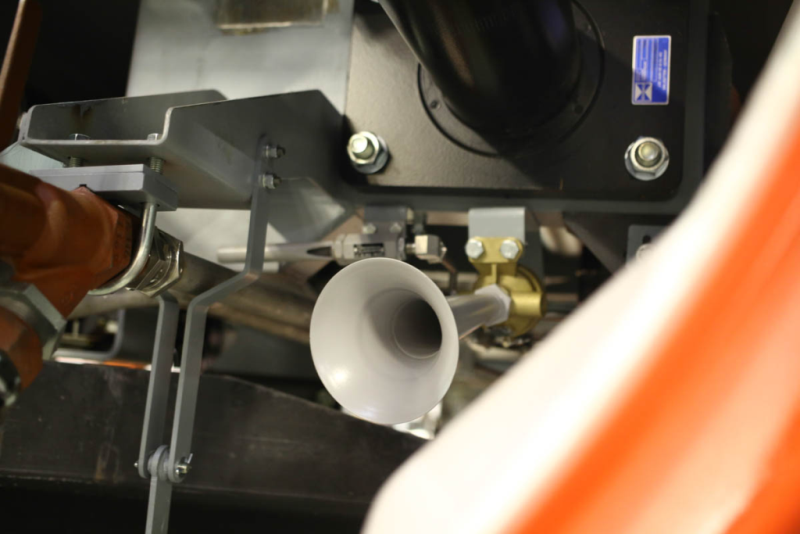

This is a side crash element. Often confused with a buffer device. The buffer device for cars is a buffer plate and a buffer cup, in fact, a spring with a rubber element. When wagons meet, these devices come in contact first and are compressed. Then they keep the train “pulled”, that is, they stretch the hitch to a certain level. When moving, smooth out strokes. And here a rigid plate is attached to a cylindrical pipe. This pipe enters a "funnel" into a pipe of smaller diameter and abuts. If the train crashes into something, for example, "wound" into a dead end, then the blow will be mitigated by forcing the plate and expanding the pipe. Extinction of energy will be achieved, but the device will become unusable. On the other hand, it is better than if the rest of the train becomes unusable.

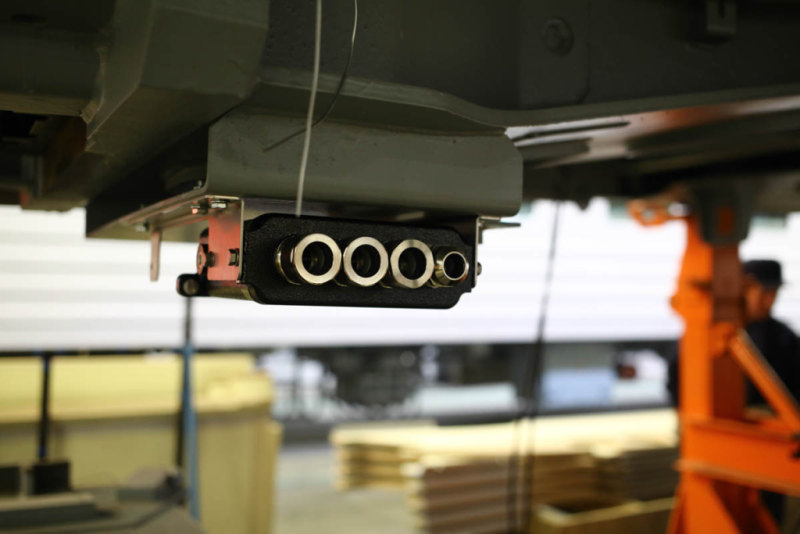

At this stage of assembly, you can look under the car and see the fuses. They are also called “bombs”, because when they are triggered they make a characteristic “bang”:

These are not just beautiful things - these are high voltage contactors:

Here is what happens inside the cars at this time:

The interior has been completely redesigned. A new 2 + 2 armchair installation scheme appeared, vibration-resistant ceilings, entrance areas changed, fiberglass fences with a display board, trash bins, newspaper trays and handouts, standing covers (yes, they are “half-chairs” or “podzhopniks” in jargon , but rightly called that way). The toilet has employment indicators - now they can be seen from the entire cabin. There was a place for installing vending machines in head cars, so now it will be possible to buy water or sandwiches directly on the train. There was a luggage rack on the Oriole v1.0: it turned out to be not a very good solution, and few used it. He was removed to win space just for the machines. Plus, a wardrobe for staff appeared: this is a very old Wishlist so that the same guards could put heavy outerwear somewhere and move on the train already in uniform. The closet is small but very pleasant for those who move on a train. New handrails.

This is the future lighting. Now it is continuous: from one end wall to another - light lines. These lines change in intensity depending on the time of day. Now they are programmed by default timer, but there are already two projects that can change ergonomics for passengers. The first idea is to change the color temperature (it varies from three to six thousand Kelvin here) so that the “warm” trains travel in one direction and the “cold” trains in the other. It will be visible from afar what light is in which train. This is not a division into female - male voice announcements about stops ("wife calls home, boss - to work", male voice - to the center, female - to residential areas), namely the distribution of directions for convenience at the interchange nodes. The second possible use is in the next "Oriole" to make ambient light sensors so that these lines themselves adjust to the light.

Truck:

The cart remained the same - with air suspension. They are the same on v1.0 and v2.0: the design is successful, there were no changes, the brakes are the same, the speed is the same - 120 kilometers per hour. The third "Oriole" is planned at a speed of 160 kilometers per hour. The gear ratio of the gearbox in the traction drive will change.

Almost the final:

The future info panel is already visible:

In the cab:

The installation in the toilet ends:

You can see the mounting points of the panels on the baffles:

And finally, here is the finished train that stands in the way. More precisely, two trains. Above you can see the new surveillance camera. Each car has eight cameras. Another one is this one upstairs. It is needed not to control crazy hooks (there were even cases of hooks to the top of the Sapsan), but to inspect the current collector and contact network. And since the train is now longer (seven wagons), a camera was added in the middle of the train to observe the passenger landing more precisely.

The exterior design has been changed in the cockpit: mainly windshields. They have increased visibility. The nose cone is different. There was a fringing of the windshield in the shape of a “horseshoe”: with white light it shows that it is the head carriage, with red it means that it is the end carriage (correctly, “horseshoes” are called buffer lights). The angle of the windshield has changed.

Outside, the entrance remained as it was: the train is intended only for high platforms. The area of glazing of the door has increased.

Here is the interior. As you can see, while the scoreboard is in developer mode:

The information panels in the interior of the train instead of LEDs with a large pixel pitch became an LCD. The exterior remained LED: there are requirements for brightness. This means that there will now be many new display graphics for passengers. WDC means a lot of interchange nodes, and the panels will have all the help about it. Plus, the panels will “know” where they are on the train, and show transplant instructions depending on their position. If the transition is in the center of the station, then the rear ones will lead along the direction of the arrow, and the front ones will be opposite the direction of movement.

In the cockpit, a lot is covered with a duster from scratches. In general, the controls have not changed much, but the cabin has become more spacious. The drivers, according to the first reviews, are delighted! It is clear that directly for control tasks the size of the cabin is not particularly important, but it is one thing to sit an armchair in the wall, and another when there is space there. And psychologically more comfortable, and you can stretch yourself right on the spot, without going into the passenger compartment.

If you read a post about what is in the driver’s cab , you already know the basic controls:

There are toilets in the head cars right behind the cab. That is, two large toilets with universal access to the train. Given that in the same metro there are none at all, it is quite convenient. We will not dwell on the toilets in detail: with the exception of cosmetic changes, they are familiar to you from the first version of the Oriole.

The only thing you need to know is that if for some reason you fell to the floor and cannot get up, then there is a SOS button. The correct wording for using this button is "for people with disabilities."

Rack for bicycles. Now there is a sign on the floor that this is for bicycles so that there are no disputes in the car.

USB charging - throughout the car:

Here it is - between the seats:

Armchairs are made of aluminum and fabric, and both are made in Russia. A new table has been added. As beta testers are already joking, it makes a great place for the fifth passenger. But this is a table. So that there is no doubt, there is a relief under two glasses.

Like the first Oriole, this train can be passed through from start to finish. Intercar doors are open by default and are in this state most of the time. Couplings - clearance-free coupling devices, as in the first. They are also imported.

The transitions themselves were updated in terms of protection. There are two main problems: hooks and protection of communications. Now most of the intercar lines are covered with a protective casing (located between the inner shell and the outer one), and two pneumatic lines remained from the important below. Due to the outer casing and the tight coupler, there is simply nowhere to rubberize for the hookers.

And here is the place for strollers (the marking is still covered with a protective coating, it will be removed when leaving the factory):

An updated rack, and there is a 220V socket:

220V sockets - only in the entrance zone. They are more official (for example, for cleaning cars with vacuum cleaners), but passengers can use them. In railway transport, depending on the country and year, two grounding schemes are used: on the chassis and on the rail (not a good idea) and on the analogue of the RCD in an electrically insulated trunk. That is, the circuits are completely isolated from the ground, and with any leakage, the assembly simply shuts down. It is safer.

The car door is on the button, like the first Oriole: you need to press it to open. Now a large bright indication of LED strips has been made: green - doors are closed, red - doors are not closed.

The passenger counting function has been greatly redesigned. The first Orioles have infrared sensors with several lines that make it possible to understand whether a person has entered or left. In v2.0, they got better, and the same sensors were added in the intercar crossings. As a result, it is now possible to know the wagon population with an accuracy of about five people. This means that in the future there are even possible signs at stations where there are more empty wagons in the approaching train. But since the WDC affects both Moscow networks and suburban networks, a sea of approvals is needed to bring this conclusion to a single standard.

And this is a handle for manual opening in case of failure:

Now the best news in train IT systems of the year. The Wi-Fi network is now network independent! If earlier it was a purely logical separation, now it is physical. Separate servers and switches. Now, finally, it will be possible to quietly implement remote control of all nodes.

The train can send telemetry to a central service department. Upon request, it begins to make a detailed log and broadcasts it from where it can.

The climate has not changed: the original was done well. Now, as there were two air conditioners of increased power, it remained, but there were many features to service this all - improved access.

The practical equipment did not change.

Training - three different courses. Locomotive crews (engineer and assistant), electrician and locksmith. Locomotive crews from the first "Orioles" do not need to be retrained, but the electrics and mechanics must be tightened. The most difficult part to maintain in training is the new approaches to the software-defined train for the railway. In the sense that the nodes behave differently depending on the firmware. For an industry where reliability is ensured by hitting a piece of iron against a piece of iron, this is somewhat new. Considering that before the train was released, there were a lot of hotfixes from different manufacturers, there were situations when, closing the minor, they caught the critical. There were situations when the correct update order on different nodes meant the ability to build a network from them after. When changing firmware, the car adapter (control server) may not pick up something, you need to catch bugs. The traction converter is very complex in behavior and often unpredictable - it is an electronic unit around which there is a clear liquid-type cooling system. But the electronic component and the algorithms work according to complex algorithms, and you can’t pick it there, while the guarantee is. The core manufacturer is not ours, so it saves its know-how. Well, or wants to be serviced only by him.

We go to the simulator. To train the driver on the Oriole, you can now use the simulator. This is the cabin from the train, where there is real equipment, which is a controller of the type of a very, very large joystick for a Win application that shows what happened to the train. Here is the admin site:

Training booth:

Instead of the landscape outside the window - render, instead of video cameras - also render:

Server for simulators:

And the most frightening thing: if you leave the cockpit, then the drawn reality will not go anywhere!

Because projectors:

Another feature of the train - the current collectors are now equipped with emergency lowering mechanisms. For example, if there is an ice block on the contact network, and somewhere there is a large congestion like an icicle, or some hero threw boots, then the first current collector will hit them and be damaged. Further, with some probability he will spark and spoil the contact wire. On the "Oriole" he immediately drops. The force of impact for folding is adjustable. A full seven-car train has more current collectors than is necessary in a regular job (this is not always the case). The train can go even on one current collector, but it is important which one is still alive - there will be a thrust of two motors or one. Now on the seven-car recommendation to keep one lowered in case of a reserve, but the owner of the train can do as he likes.

Everything. You can go to the WDC and test a new train. Bagreport can be sent both to the CPPK (carrier), and immediately to the TVZ (producer).

Here are our posts about the railway: about the head-car and why it is needed , a retro-train with a steam locomotive , FAQ about the work of the assistant driver , about the Megapolis train , what is interesting in the driver’s cabin , especially the Universiade transport , in the Aeroexpress depot , about the trans-Siberian railway , Grand Express , what kind of trains are there , railroad car systems , how a passenger carriage is arranged , how cars are assembled , how they evolved , about the Leningradsky station , about steam locomotives , about old cars , a big FAQ about long-distance trains and unobvious rules .

You can already see the schedule with us: here is Lobnya-Odintsovo (WDC-1) and Nakhabino-Podolsk (WDC-2) .