There was an idea to see how the microcircuit is arranged inside and how the Chinese friends assembled it. I want to tell and show about this. This may be interesting to those who work in the field of crystal packaging or are simply interested in what the IC looks like inside. I also want to listen to the opinions of people who know this field. All the photos below are processed in a graphical editor for better display.

The microcircuit is made in a plastic 64-pin case.

We study the sample after partial removal of the plastic.

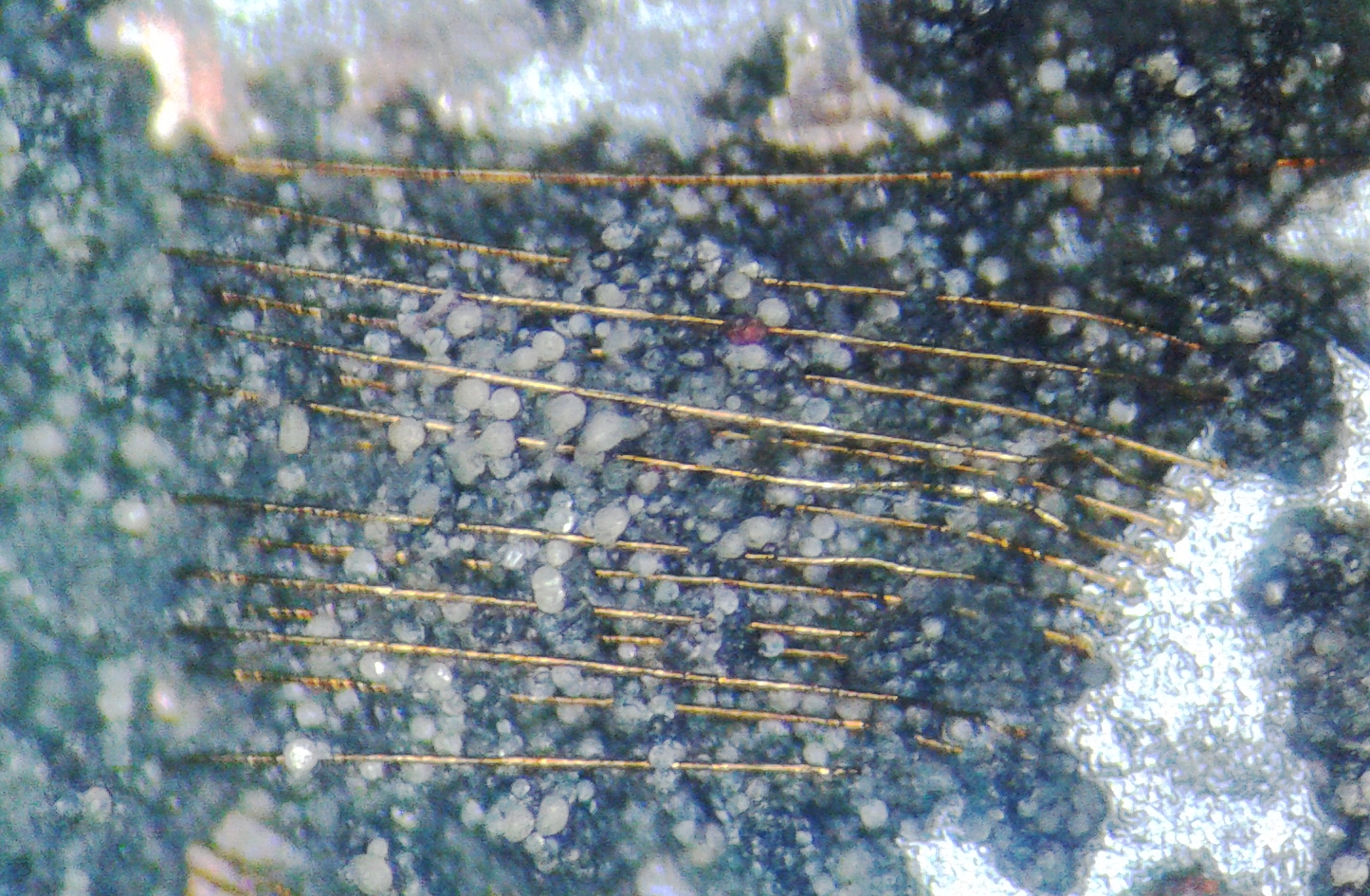

Fig 1. Plastic filler and wire weld. In the photo, the region is ~ 1x2 mm.

The plastic of the microcircuit protects it from external influences and consists of a binder and a filler, which accounts for about ~ 80% - 90% of the plastic volume. Plastic fillers are transparent balls of approximately the same diameter. Most likely this is glass. In other schemes, broken glass with sharp edges was found as a filler.

Fig 2. The general plan of the chip. The size of the IC excluding legs 10 x 10 mm. Black spots are plastic.

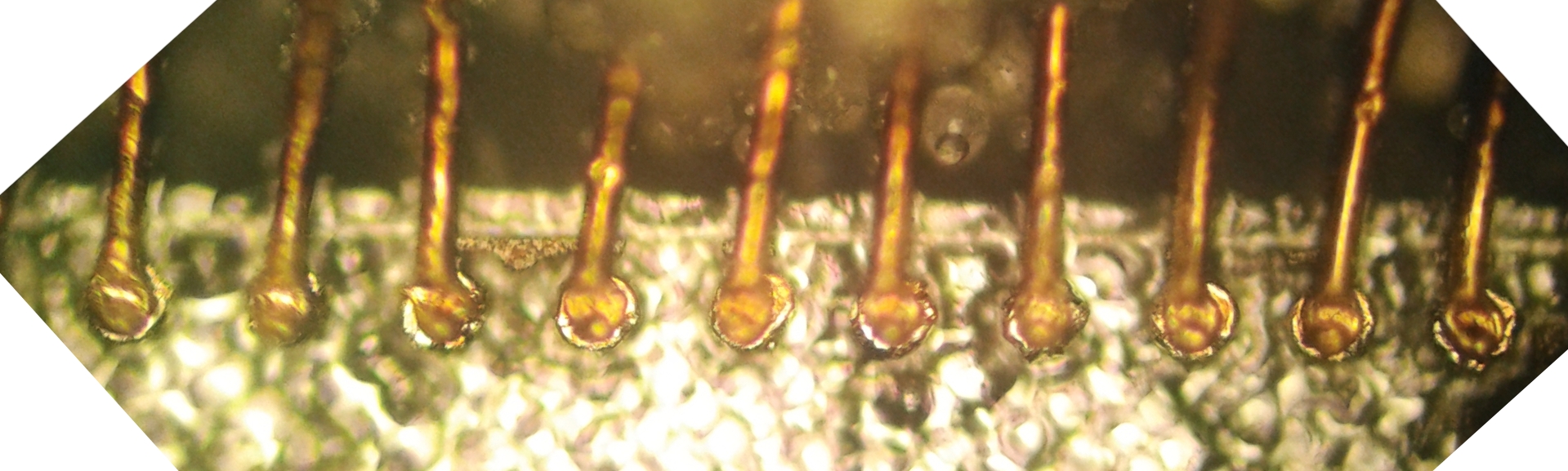

Two chips were detected in the microcircuit. One, small, glued to the other. Such an assembly is called a 2.5D assembly. The thickness of the crystals is 150 microns. This partly explains why the chip requires two supply voltages of 1.2 and 3.3 volts and why it turned out to be “hot”. The general weld is quite interesting, many jumpers are laid from the edges to the center of the crystal, and they are quite long.

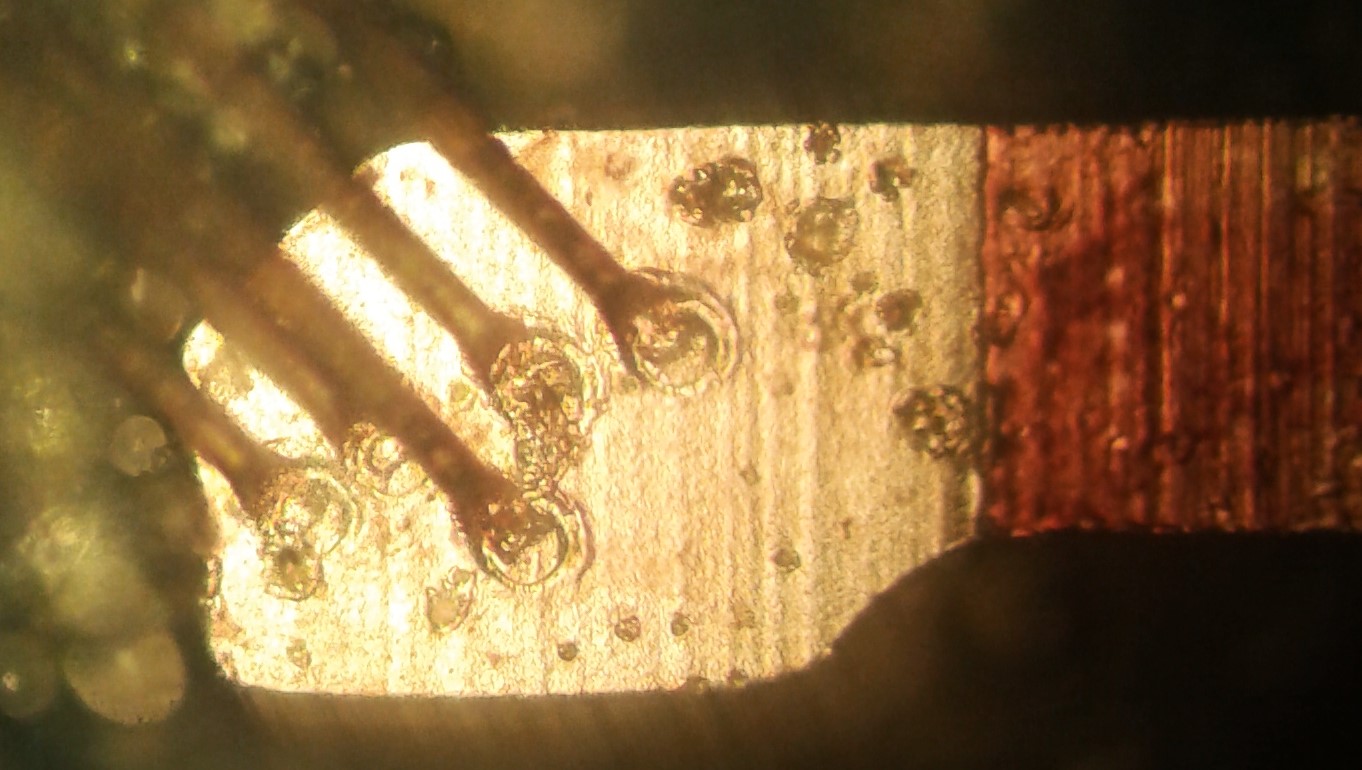

Fig. 3. Fragment of the ultrasonic welding on the power supply traverse of the integrated circuit. Platform traverses coated.

Fig. 4. Fragment of the weld on a crystal.

The wire weld is made of 2 types of wire. They are clearly different from each other. One of the wires is copper, the other is not defined. Perhaps gold, or gilded wire of copper or other metal.

Bottom line: The assembly is complex, with a large number of welds, with 2 crystals, all this is packed to a maximum in a thin case. The Chinese manage to take on the routine work of packaging and do it inexpensively. Hard work is not taken away from them. Cost reduction and reliability reduction are also there. We replaced the gold wire in the circuit (and the plastic should be gold) with copper and two birds with one stone. Both cheaper and copper corrosion processes. Next, there are two crystals in one case without proper cooling - and the degradation of the crystal will go even faster, which ultimately happened, but for the time of guarantee of operability is enough, but for the manufacturer this is important.