We earn on solar energy or passive income at 25% per annum, practical experience. Part 2

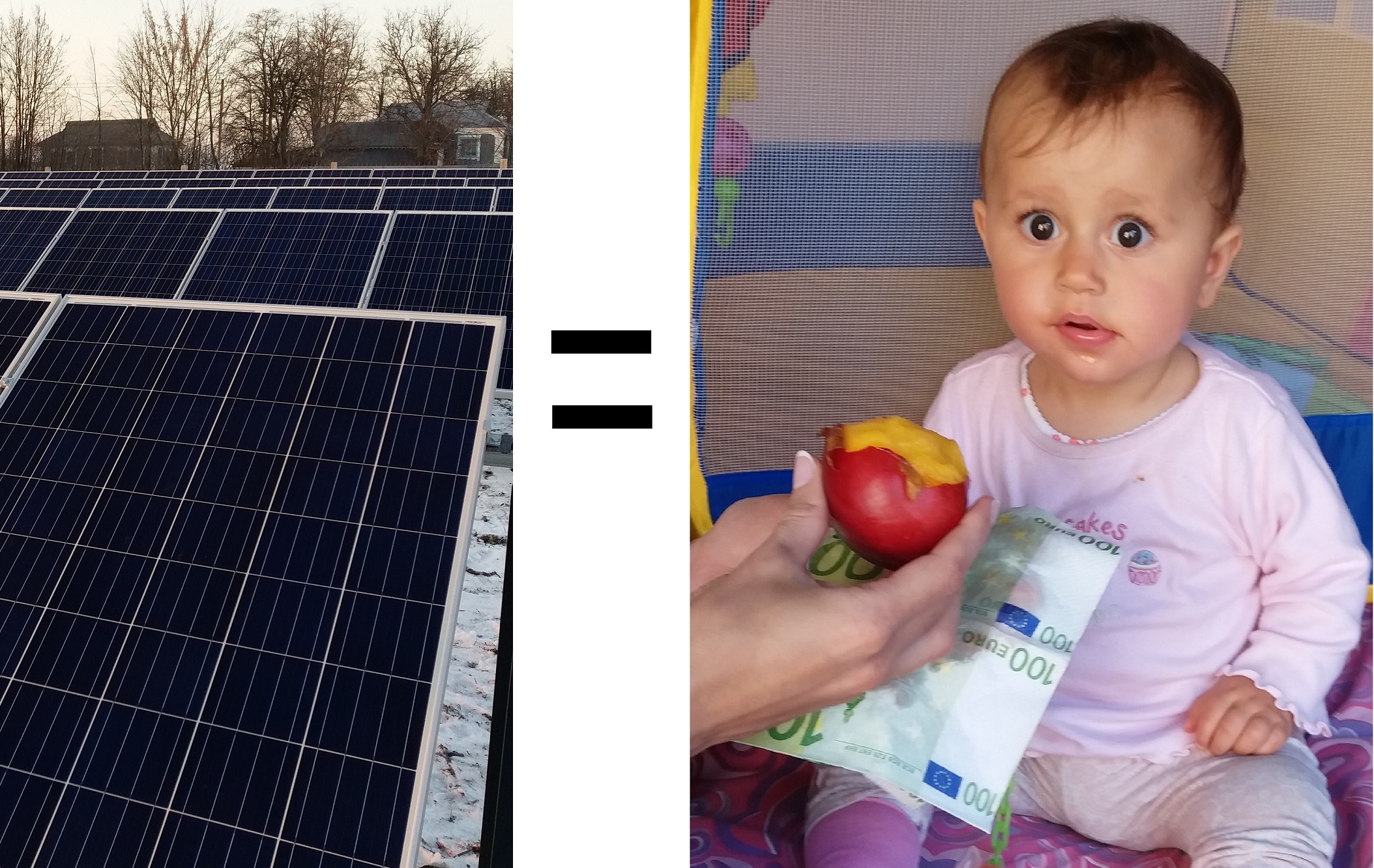

KDVP © Diana, made by Siuzanna

Part 2. Practical

Have you firmly decided to build your home solar station? Weighed all the risks, found funding, figured out where it would stand and which trees would have to be cut? Well, if you have not changed your mind yet - I ask further.

Step 1. Get the allocated power

Many start with a supplier search, equipment selection, etc. In fact, it takes the most treasured 30 kW of allocated power most of the time and nerves, and sometimes they are not given at all (from 2 months to infinity). In some cases, installers already have established connections, and if you are on the way with them, you can work through them (saving nerves and time, but not money).

Connection is now not a cheap thing, the official cost depends on oblenergo, but you can see the cost in advance, there is a calculator www.nerc.gov.ua/?calc .

In Ukraine, it ranges from ~ 1 to ~ 6K $ per 30 kW , depending on Oblenergo. This is provided that to the substation, less than 300m in a straight line (standard connection).

IMPORTANT! Line quality and stable operation of the substation are critical. In general, the connection should be made by a dedicated line to the substation. Then the neighbors are protected from raising the voltage, the station does not crash at the maximum generation, and in general it is so correct.

And if more than 300m?

And you can have more than 300m in a straight line - the connection cost can be easily multiplied by 1.5 -2x (at the same time, a dedicated line of the correct cross section is simply necessary).

And at the substation there is almost always no free power - everyone is connected as consumers, and the substations are old and loaded. No one cares that you will generate and unload the substation.

And you also need the goodwill of oblenergo and contractors. There may be no materials, the boss is on vacation, and indeed. And there is also RES ...

Therefore, the time to break through the wall of the bureaucracy from the moment of submitting the application to receiving the 3-phase input can be up to six months is very simple.

And at the substation there is almost always no free power - everyone is connected as consumers, and the substations are old and loaded. No one cares that you will generate and unload the substation.

And you also need the goodwill of oblenergo and contractors. There may be no materials, the boss is on vacation, and indeed. And there is also RES ...

Therefore, the time to break through the wall of the bureaucracy from the moment of submitting the application to receiving the 3-phase input can be up to six months is very simple.

A list of required documents can be found in your Oblenergo. It is standard, the main thing that is required is the ownership of the house. About some oblenergo, there were surprisingly very good reviews, so everyone’s revenge under one comb is also not worth it.

But here you have overcome all the bureaucratic obstacles, and installation of input begins.

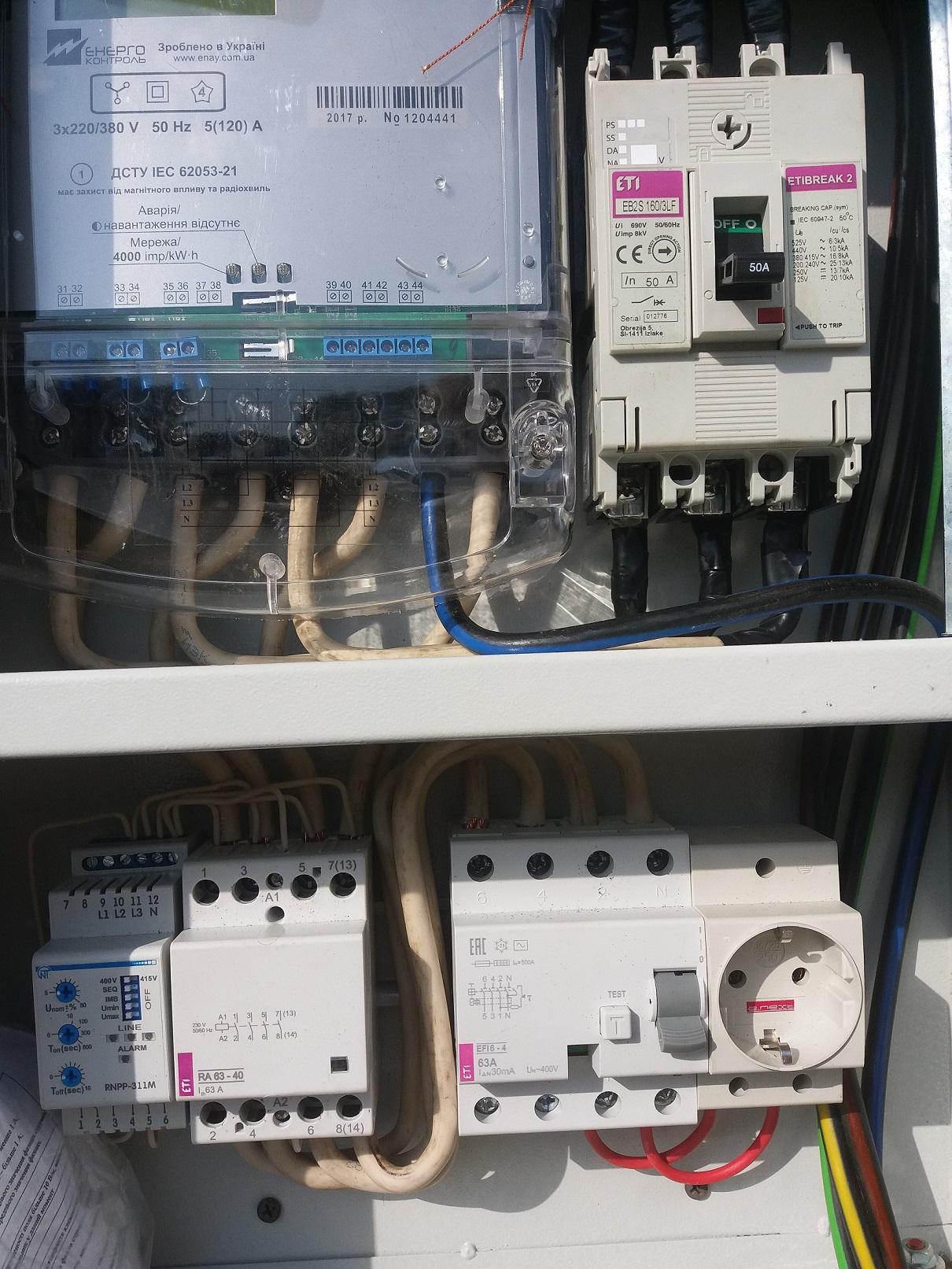

Problems with an introductory machine are really very common. Someone brings himself more power to get a 63A machine, someone “repacks”.

IMPORTANT! Buy an industrial opening machine. Under the sleeve. This will save you a lot of nerves and money. Do not listen to anyone who says that he will not fit, and why, we will not. He has to stand there. And it is advisable not to save on the brand. I managed to change 3 burned down simple branded machines until I came to this truth.

How to cram unbeatable

Why an industrial machine?

Aluminum wires, of any cross-section, have the property of "flow". And how well do not tighten the contacts, over time, slack will still form. And since it’s all under the seals, it’s so easy not to pull it all up.

The problem is typical and extremely massive.

An example of the beginning of wire melting.

Do not have time to tighten.

The problem is typical and extremely massive.

An example of the beginning of wire melting.

Do not have time to tighten.

In a set of standard connection, all other machines are put the cheapest. You should be puzzled by this separately. RNPP usually overheats, the RCD must be more than 100 mA, otherwise it will constantly knock out (total replacement of another 4 30mA RCD).

Standard connection, 2 iterations

Who guesses what turned out to be fundamentally wrong here? RCD current does not count.

Who guesses what turned out to be fundamentally wrong here? RCD current does not count.

In parallel, it is worth buying a bi-directional counter with a modem and ordering its parameterization. Extremely popular in Ukraine

ACE 6000

with a modem and parameterization ~ 500 $. Typically, the entire range of services for the desired components can be agreed with the contractor. You can also go there for a meter, grounding.

In general, it is worth making friends with contractors, sometimes they work wonders.

Total average standard connection of 30kW with all machines, meters, work and other expenses will be about 4-8K $.

I forgot to mention in the first part - in order to obtain an ST, you need the ownership of the house, land, and very often a certificate for an inverter. The rest goes quickly and does not hurt.

Step 2

Choose equipment

Solar panels.

The main thing in the price of a large DSES is solar panels. Since the start of construction, the price for them has fallen from $ 0.5 / W to $ 0.35 / W now for Tier1, and continues to fall. You can find panels at 0.25 $ / W from the Tier2 manufacturer.

All panels are divided according to the concept of Tier. Tier 1 - the best, Tier 3 - some say that such a Tier doesn’t happen. There is only the first freshness .

Not so terrible Tier, as he is painted.

Bloomberg uses the term Tier1, which describes the financial situation of a solar panel company. In addition, it has its own production line, supplies to foreign markets, certain sales volumes.

In general, a good rating, but in fact, no one said a word about quality.

The list itself cannot be given, but it is easily google. It is worth comparing independent lists, some like to push their panels in there, and people believe.

Tier2 are usually those who assemble solar panels from other people's cells. Or did not want to follow all the recommendations of Bloomberg. The main drawback of this option is that the neighbor may have panels with cool cells, and nobody will tell you which ones will come to you in advance. And how they behave in work is also not known.

Therefore, everyone can choose their own option - either we pay a little more and get hope for quality, or we play the lottery, but cheaply.

In general, a good rating, but in fact, no one said a word about quality.

The list itself cannot be given, but it is easily google. It is worth comparing independent lists, some like to push their panels in there, and people believe.

Tier2 are usually those who assemble solar panels from other people's cells. Or did not want to follow all the recommendations of Bloomberg. The main drawback of this option is that the neighbor may have panels with cool cells, and nobody will tell you which ones will come to you in advance. And how they behave in work is also not known.

Therefore, everyone can choose their own option - either we pay a little more and get hope for quality, or we play the lottery, but cheaply.

I chose JA Solar panels (Tier 1, China).

Why did I choose them? At that time, there was “Europe” on the market, cool brands like LG (with a x2-3 price tag), a bunch of small deliveries (who could bring something), and 2 companies that I found a direct way to. These firms drove Ja Solar.

Those who were trembling with the word China were offered Vietnam. But the names of the manufacturers were one more beautiful.

I read the reviews, the site and the docks are normal, local distributors respected. There were not so many options at that time. In the future there were exhibitions, acquaintance with other brands (no worse, or maybe better, acquaintance with other distributors), there was even an attempt to push the container of another manufacturer to the bottom of the bucket.

But just then the market began to fever, amid falling prices in China, and I returned to the already proven method. I am very glad that I settled on the same brand, because mounting holes for each manufacturer are made in their own way, and so I can rearrange the panels without redoing the fasteners.

My advice is anything, but only from a trusted provider. They begin to fake everything. They re-glued the nameplate, a beautiful box, and voila - Tier1.

Globally, I am for Tier1, but this is not a dogma. The Tier2 market of Ukraine is now vomiting Amerisolar, but see the paragraph on the nameplates, cell manufacturer and supplier.

Also, I had enough space, and I took panels from the best price range, first 265W. If you take the maximum power, the price is growing exponentially.

The second iteration was with the same Ja Solar, but already performed using Half-cell technology. At that time, it was just the height of the marketing wars that had

Unfortunately, this is more of a marketing ploy. Real production increased by 3-4%, and then only in hot weather.

Comparison of identical power stations, one on simple Ja Solar, the second Half Cell

The morning subsidence is caused by slight shading.

So how many panels do you need ??

Already having operational experience, I can confidently say that the size of the "solar field" directed to the South should be 37+ kW, and this will lead to minimal losses and maximize profits. It is believed that by putting 45 kW of panels, losses will also fall within a reasonable range. I don’t know, I will test.

Which panels to take now? If there is enough space, it is best to take the model in the optimal ratio of $ / W. Now there is a clear advantage towards Mono Perc. I think you can consider them, but only Tier1 (we read about LeTID ).

There is a new chip, double-sided panels. The reviews are good. Only many are silent that their fastening is again N times more expensive. Well, somehow you need to ennoble the land, white pebbles, for example, pour.

And 40kW panels work like this:

40 Half Cell VS 33.6 Half Cell VS 33.6 simple

The graph varies greatly from temperature, wind, the height of the sun above the horizon (about the dependence on the sun itself and the clouds, I hope, and so it is clear).

Inverter

The market is almost more severe than the panel market. Who brought something, he then praises. Still cool mixed up against the background of "gray supplies" from Europe. There were also offers of wonderful inverters with a 30kW nameplate, but really 35+ kW.

Now, rather, the greater the margin, it then sells.

Top manufacturers of inverters are again easily google. Todas were popular Fronius, ABB, Huawei and came across offers SMA and KACO. ABB successfully merged its inverter business, my attitude towards Fronius inverters is negative. I did not consider the rest. There was one big problem - there are almost no models in the line of high-profile (then) names of 30 kW. And here begins what killed me in general.

At best, they install 2 inverters for people, a standard circuit 27 + 3 (15 + 15) or 3 inverters (or we can!) For 10 at a time. Sometimes people are just satisfied with 27.

Moreover, they uphold their point of view with reliability, redundancy and others. For 3 * 10 money, I can buy 2 of my 30kW inverters and put 1 in a warehouse, for redundancy.

So what about me? I consider a well-deserved hit of sales in Ukraine (on insiders, not only I think so).

Huawei SUN-2000 33KTL-A

.

When it all started, the same Huawei SUN-2000 33KTL was on the market, but without the letter A. I deliberately waited a month (and then another 4 while writing complaints, see step 1), so that I would order exactly them, with the letter “ A ”by reading the specification. This is a "strangled" industrial inverter, a single line of performance for 33, 36 and 42 kVA! All the same body and a chic passive radiator. Crazy hands are beating (according to legend, someone could, the service says a lie) over the possibility of something to mumble, and get 33 kW instead of 30.

There was a certain fear (competitors' marketers tried) that it will not have time to cool down and will “lose power”, but I consider a couple of fans and a temperature sensor to be a trifling thing. But fears were in vain, and he famously holds 40kW of panels (the manufacturer’s representatives say about 45kW), and no one overheats on his own radiator.

Another plus is a wide range of input voltages, low start voltage, 4 independent MPPT trackers and a full set of protection, both for reversing and constant.

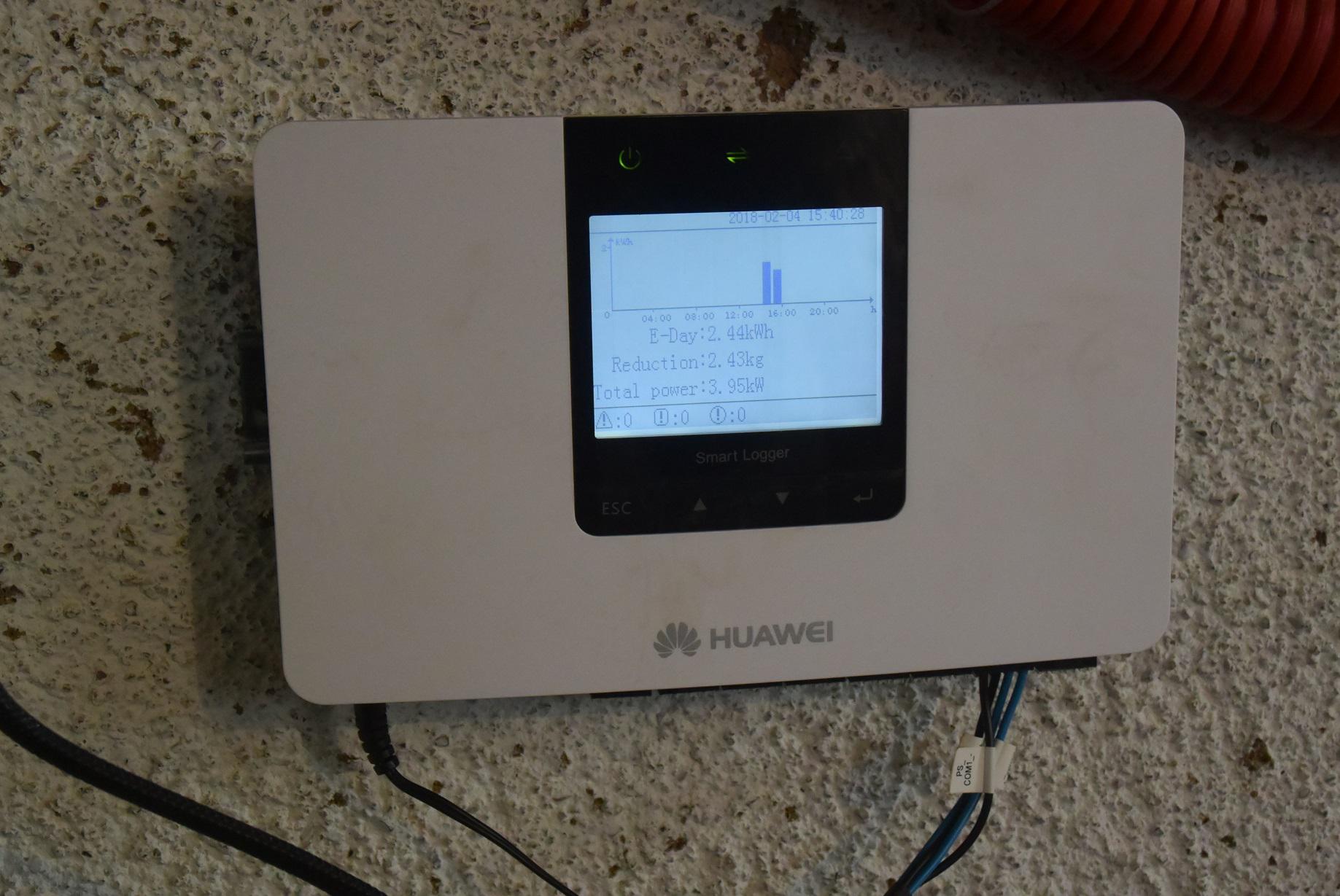

There is a minus - for communication in the kit there is only a Bluetooth whistle, but for communication with the

SmartLogger 1000, the first kilowatts.

Given that I have N to 1, I purchased it, it’s very convenient. But in the general case, you need to approach him and look at the light bulbs to understand his condition, or connect from your phone (3-5m).

Collective farm own monitoring

The simplest solution is any Android device with remote access (for example, a phone with TeamViewer).

The inverter has an RS485 sticking out, SmartLogger connects to it. I was sent a transcript of the protocol, and people have already begun to make their loggers based on Chinese RS485 gateways . Someone made an application on the phone. Saw a $ 250 solution on raspberries and a telegram. Each still has a number of minuses, as for me.

I was thinking of making my product, but here's an article and a vacation somehow pushed it. Not entirely clear with the rights to the protocol. If someone knows about the RS485 gateway with 3G, which has enough power from USB 2.0, for stable operation, I will be happy for the tips in PM.

The inverter has an RS485 sticking out, SmartLogger connects to it. I was sent a transcript of the protocol, and people have already begun to make their loggers based on Chinese RS485 gateways . Someone made an application on the phone. Saw a $ 250 solution on raspberries and a telegram. Each still has a number of minuses, as for me.

I was thinking of making my product, but here's an article and a vacation somehow pushed it. Not entirely clear with the rights to the protocol. If someone knows about the RS485 gateway with 3G, which has enough power from USB 2.0, for stable operation, I will be happy for the tips in PM.

I want to upset readers, at the time of writing, the Huawei SUN-2000 33KTL-A was in the EOL, and I was not provided with the exact information that will be in its place.

Step 3. Squeeze the maximum

Each inverter has an optimal voltage range. Huawei KTL33A is 620V. If the voltage is 800 or 500, we lose 1%. If we go beyond this, the losses will increase.

The second parameter that you need to pay attention to is the start voltage. Here it is quite low, 200 V. We will not point with a finger, but the competitors have a starting voltage of 580V. And the inverter does not start until the sun rises high enough and there is no 580V on the panels. The same thing at sunset. Also, over time, panels degrade. And as soon as in the hot season the voltage drops below 580V, we get either the departure of the optimal MPPT point or the refusal to work.

So our task is to assemble the panels so that in the summer, the most optimal period, they give out 650+ V, so that with a design degradation of 10%, we would be at the maximum.

We turn to interesting numbers from the solar panel datasheet.

Each panel has its own. We are interested in two main figures - Open circuit voltage and Temperature Coefficient of Voc. Knowing them, we can count everything. Oh, and also the power of the panel itself, of course.

Let's look at my 265 W Ja Solar panel

Open circuit voltage (Voc) - 37.95V

This is an open circuit voltage, the panel cannot give out above it, at STC (Cell temperature 25C).

But we do have winter, and when cooling (as well as heating), our voltage changes to Temperature Coefficient of Voc (BVoc) “- 0.33 / C” (the voltage rises by 0.33V when cooling 1 degree below STC, and drops by same value when heated).

According to safety rules, it is necessary to calculate not exceeding the maximum voltage of 1000V. The panels are certified specifically for this voltage, as well as the cable and SPD. It is this inverter that can withstand 1100V.

In total, on a frosty February day, the sun peeks out from behind the clouds and illuminates the panels at an angle of 90 degrees and a luminous flux of 1000W / m2. Of course, there is no snow on them. The panels have an ambient temperature, the inverter is idling (or off), and the voltage goes beyond the permissible limits, which entails a breakdown of insulation, etc. (this cannot be, but it should be considered so).

It is generally believed that panels will not be colder than 15C. I agree with this, because even under the snow (he was surprised himself), or when there are clouds in the sky, they still work and get warm.

After a couple of hours, the snow itself will begin to slide. If not melted off, an ice crust forms during the night. Here it can hang for many days.

The formula looks like this -

V max = Voc * (100+ BVoc * (- 15-Tstc)) / 100

This means the maximum voltage that can be in theory in one panel will be

V max = 37.95 * (100+ (- 0.33) * (- 40)) / 100 = 37.95 * 1.132 = 42.96V

Therefore, we cannot supply more than 1000V / 42.96V = 23.2 panels. I read and talked a lot about my type of panel, and I know that they are put on 24. But this is more at your own peril and risk. 23 panels are guaranteed not to burn. According to rumors, 26 someone got burnt.

Total we have in one chain (string) 23 series-connected panels.

This will give us a theoretical power of 265W * 23 = 6095W, a theoretical operating voltage (at NOCT) of 28.29V * 23 = 665.85V. In reality, the summer will be even lower.

Total, to achieve 40kW we need 40/6 = 6.5 strings, not beautiful.

Let's look at my 265 W Ja Solar panel

Open circuit voltage (Voc) - 37.95V

This is an open circuit voltage, the panel cannot give out above it, at STC (Cell temperature 25C).

But we do have winter, and when cooling (as well as heating), our voltage changes to Temperature Coefficient of Voc (BVoc) “- 0.33 / C” (the voltage rises by 0.33V when cooling 1 degree below STC, and drops by same value when heated).

According to safety rules, it is necessary to calculate not exceeding the maximum voltage of 1000V. The panels are certified specifically for this voltage, as well as the cable and SPD. It is this inverter that can withstand 1100V.

In total, on a frosty February day, the sun peeks out from behind the clouds and illuminates the panels at an angle of 90 degrees and a luminous flux of 1000W / m2. Of course, there is no snow on them. The panels have an ambient temperature, the inverter is idling (or off), and the voltage goes beyond the permissible limits, which entails a breakdown of insulation, etc. (this cannot be, but it should be considered so).

It is generally believed that panels will not be colder than 15C. I agree with this, because even under the snow (he was surprised himself), or when there are clouds in the sky, they still work and get warm.

After a couple of hours, the snow itself will begin to slide. If not melted off, an ice crust forms during the night. Here it can hang for many days.

The formula looks like this -

V max = Voc * (100+ BVoc * (- 15-Tstc)) / 100

This means the maximum voltage that can be in theory in one panel will be

V max = 37.95 * (100+ (- 0.33) * (- 40)) / 100 = 37.95 * 1.132 = 42.96V

Therefore, we cannot supply more than 1000V / 42.96V = 23.2 panels. I read and talked a lot about my type of panel, and I know that they are put on 24. But this is more at your own peril and risk. 23 panels are guaranteed not to burn. According to rumors, 26 someone got burnt.

Total we have in one chain (string) 23 series-connected panels.

This will give us a theoretical power of 265W * 23 = 6095W, a theoretical operating voltage (at NOCT) of 28.29V * 23 = 665.85V. In reality, the summer will be even lower.

Total, to achieve 40kW we need 40/6 = 6.5 strings, not beautiful.

In total, the best options are:

1. - we make 7 strings 23 * 265, and there will be a solar field power of 42665W

2. - we do 6 strings, 23 * 265 and the power of the solar field is 36570W

3. - we make 7 strings, but put 22 panels per string. The power of the solar field is 40810W.

I thought that 33.6kW was the earliest, so I put 6 strings on 21 panels. Now I'm sorry, but it comes down to rearranging the panels. Whether you will where to rearrange the panels is another question.

Now I am more likely for option number 1.

In modern panels, the voltage has increased, and the thermal coefficient is reduced. But you need to consider for each specific case.

Now knowing that there will be a total of 7 strings in 23 panels, a total of 161 panels, we need to place them.

Step 4. Ground Constructions

2 types of designs are popular -

double row, I really like this performance,

double row with interchangeable angle.

Two-row drawings were shared with me, and in words they described materials for a removable angle. I calculated both this and that for metal, sent requests to manufacturers of galvanized structures (space in general).

Someone suggested that single-row would be cheaper. Designers famously drew the necessary, having passed in all places. As a result, after an engineering genius,

such a miracle was born

In the course of the work, adjustments were made - the depth of concreting was 0.9 m, the first stand was 60 cm high, the farthest one was dancing from it. All struts were thrown out. The distance between the racks 2m.

concreting process

Single row construction, with rudiments of struts.

Guides under the panel can be set both with a profile and a 40 * 40 pipe. First set C profile.

Then I made 40 * 40 * 2 pipes on the basis of the pipe (some recommend 3mm) and bolts, as for me,

more reliable and better.

They also differ in the type of execution - from ferrous metal or galvanized. I also heard about aluminum. Supports can be concreted, hammered, or placed on geo-screws (according to rumors, one industrial SES, on geo-screws, notably uprooted in the wind).

The choice of the type of construction is very dependent on the terrain, and if it is possible to fit everything in 2 rows, I would probably put 1 double-row myself, in order to save land.

And of course, when there is absolutely no space, people build “sails” - one solid panel of panels.

A professional calculation is needed here, but I can’t imagine how to properly service it, and it’s scary that it will uproot. Not to mention the price of metal.

During the layout of the structures, I got a little fixated on setting the panels to the South. As a result, surveyors who measure the land for the geocadastre were noted. Now I take this more softly, and let's say twist the structure by + -5 (10) degrees, depending on the landscape and shading, it's still worth it.

Shading is avoided at all costs. It greatly affects the overall output, and if the shadow falls on at least one panel, the whole string in which it is attached normally stops working.

Built, primed, painted. In my case, we drill holes according to the template under the panel. A swarm of trenches for cables or getting ready to lead the air. It's not the same for everybody.

Step 5. Equipment arrives. Start to collect

Before this stage, we believe that you have a 30kW power supply, there is an input shield with an SPD, RNPP.

I spent half a year reading who and how to build, looked at a couple of industrial SESs, and home ones too. But like that, taking everything away without the advice of knowledgeable people was still scary. I did not see detailed instructions again. The curators were involved, I would say so. They answered my questions, calculated those constructions according to the principle of better retake, and the installation of the high-voltage part was involved. For a reasonable price and piecework.

From the total equipment we need:

Panels

Inverter

Automatic, 63A

Solar cable - 6mm2. Someone puts 4mm2, but our business is to reduce losses. If the line is long, sometimes they put SIP16 through the sleeves. Pros and cons separately. The SIP option is not entirely correct, be careful.

VVGng cable - from the inverter to the shield, 16mm2. We are still reducing losses.

Mounting guards themselves

SPD + Fuses - optional. The inverter manufacturer claims that they are not needed. I did with them

it’s very convenient to turn off the necessary shear, and installation is also more convenient. There is a hope that something will burn out outside, and will change quickly, and you won’t have to give the inverter, even for warranty repairs.

"Solar connectors" - complete with an inverter are smart, crimped. Initially, they told me that they were soldered, and I bought an additional many simple ones, and even worse.

- Fasteners for solar panels (I have M8 bolts)

- Panel gaskets - paronite (cheap and cheerful), or aluminum

- Corrugation of all colors and sizes (+ cable channels)

First of all, we put panels. In general, the installation is pretty quick. But, note that they cannot be stored horizontally. Scratch / push the glass or leave marks.

Under each panel there are gaskets. They say galvanic corrosion will be. It’s hard for me to calculate its scale (there are different opinions), but it’s not a pity to cut paronite.

Installing an inverter - causes a lot of controversy.

I believe that it is best to put it closest to the counter. Yes, the DC cable will go more (500m easily), but the DC loss is much lower than AC.

Supporters of the theory of the inverter next to the panels (also installed at all industrial stations), additionally they protect it from theft, making various conceivable and unthinkable designs.

Copyright snapped here, but if the authors want them to be mentioned here, I’m only for it.

If to put on the house - it is necessary to avoid direct hit of sunshine. Same

you need to understand that in summer it works like a 0.6 kW heater, and in the room next to it it may not always be comfortable. He also knows how to hum and cool click at the start of the start relay.

We carry cables, everywhere tips / sleeves.

We check the correct collection of strings by high-voltage clamps - if everything is done correctly, a voltage of ~ 800 V appears on the strings (idle). My difference on each string was within 1-2V.

We check everything for a break, tighten all the contacts again, and start the station.

In general, knowing the rules for working with high-voltage equipment, there is nothing complicated. From an unusual tool, it is imperative to have a crimping for the sleeves and a high-voltage tester. The rest can be replaced with improvised means.

Well, you need a full hand to work with thick wires. In my house, I spread all the electrics, but somehow I looked at the 16mm VVGng cable in thought. But it is not the gods who burn the pots, and then he was able to lay it in the shields.

After that (preferably in parallel) we write a statement to the RES about replacing the counter with a bi-directional one.

Hint - until the counter is changed, the station should not be turned on, a simple counter does not understand what generation is, and will count it as consumption.

From the moment the meter is replaced with bidirectional, all generated energy will be calculated and paid in the future.

We collect a package of documents and submit to the Green Tariff.

Then the second round of hell begins. They may ask for additional pieces of paper and certificates. Believe me - they are easier, cheaper, faster to get than to prove that, by law, they are not needed.Each oblenergo has its own "cockroaches", so there is no single recipe.

Of the saddest, one of the southern regional power companies of our country, the very same Huawei SUN-2000 33KTL-A (30 kW, 33 kVA) considers as ~ 27 kW the inverter

That's all.You get a contract in your hands and become a small, but generating installation.

The service is really simple. Closely monitor the contacts, in early spring, in the middle of summer, accurately check, tighten the connections. Grass really grows tall. Mowing the scythe is the lot of the brave. And so you can walk the remedy against weeds.

It is imperative to have an introductory machine, tips, tips for the machine in the substation in stock, preferably also a machine for the substation.

In the footsteps of the first part - yes, the issue of risks was not solved.

The main risk that I see is the termination of ST payments by the state.

Risks of theft - many are highly reinsured (including myself), but there were only 2-3 real cases of removing panels / inverters, and that was rumored. Intentional damage to the panels - yes, they say that it happens more often than 2 times (up to 10 cases). Theft of panels not yet installed, and obvious scam at the stage of ordering equipment - alas, more and more painfully.

The risks that fail will be covered by a 5-year (expandable to 20) guarantee for inverters, a 25-year guarantee on solar panels (there are nuances).

The risk of hail - over the years there have been a number of strong hail, but none of the owners complained that the hail was able to break the panels. The panels are tested for resistance to degrees and stand at an angle.

A more common situation is lightning strikes. Sometimes the inverter and / or diodes on the panels burn out. Putting lightning protection around the perimeter of the household is unprofitable. Again, it can “fly in” for a break. Therefore, we put external SPD and believe in the best.

It didn’t help. And this is the youngest model of Huawei, but the 33KTL model without A, like its competitors, looks very similar. I hope now it’s clear why I was waiting for 33KTL-A. A

small digression on the Green Tariff for private households.

Distributed generation, if approached wisely, can be useful. For this, it is necessary, for example, to balance generation within the consumption of a household / substation / 10kV line / settlement. And depending on the operating experience, issue certain limits using these numbers. The main goal is to reduce reverse flows and, as a consequence, losses.

Over the past six months, an active movement has risen from the side of state bodies against small generation. And the fact that they themselves allowed 50kW (thank God temporarily) and clutching their heads, ah ah, they do not have consumption (we don’t teach physics), they earn too much (we don’t take risks into account) - let's reduce small generation.

But at the same time they are modestly silent about the 2–3 MW sections constructed and received with ST, consisting of private houses, and made with some support from above.

They are silent about industrial SES, how money is bleached on them, VAT is returned and taxes are written off.

To summarize - at the moment, investing in the Green Tariff seems to me to be one of the most highly profitable, with certain, but non-critical risks.

All peace and sunny sky over your head!

Part 1. Financial

All Articles