Notes of the IoT provider. Impulse Exit Curse

Hello dear Internet of Things lovers. Today I would like to talk about the pulse output. One of the most popular telemetric outputs for metering devices. Simple as five cents. And the hardest to operate.

Let's start with the theory.

Pulse output (II) - these are two contacts that go out of the meter. Inside the counter there may be a reed switch or some kind of relay. Closing occurs mechanically. Between the contacts, a drop in resistance periodically occurs. One fall - one impulse. This circuit does not require any electronics at all inside the meter, only on a removal device.

In the case of an electric meter, the pulse output is realized through an open collector circuit. Here the system is already more complicated, but not by much.

The number of pulses is proportional to the consumed resource. Water, gas, electricity, heat. Or something else. We came across pulsed outputs at oil flow meters.

How to work with a pulse output? The easiest way to explain with an example:

The water meter “let through” a cubic meter of water through itself. The weight of its impulse is 0.1 m3. This means that during the passage of water we will fix 10 pulses. Knowing the weight, it is easy to calculate how many resources this or that device has wound.

Does that sound simple?

So far, yes. Problems begin during operation.

The readings are provided by special modules - pulse counters (SI). They can be wired or wireless, with a battery or from 220. But there is only one sense - a pulse counter - this is a normal converter from one interface to another. After calculating the contact closure, SI transfers this information to the server. Which way is the tenth thing already.

So where is the curse?

The main problem of the pulse output is that it gives information only about the current state of affairs. Say, if you listen to contacts for an hour, then with confidence you can only say about consumption for this past hour. And no more. It is impossible to get any information about the fact that the display is on the counter through the IW.

Is this such a big problem?

If you connect an installed meter, you just need to rewrite the initial meter reading. Make this amendment in your interface and continue working. Is everything simple?

No. Here pitfalls begin:

1) The human factor. Counters rarely stand on an illuminated pedestal. More often they are located in places where it is not so easy to get to. In the basements where it is damp, dirty and very dark. Correctly rewriting the initial testimony is not such an easy task. Therefore, we can get an error at the stage of introduction.

2) Human factor number 2. Unfortunately, not everyone has straight arms from their shoulders. If the wires from the IVs are poorly mounted in the terminal block of the pulse counter, such an unpleasant thing as the measurement error can begin. With the same probability, this can make a mistake both up and down.

3) The notorious weight of the pulse. Well, if it is applied to the meter itself by engraving. Not bad, if any, on the instrument. But often the treasured figure is only in the documentation. If we are talking about already installed metering devices, it is highly likely that the documentation was lost or it was "somewhere there." Googling will not help you, for many metering devices in the general passports only possible weights are indicated. On a specific device you need to look at a specific passport. Which is not. And here begins the game "guess the weight of the impulse from experience."

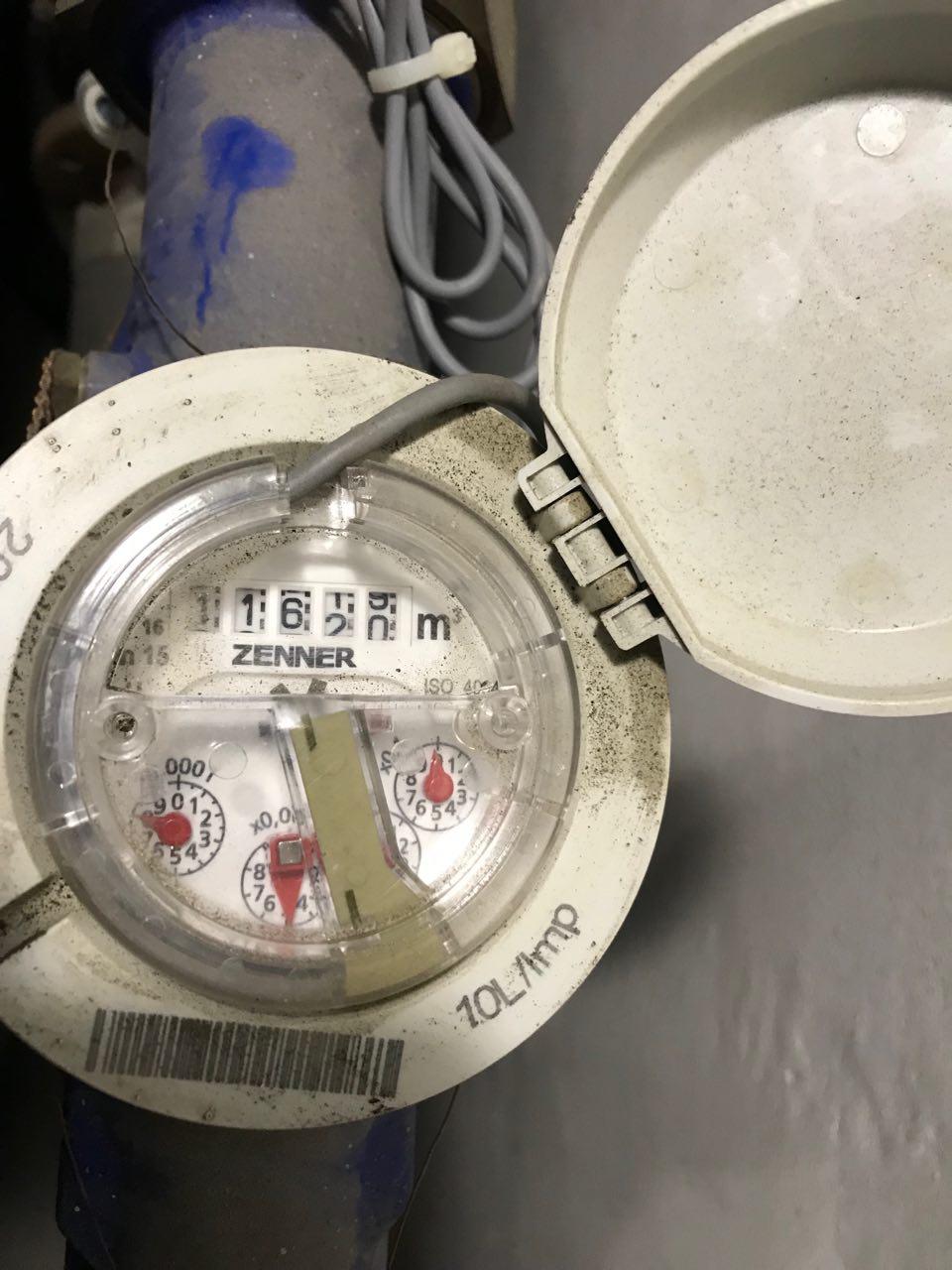

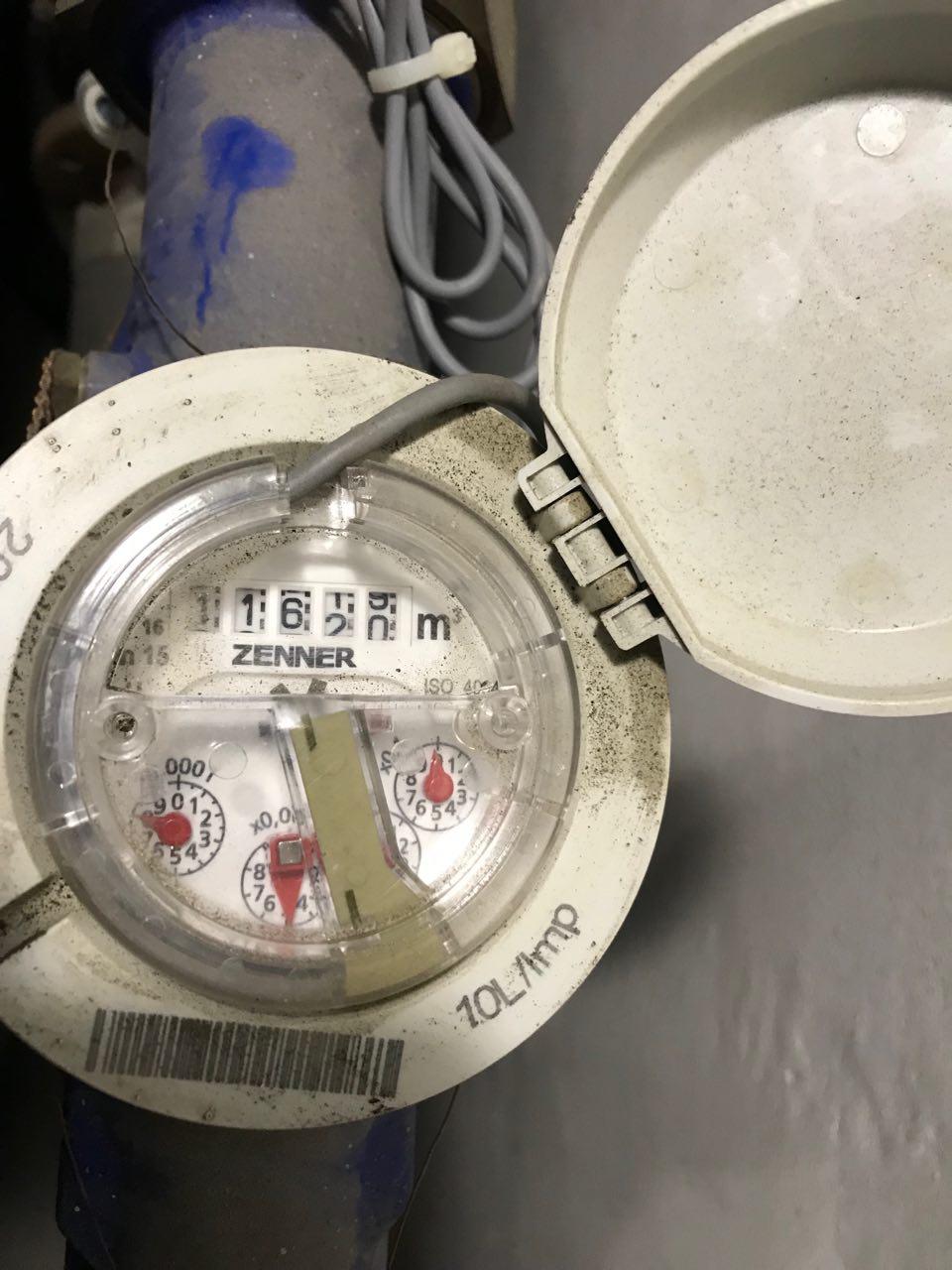

An example of a good counter. The weight of the pulse on the case, in a prominent place.

4) Additional external factors. For example, a cable that is too long from the meter to the pulse counter. Or a high voltage cable in one riser. All of this can cause calculation errors. And for IWs on an open collector, the polarity of the connection is still important - an additional opportunity to make a mistake.

It would seem that all the problems are somehow related to the quality of installation. Well, or installation map. Limit the cable length, write down where it can be laid. Do everything qualitatively the first time, finally!

In practice, installation flaws are inevitable. But if we use ModBus and RS-485, such problems are very easy to catch by an automated system. We either have a connection with the counter or not. If there is a connection, then the counter will give us its readings, it is not necessary to look at the scoreboard (with rare exceptions of glitches of the counter itself).

With a pulse output, verification is required after a while. This is the only way we can confidently say that we believe it is right. That everything is mounted qualitatively, that we did not miss the pulse weight and correctly considered the initial value. Only the fact of the presence of impulses or their absence is diagnosed remotely. Such information for yourself.

Yes friends. Twenty-first century, smart metering devices. But if they are equipped with an IW, then they definitely need reconciliation after some time. At least once, but needed.

What does this mean for exploitation? This means that reconciliation should be incorporated into your expenses. And you can’t use a pulse output on that meter that you can’t get to anymore.

If we connect a common house meter for the order of the Management Company, then everything is fine with us. The Criminal Code is vitally interested in the correct operation of telemetry and, of course, will let us check in two weeks from now. We conclude that everything is fine with us, we will make adjustments or remount.

But what to do if the meter is in the subscriber’s apartment?

Even the most crystal clear user will never be home at the time you need. Imagine the task - to verify the readings of the counters of an apartment building? A hundred apartments that way? How long will it take?

Now multiply this by the love of some users for “magic magnets” or “bugs” in the shield. You yourself give him the instrument of deception. He will pull the wire from the counter, say that he has stumbled and will not let you into the apartment for repair. What to do?

It is necessary to draw a conclusion. IW is an extremely limited interface. It should not be located in a place inaccessible to you. It requires reconciliation. It is unreliable, because it does not transmit specific numbers, only impulses. Even if it works now, it is not a fact that it will work in two years (when the contacts are oxidized). And certainly it is not suitable for the control of "tricky" subscribers.

For the counters in the apartment, assembled devices are needed, on board of which there is already a radio module and communication with the radio network. This is not a panacea, but the likelihood of tricks is less. Only such counters really interrogate.

With other types of meters (industrial, common house), the situation is easier, but even here the IW should be an extreme measure.

A few words of defense. Some users doubt that the IW is operational when there are too many pulses per unit time. Let's take an example.

Energy meter CE101. It produces 3200 pulses per kilowatt hour.

Thus, if 1 kWh passes through the meter, then in an hour we must have time to count 3200 pulses. And if ten? Then the figure will become larger, 32,000 pulses.

This is almost ten pulses per second.

Is it realistic to count them without error?

We turn to the technical documentation. The pulse counter with the LoRaWAN module from Vega (SI-11) can capture up to 200 Hz. This means that per second it can register 200 pulses.

The SI-206-D2 control device catches up to 30 pulses per second.

The CE101 energy meter is designed for current up to 100 A (the maximum value of a number of models), i.e. in an hour she will be able to "drag" up to 22 kW. Here we are already close to critical values. But this is an apartment electric meter, and the wiring of an ordinary apartment will not stand this much. Real numbers will be far from threshold values.

And manufacturers are aware of the real "throughput" of their devices and select weights in accordance with the capabilities of pulse counters.

I would like to finish like this. Pulse output is a VERY cheap interface that captivates with the cheapness of manufacturers and consumers. But here is the trouble. A lot of the savings will have to be spent on operation. Is it worth it?

PS Immediately after the calculation, this article was bombarded. I realized that some of the thoughts were not disclosed correctly, therefore I made corrections and described some things in more detail. In this form, I leave her. For many, the topic will seem petty and not worthwhile. But judging by the plans of manufacturers and integrators, they see the future behind an impulse exit. I would like to sow at least some doubts about their confidence.

Let's start with the theory.

Pulse output (II) - these are two contacts that go out of the meter. Inside the counter there may be a reed switch or some kind of relay. Closing occurs mechanically. Between the contacts, a drop in resistance periodically occurs. One fall - one impulse. This circuit does not require any electronics at all inside the meter, only on a removal device.

In the case of an electric meter, the pulse output is realized through an open collector circuit. Here the system is already more complicated, but not by much.

The number of pulses is proportional to the consumed resource. Water, gas, electricity, heat. Or something else. We came across pulsed outputs at oil flow meters.

How to work with a pulse output? The easiest way to explain with an example:

The water meter “let through” a cubic meter of water through itself. The weight of its impulse is 0.1 m3. This means that during the passage of water we will fix 10 pulses. Knowing the weight, it is easy to calculate how many resources this or that device has wound.

Does that sound simple?

So far, yes. Problems begin during operation.

The readings are provided by special modules - pulse counters (SI). They can be wired or wireless, with a battery or from 220. But there is only one sense - a pulse counter - this is a normal converter from one interface to another. After calculating the contact closure, SI transfers this information to the server. Which way is the tenth thing already.

So where is the curse?

The main problem of the pulse output is that it gives information only about the current state of affairs. Say, if you listen to contacts for an hour, then with confidence you can only say about consumption for this past hour. And no more. It is impossible to get any information about the fact that the display is on the counter through the IW.

Is this such a big problem?

If you connect an installed meter, you just need to rewrite the initial meter reading. Make this amendment in your interface and continue working. Is everything simple?

No. Here pitfalls begin:

1) The human factor. Counters rarely stand on an illuminated pedestal. More often they are located in places where it is not so easy to get to. In the basements where it is damp, dirty and very dark. Correctly rewriting the initial testimony is not such an easy task. Therefore, we can get an error at the stage of introduction.

2) Human factor number 2. Unfortunately, not everyone has straight arms from their shoulders. If the wires from the IVs are poorly mounted in the terminal block of the pulse counter, such an unpleasant thing as the measurement error can begin. With the same probability, this can make a mistake both up and down.

3) The notorious weight of the pulse. Well, if it is applied to the meter itself by engraving. Not bad, if any, on the instrument. But often the treasured figure is only in the documentation. If we are talking about already installed metering devices, it is highly likely that the documentation was lost or it was "somewhere there." Googling will not help you, for many metering devices in the general passports only possible weights are indicated. On a specific device you need to look at a specific passport. Which is not. And here begins the game "guess the weight of the impulse from experience."

An example of a good counter. The weight of the pulse on the case, in a prominent place.

4) Additional external factors. For example, a cable that is too long from the meter to the pulse counter. Or a high voltage cable in one riser. All of this can cause calculation errors. And for IWs on an open collector, the polarity of the connection is still important - an additional opportunity to make a mistake.

It would seem that all the problems are somehow related to the quality of installation. Well, or installation map. Limit the cable length, write down where it can be laid. Do everything qualitatively the first time, finally!

In practice, installation flaws are inevitable. But if we use ModBus and RS-485, such problems are very easy to catch by an automated system. We either have a connection with the counter or not. If there is a connection, then the counter will give us its readings, it is not necessary to look at the scoreboard (with rare exceptions of glitches of the counter itself).

With a pulse output, verification is required after a while. This is the only way we can confidently say that we believe it is right. That everything is mounted qualitatively, that we did not miss the pulse weight and correctly considered the initial value. Only the fact of the presence of impulses or their absence is diagnosed remotely. Such information for yourself.

Yes friends. Twenty-first century, smart metering devices. But if they are equipped with an IW, then they definitely need reconciliation after some time. At least once, but needed.

What does this mean for exploitation? This means that reconciliation should be incorporated into your expenses. And you can’t use a pulse output on that meter that you can’t get to anymore.

If we connect a common house meter for the order of the Management Company, then everything is fine with us. The Criminal Code is vitally interested in the correct operation of telemetry and, of course, will let us check in two weeks from now. We conclude that everything is fine with us, we will make adjustments or remount.

But what to do if the meter is in the subscriber’s apartment?

Even the most crystal clear user will never be home at the time you need. Imagine the task - to verify the readings of the counters of an apartment building? A hundred apartments that way? How long will it take?

Now multiply this by the love of some users for “magic magnets” or “bugs” in the shield. You yourself give him the instrument of deception. He will pull the wire from the counter, say that he has stumbled and will not let you into the apartment for repair. What to do?

It is necessary to draw a conclusion. IW is an extremely limited interface. It should not be located in a place inaccessible to you. It requires reconciliation. It is unreliable, because it does not transmit specific numbers, only impulses. Even if it works now, it is not a fact that it will work in two years (when the contacts are oxidized). And certainly it is not suitable for the control of "tricky" subscribers.

For the counters in the apartment, assembled devices are needed, on board of which there is already a radio module and communication with the radio network. This is not a panacea, but the likelihood of tricks is less. Only such counters really interrogate.

With other types of meters (industrial, common house), the situation is easier, but even here the IW should be an extreme measure.

A few words of defense. Some users doubt that the IW is operational when there are too many pulses per unit time. Let's take an example.

Energy meter CE101. It produces 3200 pulses per kilowatt hour.

Thus, if 1 kWh passes through the meter, then in an hour we must have time to count 3200 pulses. And if ten? Then the figure will become larger, 32,000 pulses.

This is almost ten pulses per second.

Is it realistic to count them without error?

We turn to the technical documentation. The pulse counter with the LoRaWAN module from Vega (SI-11) can capture up to 200 Hz. This means that per second it can register 200 pulses.

The SI-206-D2 control device catches up to 30 pulses per second.

The CE101 energy meter is designed for current up to 100 A (the maximum value of a number of models), i.e. in an hour she will be able to "drag" up to 22 kW. Here we are already close to critical values. But this is an apartment electric meter, and the wiring of an ordinary apartment will not stand this much. Real numbers will be far from threshold values.

And manufacturers are aware of the real "throughput" of their devices and select weights in accordance with the capabilities of pulse counters.

I would like to finish like this. Pulse output is a VERY cheap interface that captivates with the cheapness of manufacturers and consumers. But here is the trouble. A lot of the savings will have to be spent on operation. Is it worth it?

PS Immediately after the calculation, this article was bombarded. I realized that some of the thoughts were not disclosed correctly, therefore I made corrections and described some things in more detail. In this form, I leave her. For many, the topic will seem petty and not worthwhile. But judging by the plans of manufacturers and integrators, they see the future behind an impulse exit. I would like to sow at least some doubts about their confidence.

All Articles