Engineers and architects are already designing lunar settlements

NASA and the European Space Agency moon colonization plans require advanced life support systems and cosmic ray protection

The architectural bureau Skidmore, Owings & Merrill is known for designing and developing the Burj Khalifa Tower, the tallest building in the world. Such iconic structures are one of the company's specializations. But in their New York office, architects are working on an even more amazing project - drawings of extraterrestrial buildings, the first such project for this company. The company is developing a lunar base in conjunction with the European Space Agency (ESA) and MIT.

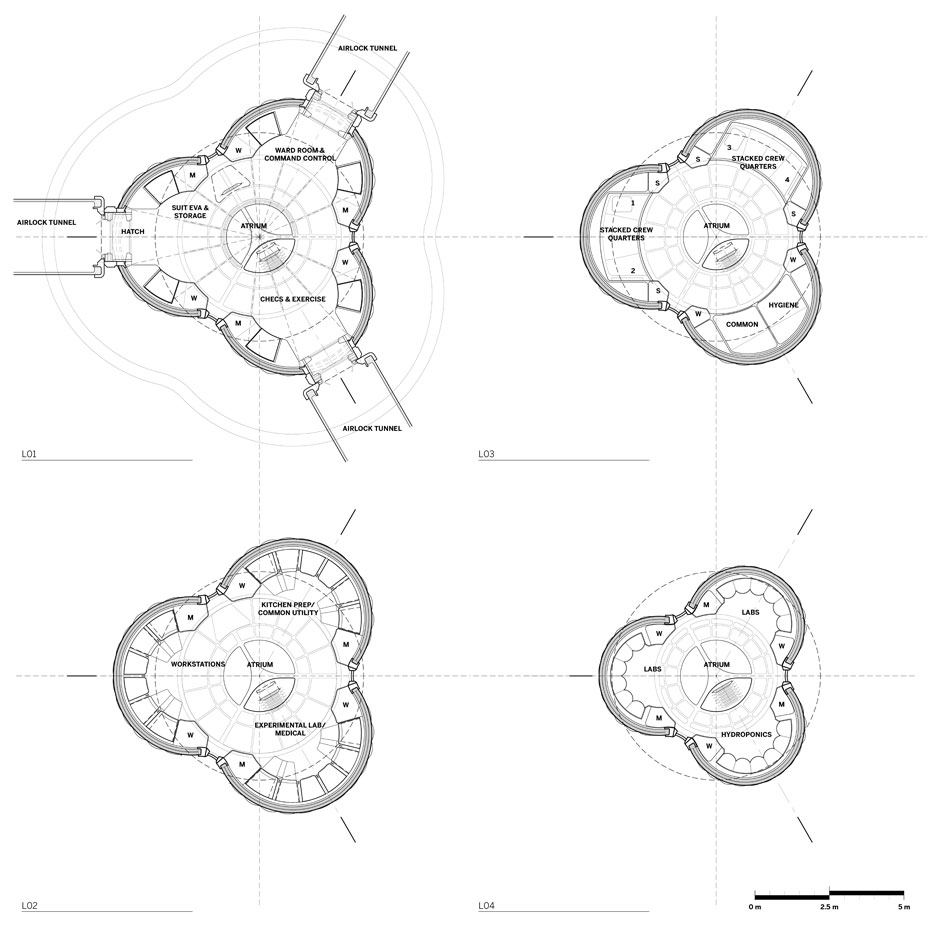

Daniel Inocente , a leading designer, shows drawings and computer-generated images of white puffy cocoons scattered across the lunar landscape, connected by transition pipes and surrounded by robots, solar panels and astronauts, and a familiar blue ball is observing all this from the sky.

These ideas may still remain unrealized, but they help ESA think through possible options for the future. The moon offers many possibilities. Planetologists want to study its composition in order to learn about the early solar system and the origin of the Earth. Astronomers want to build radio telescopes on its far side. Medical researchers want to know how the human body reacts to being in low gravity for a long time. Space scouts want to test equipment or produce fuel for flights to asteroids, Mars and beyond.

Talk of sending people to the moon — first arising after the Apollo missions ended in the 1970s — has recently gained momentum. In 2016, the head of ESA announced the launch of the Moon Village program , a deliberately vague idea that inspires private and public participants to work together on robotic and human exploration of the moon. Last year, eight Chinese volunteers completed their experiment by spending an entire year at a base simulating a lunar palace called Lunar Palace 1 to test life support systems.

And while private companies do not plan to send people to the moon in the near future, rockets from SpaceX and Blue Origin could significantly reduce the cost of such a project for governments. A few months ago, US Vice President Mike Pence promised to return the astronauts to the moon for 5 years.

However, to equip people on the moon, experts will need to solve some, to put it mildly, problems . This includes surviving in harsh conditions, building structures from local materials, perfecting life support systems, and resolving the issue with one potentially fatal complication for which we currently have no solution: with dust.

The three most important factors for determining the location for a lunar settlement, as any realtor will tell you, are: location, location, and location. At Skidmore, Owings & Merrill (SOM) they decided that the most attractive place was on the edge of Shackleton Crater near the south pole of the moon.

There is convincing evidence that surface areas in constant shadow of the crater contain water ice that got there with ancient comets - it is suitable for drinking, cooking, washing, creating concrete and separating it into hydrogen and oxygen to produce rocket fuel.

But wherever they decide to erect buildings, space architects and engineers face constraints that do not concern ordinary specialists in this field. On the moon, of course, there is almost no air, so any home should be closed and airtight. And if most of the cosmic stones burn in the Earth’s atmosphere, the surface of the moon is constantly bombarded with micrometeorites. In this regard, structures should be designed for such attacks.

Gravity is about 6 times weaker than Earth. This allows you to build elongated structures, but also requires more support points. Because of weak gravity, it’s hard to dig: you push down and squeeze you up. The temperatures there are extreme, so in the dwellings it will be necessary to equip powerful heating and cooling systems, and the materials of which they consist will have to withstand significant compression and expansion.

There is also the problem of radiation. The sun constantly emits a stream of high-speed protons and electrons - the solar wind. And if the Earth’s magnetic field protects us from most of it, the Moon does not have a magnetic field, so all particles collide with the surface. Even more dangerous are the coronal mass ejections of the Sun. During these events, groups of high-energy protons and electrons break out into space. A strong outburst may amount to several sievert (sievert - a unit of radiation) on the surface of the moon, which is enough for a person to die if he cannot return to Earth for bone marrow transplantation. And, as if these dangers are not enough, astronauts on the moon will be constantly bombarded with cosmic rays, which are likely to increase the risk of cancer.

Pre-assembled residential modules designed by SOM will be enclosed in rocket fairings

In the New York office of SOM Inocent, he talks about his company’s offer to print walls around the cocoons of moon homes on 3D printers, and thereby protect themselves from deadly radiation. Residents who are at the base for a long time will need walls up to three meters thick to protect themselves from galactic cosmic rays. It will be pointless to deliver tons of cement from the Earth, so astronauts will use local resources - that is, take advantage of what is already there.

In the SOM concept, walls will be built from lunar soil, which is called regolith , because there is no organic matter. One of the methods is 3D-printing of walls, either immediately in one piece on the spot, or on bricks that will hook onto each other during construction. Some space architects propose to layered regolith cement in layers using a robotic nozzle.

But what if the fluid in the cement mixture evaporates or freezes before the cement in the wall or bricks hardens? European researchers, together with the architectural bureau Foster + Partners, studied the possibility of binding fluids and injecting them to prevent this effect, and printed a wall section using a regolith simulator. However, then the contractors will still need to send the liquid-binding material or special cement powder to the moon.

SOM prefers extruding molten regolith through a nozzle in the manner of hot-melt adhesive . Another approach is sintering , or heating the regolith above the melting point, so that it then fuses and solidifies. In one ESA project called RegoLight, researchers concentrated sunlight into a powerful beam and drove it across the surface of a regolith simulator, sintering bricks layer by layer. The process was slow, and the test bricks were weak, so many researchers believe that microwave sintering using microwave ovens or beams to bind dust will be a winning strategy. So far, SOM is exploring a sintering option.

For relatively low dwellings, regolith can simply be poured onto metal structures (and leave room for maintenance). Another more theoretical option is to place the living modules inside the lava tubes of the moon - large empty tunnels through which molten stone once flowed.

Regolith will be used not only to protect buildings, but also the construction of launch sites and roads. Brent Sherwood , chairman of the Space Architecture Technical Committee of the American Institute of Aeronautics and Astronautics (AIAA), proposes to bake regolithic tiles in microwave ovens. A spaceship landing on platforms, or vehicles moving along roads paved with such tiles, will raise less dust. Roads will also make it easier for robots to move around the surface. “In essence, I want to turn the surface of the moon into a predictable factory floor, like in an Amazon warehouse,” he says.

Hannah Luck , an ESA space architect with experience in architecture and textile design, offers a more unconventional use of regolith. He and his colleagues managed to melt the regolith simulator and pull it into threads with which robots can twist metal farms, getting fibrous cocoons. The housing obtained by this method of manufacture can be placed in a crater, over which a web is stretched to withstand the regolith piled on top. They also used a robot to produce a miniature version of such a coating. As a result, many techniques for using regolith are likely to be adopted in future lunar colonies.

And what will the lunar residential modules look like behind these lunar regolith walls? SOM's current work projects grew out of suggestions that engineers have been making for decades, usually for domes or cylinders, sometimes completely or half immersed in the soil.

Space architects and engineers generally believe that the first dwellings on the moon will resemble modules of the international space station (ISS). “First-generation technology is a bit less sexy” compared to sci-fi images, says Jaime Benaroya , an engineer on mechanics and aerospace engineering at Rutgers University, author of The Moon Housing Construction: Engineering Approaches to Lunar Settlements . The first dwelling will be a sealed enclosure under pressure, covered with regolith to protect against radiation - in fact, buried in a tin can.

According to Sherwood, who was working on building modules for the ISS with Boeing, engineers already know how to manufacture, test, run and repair such a module. “We got a tremendous amount of knowledge through the space station,” he says.

As a result, we can move on to inflatable modules that can expand to large volumes, after we understand how to integrate them with rigid structures and pack them so that they can be laid out correctly. Bigelow Aerospace from Las Vegas sold NASA licenses for patents for the construction of an inflatable module , which docked with the ISS in 2016 for testing. And although now it is used only as a warehouse , Bigelow continues to collect data on how it reacts to temperature changes, radiation and collisions with space debris.

In its work with ESA, SOM chose a cross between a tin can and a balloon. The module under development has approximately a cylindrical shape and a height of 9.5 meters. It has three floors, and a vertical core, allowing residents to move between them. Three inflatable parts in height coincide with the module and add on each floor of the living space. On the lower level there are three doors connecting it with neighboring modules.

SOM has not yet chosen technologies for climate systems, livelihoods, food and recreation areas for staff. However, the common architectural practice of engaging users in the early stages of development should ensure that the home is comfortable for living. Larry Tups, a NASA space architect who oversees space housing contracts, says engineers sometimes need to be reminded of the user experience of their product: for example, waste should not go near the galley.

That's what SOM never had to worry about when developing the Burj Khalifa, it's about urine processing. The first lunar life support system can be “open”, like the one used during the Apollo missions: oxygen, food and water enter the system, and waste is disposed of on site. According to estimates , each person will need from 5 to 15 tons of consumables - mainly air, food and water - per year.

However, it is more likely that the physicochemical system of waste processing will be implemented at the first stage, like the one used at the ISS. The space station collects urine, wastewater and condensate from the sweat of astronauts and breathing, filters all this and turns it into drinking water. Several molecular level sieves (using silica and alumina crystals) are removed from the air by CO 2 , and water is electrolyzed to produce oxygen.

NASA's New Generation Life Support System project is working on new approaches, but “often we don’t try to invent new chemistry,” says Molly Anderson , chief technology officer. Basically, NASA is trying to increase the efficiency of existing systems. The agency also needs to facilitate the equipment, make it more reliable and maintainable. As for new toys, the team is testing compressor prototypes for recharging oxygen cylinders of spacesuits, a pyrolysis system that uses heat to decompose solid waste into useful elements, and portable DNA sequencers to track the presence of microbes on surfaces and in water.

Anderson says it’s easier to organize a life support system on the Moon than on the ISS, at least because gravity allows you to create a normal shower and toilet with a descent.

The next step in the development of lunar life support systems will be the creation of a bioregenerative system in which organisms within the housing will provide staff with food, clean air and water, and decompose waste. As part of the ESA's Alternative Microecological Life Support System ( MELiSSA ) program, an experiment is conducted in which three rats and algae live together for six consecutive months. Rats convert oxygen to CO 2 , and algae - vice versa.

Biology may even help us in construction. Luck grew bricks from mycelium and plant materials, and showed that the fungus experiences both simulated weightlessness and the radiation that it encounters on the moon. Building material locally grown can potentially replace regolith.

We are likely to see a hybrid system in which part of the food will be brought from Earth. Even if scientists can genetically modify all crops to give out all the necessary nutrients, astronauts may still need a variety of foods to maintain a healthy digestive system. People will not want to eat the same thing daily, but it takes a lot of effort to turn plants or algae into food. “We don’t want to send astronauts there as farmers,” says Anderson.

AIAA Sherwood agrees with the need for diversity - especially if space tourists travel to the moon. “You won’t open a hotel until you can mix martini or make an omelet in it,” he says. But we know little about cooking in low gravity conditions.

So that people can live on the moon, SOM plans the presence of a robotic workforce. “Geodesic surveying, regolith movement, construction, resource extraction, and routine maintenance aren’t the best people can do,” says Sherwood. SOM expects robots to build housing, and possibly a product manufacturing module, and build regolith walls before the first residents arrive.

However, one difficulty can prove fatal for both people and machines: dust. For billions of years, micrometeorite bombardment crushed the surface layer of the moon, creating dust consisting of sharp and smooth fragments, in a place where there is neither air nor water that can smooth their edges. About 10-20% of the mass of the upper layer of the regolith of the Moon consists of particles less than 20 microns in size, which is comparable to fine talc.

These particles are electrostatically charged by the solar wind, so they form a weighed mixture and stick to everything, and they are too tiny to be noticed. During the Apollo missions, in just a few hours of walking on the moon, the dust clogged the protectors of the boots, wiped out the spacesuits, scratched the lenses, destroyed the cars, clogged the air filters and irritated the astronauts eyes and noses. If inhaled, it can even cause cancer.

SOM suggests organizing rooms to get rid of dust at the entrances to dwellings, but even if they manage to make the internal rooms absolutely clean, this will not prevent the degradation of external equipment. “We know what regolith consists of, and why it is what it is,” says Sherwood, “but no one has the slightest idea how to design a reliable system in such conditions.”

Getting to the moon is hard, and staying there is even harder. But if engineers and architects can overcome all obstacles, we will have a whole world of new opportunities.

All Articles