The revolution is over. Is there an alternative to a lithium-ion battery?

Recently, we talked about the history of the invention of lithium-ion batteries, which gave a powerful impetus to the development of portable electronics. Every year, technological media inform us of the upcoming energy revolution - just a little bit, another year or two, and the world will see batteries with fantastic characteristics. As time goes on, and the revolution is not visible, in our phones, laptops, quadrocopters, electric vehicles and smart watches, various modifications of lithium-ion batteries are still installed. So where did all the innovative batteries go and is there any Li-Ion alternative at all?

When to wait for the battery revolution?

It’s a pity to upset you, but it has already passed. It just stretched for a couple of decades and therefore remained almost unnoticed. The fact is that the invention of lithium-ion batteries was the culmination of the evolution of chemical batteries.

Chemical current sources are based on a redox reaction between elements. In the periodic table there are only 90 natural elements that can participate in such a reaction. So, lithium turned out to be a metal with extreme characteristics: the lowest mass, the lowest electrode potential (–3.05 V) and the highest current load (3.83 A · h / g).

Lithium is the best cathode active substance on Earth. The use of other elements can improve one characteristic and inevitably worsen another. That is why experiments with lithium batteries have been going on for 30 years now - by combining materials, among which there is always lithium, researchers create types of batteries with the necessary characteristics that find very narrow application. The good old battery with a lithium cobalt oxide cathode, which came to us from the 80s of the last century, can still be considered the most common and universal due to the excellent combination of voltage, current load and energy density.

Therefore, when the next startup through the mouth of the media loudly promises the world an energy revolution from day to day, scientists are modestly silent about the fact that new batteries have some problems and limitations that have yet to be solved. They usually cannot be solved.

The main problem of "revolutionary" batteries

Today, there are many types of batteries with different chemical compositions, including without the use of lithium. Each of the types with its characteristics has found its application in a certain type of technology. Light, thin and high-voltage lithium-cobalt batteries have long been prescribed in compact smartphones. Hardy, powerful, but very large-sized lithium-titanate batteries fit in public transport. And low-capacity fireproof lithium phosphate cells are used as large arrays in power plants.

But still, it is lithium-cobalt batteries for consumer mobile equipment that are most in demand. The main criteria that they meet is a high voltage of 3.6 V while maintaining high energy intensity per unit volume. Unfortunately, many alternative types of lithium batteries have a much lower voltage - lower than 3.0 V and even lower than 2.0 V - from which it is impossible to power a modern smartphone.

The subsidence of any of the characteristics can be compensated by combining the batteries into cells, but then the dimensions grow. So if the next promising battery with miraculous characteristics is unsuitable for use in mobile technology or electric vehicles, its future is almost guaranteed to be predetermined. Why do we need a battery with a life of 100 thousand cycles and fast charging, from which you can only use a wristwatch with hands?

Failed experiments

Not all of the batteries described below can be considered unsuccessful - some require a very long development, some may find their application not in smartphones, but in specialized equipment. Nevertheless, all these developments were positioned as a replacement for lithium-ion batteries in smartphones.

In 2007, the American startup Leyden Energy received $ 4.5 million investment from several venture capital funds to create, as they claimed, a new generation of lithium-ion batteries . The company used a new electrolyte (Solvent-in-Salt) and silicon cathode, which allowed to significantly increase energy intensity and resistance to high temperatures up to 300 ° C. Attempts to make laptop batteries based on the development failed, so Leyden Energy shifted to the electric car market.

Despite the constant infusion of tens of millions of dollars, the company was not able to establish the production of batteries with stable characteristics - the indicators floated from copy to copy. If the company had more time and financing, perhaps in 2012 it would not have to sell equipment, patents and go under the wing of another energy company, A123 Systems.

Lithium metal batteries are not new: they include any non-rechargeable lithium battery. SolidEnergy has set out to create rechargeable lithium metal cells. The new product had double the energy intensity compared to lithium-cobalt batteries. That is, in the previous volume it was possible to fit twice as much energy. Instead of traditional graphite at the cathode, they used lithium-metal foil. Until recently, lithium metal batteries were extremely explosive due to the growth of dendrites (growing on the anode and cathode of woody metal formations), which led to a short circuit, but the addition of sulfur and phosphorus to the electrolyte helped get rid of dendrites (although SolidEnergy does not yet have the technology ) In addition to the very high price, among the known problems of SolidEnergy batteries there is a long charge - 20% of capacity per hour.

Comparison of the sizes of lithium-metal and lithium-ion batteries of equal capacity. Source: SolidEnergy Systems

Comparison of the sizes of lithium-metal and lithium-ion batteries of equal capacity. Source: SolidEnergy Systems

Active work on sulfur-magnesium elements began in the 2010s, when Toyota announced research in this area. The anode in such batteries is magnesium (a good, but not equivalent lithium analogue), the cathode consists of sulfur and graphite, and the electrolyte is an ordinary salt solution of NaCl. The problem with the electrolyte is that it destroys sulfur and makes the battery inoperative, so you had to fill in the electrolyte immediately before use.

Toyota engineers created an electrolyte from non-nucleophilic particles, non-aggressive to sulfur. As it turned out, a stabilized battery is still impossible to use for a long time, since after 50 cycles its capacity drops by half. In 2015, a lithium-ion additive was integrated into the battery, and after another two years, the electrolyte was updated, bringing the battery life to 110 cycles. The only reason that work continues on such a moody battery is a high theoretical energy intensity (1722 Wh / kg). But it may turn out that by the time successful prototypes appear, magnesium-sulfur elements will no longer be needed.

Generation instead of energy storage

Some researchers propose to go from the opposite: do not store, but generate energy directly in the device. Is it possible to turn a smartphone into a small power station? Over the past decade, there have been several attempts to rid the gadgets of the need to recharge via the mains. Judging by how we charge smartphones now, the attempts were unsuccessful - let us recall the most “successful” inventions.

Methanol Direct Decomposition Fuel Cell (DFMC). Attempts to introduce methanol fuel cells into mobile technology began in the mid-2000s. At this time, there was just a transition from long-lived push-button phones to demanding smartphones with a large screen - lithium-ion batteries lasted for a maximum of two days, so the idea of instant recharging seemed very attractive.

In the fuel cell, methanol on the polymer membrane, which acts as an electrolyte, is oxidized to carbon dioxide. The hydrogen proton passes to the cathode, combines with oxygen and forms water. Nuance: an effective reaction requires a temperature of about 120 ° C, but it can be replaced with a platinum catalyst, which naturally affects the cost of the element.

It turned out to be impossible to fit a fuel cell into the phone case: the fuel compartment turned out to be too dimensional. Therefore, by the end of the 2000s, the idea of DFMC took shape in the form of portable batteries (power banks). In 2009, Toshiba launched a serial methanol power bank called Dynario. It weighed 280 g and resembled modern portable batteries at 30,000 mAh in size, that is, it was the size of a palm. The price of Dynario in Japan was an impressive $ 328 and another $ 36 for a set of five vials of 50 ml methanol each. One “refueling” requires 14 ml, its volume was enough for two charges of a push-button telephone via USB with a current of 500 mA.

Toshiba Dynario refueling and operation video

Things didn’t go beyond the release of an experimental batch of 3000 copies, because the fuel power bank turned out to be too controversial: expensive in itself, with expensive consumables and the high cost of one phone charge (about $ 1 for a push-button). In addition, methanol is toxic and in some countries requires a license to sell it and even buy it.

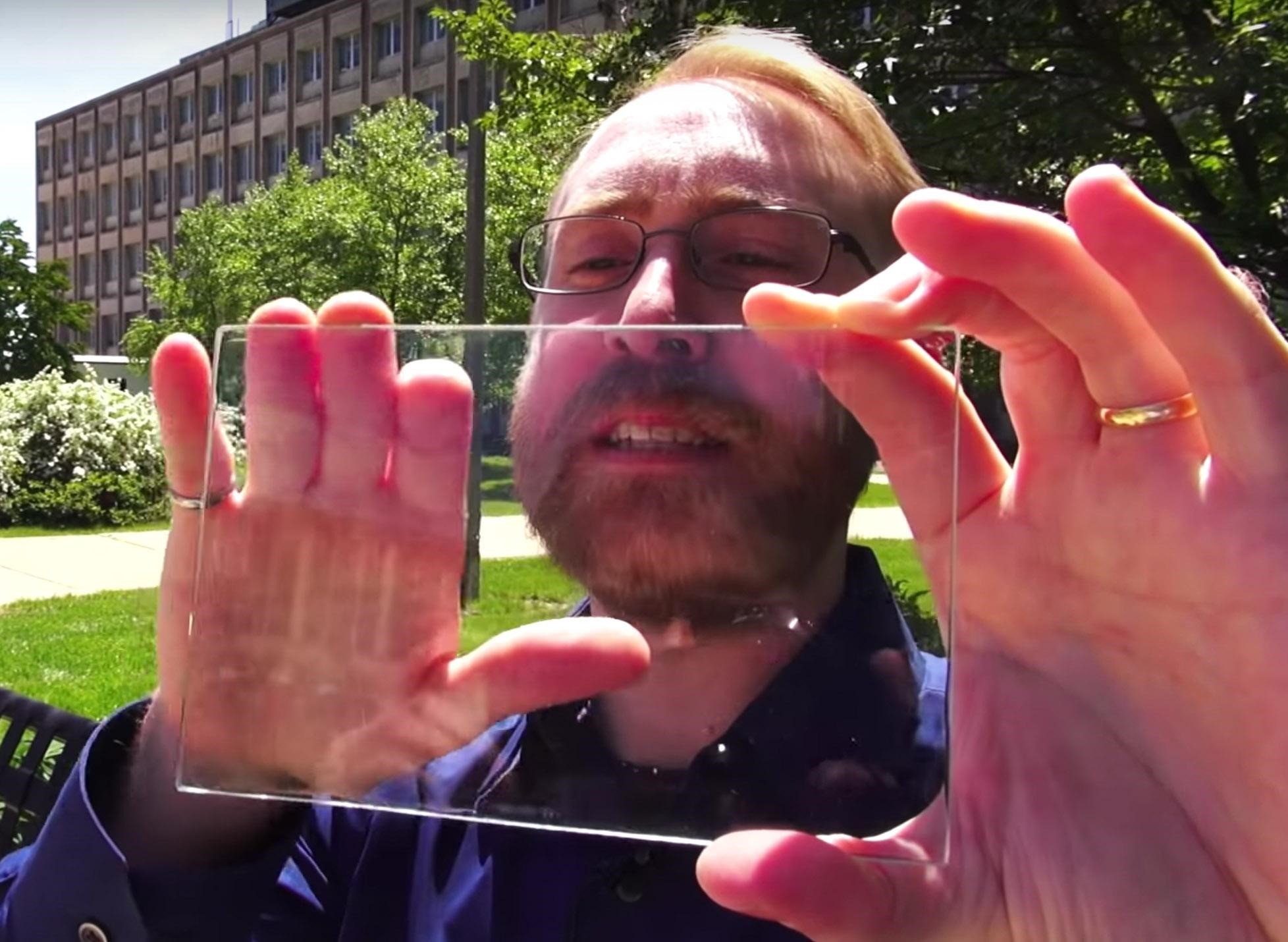

Transparent solar panels. Solar panels are an excellent solution for the extraction of endless (in our century) energy of the Sun. Such panels have low efficiency at high cost and too low power, while they are the easiest way to generate electricity. But the real dream of mankind is transparent solar panels, which could be installed instead of glass in the windows of houses, cars and greenhouses. So to say, combine business with pleasure - electricity generation and natural lighting of space. The good news is that transparent solar panels exist. The bad thing is that they are practically useless.

Developer and University of Michigan showcases a transparent panel without a frame. Source: YouTube / Michigan State University

In order to “catch” the photons of light and turn them into electricity, the solar panel, in principle, cannot be transparent, but the new transparent material can absorb UV and IR radiation, transferring everything to the infrared range and removing it to the edges of the panel. At the edges of the transparent panel, ordinary silicon photovoltaic panels are installed as a frame, which catch the light that is extracted in the infrared range and generate electricity. The system works, only with an efficiency of 1-3% ... The average efficiency of modern solar panels is 20%.

Despite the more than dubious effectiveness of the solution, the well-known watch manufacturer TAG Heuer in 2014 announced the premium tag phone Tag Heuer Meridiist Infinite, in which a transparent solar panel manufactured by Wysis was installed on top of the screen. Even during the announcement of the solution for smartphones, Wysis promised the power of such a solar charge of about 5 mW with 1 cm2 of screen, which is extremely small. For example, this is only 0.4 W for the iPhone X screen. Given that the complete adapter of the Apple smartphone is scolded for indecently low power of 5 W, it is clear that you can not charge it with 0.4 W.

By the way, it didn’t work with methanol, but the hydrogen fuel cells got a ticket to life, becoming the basis of the Toyota Mirai electric car and Toshiba mobile power plants.

And what happened: successful experiments with Li-Ion

Success was achieved by those who did not want to turn the world upside down at all costs, but simply worked on improving individual characteristics of the batteries. Changing the cathode material greatly affects the voltage, energy intensity, and battery life. Next, we will talk about the acclaimed developments, which once again confirm the universality of lithium-ion technology - for each "revolutionary" development there is a more efficient and cheaper existing analogue.

Lithium cobalt (LiCoO2, or LCO). Operating voltage: 3.6 V, energy consumption up to 200 W · h / kg, life time up to 1000 cycles. Graphite anode, lithium cobalt oxide cathode, classic battery described above. This combination is most often used in batteries for mobile equipment, where high energy consumption per unit volume is required.

Lithium Manganese (LiMn2O4, or LMO). Operating voltage: 3.7 V, energy consumption up to 150 W · h / kg, life time up to 700 cycles. The first effective alternative composition was developed even before the start of sales of lithium-ion batteries as such. At the cathode, lithium-manganese spinel was used, which made it possible to reduce internal resistance and significantly increase the output current. Lithium-manganese batteries are used in demanding current equipment, such as power tools.

Lithium-nickel-manganese-cobalt (LiNiMnCoO2, or NMC). Operating voltage: 3.7 V, energy consumption up to 220 W · h / kg, life time up to 2000 cycles. The combination of nickel, manganese and cobalt turned out to be very successful, the batteries increased both the energy intensity and the power of the given current. In the same “banks”, the 18650 capacity rose to 2800 mAh, and the maximum output current was up to 20 A. NMC batteries are installed in most electric vehicles, sometimes diluting them with lithium-manganese cells, since such batteries have a long lifespan.

The new NMC-battery electric car Nissan Leaf according to the manufacturer’s calculations will live 22 years. The previous LMO battery had less capacity and wore out much faster. Source: Nissan

Lithium iron phosphate (LiFePO4, or LFP). Operating voltage: 3.3 V, energy consumption up to 120 W · h / kg, life time up to 2000 cycles. Discovered in 1996, the composition helped to increase amperage and increase the life cycle of lithium-ion batteries up to 2000 charges. Lithium phosphate batteries are safer than their predecessors, better withstand overcharging. That's just their energy intensity is not suitable for mobile equipment - when the voltage is raised to 3.2 V, the energy intensity is reduced by at least half relative to the lithium-cobalt composition. But on the other hand, LFP shows less self-discharge and there is a special endurance to low temperatures.

An array of lithium phosphate cells with a total capacity of 145.6 kWh. Such arrays are used to safely store energy from solar panels. Source: Yo-Co-Man / Wikimedia

Lithium nickel-cobalt-aluminum oxide (LiNiCoAlO2, or NCA). Operating voltage: 3.6 V, power consumption up to 260 W · h / kg, life time up to 500 cycles. Very similar to an NMC battery, it has excellent power consumption, suitable for most equipment with a nominal voltage of 3.6 V, but its high cost and modest life (about 500 charge cycles) do not allow NCA batteries to defeat competitors. So far, they are used only in some electric vehicles.

Showdown of the Holy of Holies - Tesla Model S electric battery cell NCA

Lithium titanate (Li4Ti5O12, or SCiB / LTO). Operating voltage: 2.4 V, energy consumption up to 80 W · h / kg, life time up to 7000 cycles (SCiB: up to 15 000 cycles). One of the most interesting types of lithium-ion batteries in which the anode consists of lithium titanate nanocrystals. The crystals helped to increase the surface area of the anode from 3 m2 / g in graphite to 100 m2 / g, that is, more than 30 times! A lithium-titanate battery charges up to full capacity five times faster and delivers ten times higher current than other batteries. However, lithium-titanate batteries have their own nuances that limit the scope of the batteries. Namely, low voltage (2.4 V) and energy consumption are 2-3 times lower than other lithium-ion batteries. This means that in order to achieve a similar capacity, the lithium-titanate battery must be increased several times, which is why you can’t insert it into the same smartphone.

Toshiba SCiB module with a capacity of 45 Ah, rated voltage of 27.6 V and discharge current of 160 A (pulse up to 350 A). It weighs 15 kg and the size of a shoe box: 19x36x12 cm. Source: Toshiba

But lithium-titanate batteries immediately entered the transport, where fast charging, high currents during acceleration and resistance to cold are important. For example, electric cars Honda Fit-EV, Mitsubishi i-MiEV and in Moscow electric buses! At the start of the project, Moscow buses used a different type of battery, which caused problems even in the middle of the first passage along the route, but after installing Toshiba lithium-titanate batteries, there were no more messages about discharged electric buses. Toshiba SCiB-batteries, thanks to the use of titanium-niobium in the anode, restore up to 90% of capacity in just 5 minutes - the allowable time for the bus to stop at the final stop, where there is a charging station. The number of charging cycles that an SCiB battery can withstand exceeds 15,000.

Toshiba lithium titanate battery leak test. Will it catch fire or not?

Energy singularity

For more than half a century, humanity has been dreaming of putting atomic energy into batteries, which would provide electricity for many years. In fact, back in 1953, a betavoltaic element was invented, in which, as a result of beta decay of a radioactive isotope, electrons converted the semiconductor atoms into ions, creating an electric current. Such batteries are used, for example, in pacemakers.

What about smartphones? Nothing so far, the power of atomic elements is negligible, it is measured in milliwatts and even microwatts. You can buy such a battery even in an online store, however, even the notorious wristwatch will not work from it.

How long to wait for atomic batteries? Please, City Labs P200 - 2.4 V, 20 years of service, however, the power is up to 0.0001 W and the price is about $ 8000. Source: City Labs

More than 10 years have passed since the invention of stable lithium-ion batteries to the start of their mass production. Perhaps one of the latest news about a breakthrough power source will become prophetic, and by the 2030s we will say goodbye to lithium and the need for daily charging of phones. But for now, it is lithium-ion batteries that determine progress in the field of wearable electronics and electric vehicles.

All Articles