Development of the electronic control unit of the washing machine "Oriole"

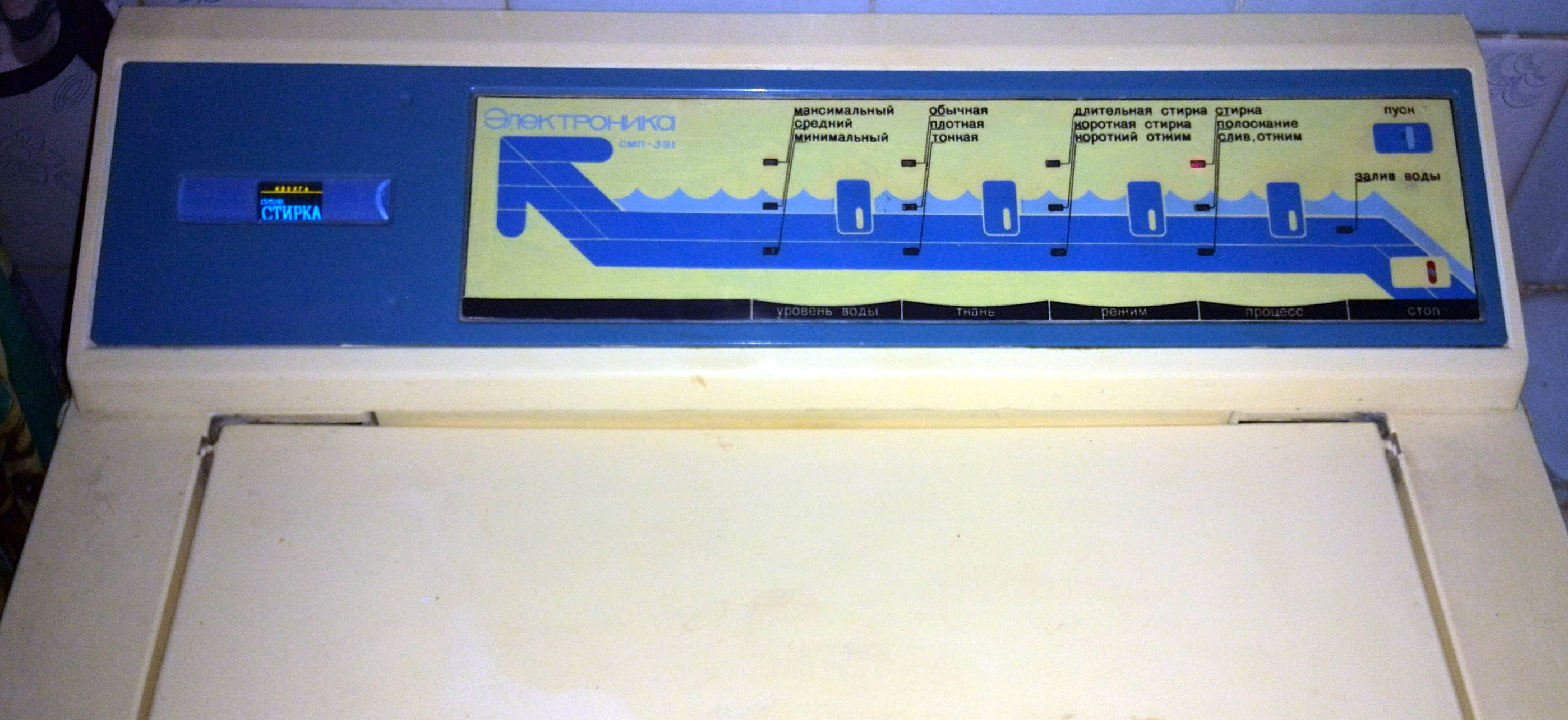

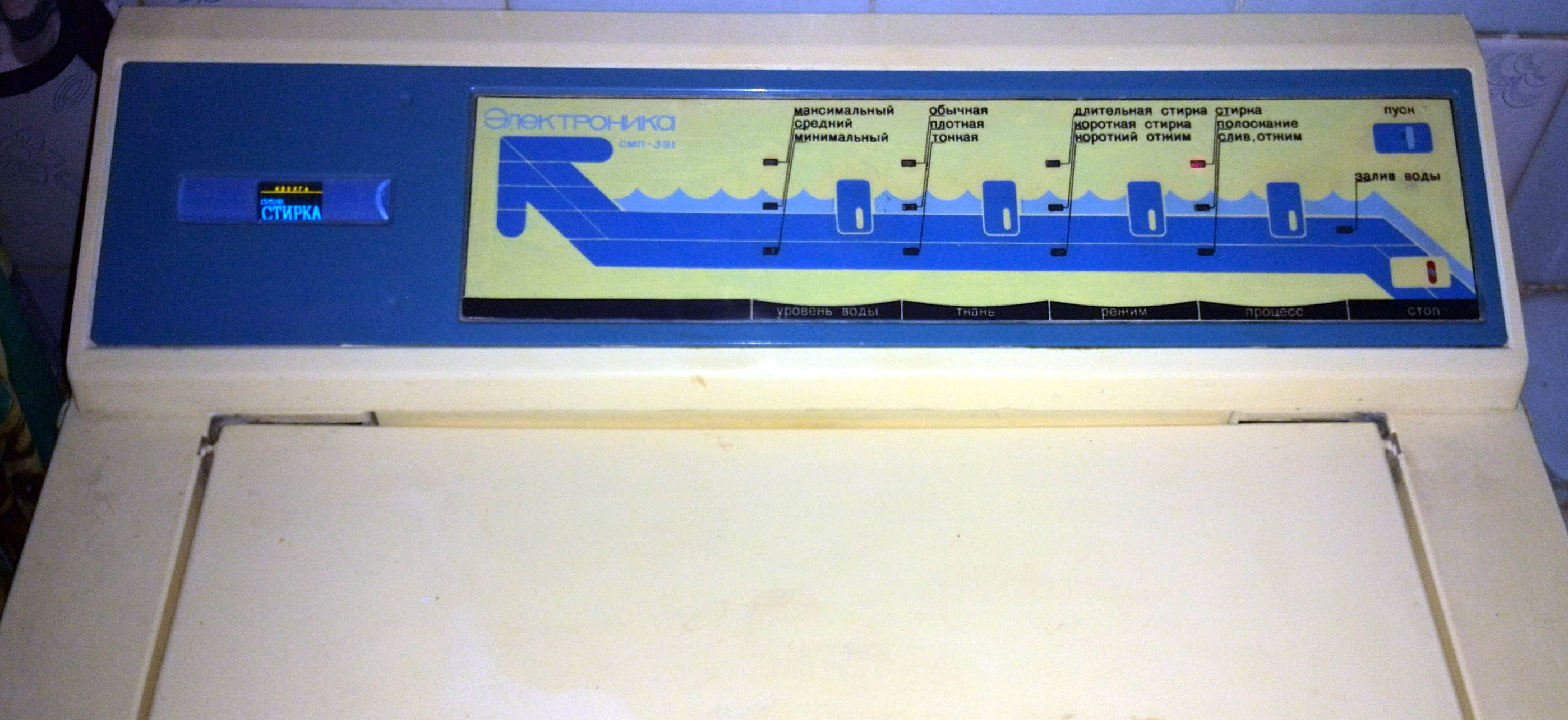

Washing machine "Oriole" SMP-3E.1 produced by PO "Barricades"

Fig.1. The appearance of the washing machine

For all the time of operation (about 30 years), the washing machine has shown itself from the good side. Weak points are the pump, water level sensor and electronic control unit. In the native control unit the logic chip failed. Replaced the chip, but soon flew K556RT1. I had to change the entire electronics board to a new one. In this board, too, after several years, the RT shone out. The idea of developing your board was in the head for a long time, but somehow there were more priority tasks. I wanted something simple, with a minimum nomenclature and its own. And yet, this day has come.

Details below.

Of course, you could buy another modern washing machine and not complicate your life, but it was interesting for me to make my own module. Well, if you make your own control unit, then you certainly need to bring something more interesting than a copy of the original unit by function.

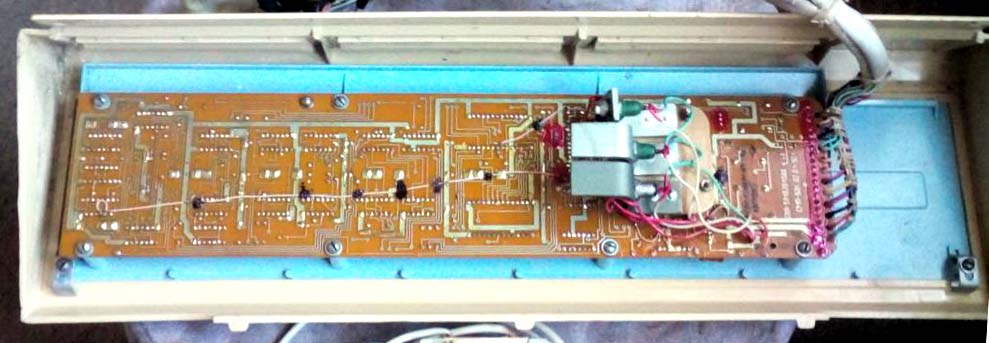

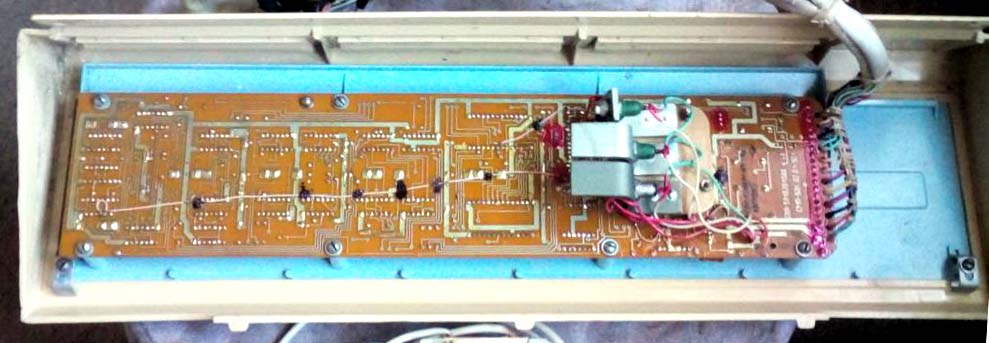

Fig.2. Original electronic control board

Of the original functions of the washing machine were left only modes: "wash", "rinse", "spin". Setting the type of fabric, water level and washing modes were excluded, since they are almost never used. The default settings are for medium water level, regular fabric, and regular wash.

As I wrote earlier, problems arose with a water level sensor. Structurally, it is made in the form of foam toroidal floats with magnets, sliding along a vertical rod, in which the reed switches are located. Contamination of the sensor elements interfered with its proper operation, and the original electronics did not include wash or rinse cycles. It was also not possible to assess the correct operation of the water level sensor.

In the described control unit, the level sensor is used mainly for clarity. If there is a "sticking" of floats inside the sensor, the level will blink on the display. You can now turn on the washing with any amount of water by pressing the “Start” button again. And it does not matter if the level sensor is working or not. Reed switch emergency water level is usually serviceable, because is always in a dry form and there are no various deposits on it. When the emergency water level is reached, the pump automatically starts, pumping water to a level below the emergency one.

All cyclograms of the washing machine were exactly repeated.

An OLED display has been added to the design, which displays the main parameters. Thermal sensors were also added to the activator / centrifuge motor, to the pump and to the radiistor of the triacs. Thus, it is possible to control the current temperature of these elements and, in case of overheating, turn off the power section.

On the control panel there was a window with the logo "Oriole". It was decided to mount a display in this window. Glass with a lens was used from the case of a medical thermometer very well suitable in size.

Fig.3. Window for OLED-display

Fig.4. Installation of temperature sensors

Fig.5. Appearance of the modified control panel

Also added Wi-Fi module ESP-12e. When the electronics are turned on, they connect to the home access point and request the current time from the NTP server. Starts the web server. You can control the operating modes of the washing machine and see the current status and modes via the Internet from the web page of the machine.

Fig.6. Schematic diagram of the control unit

The brain is the PIC controller. The power part is galvanically isolated by means of optocouplers. Applied pulse power supply. On the ESP-12E Wi-Fi module, a web server is launched that dynamically forms a page in accordance with the operation mode of the washing machine. To reduce the number of ports using analog inputs.

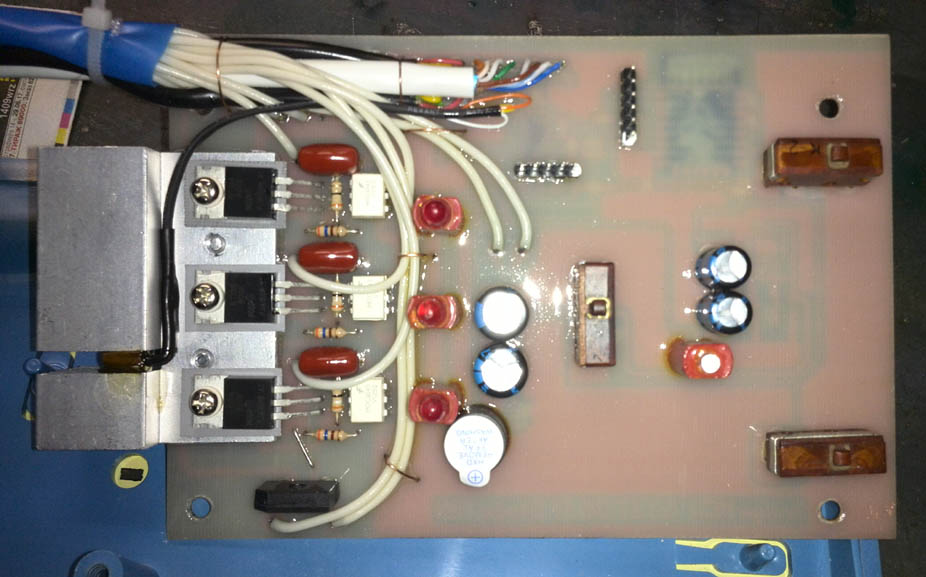

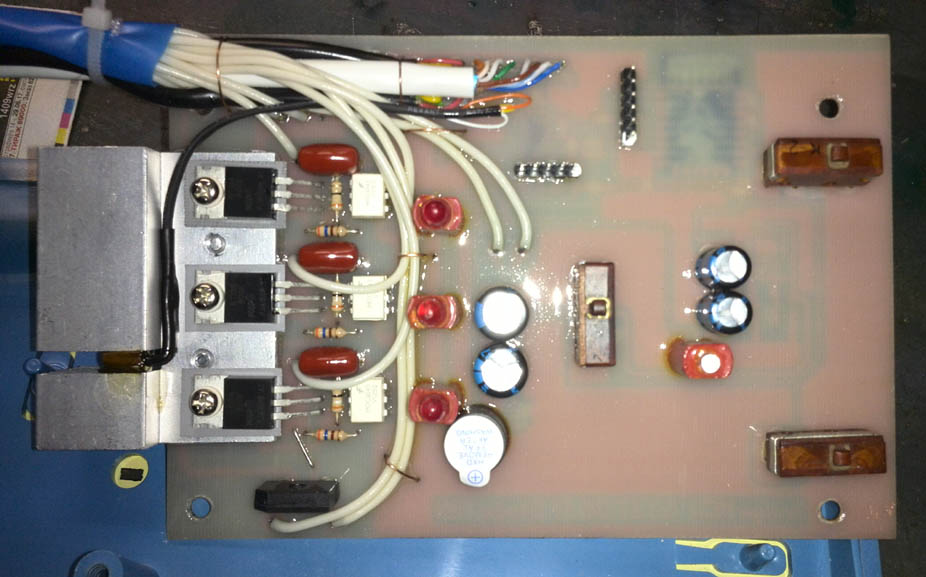

Fig.7. Board of the control unit (View from the installation of elements)

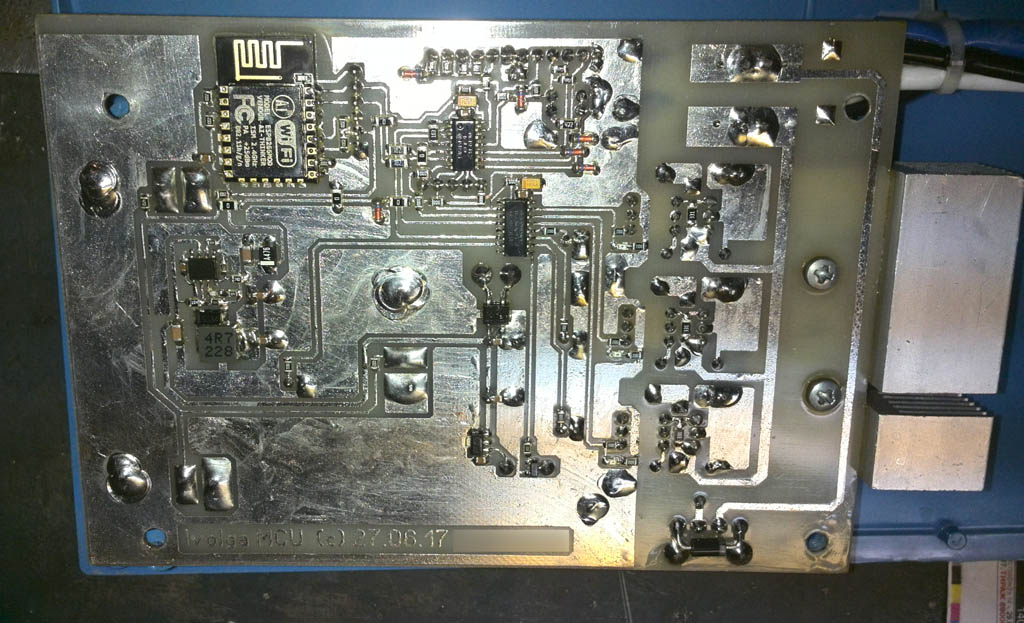

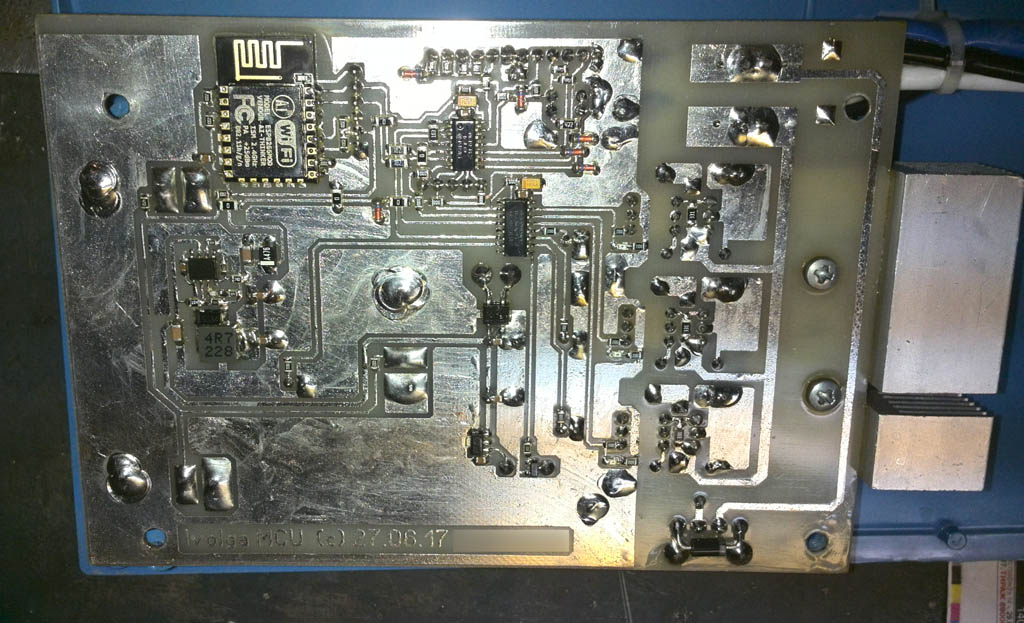

Fig.8. Control unit board (View from installation)

Fig.9. Mounting the control unit board

Software

When the power is turned on, the display shows the Oriole logo, a connection to the access point and a request for the current time from the NTP server. When you press the operation mode selection button, the corresponding LED on the panel turns on (as on the original electronics) and the display shows the name of the mode. The display also shows the remaining washing / rinsing / spinning time, engine, pump, electronics temperature. In the event of an abnormal situation, a message is displayed on the screen about overheating or exceeding the permissible vibration of the centrifuge.

From a smartphone or computer via the web interface, you can also turn on the desired mode of the washing machine or directly control the engine and pump for troubleshooting.

Video demonstration of the controller:

Fig.1. The appearance of the washing machine

For all the time of operation (about 30 years), the washing machine has shown itself from the good side. Weak points are the pump, water level sensor and electronic control unit. In the native control unit the logic chip failed. Replaced the chip, but soon flew K556RT1. I had to change the entire electronics board to a new one. In this board, too, after several years, the RT shone out. The idea of developing your board was in the head for a long time, but somehow there were more priority tasks. I wanted something simple, with a minimum nomenclature and its own. And yet, this day has come.

Details below.

Of course, you could buy another modern washing machine and not complicate your life, but it was interesting for me to make my own module. Well, if you make your own control unit, then you certainly need to bring something more interesting than a copy of the original unit by function.

Fig.2. Original electronic control board

Of the original functions of the washing machine were left only modes: "wash", "rinse", "spin". Setting the type of fabric, water level and washing modes were excluded, since they are almost never used. The default settings are for medium water level, regular fabric, and regular wash.

As I wrote earlier, problems arose with a water level sensor. Structurally, it is made in the form of foam toroidal floats with magnets, sliding along a vertical rod, in which the reed switches are located. Contamination of the sensor elements interfered with its proper operation, and the original electronics did not include wash or rinse cycles. It was also not possible to assess the correct operation of the water level sensor.

In the described control unit, the level sensor is used mainly for clarity. If there is a "sticking" of floats inside the sensor, the level will blink on the display. You can now turn on the washing with any amount of water by pressing the “Start” button again. And it does not matter if the level sensor is working or not. Reed switch emergency water level is usually serviceable, because is always in a dry form and there are no various deposits on it. When the emergency water level is reached, the pump automatically starts, pumping water to a level below the emergency one.

All cyclograms of the washing machine were exactly repeated.

An OLED display has been added to the design, which displays the main parameters. Thermal sensors were also added to the activator / centrifuge motor, to the pump and to the radiistor of the triacs. Thus, it is possible to control the current temperature of these elements and, in case of overheating, turn off the power section.

On the control panel there was a window with the logo "Oriole". It was decided to mount a display in this window. Glass with a lens was used from the case of a medical thermometer very well suitable in size.

Fig.3. Window for OLED-display

Fig.4. Installation of temperature sensors

Fig.5. Appearance of the modified control panel

Also added Wi-Fi module ESP-12e. When the electronics are turned on, they connect to the home access point and request the current time from the NTP server. Starts the web server. You can control the operating modes of the washing machine and see the current status and modes via the Internet from the web page of the machine.

Fig.6. Schematic diagram of the control unit

The brain is the PIC controller. The power part is galvanically isolated by means of optocouplers. Applied pulse power supply. On the ESP-12E Wi-Fi module, a web server is launched that dynamically forms a page in accordance with the operation mode of the washing machine. To reduce the number of ports using analog inputs.

Fig.7. Board of the control unit (View from the installation of elements)

Fig.8. Control unit board (View from installation)

Fig.9. Mounting the control unit board

Software

When the power is turned on, the display shows the Oriole logo, a connection to the access point and a request for the current time from the NTP server. When you press the operation mode selection button, the corresponding LED on the panel turns on (as on the original electronics) and the display shows the name of the mode. The display also shows the remaining washing / rinsing / spinning time, engine, pump, electronics temperature. In the event of an abnormal situation, a message is displayed on the screen about overheating or exceeding the permissible vibration of the centrifuge.

From a smartphone or computer via the web interface, you can also turn on the desired mode of the washing machine or directly control the engine and pump for troubleshooting.

Video demonstration of the controller:

All Articles