Guide to electrical materials for all. Part 12. Final

The last part of the manual. Inside the bonus chapters, some new photos, and most importantly - pdf with the manual that can be downloaded and shared with a friend.

Improvements (available in pdf version):

- Added photos of the destruction of optical polycarbonate, added photos of quartz glass, photos of conductive carbon compositions in the design of the remote control.

- The section with electrical tape was improved, we had to wait for the parcels, but it was worth it - now this is the most complete description of the insulation tapes (polyester, mastic, fabric and other types of tapes are added).

- Added a chapter on electrical connections - with the answer to the question why it is impossible.

- Well, a lot of minor edits according to the comments.

I changed the name, just for reasons of "easy to remember, easy to google."

Electrical connections

A popular joke says that electrical engineering is the science of contacts. And two main faults - there is no contact where it should be, and there is a contact where it should not be.

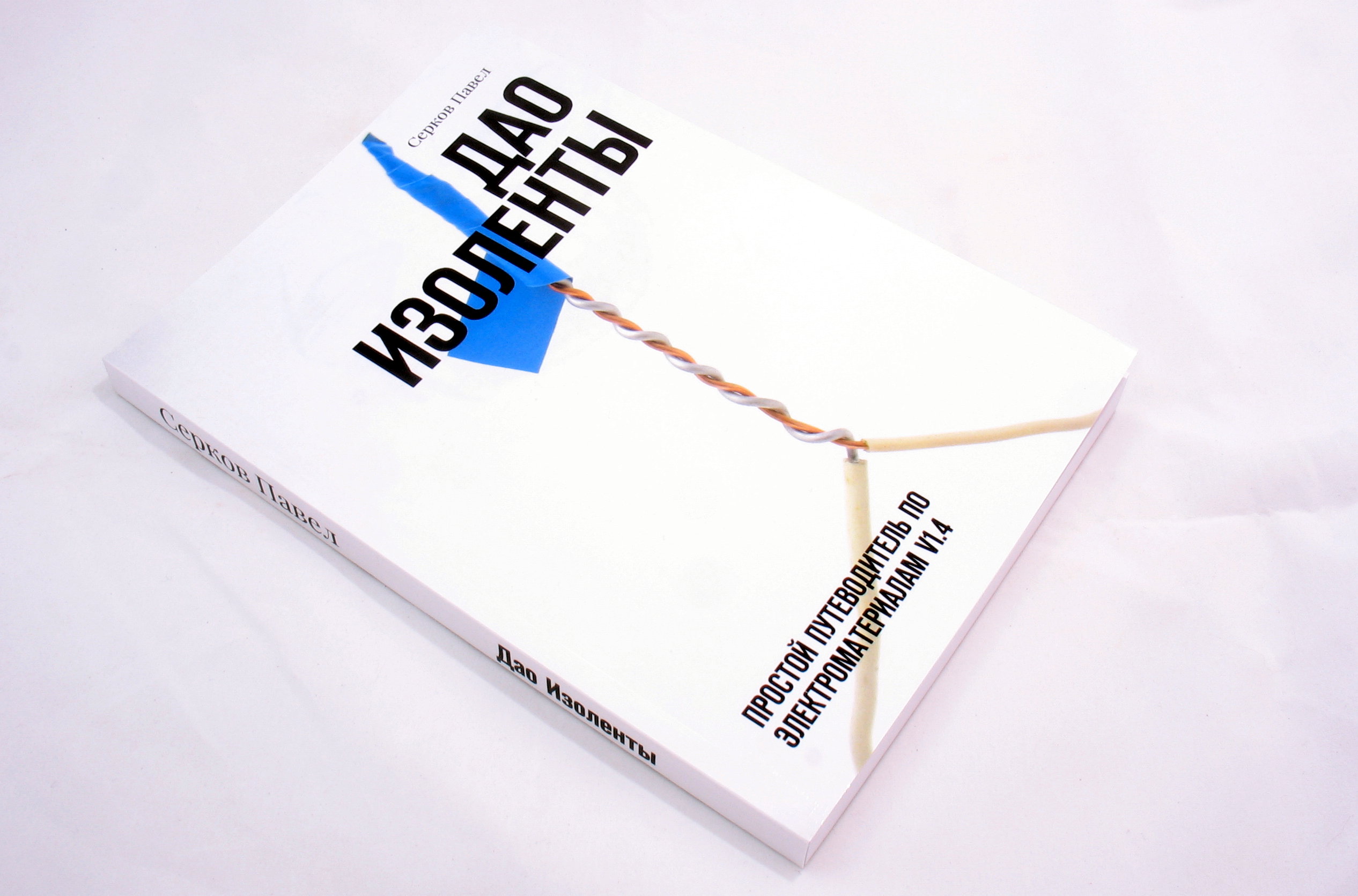

The cover of this manual shows the twist of two wires - copper and aluminum. Some readers were outraged by such a spectacle, and not without reason - it is impossible to do so. If you try to understand the reasons for this “no”, then you can find a lot of discussions on this topic, practically in each of which you can find the argument “I always did this, in the country such a twist has been working for 100,500 years”. Unfortunately, an understanding of the reasons for the ban does not bring such an approach.

What is the problem to connect two arbitrary metals into contact? The fact is that for some reasons (which are discussed below), some metals form a reliable contact and work almost smoothly, and some form a contact that also works, but is less reliable and causes problems more often. It should be understood that “more often” does not mean that if you made such a connection, it will refuse tomorrow with a probability of 100%. No, the probability of failure will not be 0.0001%, but for example 0.01%. All the same small, but you would not be satisfied with 100 times the probability of a fire?

The operating experience of various technicians has led engineers to conclude that certain combinations of metals provide acceptable contact reliability, and some too low. Once again, it is worth noting that the reliability of the contact is strongly influenced by the operating conditions; if the compound is at a constant temperature in a dry place, then it can be quite reliable, even if a pair of metals is undesirable.

The range of electrochemical activity of metals

The first reason for the breakdown of the contact that we consider - electrochemical corrosion. Some of you remember from school a number of metal activities (incomplete):

Li K Ba Sr Ca Na Mg Al MnCr Zn Fe Cd Co Ni Sn Pb H Sb Bi Cu Hg Ag Pd Pt Au

| Metal | Electrochemical potential, Volt |

|---|---|

| Lithium (Li) | -3.0401 |

| Potassium (K) | -2,931 |

| Barium (Ba) | -2,905 |

| Strontium (Sr) | -2,899 |

| Calcium (Ca) | -2,868 |

| Sodium (Na) | -2.71 |

| Magnesium (Mg) | -2,372 |

| Aluminum (Al) | -1,700 |

| Manganese (Mn) | -1,185 |

| Chrome (Cr) | -0,852 |

| Zinc (Zn) | -0.763 |

| Iron (Fe) | -0,441 |

| Cadmium (Cd) | -0,404 |

| Cobalt (Co) | -0,28 |

| Nickel (Ni) | -0,234 |

| Tin (Sn) | -0,141 |

| Lead (Pb) | -0,126 |

| Hydrogen (H) | 0 |

| Antimony (Sb) | +0,240 |

| Bismuth (Bi) | +0.317 |

| Copper (Cu) | +0.338 |

| Mercury (Hg) | +0.7973 |

| Silver (Ag) | +0.799 |

| Palladium (Pd) | +0.98 |

| Platinum (Pt) | +0.963 |

| Gold (Au) | +1,691 |

For an engineer, this series says the following: In the presence of an electrolyte (water, air humidity), in the metal pair, the metal that is in the tension row is to the left . The farther from each other the metals in the row, the more intense the corrosion will be. On the base

This phenomenon is built electrochemical protection of metals, such as galvanized steel. In the presence of water, the zinc coating first of all collapses, and only after it collapses does the corrosion of steel begin.

In the case of electrical contacts, what is more important to us is not what metal is destroyed in a pair, they need both, but how intensively the corrosion process will proceed. And in this regard, the potential created by a pair of aluminum-copper 2.038 V is very large, it is enough to break the water molecule in the electrolysis process! But if we divide these two metals with a steel galvanized plate, then two pairs are formed: zinc-aluminum with a potential of 0.937 V, and zinc-copper, with a potential of 1.101 V. These are not so large potentials, therefore the corrosion process will be slower.

Taking into account that copper and aluminum are the main metals for the manufacture of conductors, it is not necessary to learn the table and consider the potentials, it is important to remember that it is impossible to directly connect copper and aluminum to electrical contact.

The most inventive readers will ask the question: “And if the compound of copper and aluminum is coated with a layer impermeable to water (varnish, sealant, paint, grease, etc.), then

there will be no water at the point of contact, which means there will be no electrolysis and corrosion? ” This is a true observation, and allows you to solve the problem of electrochemical corrosion, but there is another problem that does not allow to connect any two metals just like that.

Thermal expansion

All bodies expand when heated, and metals are no exception. For any material there is a characteristic, such as the "coefficient of thermal expansion of bodies", which shows how many times the body size will increase, when heated by 1 degree Celsius. (In different temperature ranges, the value of the thermal expansion coefficient may differ, besides, for some anisotropic materials, the coefficient may differ in different planes. For simplicity, we will not take into account this difference using average values) Here is a small label:

| Material | Thermal coefficient of expansion α, (1 / K) |

|---|---|

| Aluminum | 23.1 cdot10−6 |

| Copper | 17 cdot10−6 |

| Steel | 10.8 cdot10−6 |

| Glass | 8.5 cdot10−6 |

| Heat-resistant glass (borosilicate) | 3.3 cdot10−6 |

| Quartz glass | 0.59 cdot10−6 |

| Invar (alloy) | 1,2 cdot10−6 |

| Platinum | 9 cdot10−6 |

From this plate it can be seen that the compound of the two materials will expand differently when heated, causing internal stresses and strains. Sometimes this is a useful property - it is used in bimetallic plates in thermostats, such plates bend and break contact when heated. But in creating a reliable electrical connection, this difference in thermal expansion can weaken the contact. If the compound does not have elastic properties, then after several cycles of heating and cooling, you can find that instead of tight tight contact, the conductor is loose.

If compounds of different materials cannot be avoided, then it must be remembered that such a connection could potentially weaken with temperature changes, and should be maintained and controlled. To seal the connection of copper and aluminum conductor in the wall under the layer of plaster is a bad idea.

Creep

Some materials tend to show the phenomenon of "creep", when, for example, a conductor under a small mechanical load that is not sufficient for plastic deformation, however, deforms with time. The magnitude of this phenomenon depends on the load and the temperature, characterized by a very small value. Thousands of hours will pass before body size changes to fractions of a percent. Nevertheless, this phenomenon is quite important in ensuring reliable contact. Creep, along with thermal expansion, contributes to the fact that the tightened terminal weakens over the years and the wire is loose in it.

Unfortunately, aluminum (pure) has a much more intensive creep than copper, which makes its electrical contacts less reliable and require regular maintenance. It is worth remembering in the repair and maintenance of wiring from aluminum cable since the USSR. Manufacturers of modern aluminum cables alloy aluminum in a conductive core, seeking to reduce creep to values comparable to copper, albeit at the price of a small decrease in electrical conductivity.

So how do you connect the wires?

The question is complicated because the answer depends on the operating conditions of the connection and there is definitely no universal way.

But so much bad was said about the aluminum-copper pair that I simply have to answer the question “how to connect them?”.

The first option is a classic one, with the help of a steel plate excluding the direct contact of copper and aluminum. The steel plate will prevent intensive electrochemical corrosion (but will not get rid of it at all), will provide an acceptable force on the contact area of the conductors. But such a connection requires routine maintenance: 1–2 times a year it is necessary to check the tightening force of the conductors.

The second option. Specialized spring terminals for aluminum conductor. (for example WAGO 2273 terminal blocks with paste). In such a terminal, the bare conductor is pressed all the time by a spring contact, preventing its weakening due to creep.

The paste inside the terminal block prevents moisture and air from entering the aluminum surface, preventing conductor oxidation. (It is important to note that the terminals should be of high quality, and the conductor cross section should be nominal. I personally observed the burned connections made by the terminals purchased at the nearest kiosk (probably counterfeit ones).)

The third option - Copper-aluminum sleeves. This type of connection is relevant for high-current lines of force with a cross section of 10 square meters. mm Copper-aluminum sleeves are designed for crimping with a special tool. Metals connected in thickness provide reliable contact of a large area; moisture and electrochemical corrosion can only damage the delicate surface of the liner without breaking the contact in the thickness.

And remember, any power electrical connection (especially from different metals) should be available for maintenance! A twisted wall buried in the wall is a guarantee that the repair team will remember you in various obscene terms.

Conclusion

Since the installation in writing this manual was at least bullshit, I wrote that I myself felt, used, with what I worked. I did not reveal some of the topics, due to the small experience (or the small amount of material collected) in these areas, but they would be worth revealing. I haven't thoughtlessly rewritten what is described in the specialized literature, why distort the source? Therefore, if you can tell something on the topic - I will be happy to include your text in the manual.

This manual is free to download, you can download the latest version.

This blog is completely free. If you like my work, I will be glad to hear from you suggestions and suggestions, as well as comments and indications of mistakes made.

Where can I download?

→ GitHub tutorial along with source text and photos. There's a pdf with a book.

→ Homepage guide on my site.

If you want a paper copy to your shelf, you can purchase it (on-demand printing technology). This is not an advertisement - I put out a manual on cost price - I won’t earn a single penny. Unfortunately in paper form illustrations will be black and white.

Thanks

I express my gratitude to Alexei Gall Galakhov for valuable additions to the manual and assistance in the layout of the manual.

Talion_amur for providing a sample of a mercury hour meter.

I also want to thank the users Firz , GavrisAS , 4sadas4 , Leon010203 , rexen , juray , Osnovjansky , NickyX3 , impetus , ploop , BarsMyster , OldGrumbler , YRevich , Nubus , jar_ohty , dlinyj , ioccy , imathychurs , dublinj , imachrist , Nubus , jar_ohty , dlinyj , ioccy , imathychris , Nubus , jar_ohty Serge78rus , Otard , Ocelot , Goruhin for valuable comments that caused the edits of the manual.

Thanks to everyone who wrote the comments, they gave valuable feedback.

Taking this opportunity, I want to say hello to Meklon DIHALT Milfgard lozga superhimik tnenergy BarsMonster - I enjoy reading your posts and tried to keep the bar no lower.

Links to parts of the manual:

1 : Conductors: Silver, Copper, Aluminum.

2 : Conductors: Iron, Gold, Nickel, Tungsten, Mercury.

3 : Conductors: Carbon, nichrome, thermostable alloys, solders, transparent conductors.

4 : Inorganic dielectrics: Porcelain, glass, mica, ceramics, asbestos, gas and water.

5 : Organic semi-synthetic dielectrics: Paper, click, paraffin, oil and wood.

6 : Synthetic dielectrics based on phenol-formaldehyde resins: carbolite (bakelite), getinax, textolite.

7 : Dielectrics: Glass fiber (FR-4), varnished cloth, rubber and ebonite.

8 : Plastics: polyethylene, polypropylene and polystyrene.

9 : Plastics: polytetrafluoroethylene, polyvinyl chloride, polyethylene terephthalate and silicones.

10 : Plastics: polyamides, polyimides, polymethyl methacrylate and polycarbonate. History of the use of plastics.

11 : Insulating tapes and tubes.

All Articles