How for a couple of minutes to independently calculate the price of the device

Greetings, Habr! There are so many questions that cannot be answered unambiguously, but the answer is needed. For example, they ask me every day how much the case costs for such a device . With all the obviousness of the question immediately say it does not work. Need to count.

As the answer I offer this article. After reading it, you will be able to figure out for yourself a couple of minutes how much the case for your product will cost and what technology to choose so that its price will be profitable for your business. Of course, the numbers are very conditional and come from the cumulative experience of the years that we in the Formlab are engaged in buildings.

I could send you directly to the numbers in the table below, but you will surely be mistaken if you do not take into account the following information.

Crucial is the current stage of your project. Choose the appropriate stage from the list below so that we can go further:

1. We made the first board, wrote software, we need a case for assembling a prototype.

2. The electronics are ready, everything is tested, you need 10 cases to sell to the first customers (or give them to the test in real conditions).

3. The tests are completed, you need 100 cases for the first test batch.

4. The first batch sold successfully, you need 1000 cases.

5. Sales are coming, you need 5,000 packages next year.

- They chose at what stage they stopped?

Now, when you know at what stage the project, I will paint with examples, where you need as much money and time.

Imagine that you and I come to the factory and ask us to make 10 buildings. We give documentation, an example and everything that is needed. And the plant says, there are no problems, come in a couple of days, each building will cost 500 rubles.

Doubt, they say, a little expensive and go to pay to the cashier. But in general, we are satisfied, only 5000 were given away. By the end of the week we will be ready and send out to the clients on Monday.

Or another situation - we find a large, serious factory, we come and ... make us 100 buildings. And the manager from there embraces him by the shoulders and leads him through the snow-white workshops, where the robots stand in the line and synchronously do something necessary! Then we are told - come in a week, you will get everything. We go to the cashier and wait. It should be like that, but ...

... in the real world, the plant will not even respond to our email.

The reasons can be argued for a long time. There is no middle layer of production in the country, everything is awry, etc. - An article on how to do everything to do everything and not

What is the main problem for us as a small customer? We choose the wrong honey (technology) for our task. And that means wrong production. And this means that we are building our business processes in this part of the project incorrectly.

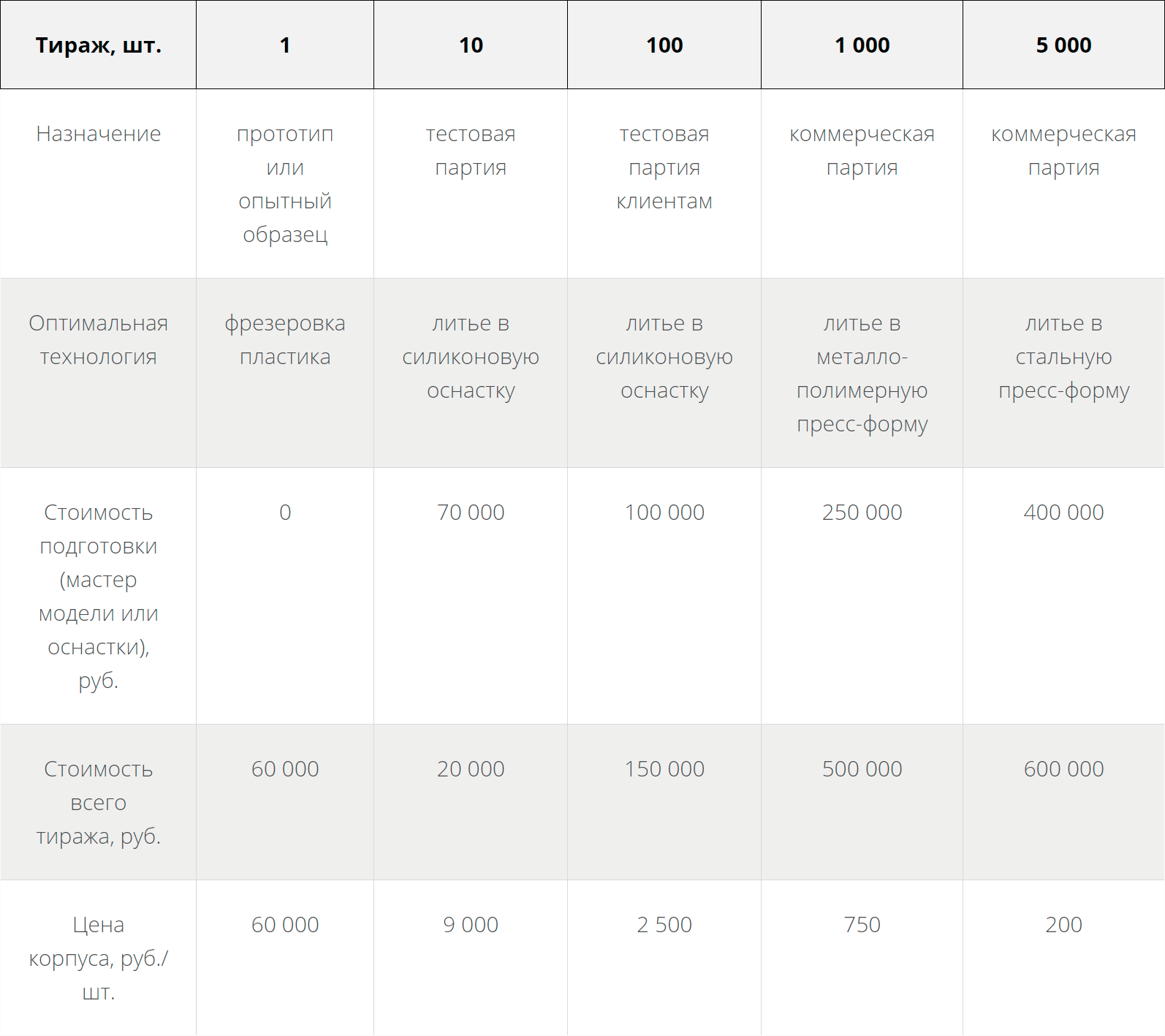

In the plate below is the calculation of a simple plastic case. On it you can navigate, under which circulation which technology is more suitable for us, and what costs must be taken into account at the start:

Of course, the numbers are conditional. But their order completely allows us to draw the following conclusions:

1. You need to choose a contractor specifically for your circulation

But with an eye to what the next stage awaits us. For example, we expect that next year we just need 1000 pieces of cases - then we must immediately go to the company for which such circulation is normal and acceptable. Such a plant is likely to be able to make a smaller stage (100 buildings) cheaper.

2. You can not expect that we can order a little bit

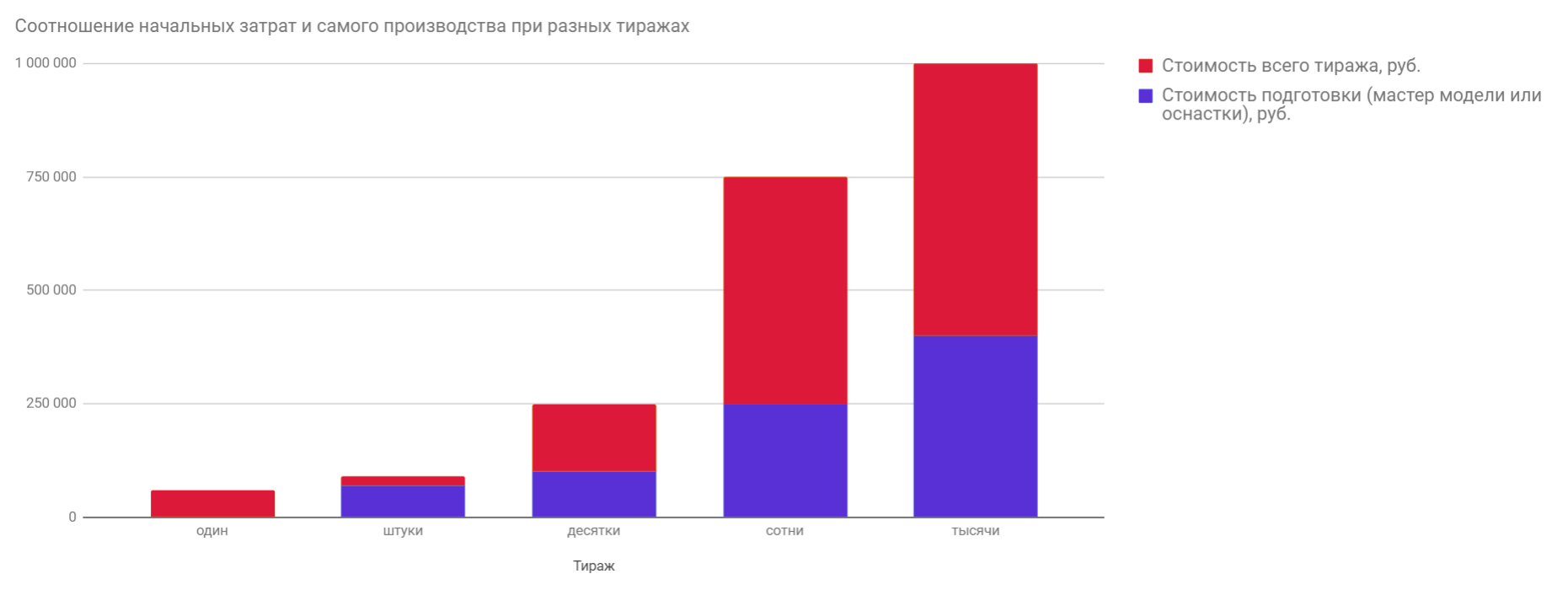

We must immediately look at the circulation, which will be tomorrow, and plan the costs for it in advance. Nobody will stop the conveyor under our small, but rather UNTIMIFIC task for the plant. A small order will fulfill the production, there are no problems, but they have to do it every day. We, unfortunately, forget it all the time or do not take it into account. For clarity, I cite a schedule where you can see the ratio of starting costs to the cost of the production itself, as well as the amount of funds required for each level (order) of circulation:

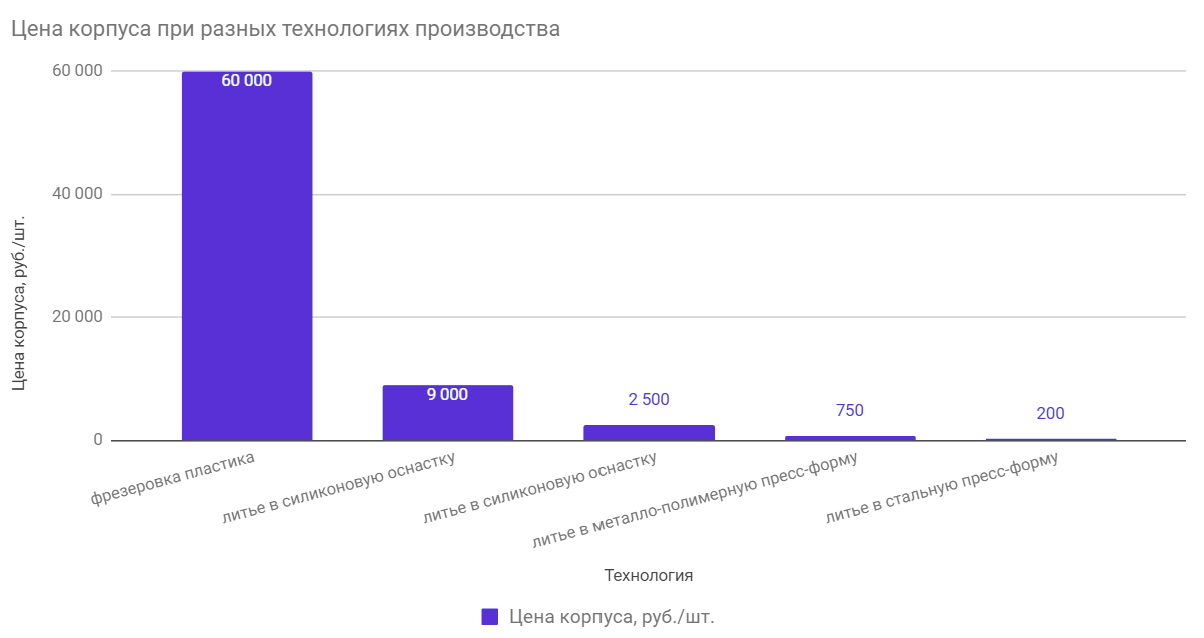

3. The less circulation - the more expensive the body

The very first prototype is very expensive, but it is not for sale. Therefore, it is necessary to look at the price of the hull from the bell tower of the task for which this batch is intended. Conventionally, if you need cases for assembly and sale, then it makes no sense to look at the units and dozens of buildings. The cost price will kill the margin or make the device noncompetitive for money. Here is a graph where you can see the cost of the case in different technologies:

4. If there is no money at all to launch your production, you need to look for a typical case, which you can simply buy from the warehouse

This is a question of several hundred rubles apiece, but you need to be ready to change your electronics for such a case. And of course, a typical case is difficult to fight with competitors. We'll have to invent something.

Examples

The text would be incomplete without specific examples, what for. All cases are atypical, with their own design, i.e. developed for a specific task and circulation:

200 rubles (plastic injection molding, batch from 5000 pieces)

3000 rubles (cast in metal-polymer equipment, a batch of 1000 pieces)

5000 (polyurethane casting with embedded elements, batch from 3 pieces)

25 000 rubles (polyurethane casting, batch from 50 pieces)

Following the method described above, you can easily, without going into details, you can evaluate:

- the price of the future corps;

- The volume of costs for a new building in general

And most importantly, you can understand how justified for you is the development and production of your body in principle.

Write if you have questions or need some other examples - there are a lot of numbers and cases, there is always something to compare with.

All Articles