Silicon Valley: what has changed in three years, part 2

Development of a silicon valley: day in technical shops, general qualities of mobilizers, partner business models. The first part is here .

Tech shops are another example of developing digital production formats. Today in the world there are 11 technical shops, which are visited by more than 10,000 people. 8 are located in the USA, one each in France, Japan and the United Arab Emirates. Net sales in 2015 amounted to $ 14 million.

Saturday night at the San Jose tech shop

There are three technical shops in California - in San Francisco, San Jose and halfway between them in Redwood City. The technical workshop in San Jose includes 12 workshops: Laser Studio, 3D Studio, Machine Shop, Hot Shop, Plastics Area, Grinding Room, Finishing Room, Electronics Lab, Metal Shop, Wood Shop, Textiles Area, Garage Area.

Hundreds of types of equipment in them - a water jet machine, plasma cutting machines, a 15-ton press, laser engravers and cutters, 3D printers, sewing machines. The highest demand for laser cutters, sometimes they need to be booked in advance and wait in line. Many computers with CAD / CAM software. More than one million dollars was invested in each technical shop in machines and tools, technologies and equipment. Tech shops are open to everyone and work from early morning until midnight.

The technical workshop in San Jose has been operating since 2006. The business model provides everything necessary in order to implement any ideas, including a digital control system for the projects planned. Those who have no experience in production will be fascinated and those who are experienced will be offered assistance in design and experiments. For $ 120 and a few evenings newbies here will teach, for example, welding.

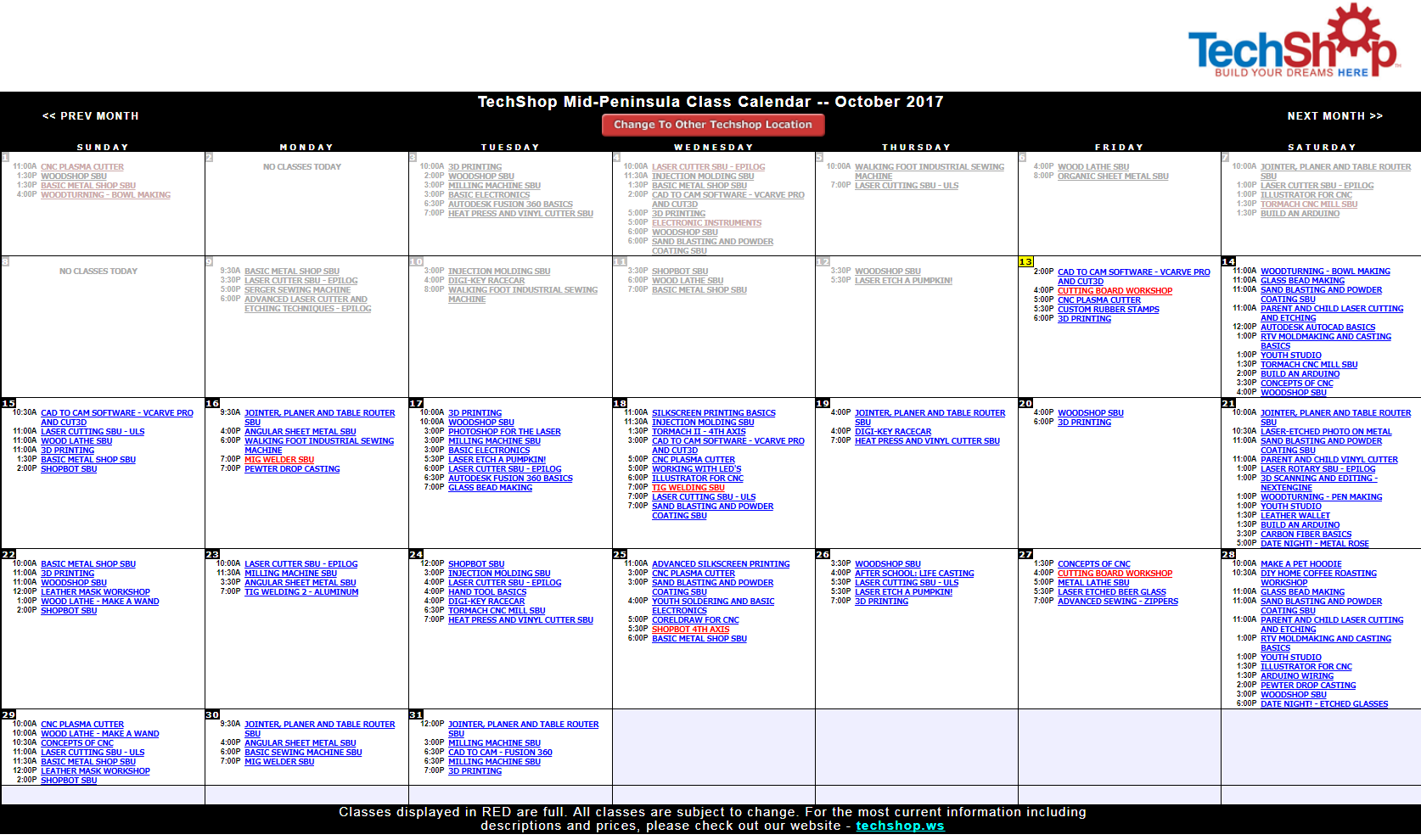

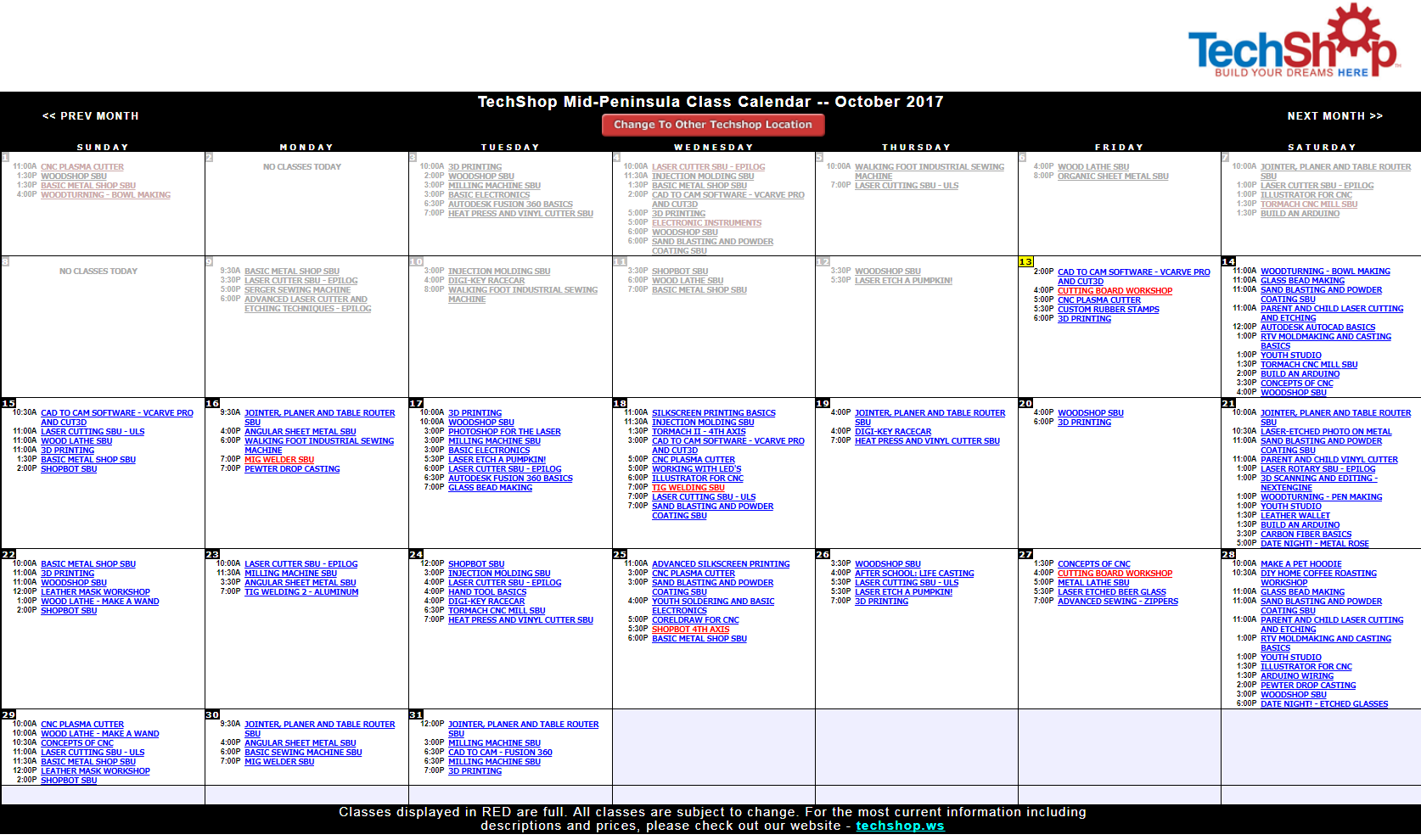

5-10 group lessons for adults and children are held every day in technical shops. Among them are courses such as the production of composites, the design and manufacture of furniture for milling CNC, beautiful embroidery with CNC sewing machines and many others.

Schedule for a month

The annual subscription to the technical workshop costs $ 1,650 a year, the principle of operation is very similar to fitness clubs: all the equipment available for materializing their ideas is available to club card holders. Unfortunately, Techshop San Jose did not have a book and souvenir shop, brochures, magazines and books about technical shops and modern production. It seemed to us that there was a lack of a normal explanation of what a technical shop is, what makes classes interesting, what can be done with the equipment. At the same time, the books and magazines of the Maker Media publishing house, fascinatingly telling about the methods of modern production and all possible “do it yourself” directions, are sold in every book and almost every California newspaper counter.

When we left late Saturday evening, we continued to solder and cut something in the workshops of the technical shop, about a dozen people were programming something. And on the Sunday morning of the next day, we met a team of several teachers and a half dozen visitors who worked enthusiastically on the design of autonomous cars at the Redwood Technical workshop. A group of 7 girls learned to sew with the help of numerical control sewing machines.

The main common qualities of mobilizing spaces and other similar technical shops of places are active community, accessibility and openness, complex infrastructure.

Community. A community of passionate enthusiasts gather around, who are happy to work with equipment and solve the problems of their projects. Entrepreneurs, students, production workers, inventors, investors - all of them are included in the ecosystem, with the help of which projects that are in the earliest stages of development can sometimes be transformed into a business with a tangible return on investment. Mobilizers often hold events (you can track and sign up for them at eventbrite.com and meetup.com ), where people from different communities meet and discuss projects, new ideas, develop relationships.

Availability. Mobilizers, as a rule, are located in the center of cities with the expectation that passing by may enter them even late in the evening.

Saturday night technical shop windows - technical shop products including wooden barbecue boxes in the shop windows

As a guest of a technical workshop, people with zero knowledge in production, design or programming may well be. In 2016, a technical workshop in Redwood launched a mobile project with Fujitsu - “Techshop inside”, a mobile workshop for fascinating, project-oriented learning STEAM (science, technology, engineering, arts, math) in those urban areas whose residents do not have access to modern technical education.

Infrastructure. The team, equipment, software, educational programs - everything needed to turn your idea into the first prototype, into an MVP (Minimum Viable Product), go through the validation of hypotheses and bring the product to a crowdfunding platform. The posts of assistants in the technical shop teams are “dream consultant”, in fact - a consultant on the materialization of the dream. Their key performance indicators are the speed with which you master tools, equipment, CAD / CAM to implement your idea.

Another trend of the valley is the development of business models for the mutual expansion of the resources of various companies with resources. An example is the work of three manufacturing companies, contract manufacturers fictiv.com and sculpteo.com, the global giant flex and technological coworking Techshop. These companies are located in San Francisco at a minimum distance from each other.

Including thanks to this, their business model works through the synergy of various resources.

Fictiv and Sculpteo resources are a convenient and simple online marketplace for b2c orders, a young and energetic team of entrepreneurs. Speed in the execution of orders: the willingness to manufacture and deliver parts in 24 hours.

TechShop Resources - a fleet of equipment that is open until midnight for the production of small orders and prototypes and a very energetic, very young team with almost no business experience.

Flex resources, micro factories and innovative laboratories are high-precision, expensive production equipment and highly qualified expensive specialists.

Thanks to an informal (or formal, not the essence) partnership, all three companies earn money by what it is impossible or very difficult to earn individually. Fictiv and Sculpteo take orders (3D models of parts) through a simple and convenient web interface. At the same time, there is no need for the company to bear the cost of maintaining a fleet of production equipment and expensive specialists: this is performed by Flex micro-production. The task of “spark the curiosity”, in fact, marketing, creating and developing a new market for complex DIY products is solved by TechShop.

Also, imagine what happens when people from these companies, teams, customers and customers meet in meetings or in the evening for a beer. From the discussion of their ideas, thoughts and desires, they begin to create new products, services and companies. And thanks to the ecosystem grow relatively quickly.

Summary of Part 2:

1. In the cities of Silicon Valley, everyone has the opportunity to go in with the idea and leave with the product, using the machines, equipment, tools and help from the technical shop team. Over the past three years, the number of technical shops has increased, they are popular, including in France, Japan, the United Arab Emirates. The launch plan for the coming years is in dozens of other countries.

2. Tech shops are open and located in the centers of cities, realizing, among other things, marketing the values of individual and team production and creation - for the balance of consumer models.

3. Valley companies take advantage of the business models of mutual addition of resources of various companies and synergies through the exchange of resources. Examples are Fictiv, Sculpteo, Flex and Techshop.

The role of new companies in the transformation of industries, conclusions and summaries - in the third part of the article.

For more information about technical shops, development statistics, projects, success stories - here.

The third part of the article is here .

Authors: Pavel Bilenko (Pavel_Bilenko at skolkovo.ru), Maxim Feldman (Maxim_Feldman at skolkovo.ru). Moscow School of Management SKOLKOVO, 2017.

Tech shops are another example of developing digital production formats. Today in the world there are 11 technical shops, which are visited by more than 10,000 people. 8 are located in the USA, one each in France, Japan and the United Arab Emirates. Net sales in 2015 amounted to $ 14 million.

Saturday night at the San Jose tech shop

There are three technical shops in California - in San Francisco, San Jose and halfway between them in Redwood City. The technical workshop in San Jose includes 12 workshops: Laser Studio, 3D Studio, Machine Shop, Hot Shop, Plastics Area, Grinding Room, Finishing Room, Electronics Lab, Metal Shop, Wood Shop, Textiles Area, Garage Area.

Hundreds of types of equipment in them - a water jet machine, plasma cutting machines, a 15-ton press, laser engravers and cutters, 3D printers, sewing machines. The highest demand for laser cutters, sometimes they need to be booked in advance and wait in line. Many computers with CAD / CAM software. More than one million dollars was invested in each technical shop in machines and tools, technologies and equipment. Tech shops are open to everyone and work from early morning until midnight.

The technical workshop in San Jose has been operating since 2006. The business model provides everything necessary in order to implement any ideas, including a digital control system for the projects planned. Those who have no experience in production will be fascinated and those who are experienced will be offered assistance in design and experiments. For $ 120 and a few evenings newbies here will teach, for example, welding.

5-10 group lessons for adults and children are held every day in technical shops. Among them are courses such as the production of composites, the design and manufacture of furniture for milling CNC, beautiful embroidery with CNC sewing machines and many others.

Schedule for a month

The annual subscription to the technical workshop costs $ 1,650 a year, the principle of operation is very similar to fitness clubs: all the equipment available for materializing their ideas is available to club card holders. Unfortunately, Techshop San Jose did not have a book and souvenir shop, brochures, magazines and books about technical shops and modern production. It seemed to us that there was a lack of a normal explanation of what a technical shop is, what makes classes interesting, what can be done with the equipment. At the same time, the books and magazines of the Maker Media publishing house, fascinatingly telling about the methods of modern production and all possible “do it yourself” directions, are sold in every book and almost every California newspaper counter.

When we left late Saturday evening, we continued to solder and cut something in the workshops of the technical shop, about a dozen people were programming something. And on the Sunday morning of the next day, we met a team of several teachers and a half dozen visitors who worked enthusiastically on the design of autonomous cars at the Redwood Technical workshop. A group of 7 girls learned to sew with the help of numerical control sewing machines.

The main common qualities of mobilizing spaces and other similar technical shops of places are active community, accessibility and openness, complex infrastructure.

Community. A community of passionate enthusiasts gather around, who are happy to work with equipment and solve the problems of their projects. Entrepreneurs, students, production workers, inventors, investors - all of them are included in the ecosystem, with the help of which projects that are in the earliest stages of development can sometimes be transformed into a business with a tangible return on investment. Mobilizers often hold events (you can track and sign up for them at eventbrite.com and meetup.com ), where people from different communities meet and discuss projects, new ideas, develop relationships.

Availability. Mobilizers, as a rule, are located in the center of cities with the expectation that passing by may enter them even late in the evening.

Saturday night technical shop windows - technical shop products including wooden barbecue boxes in the shop windows

As a guest of a technical workshop, people with zero knowledge in production, design or programming may well be. In 2016, a technical workshop in Redwood launched a mobile project with Fujitsu - “Techshop inside”, a mobile workshop for fascinating, project-oriented learning STEAM (science, technology, engineering, arts, math) in those urban areas whose residents do not have access to modern technical education.

Infrastructure. The team, equipment, software, educational programs - everything needed to turn your idea into the first prototype, into an MVP (Minimum Viable Product), go through the validation of hypotheses and bring the product to a crowdfunding platform. The posts of assistants in the technical shop teams are “dream consultant”, in fact - a consultant on the materialization of the dream. Their key performance indicators are the speed with which you master tools, equipment, CAD / CAM to implement your idea.

Another trend of the valley is the development of business models for the mutual expansion of the resources of various companies with resources. An example is the work of three manufacturing companies, contract manufacturers fictiv.com and sculpteo.com, the global giant flex and technological coworking Techshop. These companies are located in San Francisco at a minimum distance from each other.

Including thanks to this, their business model works through the synergy of various resources.

Fictiv and Sculpteo resources are a convenient and simple online marketplace for b2c orders, a young and energetic team of entrepreneurs. Speed in the execution of orders: the willingness to manufacture and deliver parts in 24 hours.

TechShop Resources - a fleet of equipment that is open until midnight for the production of small orders and prototypes and a very energetic, very young team with almost no business experience.

Flex resources, micro factories and innovative laboratories are high-precision, expensive production equipment and highly qualified expensive specialists.

Thanks to an informal (or formal, not the essence) partnership, all three companies earn money by what it is impossible or very difficult to earn individually. Fictiv and Sculpteo take orders (3D models of parts) through a simple and convenient web interface. At the same time, there is no need for the company to bear the cost of maintaining a fleet of production equipment and expensive specialists: this is performed by Flex micro-production. The task of “spark the curiosity”, in fact, marketing, creating and developing a new market for complex DIY products is solved by TechShop.

Also, imagine what happens when people from these companies, teams, customers and customers meet in meetings or in the evening for a beer. From the discussion of their ideas, thoughts and desires, they begin to create new products, services and companies. And thanks to the ecosystem grow relatively quickly.

Summary of Part 2:

1. In the cities of Silicon Valley, everyone has the opportunity to go in with the idea and leave with the product, using the machines, equipment, tools and help from the technical shop team. Over the past three years, the number of technical shops has increased, they are popular, including in France, Japan, the United Arab Emirates. The launch plan for the coming years is in dozens of other countries.

2. Tech shops are open and located in the centers of cities, realizing, among other things, marketing the values of individual and team production and creation - for the balance of consumer models.

3. Valley companies take advantage of the business models of mutual addition of resources of various companies and synergies through the exchange of resources. Examples are Fictiv, Sculpteo, Flex and Techshop.

The role of new companies in the transformation of industries, conclusions and summaries - in the third part of the article.

For more information about technical shops, development statistics, projects, success stories - here.

The third part of the article is here .

Authors: Pavel Bilenko (Pavel_Bilenko at skolkovo.ru), Maxim Feldman (Maxim_Feldman at skolkovo.ru). Moscow School of Management SKOLKOVO, 2017.

All Articles