Hyaluronic acid: what this polymer does in medicine

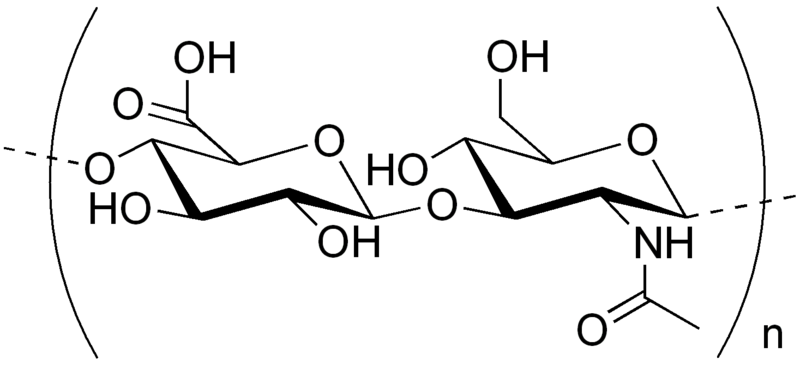

First, hyaluronic acid is not a acid, but a polymer. More precisely, the fact that in the composition of cosmetic and medical products is written as “hyaluronic acid” is its sodium salt. The high molecular weight form of the hyaluronic acid salt is a very large and heavy molecule with many links. By the way, the word "polymer" does not mean that it is plastic, in any case. This is a mucopolysaccharide, that is, cyclic units are attributed to sugars. But this is not a pure polysaccharide.

Molecules of hyaluronic acid are really large (hereinafter I will follow the traditional terminology and call the sodium salt of hyaluronic acid, that is, the mucopolysaccharide described above). The high molecular weight fraction, which is usually present in our body, usually reaches one to two million units of atomic mass. A water molecule is just 18 units of atomic mass. Due to its properties, one large molecule of hyaluronic acid can capture a lot of water molecules - up to 1000% of its mass. It turns out such a highly efficient sorbent that collects water and holds it until the molecule collapses as a result of life processes in the body.

Structures that are almost entirely composed of hyaluronic acid are, for example, a rooster's comb or a baby's umbilical cord. These are such gentle soft educations - as a matter of fact, the swelled gel. The vitreous of the eye is 80% composed of this polymer. A lot of this polymer in any mucous membranes.

Secondly, it is necessary to distinguish in marketing "natural" hyaluronic acid and biosynthesized. “Natural”, which is obtained from the scallops of roosters, is practically not suitable for injections without additional rather expensive purification (that is, almost not used in medicine) and less often used in cosmetics than biosynthesized (ensures uneven composition of products, reduces shelf life, and so on - more precisely, it can do it, but it does not necessarily work that way). The reason is easily explained. A large amount of hyaluronic acid can be obtained for the medical or cosmetic industry, either by processing animal parts or by bacteria production (biotechnology).

The first method, for example, is used here: in the Moscow region there is a poultry farm, which, among other things, collects the cut scallops from dead birds and gives them back for processing. With the help of chemical agents, as a result of complex reactions, the covers are first separated, and then hyaluronic acid itself is released. But since it is a large and rather “tenacious” molecule, to which many different substances can join (this explains its properties important in medicine and cosmetics), it is always associated with protein molecules at the level of molecular bonds. That is, we are talking about a tight grip, and not about any easily filtered emulsion.

To separate these embedded protein molecules, you need a chain of complex, long and, importantly, expensive chemical reactions and procedures with resultant substances. As a result, the cleaning is still not fully completed, so the hyaluronic acid obtained in a “natural” way is quite a strong allergen. As long as you apply it on the skin - nothing will be terrible. If you start to crush the fraction for subcutaneous administration or use injections, the risk of unwanted reactions increases dramatically. Plus, this protein tends to destructurize or denature over time, which causes the release of degradation products into solution. With different changes in its properties.

Another reason why such a substance is extremely rarely used in serious formulas of both cosmetics and medicine is that it means the poor quality of the basic formula. As a rule, the active substance is not one (and in our case, for example, means for rapid regeneration or special medical gels — not two and not three), and all of them must be stably combined. Trace amounts of protein change the stability of the formula - reactions with other active substances begin, and not always predictable.

Therefore, for medicine (and many for cosmetics) use biosynthesis. These are bioreactors with bacteria selected to produce the desired substance. In similar reactors antibiotics are made. For different industries using different strains of bacteria.

We buy hyaluronic acid for our tasks only from a proven European supplier for many years in a row - even a simple change of counterparty leads to long-term rebalancing or at least to long tests of the formulas of all substances.

Fractions

The initial form of hyaluronic acid after biosynthesis or isolation from cadaveric material is a high molecular weight fraction. Large heavy molecules weighing 1–2 million units. They can be subjected to destruction and "disassemble" into smaller ones. The resulting properties are different substances, but with a common name. That is, the fraction directly affects the properties of this polymer.

What is important for us is that the smaller the molecule, the easier it can be used as a transport for other compounds. The one that is often used in household cosmetics in small quantities is usually large molecules. They fit perfectly on the skin surface and keep moisture there for a long time. It is on top. Then, under the action of enzymes secreted by humans, they are gradually destroyed.

If the molecules are destructed to shorter ones, weighing from 100 to 400 thousand units, they will begin to penetrate the horny layer of the epidermis. We still use such molecules as a transport for water. They can be used for another, but in our case - moisturizers (used both for maintenance treatment and, more rarely, in resuscitation as accompanying). Speech is about the transportation of water that occurs along with the dissolved ingredients.

In professional cosmetics (the term is fundamentally incorrect, but it rather accurately indicates the class of formulas), this fraction has another interesting property: since it puts all the water deep enough into the skin (where it belongs), it has a deeper moisturizing effect.

If you break the molecules further, up to 10–40 thousand units, then they almost do not hold water for the purposes necessary for our tasks. But with the help of them you can collect very interesting formulas that trigger regenerative processes and have a more pronounced anti-inflammatory, immunostimulating action. Plus, transport a variety of substances captured by these molecules, as deep as possible through the skin. The action of such fractions is very different from the high-molecular: almost no moisture, but very good penetration. My colleagues from the laboratory, already in the development of the substances themselves, will be able to tell how we balanced the formula of the regenerating agent, there it would be impossible to do without good raw materials. I am not a biochemist, I deal with polymers, so the story is almost over.

Typically, polymer manufacturers have up to 5 fractions to choose from. They get them by chemical processing after separation from cadaveric material or biosynthesis - different reactions give different degrees of destruction of molecules. This is a more expensive process, so low molecular weight fractions are naturally more expensive. The more steps of destruction - the more expensive the production.

As the sodium salt of hyaluronic acid, obtained by biosynthesis, metabolizes, is simple to describe. Just like the same hyaluronic acid synthesized by our body inside the body. No difference. The stock of opportunities to metabolize such compounds in the body is large. If the mouse is pumped with hyaluronic acid, it will die from the deformation injuries of various body systems, and not from reaching the limit of metabolization. So do not be afraid of this wonderful polymer in the composition. But do not ascribe to it the unambiguous properties of improving the skin's trophism or moisturizing, until you know which particular fraction is being discussed. And when using substances that penetrate deeper into the corneal layer of the epidermis and contain a non-biosynthetic version, always carefully check for a possible allergic reaction by applying a small amount before the main use.

All Articles